Jack_Shaft

TY 4 Stroke Junkie

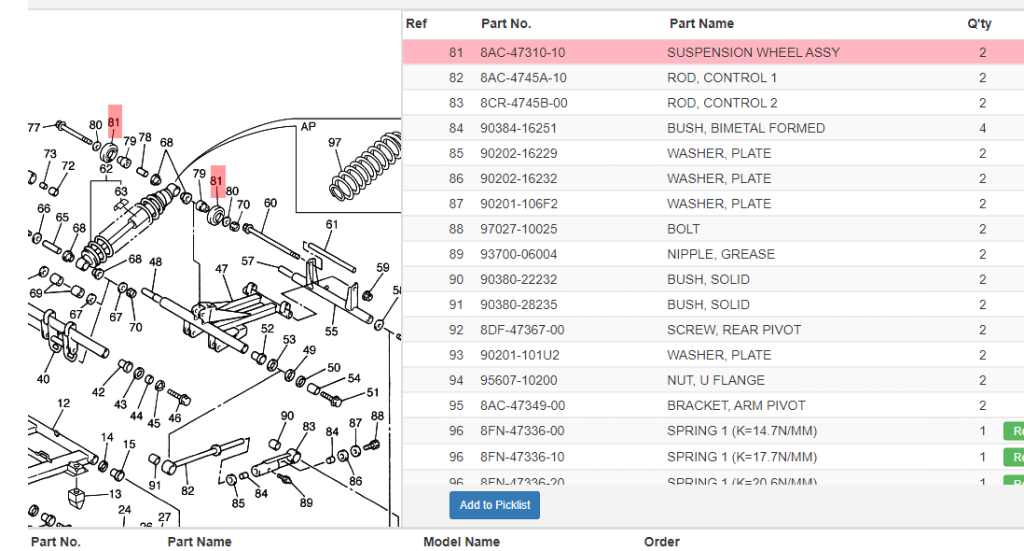

Couldn't call this one properly maintained without pulling the rear skid for inspection and maintenance at 11000kms, I really don't know the sleds maintenance history so I wanted to be sure that I could trust it to groom next season.

The bushings in the relay rods are of utmost importance to be fresh and without play. Once play gets established, they "jarr" under motion and will break the ends off.

Idler wheels. What kind of a ridiculous person thought that it would be a good idea to build a snowmobile with non-removable brgs. Wow. I will be replacing the rear idlers with a trio of BRP 165mm wheels and several of the in-skid idlers with BRP 135mm wheels. Not exact matches, but very close.

Then I came to the tiny upper wheels on each side of the rear shock mount. Again, non-removable brg and you can't even get the seal out of this one. One is seized and the other is rough, so they have to be replaced. Only $115CDN each. Ouch.

The bushings in the relay rods are of utmost importance to be fresh and without play. Once play gets established, they "jarr" under motion and will break the ends off.

Idler wheels. What kind of a ridiculous person thought that it would be a good idea to build a snowmobile with non-removable brgs. Wow. I will be replacing the rear idlers with a trio of BRP 165mm wheels and several of the in-skid idlers with BRP 135mm wheels. Not exact matches, but very close.

Then I came to the tiny upper wheels on each side of the rear shock mount. Again, non-removable brg and you can't even get the seal out of this one. One is seized and the other is rough, so they have to be replaced. Only $115CDN each. Ouch.

sxr70001

Lifetime Member

- Joined

- Dec 4, 2010

- Messages

- 1,109

- Location

- Michigan

- Country

- USA

- Snowmobile

- Sidewinder LTX SE

SR Viper RTX SE

Luckily most of the replacement wheels have removable bearings. Good luck!

- Joined

- Jun 1, 2004

- Messages

- 7,690

- Location

- sudbury on

- Country

- Canada

- Snowmobile

- 2016 apex xtx

2011 apex xtx

2009 phaser rtx/x

1997 et410t/r

1988 vk 540

yup, #81 sucks on the vk540 III as well. i got lucky with the one i rebuilt/mainteneced last year and was able to use an grease injection needle on my grease gun to get grease into the bearings on them with the help of a pick to lift the seal lip.

Jack_Shaft

TY 4 Stroke Junkie

yup, #81 sucks on the vk540 III as well. i got lucky with the one i rebuilt/mainteneced last year and was able to use an grease injection needle on my grease gun to get grease into the bearings on them with the help of a pick to lift the seal lip.

Man it's pretty tight in there, good on ya for managing to do that much. These ones were so far gone they couldn't be saved with a grease needle but I am hoping some of the other larger dia wheels will cooperate in that way as I can manipulate the seal a little on those. Job for the weekend but I'll be held up wrt skid installation for a couple of weeks waiting for those small wheels anyways.

Update: Well, I ate my words on the tiny wheels, I was able to blow them out with brake cleaner and then push all the old dirt/grease out and repack with a grease needle. Quite the piece of equipment that thing is. Saved me mucho dinero this time.

Last edited:

- Joined

- Jun 1, 2004

- Messages

- 7,690

- Location

- sudbury on

- Country

- Canada

- Snowmobile

- 2016 apex xtx

2011 apex xtx

2009 phaser rtx/x

1997 et410t/r

1988 vk 540

i did them with the skid out. that was the worst proaction style skid i have ever put back in a sled in my life. would not go it with rear wheels installed and i had to pull the relay rods with the wheels off still to get the bolts in even with a ratchet strap. took over 4 hrs and i usually do one on a sx/rx sled in about 45 min for reinstall.

Jack_Shaft

TY 4 Stroke Junkie

i did them with the skid out. that was the worst proaction style skid i have ever put back in a sled in my life. would not go it with rear wheels installed and i had to pull the relay rods with the wheels off still to get the bolts in even with a ratchet strap. took over 4 hrs and i usually do one on a sx/rx sled in about 45 min for reinstall.

Awesome LOL. I have a lot to look forward to apparently

Skid is nearly back together now, hopefully final assembly tonight and I can start at the re-install. This thing has to get out of my garage... time to start at the bike.

Jack_Shaft

TY 4 Stroke Junkie

Waiting for one tiny plastic front torque arm bushing before I can re-install, pretty sure I lost it during maintenance, crap.

The word on the street is to install the front bolts, then rears, then middles. Hopefully that strat is workable.

The word on the street is to install the front bolts, then rears, then middles. Hopefully that strat is workable.

Jack_Shaft

TY 4 Stroke Junkie

That went quite well. Skid is in using the process described above along with a chain hoist to adjust the rear height during the job. Sled is now fully maintained and covered / in storage. Looking forward to a solid grooming season next year on her.

Jack_Shaft

TY 4 Stroke Junkie

A few shots of her in action

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.