Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I had a little trouble getting 'er started and running good. First off, I turned the key and NOTHING! I checked all the fuses, checked battery voltage and even jumped the starter solenoid...NOTHING! I hooked up a lawn mower battery and she fired up!  Time for a battery; the voltage checked good, but it's junk!

Time for a battery; the voltage checked good, but it's junk!

Next, fuel started puking out the PTO carb, so I had to remove the rack and chcek the float and needle. I didn't find anything, so I put it back together and all is good now. I'm guessing the float stuck down.

I'm guessing the float stuck down.  Either way, it's going!

Either way, it's going!

Next, fuel started puking out the PTO carb, so I had to remove the rack and chcek the float and needle. I didn't find anything, so I put it back together and all is good now.

I'm guessing the float stuck down.

I'm guessing the float stuck down.  Either way, it's going!

Either way, it's going!ghost rider

Suspended

- Joined

- Nov 13, 2013

- Messages

- 495

- Age

- 65

- Location

- Muskoka, Ontario, Canada

- Country

- Canada

- Snowmobile

- Rxwarrior

- LOCATION

- Muskoka , Ontario

Fantastic work!!!

rxrobmeyers

Veteran

Wow amazing story and photo's thanks!! My 04 RXW would love this TLC...still praying to the garage gods for lift etc. Soon to do skid and track. Has 13000 km on it, but currently runs great. I noticed your comment above, gas puking from the carbs. Just a watch item, I had this, intermittently, would drain to the cylinder, contaminate oil. Went through about 5 oil changes until I found the problem. It wasn't the float valve itself, which is what I focused on. It was the O ring on the float valve seat assembly. Small brass cylinder fits in the alum carb body. Guess it dried out, and failed at times. Have a look behind your slides, see if there is any gas pooling against the butterfly, when its parked. All O rings replacement is a good maintenance item on these carbs. Can't wait to hear more about the mono performance in this sled.

ghost rider

Suspended

- Joined

- Nov 13, 2013

- Messages

- 495

- Age

- 65

- Location

- Muskoka, Ontario, Canada

- Country

- Canada

- Snowmobile

- Rxwarrior

- LOCATION

- Muskoka , Ontario

Great tip!!!!Wow amazing story and photo's thanks!! My 04 RXW would love this TLC...still praying to the garage gods for lift etc. Soon to do skid and track. Has 13000 km on it, but currently runs great. I noticed your comment above, gas puking from the carbs. Just a watch item, I had this, intermittently, would drain to the cylinder, contaminate oil. Went through about 5 oil changes until I found the problem. It wasn't the float valve itself, which is what I focused on. It was the O ring on the float valve seat assembly. Small brass cylinder fits in the alum carb body. Guess it dried out, and failed at times. Have a look behind your slides, see if there is any gas pooling against the butterfly, when its parked. All O rings replacement is a good maintenance item on these carbs. Can't wait to hear more about the mono performance in this sled.

rxrobmeyers

Veteran

Does anyone know where I would pickup a 136 inch mono for an 04 warrior, and how much should I budget? I'm getting to point I need a new track, so could do this all at once. I'm in Ottawa Canada. Thanks for any suggestions!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Do any of you guys have interest in seeing this sled converted to air ride with a 151" M10 W2 skid and Assault ski shocks?

Al Bundy

Lifetime Member

Well yeah!Do any of you guys have interest in seeing this sled converted to air ride with a 151" M10 W2 skid and Assault ski shocks?

Dusty Dan

Lifetime Member

- Joined

- Jan 24, 2015

- Messages

- 211

- Country

- Canada

- Snowmobile

- 2016 SRViper LTX LE

2012 Vector

Absolutely!Do any of you guys have interest in seeing this sled converted to air ride with a 151" M10 W2 skid and Assault ski shocks?

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

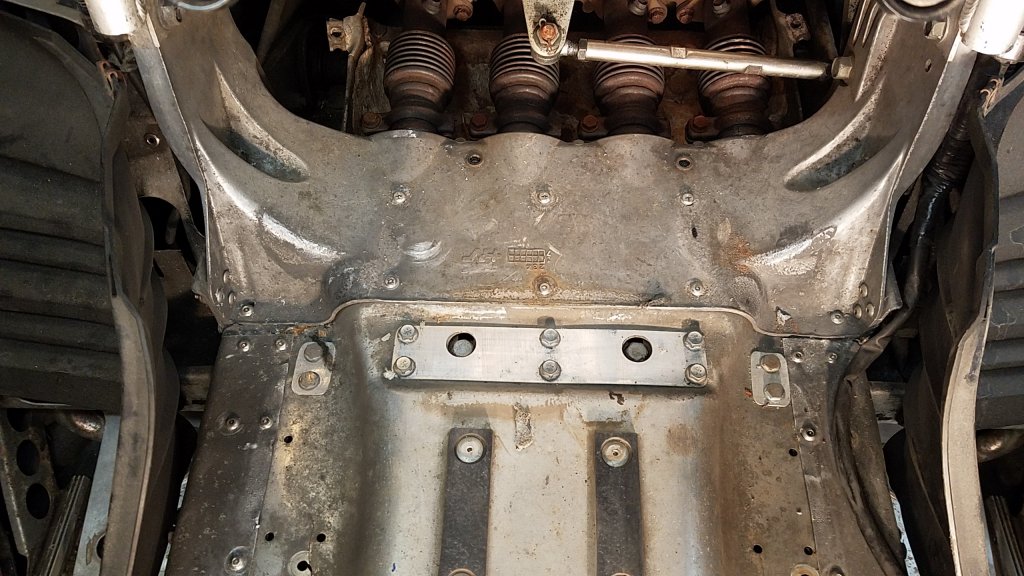

Purely just a thought for now, but here's what I'm dreaming...Well yeah!

First - My primary choice would be an M20, hands down! However, my 151 M10, which was removed from my Vector in 2016, is just laying on the shelf collecting dust. It makes the most sense to reuse it.

Second - I have a brand new 151 x 1.5 lug Crossover track that's been laying around for 4 years! It was going to be an updated track for the Vector, but those plans obviously changed in this link: https://ty4stroke.com/threads/team-fast-m20-vector-ltx.141902/

Third - I will not have to make ANY custom brackets to mount the skid, as the current stock rear brackets will work perfectly in in their current position. I'll have to drill new front arm holes, but my band-aid brackets (from repairing the cracked tunnel) are already there and more than sufficient as a reinforcement for this area.

Fourth - I purchased a like-new set of Assault front shocks from another member back in December. I only bought them as spares, but they definitely have a purpose now!

Fifth - Now here's where I'm the most uncertain?? Do I keep this sled as 100% trail, or do I make it more cross-over-ish??

The M10 W2 was actually designed for mountain riders and excels in deeper snow compared to the M20. I'm not talking about push ability from a longer track, but more in the nature of the skid. The mounting locations and physical geometry are different than the M20 and even the M10. The approach angle is also more shallow, which let's it climb out of the hole with less trenching. This skid also has what Fast calls a "Live rear axle!" There is a control rod that connects the rear arm to the rear axle, which moves the rear axle forward and keeps the track from becoming impossibly tight during full compression. Don't get me wrong...the M10 W2 rides well compared to stock. I always preferred this skid over the M20 when riding at home in drifted fields and ditch lines, but the M20 still takes top honors for trail.

So...I told myself that I was talking this summer off from any sled projects, but that may change!

Last edited:

DGZRT

VIP Member

- Joined

- Feb 23, 2006

- Messages

- 1,181

- Location

- Stevens Point Wisconsin

- Country

- USA

- Snowmobile

- 2008 Vector shorty, 17 Shitdoo 1200X, 2000- pullmyass-340 for Grandkids

Summer Sled projects  I'm always in for some cool upgrades. Now when I need a break from yard work I can check on your updates

I'm always in for some cool upgrades. Now when I need a break from yard work I can check on your updates

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Well, I didn't even turn one wrench on any of my sleds this summer, but thought I'd follow up on this thread.

I'll admit this sled didn't even leave my shop last winter; didn't even service, start it...nothing! It had developed some issues the last time it ran in February 2017, but I just never found time to touch it.

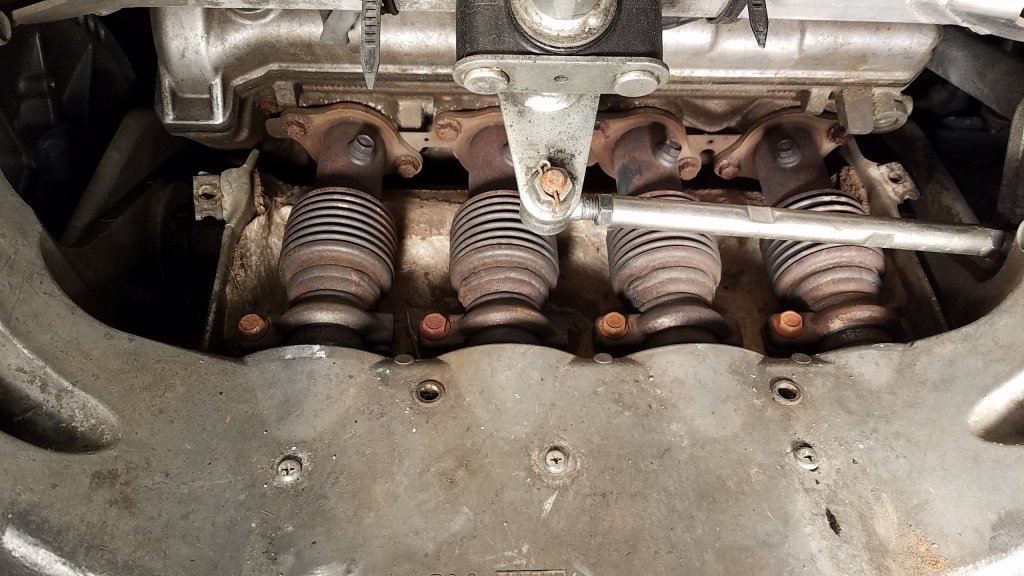

For starters, it began puking gasoline out the carb overflow at idle. In addition, it developed a rattle somewhere in the exhaust and I feared my header repair or a bellow had failed.

I started with the carbs first! All the gas was drained from the entire system in the spring of '17, so there was no scum or gunk inside the float bowls or inside any of the jets. I then removed the floats and discovered the rubber tips on the needles were hard as stone! Makes me think one or more carbs had a needle not seating properly. So, I threw in all new needle and seat assemblies for all 4 carbs. Each assembly includes: needle, seat, o-ring and ultra fine fuel screen.

Second, I removed the seat and gas tank to inspect the exhaust bellows and my header hanger repair (page 3, post #34). It was secure, but I did find some squeaky rivets back around the exhaust outlet. I'm not even sure what these use to secure (last pic)?

I'll report back again once I get this thing running again. Kind of ashamed of myself for not touching it in a year and a half.

I'll admit this sled didn't even leave my shop last winter; didn't even service, start it...nothing! It had developed some issues the last time it ran in February 2017, but I just never found time to touch it.

For starters, it began puking gasoline out the carb overflow at idle. In addition, it developed a rattle somewhere in the exhaust and I feared my header repair or a bellow had failed.

I started with the carbs first! All the gas was drained from the entire system in the spring of '17, so there was no scum or gunk inside the float bowls or inside any of the jets. I then removed the floats and discovered the rubber tips on the needles were hard as stone! Makes me think one or more carbs had a needle not seating properly. So, I threw in all new needle and seat assemblies for all 4 carbs. Each assembly includes: needle, seat, o-ring and ultra fine fuel screen.

Second, I removed the seat and gas tank to inspect the exhaust bellows and my header hanger repair (page 3, post #34). It was secure, but I did find some squeaky rivets back around the exhaust outlet. I'm not even sure what these use to secure (last pic)?

I'll report back again once I get this thing running again. Kind of ashamed of myself for not touching it in a year and a half.

DGZRT

VIP Member

- Joined

- Feb 23, 2006

- Messages

- 1,181

- Location

- Stevens Point Wisconsin

- Country

- USA

- Snowmobile

- 2008 Vector shorty, 17 Shitdoo 1200X, 2000- pullmyass-340 for Grandkids

I want that table in the back ground  That would be perfect up north at the cabin ! Except I would build a ramp so I could drive the 4 wheeler right up......

That would be perfect up north at the cabin ! Except I would build a ramp so I could drive the 4 wheeler right up......

That would be perfect up north at the cabin ! Except I would build a ramp so I could drive the 4 wheeler right up......

That would be perfect up north at the cabin ! Except I would build a ramp so I could drive the 4 wheeler right up......

yamadoo

Yamadoo is a snowmobile ' aholic'.

- Joined

- Jun 3, 2003

- Messages

- 3,645

- Country

- USA

- Snowmobile

- 15 Viper STX DX red/white- GPS and KING AIR suspension 4kmiles

13 Apex XTX 45 anniversary RED/WHITE/BLACK 3K miles

10 Vector LTX Blue 9kmiles

11 Venture GT 4k miles

86 SnoScoot(2) for grand kids

Just reread the whole thread and loved it buddy!

I agree with DGZRT that table your son made is fantastic.

I haven’t gotten to anything sledding yet either, something about life, family work and house,home ... takes all my time

I agree with DGZRT that table your son made is fantastic.

I haven’t gotten to anything sledding yet either, something about life, family work and house,home ... takes all my time

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I'd lend it to you, but it weighs 1,400 lbs and kinda tough to move around!I want that table in the back groundThat would be perfect up north at the cabin ! Except I would build a ramp so I could drive the 4 wheeler right up......

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I agree! Life, family and work trumps all!Just reread the whole thread and loved it buddy!

I agree with DGZRT that table your son made is fantastic.

I haven’t gotten to anything sledding yet either, something about life, family work and house,home ... takes all my time

Similar threads

- Replies

- 13

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.