Re: Hey Cannondale

No there are no instructions.Everything is pretty straightforward except for that washer.Also remember to torque the link and bottom shock bolts before putting the assembly in the rails.With the new wheels without holes you cant get the bolts in with it in the rails.I believe I posted the torque values somewhere here.

Ricketts said:Hey Cannondale;

Do you have instructions that came with your rear link update kit? I just recieved my kit (no instructions in box) and I figured "no problem" but your mention of this washer changing positions and the subsequent damage to your rail has me thinking, better follow the instructions...

Unless this is the only change there is, I can fake it.

No there are no instructions.Everything is pretty straightforward except for that washer.Also remember to torque the link and bottom shock bolts before putting the assembly in the rails.With the new wheels without holes you cant get the bolts in with it in the rails.I believe I posted the torque values somewhere here.

Ricketts

Pro

Cannondale, I think I have it figured out... there's 3 longer bolts for each part that attaches to the new billet piece, 2 washers for the extra space where the bottom of the rear shock mounts (why they just didn't make the billet thicker there instead of needing washers I'm not sure) The one darker colour bolt that mounts the billet piece to the new axle assembly seemed loose in its bushing, but the one I pulled out of the old assembly was just as loose in its bushing so I guess its OK.

I'm a little concerned about the 2 new large bushings and shorter aluminum axle that replaces the longer steel axle (the axle where the new washers go on the outside of the rail instead of the inside as originally built). I don't see how that can be stronger than one long steel axle. But here's hoping they know what they are doing...I do seem to have two extra new bolts left over. They're shorter ones, a "10" is stamped on the head of the bolts, the part number is 90109-10032. They seem too short to go anywhere...

PS I'm sorry to have hijacked your thread, terret.

Thanks,

Rick

I'm a little concerned about the 2 new large bushings and shorter aluminum axle that replaces the longer steel axle (the axle where the new washers go on the outside of the rail instead of the inside as originally built). I don't see how that can be stronger than one long steel axle. But here's hoping they know what they are doing...I do seem to have two extra new bolts left over. They're shorter ones, a "10" is stamped on the head of the bolts, the part number is 90109-10032. They seem too short to go anywhere...

PS I'm sorry to have hijacked your thread, terret.

Thanks,

Rick

I think the new steel bushings should be fine.There is a coating on them that should make them last.Other makes use same setup.I believe the shorter shaft is still steel.Check it with a magnet.Those bolts #90109-10032 are for the front arm/tunnel mount Make sure you torque and Loctite them.They are a special alloy bolt.

Ricketts

Pro

Hi again, Cannondale. That shorter axle is definitely aluminum, no magnetism. I'm assuming most of the stress will be at the ends of the shaft where the new heavy duty bushings are, maybe Yamaha felt that there is too little stress for the shorter axle to worry about (I hope)?

Thanks again,

Rick

Thanks again,

Rick

terret725

TY 4 Stroke Junkie

parts are ordered just waiting for them to come in and im telling them to perminate locktight the bolts. i dont care if they ever come out aslong as its not by them self. lol

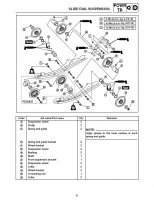

Yes that shaft really isnt doing anything other than keeping everything in place with new setup.Here are the torque values for 08 suspension.

Attachments

Ricketts

Pro

Thanks, Cannondale, you're a lifesaver

I have the skid back in the machine, can't wait for the weekend. Winter's showing no sign of letting up here, so I have a couple of good weekends yet...

Rick

I have the skid back in the machine, can't wait for the weekend. Winter's showing no sign of letting up here, so I have a couple of good weekends yet...

Rick

No Problem I just want you all to enjoy whats left of season.I think if everyone goes over thier sleds this summer and Loctite and torques everything possible we will have much fewer issues next year.

Reaper

TY 4 Stroke Junkie

- Joined

- Nov 10, 2005

- Messages

- 667

- Location

- Starbuck, Manitoba

- Country

- Canada

- Snowmobile

- 2014 SR Viper XTX. COTC, Hygear 141 pro link.

Wow, had the same issue after the update will have to check the washer deal.

Reaper

TY 4 Stroke Junkie

- Joined

- Nov 10, 2005

- Messages

- 667

- Location

- Starbuck, Manitoba

- Country

- Canada

- Snowmobile

- 2014 SR Viper XTX. COTC, Hygear 141 pro link.

cannondale27 said:If it was like this it is wrong assembly:

I have the washer out but still backed out, put some loctite on and hope it stays put.

As long as it was cleaned with BrakeCleaner before Loctite/torque I have confidence it will hold.If not some of these will definitly work.

http://www.nord-lock.com/

http://www.nord-lock.com/

Reaper

TY 4 Stroke Junkie

- Joined

- Nov 10, 2005

- Messages

- 667

- Location

- Starbuck, Manitoba

- Country

- Canada

- Snowmobile

- 2014 SR Viper XTX. COTC, Hygear 141 pro link.

Problem is when you grease the skid it fill the threads with grease (cause of the problem I think)

terret725

TY 4 Stroke Junkie

grease shouldnt get in the threads if they are cleaned befor and u use lock tight. the locktight should act as a sealent and keep grease out. also any moister will cause the locktight not to set right. they need to beed clean and dry befor u lock tight it. alot of people dont realize this and just gob it on a greasy bolt and then are all POed when it falls out again. this is my guess is what happened to mine the second time. the mechanic said he used extra lock tight not just the thread patch. but then again he could just be covering his A$$

Weapon X

TY 4 Stroke Junkie

Its almost worth sealing the bushing off from the greased area so it doesn't get contaminated, I had this same problem with 2 of my ski-doo's. I put moto seal in the back of the threads.

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.