Phatboyc

TY 4 Stroke Master

- Joined

- Apr 2, 2007

- Messages

- 1,038

- Location

- Ottawa, Ontario

- Country

- Canada

- Snowmobile

- 2022 Sidewinder

Richard Hodgins

Expert

- Joined

- Mar 5, 2019

- Messages

- 244

- Age

- 46

- Location

- Ottawa ontario

- Country

- Canada

- Snowmobile

- Yamaha powered CAT

The 20 and 21 have the part numbers I listed, but the 22 has the same spring as all regular winders! Wierd!

Check the 20 and 21s.....different part numbers. So it means that the 22 and newer SRX were higher in the rear.

Check the 20 and 21s.....different part numbers. So it means that the 22 and newer SRX were higher in the rear.

Phatboyc

TY 4 Stroke Master

- Joined

- Apr 2, 2007

- Messages

- 1,038

- Location

- Ottawa, Ontario

- Country

- Canada

- Snowmobile

- 2022 Sidewinder

Perhaps a covid supply issue. AC site shows using same torsion springs for MY21 and MY22 on non ATAC regular Thundercat, ATAC or EPS. The same ones they used for MY20 for non ATAC.

3704-380

3704-381

Then for MY23 they show EPS with ATAC model going back to using spring they used in ATAC 2020?

2704-026

2704-027

The quicker is AC has this lower torsion springs cheaper than regular. Which is the opposite pricing from Yam.

So now I wonder, is the Yam/AC '22 with their lower front running standard height in the rear...I though that would unbalanced the sled?

3704-380

3704-381

Then for MY23 they show EPS with ATAC model going back to using spring they used in ATAC 2020?

2704-026

2704-027

The quicker is AC has this lower torsion springs cheaper than regular. Which is the opposite pricing from Yam.

So now I wonder, is the Yam/AC '22 with their lower front running standard height in the rear...I though that would unbalanced the sled?

Last edited:

duhr8m

VIP Member

- Joined

- Oct 27, 2007

- Messages

- 65

- Location

- Minocqua WI

- Country

- USA

- Snowmobile

- sidewinder, SRXs, snow scoot + sport, vmaxs, enticers

or maybe the newer spindle moves the lower ball joint up and you can run a shorter spring with the same ride height. maybe the new SRX is same height as the rest of them now.

I was told by a highly respected suspension shop that the collapsed coils at the top of the front shock springs are merely for ride height adjustment. There is no "dual rate" in play.

duhr8m

VIP Member

- Joined

- Oct 27, 2007

- Messages

- 65

- Location

- Minocqua WI

- Country

- USA

- Snowmobile

- sidewinder, SRXs, snow scoot + sport, vmaxs, enticers

I'ld loose some respect for them. The suspension specs even show 90/ 145 lb/in front springs. Srx, Gt, Le

I was told by a highly respected suspension shop that the collapsed coils at the top of the front shock springs are merely for ride height adjustment. There is no "dual rate" in play.

I'ld loose some respect for them. The suspension specs even show 90/ 145 lb/in front springs. Srx, Gt, Le

Edit: I did misquote my source. He did not say they were not dual rate but what he did say is: If the "tender" portion of the suspension is used up at rider sag, then it is actually a helper spring. This scenario is used to lower ride height and then get strong. Unfortunately, you won't gain much comfort from the soft portion of travel.

Last edited:

I was told by a highly respected suspension shop that the collapsed coils at the top of the front shock springs are merely for ride height adjustment. There is no "dual rate" in play.

The eye is naturally drawn towards those tight coils at the top. The next open coil down however has more spacing and so on until you hit the second spring rate of the shock where spacing is consisstent. It works just like a hygear but is pre-set in the crossover between dualrate and single rate. Its quite obvious if you look at the coils below the tight coils at the top.

The second job of those tight coils (which do open up) is for when the shock extends past the normal ride height, to ensure that there is always tension in the spring. When you are going thru small chatter bumps the part of the spring that is working is the upper part, as you go through the bigger woops, its the entire spring with a transition to the lower (stiffer) part. Lets say you go off a jump, shock fully extends, the spring extends, on the way back down those tight coils act like a very soft spring until they compress and hit the 'bound' state at which the shock transitions into its linear, single rate articulation.

This is just like a hygear- except. The hygear is more adjustable, and you can change the rates of the separate springs by simply changing springs but the crossover gap between them is going to be very small, just like that first open coil on the stock spring). I actually tried to find some installed hygear springs but almost every image I found after a quick search showed the crossover gap almost fully closed.

The dualrate spring Yamaha/Fox uses will have less of a sharp transition between the combined (softer) spring rate, and the single (stiffer) spring rate of the lower portion of the springs.

When you set sag on a sled (or any vehicle) the goal is to pick a spring that is soft enough for the sled to 'settle' into the working area of the shock. If the spring is too stiff, the shock shaft will have little room to extend. Too soft, you will be too far into the shock stroke and the shock will easily bottom out. A dual rate spring is initially softer than the single rate spring. That is because the two springs both move at the same time, and you are running two different spring rates.

Spring rates are not just about the coil diameter and material, the actual coil angles and number of wraps matter as well. Take two springs, one of them has 10 wraps and the other has 20 both are the same overall length. Unwrap both springs so each is one long chunk of metal bar. All other things being equal, the bar that is longer will be easier to bend and that longer bar will come from the coil with more winds. The actual resistance to bending is the same and dictated by wire/coil/bar diameter and material but length matters which is where the leverage comes from. The SRX spring is more spring wrapped into less space. This makes the top (visually) softer as it has more coils in less space. The bottom part of the spring will be stiffer. The crossover point happens when the softer spart (less spacing) crushes under load (that first open coil and the next) until you are only using the more open, stiffer part (bottom) of the spring.

Last edited:

Love to learn. Good post. One observation though, the tight coils do not open up and I know this because mine are still collapsed off the shock and in a box.The eye is naturally drawn towards those tight coils at the top. The next open coil down however has more spacing and so on until you hit the second spring rate of the shock where spacing is consisstent. It works just like a hygear but is pre-set in the crossover between dualrate and single rate. Its quite obvious if you look at the coils below the tight coils at the top.

The second job of those tight coils (which do open up) is for when the shock extends past the normal ride height, to ensure that there is always tension in the spring. When you are going thru small chatter bumps the part of the spring that is working is the upper part, as you go through the bigger woops, its the entire spring with a transition to the lower (stiffer) part. Lets say you go off a jump, shock fully extends, the spring extends, on the way back down those tight coils act like a very soft spring until they compress and hit the 'bound' state at which the shock transitions into its linear, single rate articulation.

This is just like a hygear- except. The hygear is more adjustable, and you can change the rates of the separate springs by simply changing springs but the crossover gap between them is going to be very small, just like that first open coil on the stock spring). I actually tried to find some installed hygear springs but almost every image I found after a quick search showed the crossover gap almost fully closed.

The dualrate spring Yamaha/Fox uses will have less of a sharp transition between the combined (softer) spring rate, and the single (stiffer) spring rate of the lower portion of the springs.

View attachment 170126

When you set sag on a sled (or any vehicle) the goal is to pick a spring that is soft enough for the sled to 'settle' into the working area of the shock. If the spring is too stiff, the shock shaft will have little room to extend. Too soft, you will be too far into the shock stroke and the shock will easily bottom out. A dual rate spring is initially softer than the single rate spring. That is because the two springs both move at the same time, and you are running two different spring rates.

Spring rates are not just about the coil diameter and material, the actual coil angles and number of wraps matter as well. Take two springs, one of them has 10 wraps and the other has 20 both are the same overall length. Unwrap both springs so each is one long chunk of metal bar. All other things being equal, the bar that is longer will be easier to bend and that longer bar will come from the coil with more winds. The actual resistance to bending is the same and dictated by wire/coil/bar diameter and material but length matters which is where the leverage comes from. The SRX spring is more spring wrapped into less space. This makes the top (visually) softer as it has more coils in less space. The bottom part of the spring will be stiffer. The crossover point happens when the softer spart (less spacing) crushes under load (that first open coil and hte next) until you are only using the more open, stiffer part (bottom) of the spring.

Love to learn. Good post. One observation though, the tight coils do not open up and I know this because mine are still collapsed off the shock and in a box.

Sure they do. Loosen the adjuster nut. If you just pulled the shock from the sled they are still adjusted to your weighted ride height. If the shock is fully extended, the coils have unwrapped some, the tighter coils will unwrap some but keep in mind that they are softer and with tension from the adjuster nut they are being held in place. If you measure the compression on the spring it is more obvious (with a shock dyno or in a compression jig). I just went out in the shop and took the following images, on the left is compressed (sag) and on the right I am lifting up slightly on the nose of the sled (one handed, who says these things are unghh.. heavy). Mind you I didn't pick it up all that far. If your shocks are set to your proper sag, and the springs are still closed after you pull the shock (and it is fully extended) that spring may be too light for you.

I have one or our LTX GT's (the other has actual dual rate springs from Elka) set at 2 turns tightened from full loose if that makes sense...just enough tension to hold the perch in place. At rest the upper coils are near touching and at the slightest of compression they are touching. I just can't see that coils that are touching are doing anything for ride quality.Sure they do. Loosen the adjuster nut. If you just pulled the shock from the sled they are still adjusted to your weighted ride height. If the shock is fully extended, the coils have unwrapped some, the tighter coils will unwrap some but keep in mind that they are softer and with tension from the adjuster nut they are being held in place. If you measure the compression on the spring it is more obvious (with a shock dyno or in a compression jig). I just went out in the shop and took the following images, on the left is compressed (sag) and on the right I am lifting up slightly on the nose of the sled (one handed, who says these things are unghh.. heavy). Mind you I didn't pick it up all that far. If your shocks are set to your proper sag, and the springs are still closed after you pull the shock (and it is fully extended) that spring may be too light for you.

View attachment 170127

If I pull the springs off my shocks they will expand more than the picture I posted show. I really did pick it up with one hand while bending over to snap the pic so its not like I was trying to pick the sled up. See pic above. There is expansion across the entire length of the spring but most of the expansion is happening in the stiffest part of the spring (the coils furthest apart).

Starting at the very top of the coil where it contacts the adjuster collar, count down 6 wraps. Note the distance between the 5th and 6th wrap grows as the shock extends (as shown in pic) but less than the gap between the 6-7th wrap, and 7-8th wrap and so on. The very small bumps will be taken up by those very tight coils (they will open slightly as shown in the picture), this all but eliminates small chatter bumps, as you hit bigger bumps you get into the gap between the 5th and 6th coils and the bigger the bump the more you collapse the rest of the spring. Does that help? If not, I can draw something later tonight. I might do this anyhow as the subject keeps coming up.

Starting at the very top of the coil where it contacts the adjuster collar, count down 6 wraps. Note the distance between the 5th and 6th wrap grows as the shock extends (as shown in pic) but less than the gap between the 6-7th wrap, and 7-8th wrap and so on. The very small bumps will be taken up by those very tight coils (they will open slightly as shown in the picture), this all but eliminates small chatter bumps, as you hit bigger bumps you get into the gap between the 5th and 6th coils and the bigger the bump the more you collapse the rest of the spring. Does that help? If not, I can draw something later tonight. I might do this anyhow as the subject keeps coming up.

Last edited:

How is a small bump taken up by coils that are touching at rest? Look at the first post in this thread. The LTX GT coils are touching at the top while at rest. (very little gap if not touching) If touching at rest they will still be touching until you go over a rise to decompress. The 180# per side of resting weight on each shock spring has the "tender portion" flattened. Gonna have a hard time making the physics of this sink in my thick skull. Lol. Especially since I have one sled with Elka dual rate springs on the QS3's to compare the stock spring setup to. (dual rates are much better by the way)If I pull the springs off my shocks they will expand more than the picture I posted show. I really did pick it up with one hand while bending over to snap the pic so its not like I was trying to pick the sled up. See pic above. There is expansion across the entire length of the spring but most of the expansion is happening in the stiffest part of the spring (the coils furthest apart).

Starting at the very top of the coil where it contacts the adjuster collar, count down 6 wraps. Note the distance between the 5th and 6th wrap grows as the shock extends (as shown in pick) but less than the gap between the 6-7th wrap, and 7-8th wrap and so on. The very small bumps will be taken up by those very tight coils (they will open slightly as shown in the picture), this all but eliminates small chatter bumps, as you hit bigger bumps you get into the gap between the 5th and 6th coils and the bigger the bump the more you collapse the rest of the spring. Does that help? If not, I can draw something later tonight. I might do this anyhow as the subject keeps coming up.

Note; the full version of this explanation is 2000 words. A lot, even for me. Believe me, this is the shorter version. Hopefully it helps.Edit: I did misquote my source. He did not say they were not dual rate but what he did say is: If the "tender" portion of the suspension is used up at rider sag, then it is actually a helper spring. This scenario is used to lower ride height and then get strong. Unfortunately, you won't gain much comfort from the soft portion of travel.

It is a conceptually subtle problem.

Your source is a little bit off. The tender portion isn't 'used up', that is a very poor description of what is happening. It of course isn't and even small chatter does more than just compress the shock, it (the spring) is always compressing and extending. He also has his terminology confused. A helper spring is always of a completely different cross section than the main spring. It is a super weak spring that only exists to keep the spring in the seats. A single spring of uniform diameter in cross section cannot be both a main and a helper spring. I can explain this to him both mathematically and in the real world. To put it simply, a helper spring only exists to keep the spring in the seats, it has little to no spring rate. This spring (SRX) is never a helper spring although ultimately the fact that it can extend to full length keeps the spring in its seat. He is also wrong about where the comfort comes from, more later .

Helper on left, tender on right. It should be obvious that the helper spring has little to no spring rate and only exists to keep the spring in its seats. The tender spring on the right is much thicker, has a substantial spring rate, and in the case of the particular one below is additionally progressive (rising rate) in resistance.

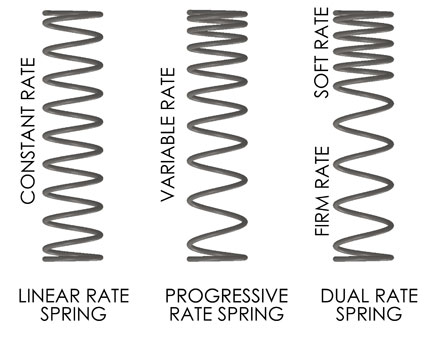

Here is a comparison between a linear spring, a progressive spring, and a dual rate spring.

It should be clear that for the linear rate all spacing is equal. The progressive spring gets progressively smaller wraps (tighter, less space) and the dual rate spring has the obvious loose and very tight wraps. But its impossible to have the dual rate spring as shown above without having some progressive element (transition from wider to narrower springs).

How a spring works. A spring is a lever wrapped around an imaginary cylinder. The more wraps you can fit in the same overall height of spring (wire diameter being equal) the softer the spring. you can prove it by unwrapping the spring back to a straight bar, the longer bar from the spring with more wraps will be easier to bend so when you look at the springs above, tighter wraps = softer.

If you were to plot a graph of force vs travel. The linear rate spring would be a straight line up and to the right with resistance building linearly with travel, the progressive spring would be a steeply rising curve as force starts low and builds, the dual rate spring would split the difference.

As an aside, a two or more spring system like the elka or hygear will have a knee or two in the graph, straight lines with a sharp bend as the transition between them.

Here is your spring fully extended as posted by @Jefro

Notice (its a bit hard to see) that the coil spacing is not uniform across the whole spring, it has that progressive spacing. There are of course the the tighter coils at the top but that transition from 5th to 6th wrap is larger (measured at ~16mm on my sled), then the 6th to 7th wrap is larger still (~17.x) then some equally spaced gaps (19.x mm). Now look at the bottom of the spring. The coils down there get closer together as you get to the bottom. (last few). Your small bump ride comfort comes from two places, those transition coils at the top and bottom and the very top coils when the shock extends. That's what I meant by 'the eye is drawn to those tight coils' everyone tends to ignore the rest of the spring spacing. Tighter coils anywhere in the spring equals a softer part of the spring. And of course because the sled is constantly extending and compressing around the zero point, the tightest coils are not 'used up'.

This makes for nice smooth transitions from chatter to small to medium to large bumps. The bonus is that on bigger hits where the shock fully extends, the initial spring compression is very plush (those tight coils start open then get closer together) and the spring progressively becomes stiffer. The force graph is a curve but still ends up at the same place (maximum spring rate) as a single linear spring, it just has a much nicer way of getting there.

So, why buy an Elka or Exit or other upgraded shock. Simply put, the SRX spring is not for everyone it is targeting a certain rider weight and style of riding, and while I don't have an opinion on Fox vs Elka, what my shock guy tells me is that Ohlins, Elka, etc are better shocks (parts quality, finish, etc). You buy the far superior Elka for better valving control and more spring rate selection, better tunability and broader ride quality characteristics. But the stock setup is pretty good if it fits you.

Hope that helps.

Similar threads

- Replies

- 16

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.