- Joined

- Jun 28, 2004

- Messages

- 2,436

- Age

- 64

- Location

- Clinton, Wi.

- Country

- USA

- Snowmobile

- '11 Apex XTX, '09 Venture GT, '06 Attak, 08 Nytro Hybrid

Hmmmm, ready to RIDE, not ready to roll. Roll and sled are are 2 things that do NOT go together!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

You are correct, my friend!Hmmmm, ready to RIDE, not ready to roll. Roll and sled are are 2 things that do NOT go together!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I rode the Apex quite a bit this last week in the UP. Upon inspection at home, there is NO evidence of the track making contact with tunnel runners. That tells me the runners probably aren't necessary, but it's better to be safe than sorry.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I'd like to share my recent experience with tunnel air line to air spring durability...

We were taking a trail side break when my buddy says, "Look at that huge chunk of ice hanging from inside your track!" I walk over and find what I'm guessing to be a 10 pound snowball hanging from just the air line that runs inside the tunnel to the rear air spring...YIKES! So...I chiseled it out to find the line slightly kinked from all the weight, but still in service, and I ran the rest of the trip with no issues. I'm still wondering how that much weight and hammering around didn't pull the line apart, but it held. These poly, stainless braided lines I use aren't cheap, but I am convinced with their durability!

I wish I would have thought to take a picture before I removed the chunk.

We were taking a trail side break when my buddy says, "Look at that huge chunk of ice hanging from inside your track!" I walk over and find what I'm guessing to be a 10 pound snowball hanging from just the air line that runs inside the tunnel to the rear air spring...YIKES! So...I chiseled it out to find the line slightly kinked from all the weight, but still in service, and I ran the rest of the trip with no issues. I'm still wondering how that much weight and hammering around didn't pull the line apart, but it held. These poly, stainless braided lines I use aren't cheap, but I am convinced with their durability!

I wish I would have thought to take a picture before I removed the chunk.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

COMING SOON - Apex XTX M20 (version 2.0)

I am currently gearing up for my third M20 installation in a buddy's 2011 Apex XTX. This install will be an improved version of my Apex, so a new thread will follow this spring and summer.

Stay tuned....

I am currently gearing up for my third M20 installation in a buddy's 2011 Apex XTX. This install will be an improved version of my Apex, so a new thread will follow this spring and summer.

Stay tuned....

you sure are good at them and can't wait to follow the thread. I hope you had a good riding season!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Got 'er serviced and ready to ride! The slides we're shot from last year, so I replaced them with graphite slides from Dennis Kirk. With a little research, I found that slides from a 2006 Polaris RMK trail fit with minimal trimming.

Everything works as it should! All solenoids, compressor and switches powered after their summer hiatus. This system has proved very reliable.

Everything works as it should! All solenoids, compressor and switches powered after their summer hiatus. This system has proved very reliable.

Last edited:

Dusty Dan

Lifetime Member

- Joined

- Jan 24, 2015

- Messages

- 211

- Country

- Canada

- Snowmobile

- 2016 SRViper LTX LE

2012 Vector

Looking great Joe, just about time for some adventure.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Yes sir! We're taking a small trip the second week of January, then we have a mega trip planned for February.

I CANT WAIT!

I CANT WAIT!

Dusty Dan

Lifetime Member

- Joined

- Jan 24, 2015

- Messages

- 211

- Country

- Canada

- Snowmobile

- 2016 SRViper LTX LE

2012 Vector

Have a great one. I am hoping to talk a few of our guys to head Cochrane way early January. I am also biting the bullet.Yes sir! We're taking a small trip the second week of January, then we have a mega trip planned for February.

I CANT WAIT!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

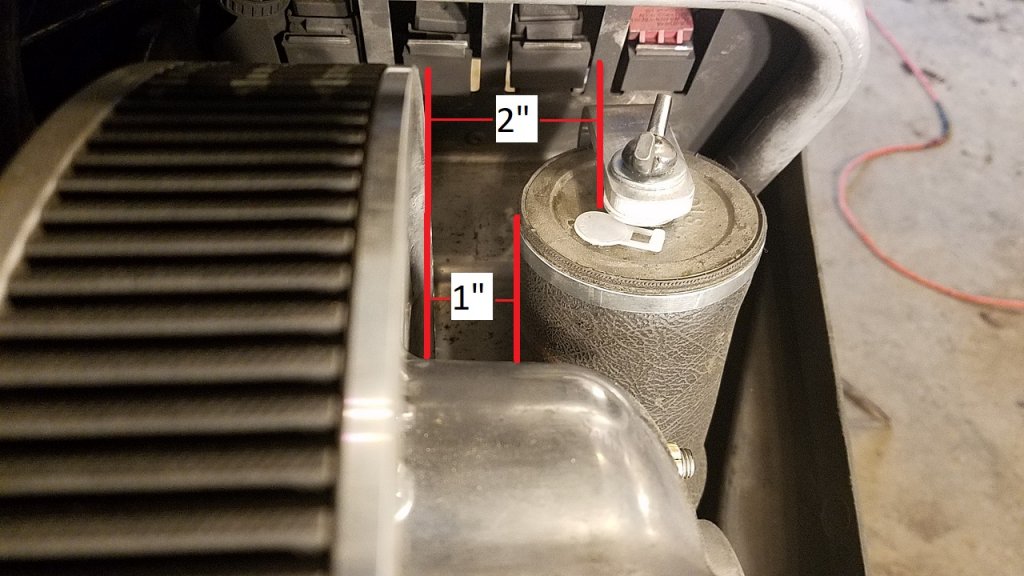

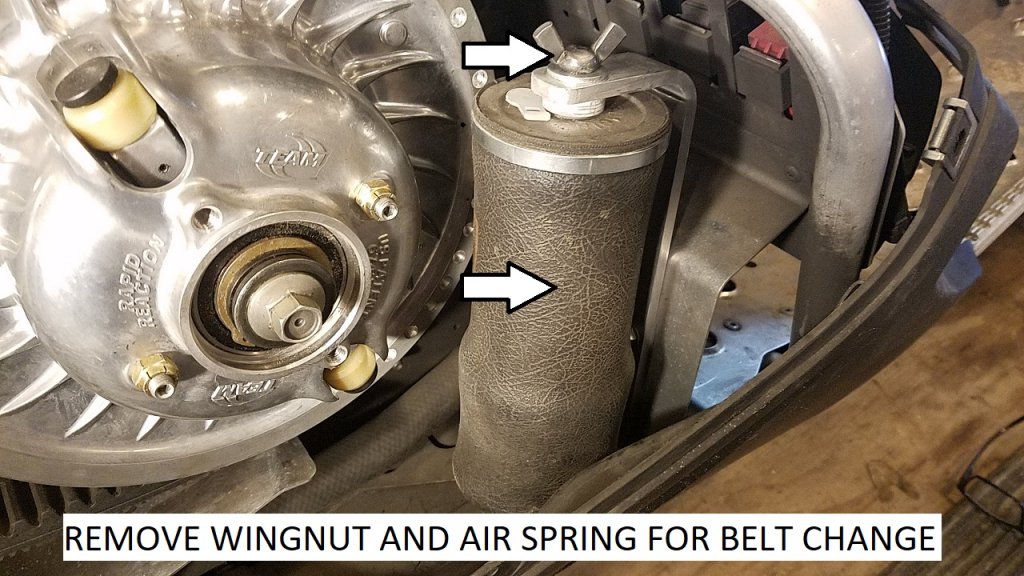

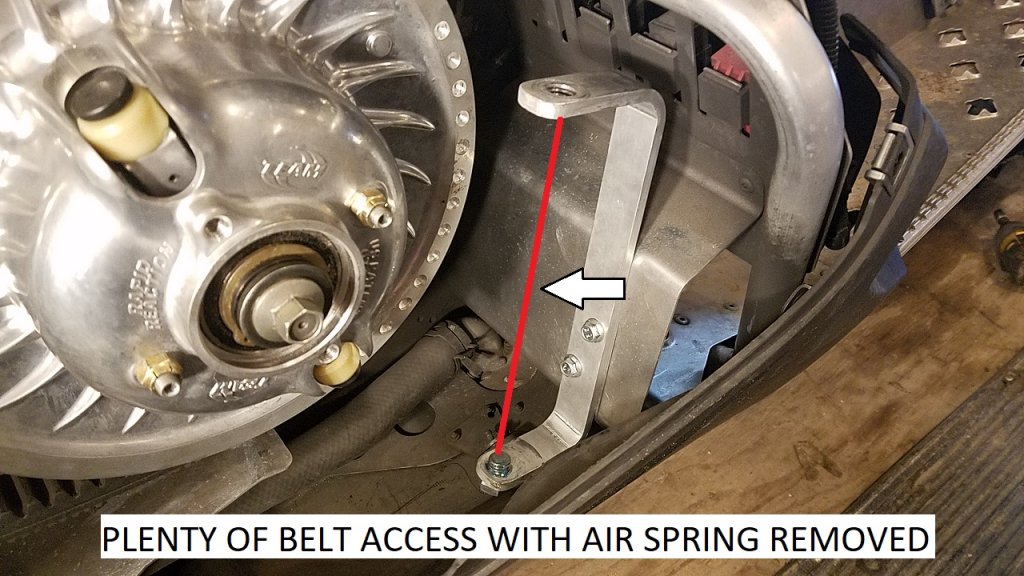

I mounted a spare air spring under the hood in case it's ever needed. It sits about an inch away from the secondary, but easily removes for full access to the drive belt if needed.

If I have it, I'll never need it... right!

If I have it, I'll never need it... right!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

We just returned home from a week of riding the UP. This trip was a blend of riding out of Munising every morning for three days, followed by three days of backpacking. The TY Giveaway event was right in the middle!

This is my fifth consecutive winter aboard my Apex equipped with an M20. In this time, I've never once had an issue with the skid itself: no broken or bent parts, or air spring failures. The skid still rides like it did the first year (with regular shock service) and it still amazes me on how well it soaks up bumps. I've literally beat the hell out of this skid, but it just keeps on taking it. I'm sure a breakdown will eventually happen some day, but I couldn't be happier!

Those who ride my M20 for the first time, especially those that rode my old M10, are simply amazed by the ride! The difference in ride quality between the M10 and the M20 are very different. The M10 rode well, but it would always spin-out at take off. The M20 just hooks up and goes, especially when coupled with a 1.5" lug track. It does have its limit, as there are times we encounter trail junk that no suspension is capable of handling with comfort. Long story short...for the way I ride, I would buy this suspension all over again...no question!!

In 5 winters of riding, I've have had one or two minor electrical glitches with a switch and one issue with a frozen check valve. Never once have I had an issue with the solenoids opening/closing, or the compressor failing to work...until this year. "ICE" gave me and my buddy's a fit this past week, as excessive moisture formed in the air system and prevented the solenoids from fully closing. We confirmed this by making a trail-side disassembly and finding the solenoid plunger seats caked with ice chunks. If you tried to air-up the front or rear, it would simply just bleed out the dump port. Sometimes, engine heat would get everything perking again, but they usually stayed iced-up for the entire day.

We also encountered another "new-to-me" issue. Even if the solenoids were seating and holding air properly, we would sometimes get a loss of air pressure in the rear air spring during a full compression scenario (deep moguls and jumps). It was very cold (-0's to single digit highs), so I'm wondering if these solenoids just can't hold a high pressure bulge when you throw the super cold into the mix, not to mention moisture?? Maybe the plunger springs aren't strong enough?? This is a condition that I thought could happen, and it's why I run two solenoids in tandem, but they're falling shorter in performance than I'd like in this extreme case?? Fortunately, the 4 M20 equipped sleds in my group all have a bleed valve that can be fully closed to prevent air from leaving the system. We simply closed the valve, set our desired air pressure and all was good, until we needed to vent-off some pressure. As mentioned above, this is the FIRST time this has ever happened! Who knows, maybe it's just a fluke thing this winter?? We've had a tremendous temperature swing at home; anywhere from -10 to +50's. This HAS to be what's causing the excessive moisture to build up inside the system!

These issues have me thinking about the solenoids themselves. They use a basic, spring-loaded plunger with a rubber face that seals against a machined brass valve seat. They're rated at 200 psi, but maybe it's time to find a higher pressure rated solenoid with a higher quality seat?? I also think it's time to treat the system with some air line antifreeze at least once, maybe twice a season.

Even with the minor issues we've experienced, I will STILL say that having an air compressor for on-the-fly adjustments is THE only way to go!

So...stay tuned my friends! I am already researching new and better components to keep my M20 as a reliable, fully adjustable, on-the-fly system!

This is my fifth consecutive winter aboard my Apex equipped with an M20. In this time, I've never once had an issue with the skid itself: no broken or bent parts, or air spring failures. The skid still rides like it did the first year (with regular shock service) and it still amazes me on how well it soaks up bumps. I've literally beat the hell out of this skid, but it just keeps on taking it. I'm sure a breakdown will eventually happen some day, but I couldn't be happier!

Those who ride my M20 for the first time, especially those that rode my old M10, are simply amazed by the ride! The difference in ride quality between the M10 and the M20 are very different. The M10 rode well, but it would always spin-out at take off. The M20 just hooks up and goes, especially when coupled with a 1.5" lug track. It does have its limit, as there are times we encounter trail junk that no suspension is capable of handling with comfort. Long story short...for the way I ride, I would buy this suspension all over again...no question!!

In 5 winters of riding, I've have had one or two minor electrical glitches with a switch and one issue with a frozen check valve. Never once have I had an issue with the solenoids opening/closing, or the compressor failing to work...until this year. "ICE" gave me and my buddy's a fit this past week, as excessive moisture formed in the air system and prevented the solenoids from fully closing. We confirmed this by making a trail-side disassembly and finding the solenoid plunger seats caked with ice chunks. If you tried to air-up the front or rear, it would simply just bleed out the dump port. Sometimes, engine heat would get everything perking again, but they usually stayed iced-up for the entire day.

We also encountered another "new-to-me" issue. Even if the solenoids were seating and holding air properly, we would sometimes get a loss of air pressure in the rear air spring during a full compression scenario (deep moguls and jumps). It was very cold (-0's to single digit highs), so I'm wondering if these solenoids just can't hold a high pressure bulge when you throw the super cold into the mix, not to mention moisture?? Maybe the plunger springs aren't strong enough?? This is a condition that I thought could happen, and it's why I run two solenoids in tandem, but they're falling shorter in performance than I'd like in this extreme case?? Fortunately, the 4 M20 equipped sleds in my group all have a bleed valve that can be fully closed to prevent air from leaving the system. We simply closed the valve, set our desired air pressure and all was good, until we needed to vent-off some pressure. As mentioned above, this is the FIRST time this has ever happened! Who knows, maybe it's just a fluke thing this winter?? We've had a tremendous temperature swing at home; anywhere from -10 to +50's. This HAS to be what's causing the excessive moisture to build up inside the system!

These issues have me thinking about the solenoids themselves. They use a basic, spring-loaded plunger with a rubber face that seals against a machined brass valve seat. They're rated at 200 psi, but maybe it's time to find a higher pressure rated solenoid with a higher quality seat?? I also think it's time to treat the system with some air line antifreeze at least once, maybe twice a season.

Even with the minor issues we've experienced, I will STILL say that having an air compressor for on-the-fly adjustments is THE only way to go!

So...stay tuned my friends! I am already researching new and better components to keep my M20 as a reliable, fully adjustable, on-the-fly system!

Last edited:

- Joined

- Jun 28, 2004

- Messages

- 2,436

- Age

- 64

- Location

- Clinton, Wi.

- Country

- USA

- Snowmobile

- '11 Apex XTX, '09 Venture GT, '06 Attak, 08 Nytro Hybrid

Right on sir ! A tad under 1300 miles in 5 full days of riding and THIS old man came home with minimal aches and pains. Definitely a high mile per day suspension. I so much appreciate all the work that Northernsledder has put in to this install and set up ! Definitely 2 thumbs up here!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Thank you, Dave! What a great trip!Right on sir ! A tad under 1300 miles in 5 full days of riding and THIS old man came home with minimal aches and pains. Definitely a high mile per day suspension. I so much appreciate all the work that Northernsledder has put in to this install and set up ! Definitely 2 thumbs up here!

Last edited:

Similar threads

- Replies

- 20

- Views

- 6K

- Replies

- 46

- Views

- 146K

- Replies

- 4

- Views

- 31K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.