If you want to test the gears take off the servo. There is a peace of metal called the fork that you can touch with you finger. Push it to the chain case side, hold it, turn the shaft until it locks in to place, then let go it will stay in place. Transfer to reverse push it to the clutch side and rotate the shaft half turn should go it to place. Forward both shaft will rotate same direction reverse the the shaft will rotate opposing each other. Make sure the smaller chain case shaft is pushed in to the the gear case.

Test the servo- Have the servo off the gear case. Get a 12v battery and two wires. Connect one wire to positive the to negative. On the servo there is 3 pins (1 pin is on the left side from the top looking at the pins it will be alone and 2/3 will be next to each other). Read carefully as it just does not swap for F/R

For Forward connect Neg(-) to 1 and Pos(+) to 2. For Reverse Connect Pos(+) to 1 and Neg(-) to 3.

If actuator moves to the right is in F and if it goes to the right its in R.

The actuator is spring loaded. This will keep constant pressure on the fork until it is shifted in to place and keep it in place once it has. The servo is not supplied constant power to do so.

Testing the sensors-There is on the F side and one on the R side (they are interchangeable with each other). They work just by simple contact from the fork. To test it you cant get a self powered test light and past current from the fork to the sensor (the side it is on) or you cant take of the sensor and test from the ends.

Dry Run-Place the servo in F position. Push the fork in to F position. Place servo back on case. Test it by supplying power to change fork locations for F/R shifts. A fast twist may need to be applied due to tension from the spring. Make sure there there gear are lubed, friction will not help a shift. If it does not fully shift in to place, make sure small shaft is pushed in. If it still does not, the servo gear may be re-indexing if taken apart.

If this all work try a full hook up with everything back together. If this does not work you problem lies with in the Control Pod or ECU. They control when the servo is supplied power to shift (to prevent damages a high RPM shift), D and R lights, and back up alarm.

When putting everything back to getter 1 wire for the sensor will have F on it for Forward, so you know witch sensor is witch.

To make a direct override for addition of reverse - Diagram coming soon for battery connection, switches, and connection to servo.

Pic 1- Yellow Arrow, push the shaft in to direction arrow points. The other Yellow Arrow, what part of the gears the shaft controls. Red Arrows, the shaft and gears it controls. Blue box, inside the box indicates how the gears are aligned and touch. Black indicates the fork.

Pic 2- In Forward gear position.

Pic 3- In Reverse gear position.

Pic 4- Yellow Arrows, indicate witch direction the shaft will rotate in Forward. Red Arrows indicate witch direction the shaft will rotate in Reverse.

pic 5- Testing sensor in Forward with out removing sensor.

Pic 6- Testing sensor with sensor removed.

Pic 7- Servo wire application to change actuator position.

Pic 8- Corresponding Actuator position. Left is Reverse and Right is Forward.

Pic 9- Heavy spring shown in Servo.

Pic 10- Gear re-indexing. Place for in Forward position and place Actuator in Forward position. Top arrow pointing right is the a stop and the bottom is stop. They will contact each other to stop from going to far (unknown how long power is supplied but easier to make that then make senors and some a device for it) When re-indexing make sure they just touch each other and place cover back on.

Pic 11- Just a under view of the cover. # Color Corresponds with the Arrow color for current testing with self power test light. (With #1 sometimes I would get a light sometimes the motor would turn). White Arrow (the stop) is to make sure the gear to go to far and slip out of place.

You will notice the are not all the same length. This is to automatically kill the power once it is full shifted in place. If it was to be bumped out of place it would re-engaged. If the gears are fully in place but the Actuator Arm is not, the power will still be cut. The Arm is spring loaded to keep constant presser until it is engaged and should still do so once its in place.

Pic 12- Yellow Arrow, 3 wires that are used to control the Servo. Red Arrow, wire to Forward Sensor. Blue Arrow, wire to Reverse Senor.

Pic 13- Example of testing.

Pics 14- Contact points (also could be called a brush) for D/R to the complete the circuit.

Do you think all the problems with this electronic reverse has been fixed on the 2018 Vectors. I would like to buy a 2018 but with all the problems maybe I should look for a 2017 instead

jamm999

Veteran

Ok so I am having a similar issue as mooseman with the skipping. Mine goes in and out of reverse perfectly though. It seems to skip more after it is warmed up. I took it for a ride and had no issues at all. Got back to my house and put it into reverse, went in perfectly, backed up no problem then went back into drive no problem. Then when I start moving forward around 15 to 25 mph it starts to skip, I did notice the D light blink as it was trying to skip. I am wondering if it is just trying to go back into reverse? If that's the case would it be caused by a weak servo motor or possibly a bad sensor ? Like I said it Always goes in and out of reverse perfectly. Seems like I could drive all day and not have a problem until I put it into reverse , Then it starts to act up. What about disabling reverse all together either by a fuse or unplugging it ?

1bad10tacoma

Veteran

- Joined

- Oct 20, 2015

- Messages

- 27

- Age

- 54

- Location

- Maine

- Country

- USA

- Snowmobile

- 2007 Yamaha Phazer GT

1988 Yamaha Bravo LT

1986 Yamaha Bravo ST

Solved my reverse problem, sold the phazer now I'm rocking a bravo this winter.

Koebes

Newbie

- Joined

- Apr 1, 2018

- Messages

- 8

- Age

- 45

- Location

- Jamtland

- Country

- Sweden

- Snowmobile

- Venture Multipurpose

Seems like i have a servo/gearbox problem on my MP. Did some 20km through 20cm snow and almost at the end of the trip there was like a ratcheting every now and then. Green D light turns off at the same time. I first checked the chain tension and track tension, but nothing bad there. So I pulled the seats and tank of, and squeezed my sausage fingers into the engine compartment to pull that servo out (shifting forward and reverse works fine). Looks like the axle that holds the shifter arm was bend. straightend it and put everything back together. Tomorrow it's test time. I will have a look at those gears as well before assembling everything again. Hopefully that solves the problem. hopefully I don't need a gearbox rebuild. When shifting ther is quite a loud clonk noise. Is that normal or could the shims on the secondary be missing? No Idea if the previous owner did the upgrade. Would have been much easier to install a decent hand lever to shift.

Mooseman

I'm not all knowing. Post your question in forum.

- Joined

- Nov 3, 2009

- Messages

- 3,944

- Location

- Greely, Ontario

- Country

- Canada

- Snowmobile

- '07 Venture MP (gone)

'07 Phazer FX (gone)

'09 Phazer GT (gone)

'10 RS Venture GT (My current ride)

'10 Nytro FX (son's)

- LOCATION

- Greely, ON Canada

A clunk when shifting is normal. You should make sure that washer is there for the secondary because I'm pretty sure that's what screwed up my son's Phazer reverse box with the excessive play and banging on the bearing in the box.

Koebes

Newbie

- Joined

- Apr 1, 2018

- Messages

- 8

- Age

- 45

- Location

- Jamtland

- Country

- Sweden

- Snowmobile

- Venture Multipurpose

Thanks for the quick reply. Could you point me to what washer it is in the parts diagram, or where I can find the service bulletins? The weird thing is that I hardly use the reverse and did definetly not use it yesterday when ratcheting started. I don't really feel I am losing propulsion . It's hacking a short moment and works fine afterwards until the next hack. If yamaha had designed the side covers of the driver seat in a smarter way it would be quite easy to remove the tank. and leave the passenger seat on. One multipin electrical connector two bolts from the side and the two for the tank and the tank would be out in notime. Well I hope I get it back to work until the end of the season and can tear it apart in the sun together with the mosquitos.A clunk when shifting is normal. You should make sure that washer is there for the secondary because I'm pretty sure that's what screwed up my son's Phazer reverse box with the excessive play and banging on the bearing in the box.

Koebes

Newbie

- Joined

- Apr 1, 2018

- Messages

- 8

- Age

- 45

- Location

- Jamtland

- Country

- Sweden

- Snowmobile

- Venture Multipurpose

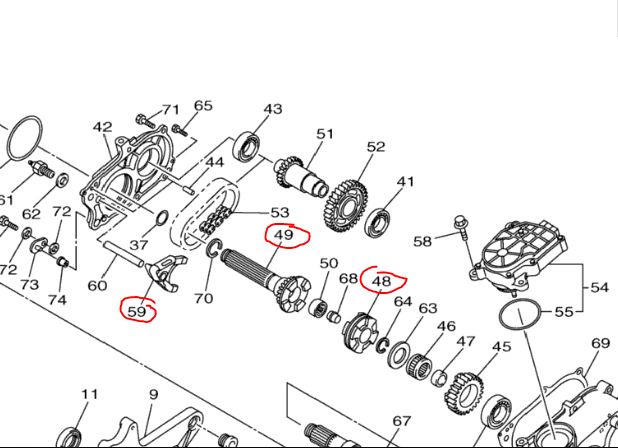

Did a quick test run this morning but after a short while of joy, the ratcheting reappeared. So now I pulled the sled apart and took the gearbox out. Definetly not a masterpiece of japanese engineering. The castings of my east german made motorcycle are better. As suspected the slightly chamfered surfaces on item 48 and 49 are worn. Obviously Yahama couldn't make 48 symetrical so you would be able to twist it around and have some more troublefree kilometers. The sad part is item 49. Not really cheap in the US and even more expensive in Sweden for sure. One option would be a plastic spacer between 48 and 45 and sacrifice reverse until I find some cheaper spares.

I could remove the chain and all reverse stuff that I won't need and make some plastic spacer to help Item 48 to stay in place. Quick and dirty. Just sad that it is quite a bit of work to get to the gearbox.

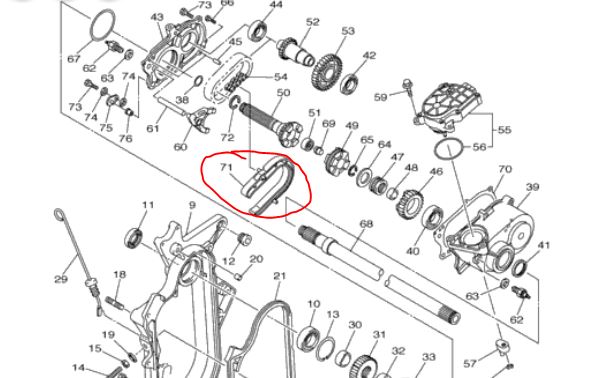

From 2008-2009 Item 49 changed part numbers and another item 71 in picture two was added. I think I will look for a newer used gearbox in order to get all the upgrades. 500+ dollars to rebuild mine seems like a bit expensive.

Edit: Found a Gearbox from a 2011 Phazer RTX with only 250km on it. Seems like the main difference is the shaft from the secondary to the gear box most probably because of the wider track. Not cheap but under 400 dollars and I will get another Servo as well.

I could remove the chain and all reverse stuff that I won't need and make some plastic spacer to help Item 48 to stay in place. Quick and dirty. Just sad that it is quite a bit of work to get to the gearbox.

From 2008-2009 Item 49 changed part numbers and another item 71 in picture two was added. I think I will look for a newer used gearbox in order to get all the upgrades. 500+ dollars to rebuild mine seems like a bit expensive.

Edit: Found a Gearbox from a 2011 Phazer RTX with only 250km on it. Seems like the main difference is the shaft from the secondary to the gear box most probably because of the wider track. Not cheap but under 400 dollars and I will get another Servo as well.

Last edited:

Mooseman

I'm not all knowing. Post your question in forum.

- Joined

- Nov 3, 2009

- Messages

- 3,944

- Location

- Greely, Ontario

- Country

- Canada

- Snowmobile

- '07 Venture MP (gone)

'07 Phazer FX (gone)

'09 Phazer GT (gone)

'10 RS Venture GT (My current ride)

'10 Nytro FX (son's)

- LOCATION

- Greely, ON Canada

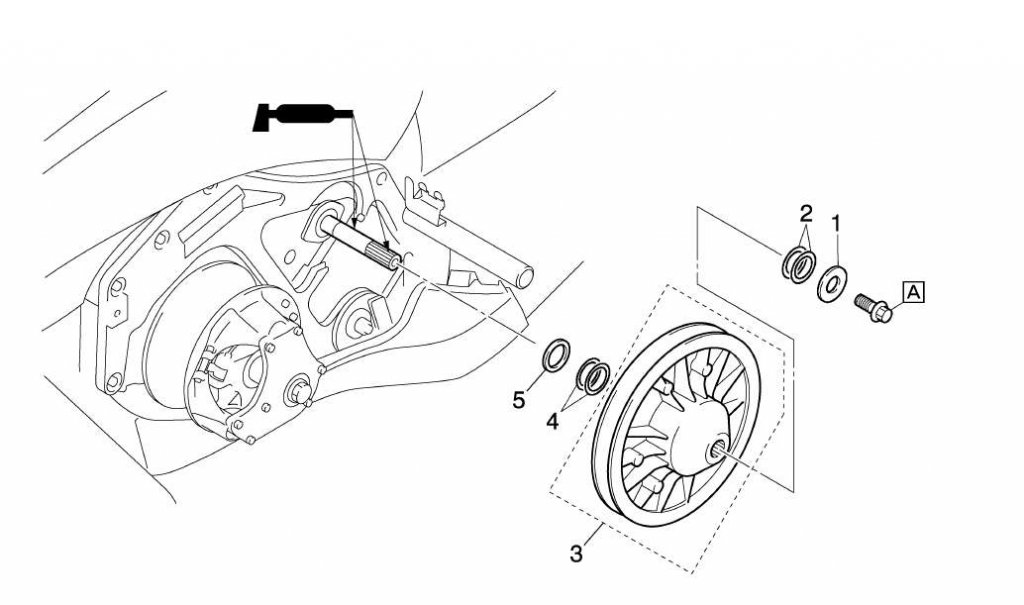

The washer I was referring to is the one directly under the large bolt that holds the secondary to the shaft. There are also shims. Side play of the secondary should be 2-3mm max. It's 1-2-4-5

JetAv8r

Newbie

- Joined

- Jul 5, 2019

- Messages

- 5

- Age

- 61

- Location

- Las Vegas

- Country

- USA

- Snowmobile

- 2007 Yamaha Venture Lite (2x)

Ugghh. I'm fully into this one. Warmed up sled, idle'd at 1800 RPM. REV button pushed - zero nada. Hit the reset button. Nothing. Turned it off. Still nothing. Ran the sled for awhile. Changed the gear oil out, adjusted the chain tension - still no change--Intermittent. Tear down begun. Tested all solenoids, took out servo motor and tested it on the bench - good both directions. Although when I first took the servo motor out the FWD pinion gear (lug) was a little to the right (clockwise) stop from the FWD window specified in the manual. Once tested a few times in both directions it never went that far clockwise in "FWD" stop. I think its time to pull apart the servo motor and take a look. Tested the Reverse Position Switch on the left side - OHM check good. Can't check the Drive Position Switch on the right side unless I take the entire assembly out. Check the harness - ohm checked good. I think I'll put the servo back in and put independent (12v) power to the servo and see if it moves the internals in the reverse drive case. What a pain...

Similar threads

- Replies

- 21

- Views

- 4K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.