02ViperMody44

Lifetime Member

- Joined

- Jan 26, 2009

- Messages

- 580

- Location

- Utica, NY

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

2013 Yamaha XTX

- LOCATION

- Old Forge, NY

- YAHOO

- ramody44@yahoo.com

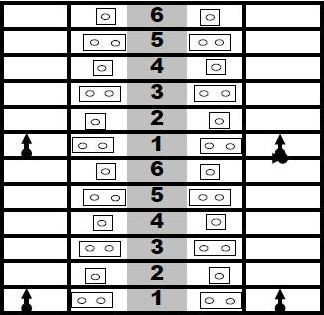

I have 1514 miles on my swapped track on my 2020 SRX. Wanted a 1.25" track instead of the factory 1". Doing some testing after installing an O2 sensor and some other improvements and my track split perfectly in half. Took out my heat exchangers!!!! First trip out all year nonetheless. It was studded up the middle with 192 1.52" Extreme Max studs. The track appeared in perfect shape. No tear outs, no missing clips. It was a Composit T320 brand/model track. I went with them after seeing them at the Syracuse Powersports show, and I am now thinking I went with the wrong horse in this race. Looking for opinions as to what may have happened here? Stud length too much, bad pattern was on a lake doing some clutch testing. Not at max speed when it blew.

I am now going to go with a Ripsaw 2, but was wondering about opinions on my studding pattern, as to whether or not it may have contributed to it. Never had something like this happen on my Apex, but am running a lot more ponies. The track split perfectly right where the make and model of the track is molded into it.

I am now going to go with a Ripsaw 2, but was wondering about opinions on my studding pattern, as to whether or not it may have contributed to it. Never had something like this happen on my Apex, but am running a lot more ponies. The track split perfectly right where the make and model of the track is molded into it.

Attachments

Last edited:

actionjack

TY 4 Stroke God

- Joined

- Apr 9, 2005

- Messages

- 2,510

- Location

- Westminster, Maryland

- Website

- www.inspectorjack.com

- Country

- USA

- Snowmobile

- 2017 SideWinder LTX-LE

I wouldn't use a Composit track if it was given to me.

TPAY243

Lifetime Member

- Joined

- Apr 14, 2013

- Messages

- 834

- Age

- 57

- Location

- Northern Wis

- Country

- USA

- Snowmobile

- 2020 Yamaha Sidewinder LTX SE

Yep there junk, with all those studs you should have just left the stock track on it that 1\4 inch you gained with changing your track was minimal and not worth the effort in my eyes. Call them up and scream warranty ya never know what they will say.

Wow scary. Glad you are alright.

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,164

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2022 SIDEWINDER LTX GT

- LOCATION

- Vermont

Thats ugly. Looks like poor quality. That Ripsaw2 is a tough track, it will take a beating.

After riding almost identical sleds on trail, one with an inch track and the other with 1 1/4, same stud pattern, I have to say there is a noticeable difference, especially braking.....

After riding almost identical sleds on trail, one with an inch track and the other with 1 1/4, same stud pattern, I have to say there is a noticeable difference, especially braking.....

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,226

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Glad I didn't try one...wow. I think CM put one on.

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,164

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2022 SIDEWINDER LTX GT

- LOCATION

- Vermont

speaking of CM, anyone seen or heard from him?????

02ViperMody44

Lifetime Member

- Joined

- Jan 26, 2009

- Messages

- 580

- Location

- Utica, NY

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

2013 Yamaha XTX

- LOCATION

- Old Forge, NY

- YAHOO

- ramody44@yahoo.com

Well if it helps someone make a decision one way or the other, if they are in the market. This is just my personal experience. If I saw a post like this before hand, I probably wouldn't have made the purchase.Glad I didn't try one...wow. I think CM put one on.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,672

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

3 things I'd never do here. Run 192 studs down the middle, run tall nuts on the studs and run a Russian track.

02ViperMody44

Lifetime Member

- Joined

- Jan 26, 2009

- Messages

- 580

- Location

- Utica, NY

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

2013 Yamaha XTX

- LOCATION

- Old Forge, NY

- YAHOO

- ramody44@yahoo.com

What would you recommend for a stud pattern? 192 Woody's with some on the outside? That is a pattern from Studboy that I used.3 things I'd never do here. Run 192 studs down the middle, run tall nuts on the studs and run a Russian track.

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,672

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

What would you recommend for a stud pattern? 192 Woody's with some on the outside? That is basically a pattern from Studboy.

I'd only put a max of 144 in the middle and don't use the long nuts, let the stud bend if it snags something so it doesn't try to rip out from the track. Something has to give when a stud snags too hard, its either bend the stud or rip out, I'll take a bent stud.

To run 192 studs down the middle is worthless other than adding weight. All the studs do is run in one anothers close scratch line and spin. It's about the quality of the scratch lines and the distance to repeat the pattern without cutting cords in the track.

ateick

Expert

- Joined

- Mar 11, 2019

- Messages

- 408

- Location

- Ontario

- Country

- Canada

- Snowmobile

- '24 Rene XRS 900R

'18 SR Viper RTX (SOLD)

'20 Poo XCR 850 (SOLD)

I ran 1.52 Extreme Max on a 1.25 Ripsaw 2 on my turbo'd Viper. Only 3 per bar but it held up all last year over a couple thousand Km's

02ViperMody44

Lifetime Member

- Joined

- Jan 26, 2009

- Messages

- 580

- Location

- Utica, NY

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

2013 Yamaha XTX

- LOCATION

- Old Forge, NY

- YAHOO

- ramody44@yahoo.com

I'd only put a max of 144 in the middle and don't use the long nuts, let the stud bend if it snags something so it doesn't try to rip out from the track. Something has to give when a stud snags too hard, its either bend the stud or rip out, I'll take a bent stud.

To run 192 studs down the middle is worthless other than adding weight. All the studs do is run in one anothers close scratch line and spin. It's about the quality of the scratch lines and the distance to repeat the pattern without cutting cords in the track.

Okay, thanks for your reply. I may just take some of the weight out!

RobX-1

VIP Member

- Joined

- Apr 13, 2003

- Messages

- 2,084

- Location

- Coldwater, OH

- Country

- USA

- Snowmobile

- 18 50th Apex XT-X, 08 40th Apex LTX GT, 08 40th Nytro RTX, & 03 RX-1

I use this down-the-center pattern which uses a combination of singles and backers. Can't remember the total scratch lines but it was more than what I had been using or other patterns I had found. It's a Stud Boy pattern though.

- Joined

- Jun 1, 2004

- Messages

- 7,693

- Location

- sudbury on

- Country

- Canada

- Snowmobile

- 2016 apex xtx

2011 apex xtx

2009 phaser rtx/x

1997 et410t/r

1988 vk 540

glad you are ok.

Similar threads

- Replies

- 91

- Views

- 40K

- Replies

- 2

- Views

- 579

- Replies

- 12

- Views

- 3K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.