Glenn_the_Pilot

Newbie

Glad I found this forum. I hope you guys can help.

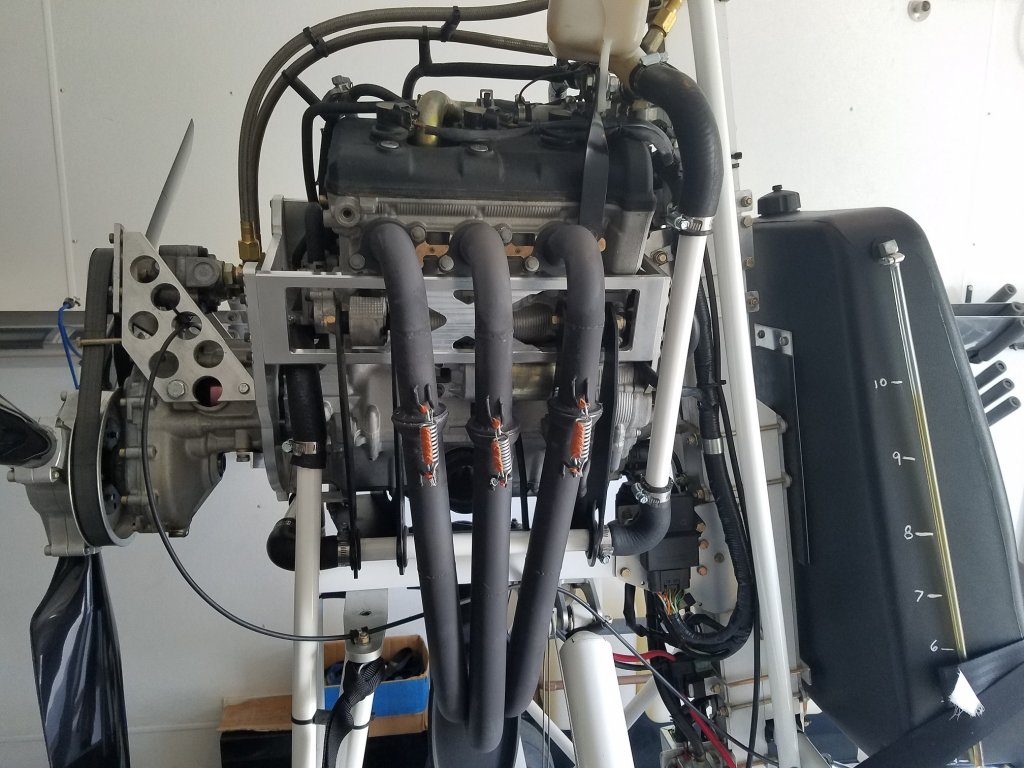

I have a YG3 that I'm told is from a 2007 snowmobile. It is installed as an aircraft engine on my gyrocopter. I have the propeller pitch adjusted for 7500 max engine rpm.

The engine has been working great until recently. I was climbing, WOT at ~7200 rpm. Suddenly the rpm dropped by about 400. I leveled out and checked fuel flow by changing fuel pumps, no change. It now has a noticable reduction in power at WOT with a max rpm of ~6800. I've overhauled all 3 carburetors and replaced all the rubber in them, except for the diaphrams. Replaced the fuel filters and spark plugs as well. Low and mid throttle power seems good, but the top is definitely chopped off. Verified good fuel pressure and volume.

Can anyone advise me on what may have gone wrong here?

I have a YG3 that I'm told is from a 2007 snowmobile. It is installed as an aircraft engine on my gyrocopter. I have the propeller pitch adjusted for 7500 max engine rpm.

The engine has been working great until recently. I was climbing, WOT at ~7200 rpm. Suddenly the rpm dropped by about 400. I leveled out and checked fuel flow by changing fuel pumps, no change. It now has a noticable reduction in power at WOT with a max rpm of ~6800. I've overhauled all 3 carburetors and replaced all the rubber in them, except for the diaphrams. Replaced the fuel filters and spark plugs as well. Low and mid throttle power seems good, but the top is definitely chopped off. Verified good fuel pressure and volume.

Can anyone advise me on what may have gone wrong here?

- Joined

- Jun 1, 2004

- Messages

- 7,693

- Location

- sudbury on

- Country

- Canada

- Snowmobile

- 2016 apex xtx

2011 apex xtx

2009 phaser rtx/x

1997 et410t/r

1988 vk 540

has it ever had the valves set? might have enough hours on it to need it done.

Glenn_the_Pilot

Newbie

Thanks for the suggestion.

When I got the motor, the instrument cluster showed about 5300 miles. Using a guess at an average speed we figure it had between 130 and 150 hours. I've added another 40 hours to that. Figure an equivalent of about 7500 miles or so. The manual says it should be done at 25000 miles.

Is it likely that the valves could go out of adjustment that quickly to have that dramatic an effect?

The procedure requires tools and parts I don't have access to. What do you think the likelihood would be that I could take my gyrocopter to a shop and get somebody to work on it?

When I got the motor, the instrument cluster showed about 5300 miles. Using a guess at an average speed we figure it had between 130 and 150 hours. I've added another 40 hours to that. Figure an equivalent of about 7500 miles or so. The manual says it should be done at 25000 miles.

Is it likely that the valves could go out of adjustment that quickly to have that dramatic an effect?

The procedure requires tools and parts I don't have access to. What do you think the likelihood would be that I could take my gyrocopter to a shop and get somebody to work on it?

DGZRT

VIP Member

- Joined

- Feb 23, 2006

- Messages

- 1,181

- Location

- Stevens Point Wisconsin

- Country

- USA

- Snowmobile

- 2008 Vector shorty, 17 Shitdoo 1200X, 2000- pullmyass-340 for Grandkids

How is the rotor driven ? Is it still a CVT clutch or some kind of direct drive with a coupling? If it has a clutch drive , first thing to check is the belt and then the clutches. If it's has a coupling system like a Personal water craft has for the Jet Drive then check that out.

- Joined

- Jun 1, 2004

- Messages

- 7,693

- Location

- sudbury on

- Country

- Canada

- Snowmobile

- 2016 apex xtx

2011 apex xtx

2009 phaser rtx/x

1997 et410t/r

1988 vk 540

what dgzrt said also applies as well.

some times valve adjustment intervals are different for how it has been used.

some times valve adjustment intervals are different for how it has been used.

Glenn_the_Pilot

Newbie

The rotorblades are driven by air only. They're not connected to the engine. The engine turns the propeller, creating forward motion and causing air to move through the rotorblades to keep them spinning.

The propeller is connected to the engine through a Rotax reduction gearbox which has a 3:1 ratio. It is fitted with an RK400 clutch in the gearbox. However, if the clutch were to have an issue, I would see an increase in engine rpm and a decrease in available thrust. That's not the condition I'm experiencing.

The propeller is connected to the engine through a Rotax reduction gearbox which has a 3:1 ratio. It is fitted with an RK400 clutch in the gearbox. However, if the clutch were to have an issue, I would see an increase in engine rpm and a decrease in available thrust. That's not the condition I'm experiencing.

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,848

- Age

- 40

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

Simplest thing that comes to mind is bad spark plug coil. Mist valve cover with spray bottle of water, run it in the dark and look for arcing.

Another more involved issue would timing chain jumped a tooth on one of cams. Tensioner failure was an issue on some 05-07 motors. Updated tensioners were created in 08 an would have a blue paint mark vs orange.

Another more involved issue would timing chain jumped a tooth on one of cams. Tensioner failure was an issue on some 05-07 motors. Updated tensioners were created in 08 an would have a blue paint mark vs orange.

DGZRT

VIP Member

- Joined

- Feb 23, 2006

- Messages

- 1,181

- Location

- Stevens Point Wisconsin

- Country

- USA

- Snowmobile

- 2008 Vector shorty, 17 Shitdoo 1200X, 2000- pullmyass-340 for Grandkids

Any video of you flying ?

DGZRT

VIP Member

- Joined

- Feb 23, 2006

- Messages

- 1,181

- Location

- Stevens Point Wisconsin

- Country

- USA

- Snowmobile

- 2008 Vector shorty, 17 Shitdoo 1200X, 2000- pullmyass-340 for Grandkids

I'm still going to the gear box and clutch is loading the motor down at full RPM's . Have you changed the oil in the gear box or changed the pads in the clutch? Wear on the pads I would think cause loss of Rpm's . I would also replace the belt for good measure.

Scratch this LOL I did some reading on the Rotax Clutch . the primary purpose of the clutch is to disengage the prop from the engine allowing it to start and operate at idle without vibration. When the engine is idling (below 2350 RPM) the prop is not turning.

Scratch this LOL I did some reading on the Rotax Clutch . the primary purpose of the clutch is to disengage the prop from the engine allowing it to start and operate at idle without vibration. When the engine is idling (below 2350 RPM) the prop is not turning.

Last edited:

Glenn_the_Pilot

Newbie

No worries DGZRT. I really appreciate the advice from everyone. There are plenty if videos on my YouTube channel https://www.youtube.com/user/gakjarr/

The latest 3 are with the Yamaha. All the others are Rotax engines.

Thanks hibshman25 (recognize you from RWF). Your suggestion about the coils seems a very likely candidate. Is there a way to check the cam timing without disassembly?

The latest 3 are with the Yamaha. All the others are Rotax engines.

Thanks hibshman25 (recognize you from RWF). Your suggestion about the coils seems a very likely candidate. Is there a way to check the cam timing without disassembly?

Similar threads

- Replies

- 5

- Views

- 1K

- Replies

- 2

- Views

- 496

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.