Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I got the Apex up on the stands last night. Here's a short list of updates being made:

1) Removing all tunnel protectors

2) Checking the EXUP valve (as per MrSled video below)

3) Replace all M20 idler wheel bearings

4) Replace drive alxe bearings

5) Install new track

6) Install reconfigured M20 air system control switches

7) Install clutch kit and 911 Response primary cover

MrSled EXUP video:

1) Removing all tunnel protectors

2) Checking the EXUP valve (as per MrSled video below)

3) Replace all M20 idler wheel bearings

4) Replace drive alxe bearings

5) Install new track

6) Install reconfigured M20 air system control switches

7) Install clutch kit and 911 Response primary cover

MrSled EXUP video:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

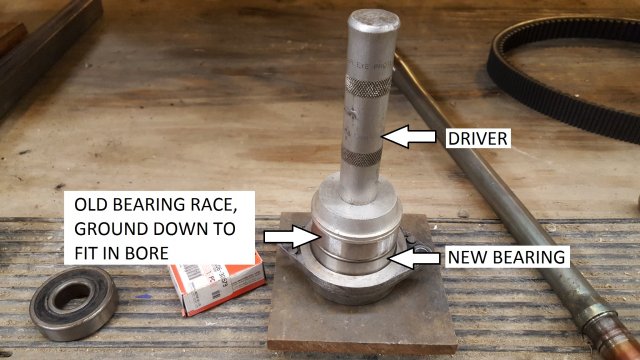

Chaincase is disassembled and the Ripsaw II track is removed. Upon inspection, I discovered the left jackshaft bearing (behind secondary) felt dry and gritty. I don't repack roller ball bearings, so time to changer 'er out...especially since I already have the chaincase apart for track change.

WOW! I did not realize the improvements Yamaha had made to this area until now. This bearing use to press directly into the diecast bulkhead and could be tricky to remove. Now all you do is remove two screws and the shaft / bearing assembly pulls straight out of the bulkhead (upper chaincase needs disassembled first). This is a huge improvement for 2 reasons:

1) Easier to change bearing without beating on your sled!

2) Doesn't ruin the entire bulkhead in the event of a catastrophic bearing failure.

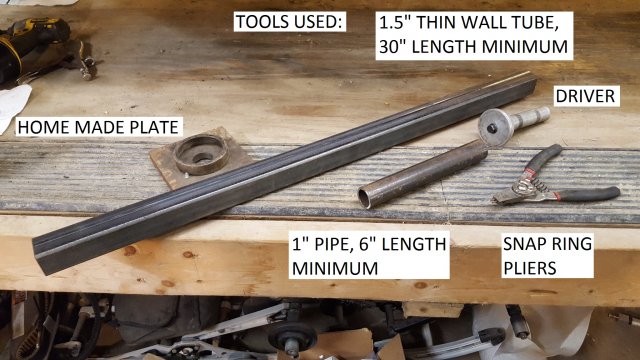

Here's a few pics of how I removed and installed a new bearing on the jackshaft:

WOW! I did not realize the improvements Yamaha had made to this area until now. This bearing use to press directly into the diecast bulkhead and could be tricky to remove. Now all you do is remove two screws and the shaft / bearing assembly pulls straight out of the bulkhead (upper chaincase needs disassembled first). This is a huge improvement for 2 reasons:

1) Easier to change bearing without beating on your sled!

2) Doesn't ruin the entire bulkhead in the event of a catastrophic bearing failure.

Here's a few pics of how I removed and installed a new bearing on the jackshaft:

Nice work. I pull the bearing covers off both jack and drive shafts and repack every season. The jack shaft bearing is original with 10k. Keep the updates coming.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Well, I just checked the EXUP cable adjustment and one of the cables broke during diagnostic cylce as displayed in the video. Looks like new cables are in order.

Is the EXUP worth the trouble...I have heard both opinions..?

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Honestly, I don't know. This is the only Apex I've owned and I've never even ridden a pre 2011 Apex to compare the difference.Is the EXUP worth the trouble...I have heard both opinions..?

I've just heard that there is a loss of performance and mpg if the valve is either out of adjustment or has a broken cable. I've read where guys have had a broken cable pretty quick and some guys are getting high miles with no issues.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

OK.....jackshaft, drive axle, chaincase and new track are in place. New hyfax and idler wheel bearings have been installed on the skid as well. The new EXUP cables have arrived, so hopefully I can get those installed tomorrow.

Now I'd like to talk about M20 mounting locations in the 2011+ Apex. A recent online conversation has made me aware that FAST has changed the mounting location for the rear arm on the 128" Apex. The new rear arm location is now 200 millimeters down from top, inside tunnel, verses 179 millimeters. I would think this applies to the 144" XTX as well, but should be verified before installation.

IMO, the new mounting location is GOOD for 2 reasons:

1) Much easier rear arm installation

2) More track lug - tunnel clearance

The M20 rear arm in my Apex is located down 179 millimeters, as per Fast instructions at that time (spring 2013). This dimension works, but it makes the rear arm difficult to install or remove because you can't get a socket on the cross-shaft bolts (both drop brackets have to be completely removed). This is a bit of a nuisance, but a small price to pay for the ride quality! The new M20 in my 2008 Vector is still at 179 millimeters, but it installs differently due to different drop brackets. Fast really did a nice job engineering the brackets for that sled!

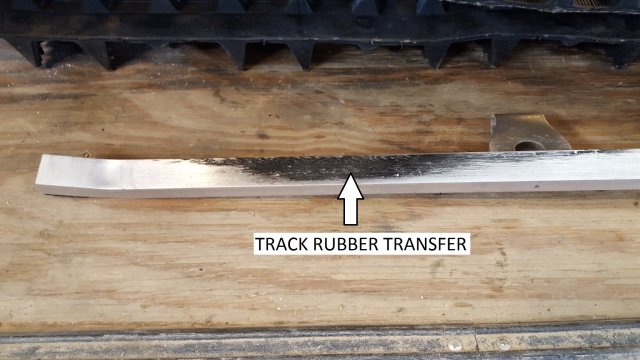

My biggest concern from day one was track lug - tunnel protector clearance. With a 1.25" lug track, there is only 1/2 inch clearance! I thought about removing the tunnel protectors, but left them because I worried the track might slap the EXUP. Now that I have a 1.5" lug track, I felt the protectors had to come out, but then the whole "track slapping the EXUP" concern came back.

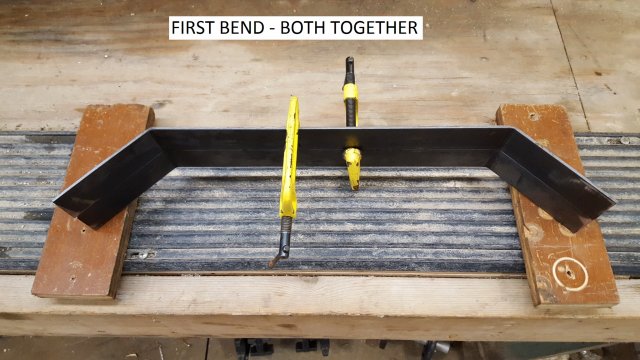

Upon removal, I noticed some rubber transfer to the protectors towards the front. This is no big deal, but I felt there should be some form of EXUP/header protection and still have good lug clearance. I experimented with a few ideas and finally settled on making two small runners that stick down about 1/8" father than the exhaust. The center of the track could still make light contact, but should (for the most part) protect the EXUP/header assembly from a heavy track slap.

More to come after the skid gets re-installed tomorrow.

All parts will be powder coated!

Now I'd like to talk about M20 mounting locations in the 2011+ Apex. A recent online conversation has made me aware that FAST has changed the mounting location for the rear arm on the 128" Apex. The new rear arm location is now 200 millimeters down from top, inside tunnel, verses 179 millimeters. I would think this applies to the 144" XTX as well, but should be verified before installation.

IMO, the new mounting location is GOOD for 2 reasons:

1) Much easier rear arm installation

2) More track lug - tunnel clearance

The M20 rear arm in my Apex is located down 179 millimeters, as per Fast instructions at that time (spring 2013). This dimension works, but it makes the rear arm difficult to install or remove because you can't get a socket on the cross-shaft bolts (both drop brackets have to be completely removed). This is a bit of a nuisance, but a small price to pay for the ride quality! The new M20 in my 2008 Vector is still at 179 millimeters, but it installs differently due to different drop brackets. Fast really did a nice job engineering the brackets for that sled!

My biggest concern from day one was track lug - tunnel protector clearance. With a 1.25" lug track, there is only 1/2 inch clearance! I thought about removing the tunnel protectors, but left them because I worried the track might slap the EXUP. Now that I have a 1.5" lug track, I felt the protectors had to come out, but then the whole "track slapping the EXUP" concern came back.

Upon removal, I noticed some rubber transfer to the protectors towards the front. This is no big deal, but I felt there should be some form of EXUP/header protection and still have good lug clearance. I experimented with a few ideas and finally settled on making two small runners that stick down about 1/8" father than the exhaust. The center of the track could still make light contact, but should (for the most part) protect the EXUP/header assembly from a heavy track slap.

More to come after the skid gets re-installed tomorrow.

All parts will be powder coated!

Last edited:

Rich Kay

TY 4 Stroke Guru

Again ... nice work! Your new name is FAB MAN! I love doing the same kinda thing, making a solution to a problem.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Thanks Rich! I probably worry about things too much, but this is the time to eliminate the concern.

I'm going to hammer away on this sled tomorrow and hopefully finish it by next weekend.

Time is running out. I can't wait to ride!

I'm going to hammer away on this sled tomorrow and hopefully finish it by next weekend.

Time is running out. I can't wait to ride!

Rich Kay

TY 4 Stroke Guru

Its coming... next week up at camp it should turn to winter. Colder temps and snow are forecast. Been checking the web cams around the area and its trying! My neighbor sent a pic the other morning headed to work and they had ground cover but it just is not staying yet so your timing is all good.

Dusty Dan

Lifetime Member

- Joined

- Jan 24, 2015

- Messages

- 211

- Country

- Canada

- Snowmobile

- 2016 SRViper LTX LE

2012 Vector

Well done Joe.Chaincase is disassembled and the Ripsaw II track is removed. Upon inspection, I discovered the left jackshaft bearing (behind secondary) felt dry and gritty. I don't repack roller ball bearings, so time to changer 'er out...especially since I already have the chaincase apart for track change.

WOW! I did not realize the improvements Yamaha had made to this area until now. This bearing use to press directly into the diecast bulkhead and could be tricky to remove. Now all you do is remove two screws and the shaft / bearing assembly pulls straight out of the bulkhead (upper chaincase needs disassembled first). This is a huge improvement for 2 reasons:

1) Easier to change bearing without beating on your sled!

2) Doesn't ruin the entire bulkhead in the event of a catastrophic bearing failure.

Here's a few pics of how I removed and installed a new bearing on the jackshaft:

View attachment 123137 View attachment 123138 View attachment 123139 View attachment 123140 View attachment 123141 View attachment 123142 View attachment 123143 View attachment 123144 View attachment 123145 View attachment 123146

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

The tunnel runners got Powder coated and installed this morning. I used silver so I could look and see if any track rubber is transferring.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

The skid is installed and everything is coming back together! I now have a taller lug track with 1/4" more clearance than I had with the 1.25". I also installed a new line for the rear air spring; the old line was kind of set in its ways! (pun intended)

Last edited:

Similar threads

- Replies

- 20

- Views

- 6K

- Replies

- 46

- Views

- 146K

- Replies

- 4

- Views

- 31K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.