Scotty Mac

Newbie

- Joined

- Feb 13, 2017

- Messages

- 14

- Age

- 25

- Location

- Muskegon Michigan

- Country

- USA

- Snowmobile

- Yamaha nytro

so over the summer I bought a 2009 nytro from a friend, they never had problems with the front end, after riding it, the top a arm bolt had stretched the hole so much the bolt fell thru.. So I took it home it it on the lift and tore everything apart, a arMs and spindles. I had the spindle holes welded shut and re drilled and I put ulmer oilite bushings in the a arMs. I also replaced the nuts and bolts that connect the top and bottom a arm to the spindle. After all this I thought it would be fixed and problem free. About 200 miles in, I noticed the right hand side(from sitting in riding position) top a-arm spindle bolt Had stretched open again! So I had it welded shut and drilled again, this time I put in a small oil impreganated bushing to reduce the wearing out. Thought forsure the problem was fixed and sure as hell 300 miles in I noticed it was starting to stretch again. What do I do? Do I buy a new right hand spindle? This problem only occurs on the spindle with the holes re drilled. Thanks

pedros83

Pro

- Joined

- Nov 19, 2015

- Messages

- 195

- Age

- 40

- Location

- Blackstock, ON

- Country

- Canada

- Snowmobile

- 2010 Nytro XTX

Did you re tighten the allen nut amd bolt with red loctite? I had the same issue. The nut underneath loosens off and egg shapes the hole. Red loctite solved my issues

Scotty Mac

Newbie

- Joined

- Feb 13, 2017

- Messages

- 14

- Age

- 25

- Location

- Muskegon Michigan

- Country

- USA

- Snowmobile

- Yamaha nytro

Yes I did, I used plenty of it with each bolt.Did you re tighten the allen nut amd bolt with red loctite? I had the same issue. The nut underneath loosens off and egg shapes the hole. Red loctite solved my issues

Not sure why there are so many egged out right side spindles out there. How do your threads look?

Maybe try a new bolt and nut. Maybe Nord lock washers will do it for you?

http://www.nord-lock.com/

Maybe try a new bolt and nut. Maybe Nord lock washers will do it for you?

http://www.nord-lock.com/

ouhockeyplayer

Veteran

Mine did this. But it was mostly due to the washer not being in the right spot (between the ball joint and upper spindle hole). I ended up buying a new spindle. Now I have another issue due to the previous owner not putting the washers in the correct spot in the lower spindle holes for mounting the skis. They were supposed to be between the collars and the lower hole and they were on the outside next to the skis. This caused the collars to beat up the spindles. You've got to watch those washers.

markyb

Veteran

- Joined

- Feb 6, 2015

- Messages

- 35

- Location

- Twillingate, NL

- Country

- Canada

- Snowmobile

- 2009 Nytro XTX

- LOCATION

- Twillingate, NL

Had the same issue but luckily caught it before hole would wear. Problem never stopped until i torqued it properly (41 ft.lb i believe). I always thought it was tight but turns out you can only tighten so much with an allen key or 3/8 ratchet. And of course like you previously mentioned, Loctite.

porkchop

TY 4 Stroke Master

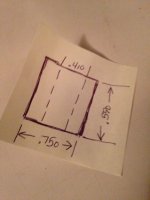

I made simple aluminum spacers and dropped the nuts down to the next solid piece on the spindles for both of mine, more meat holding it all together now.

The spindle design just has too much cut out of it for my liking with that mounting.

The spindle design just has too much cut out of it for my liking with that mounting.

Attachments

Scotty Mac

Newbie

- Joined

- Feb 13, 2017

- Messages

- 14

- Age

- 25

- Location

- Muskegon Michigan

- Country

- USA

- Snowmobile

- Yamaha nytro

THats so smart!! I'm definently going to try that! I'll let you know next year how it works lol, since it looks like the seasons overI made simple aluminum spacers and dropped the nuts down to the next solid piece on the spindles for both of mine, more meat holding it all together now.

The spindle design just has too much cut out of it for my liking with that mounting.

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 4

- Views

- 2K