Bradford

Expert

Well, my original RS Nytro clutch finally hit 40K KM or about 24K miles. Basically, everything needs to be replaced and the shives are wearing so I decided to go with a new Power Bloc PB-80 model 1100-0222 primary clutch after reading Redbeard’s report on his Vec and Apex (thanks for that). The first thing that I noticed when ordering is that CV Tech has the same calibration for all 973 carbed motors regardless of the year or model of sled while Yamaha lists 3 or 4 different calibrations. However, the new clutch came with 9 extra weights to aid in fine tuning which was good to see. Price was $500 CDN plus $15 shipping. I also ordered the clutch holding tool which set me back another $29 and picked up a new OEM belt.

To remove the old clutch, I used the famed “water trick”. Essentially an M18 X 1.5 bolt with a few wraps of Teflon tape on the threads. After removing the primary bolt, I put the sled on its side and filled the bolt hole to within 1” of the clutch face with water, threaded in the M18 bolt and started cranking and POP, it came right off! It was a lot easier than what I was expecting. I used a cloth wrapped bar through the clutch openings to keep it from turning.

Installing the new clutch was dead simple using a 1/2" torque wrench and the CV Tech holding tool. Torque specs are Step 1: Tighten the CV Tech supplied bolt using the supplied crown washer to 85 ft-lb. Step 2: loosen the bolt and retighten to 43 ft-lb. It’s worth noting that the supplied bolt is not a metric bolt but is a standard ½” fine thread grade 8 bolt. I read some threads on here where people were concerned about this but personally I don’t think it’s an issue given how close these threads actually are over the length of thread that are actually used.

Testing the clutches on the stand looked good. Shifting was very smooth, back-shift was quick it seemed to shift out nicely. I left the new primary with the stock calibration and the secondary stock at 3-3 wrap and stock spring. Bushings, slides and spring were all changed last year. I’ll be testing this setup over the weekend and will report back with the results and any calibration change considerations.

A couple of things worth noting: I swapped out the skid to a 136 Mono 2 and stretched it to 144". The track is a 1.22 Ice Attack and the gearing was changed from 21/40 to 22/40. I do a lot of big trails which is why I geared up a bit.

Something that I forgot to mention. The clutch "clack clack clack" has been reduced by about 90%! Having said that, any clutch with 40K KM is going to clack more than normal.

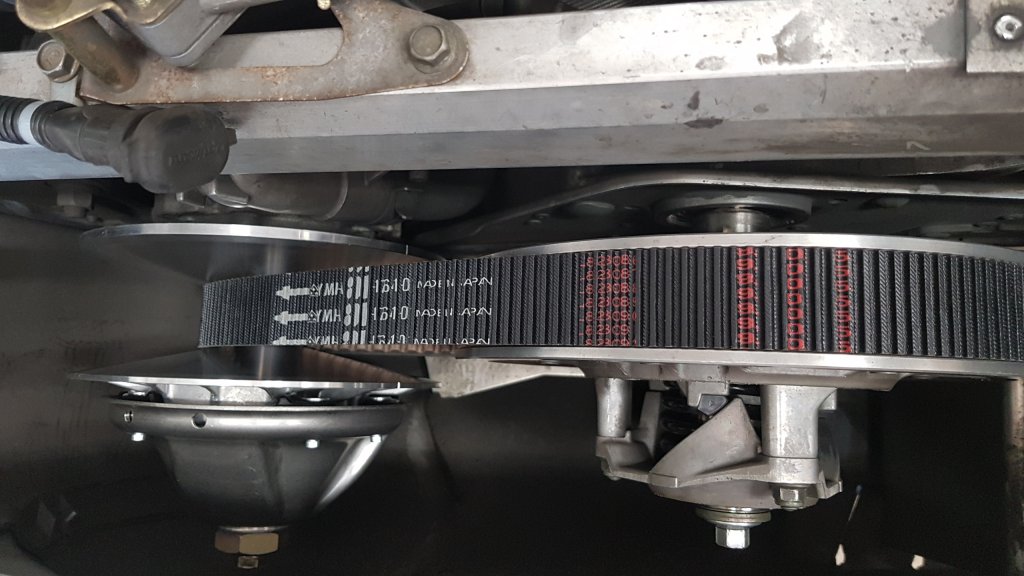

Clutch installed with new belt:

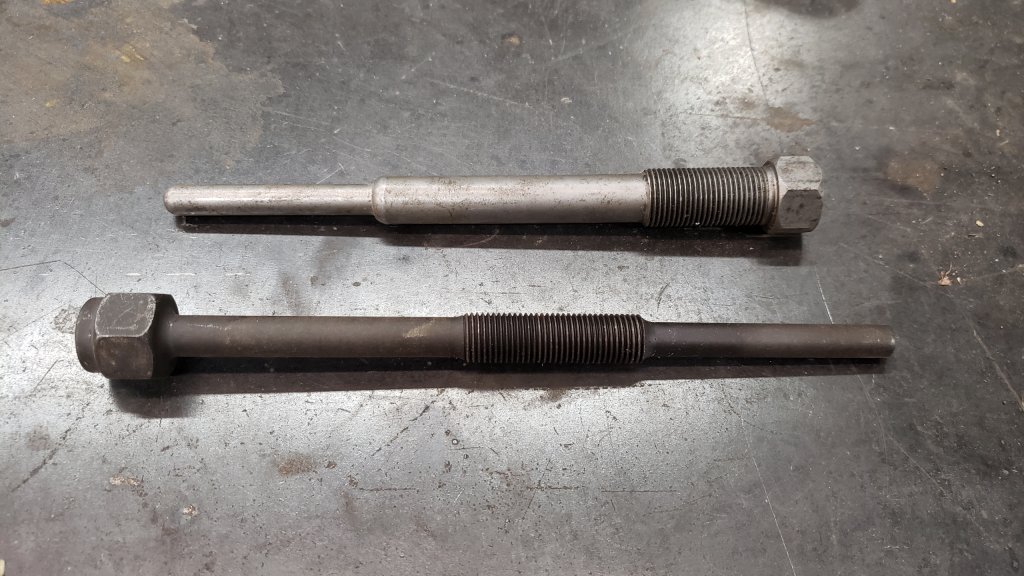

Clutch holding tool, extra weights and the M18 X 1.5 bolt for removing the old clutch:

To remove the old clutch, I used the famed “water trick”. Essentially an M18 X 1.5 bolt with a few wraps of Teflon tape on the threads. After removing the primary bolt, I put the sled on its side and filled the bolt hole to within 1” of the clutch face with water, threaded in the M18 bolt and started cranking and POP, it came right off! It was a lot easier than what I was expecting. I used a cloth wrapped bar through the clutch openings to keep it from turning.

Installing the new clutch was dead simple using a 1/2" torque wrench and the CV Tech holding tool. Torque specs are Step 1: Tighten the CV Tech supplied bolt using the supplied crown washer to 85 ft-lb. Step 2: loosen the bolt and retighten to 43 ft-lb. It’s worth noting that the supplied bolt is not a metric bolt but is a standard ½” fine thread grade 8 bolt. I read some threads on here where people were concerned about this but personally I don’t think it’s an issue given how close these threads actually are over the length of thread that are actually used.

Testing the clutches on the stand looked good. Shifting was very smooth, back-shift was quick it seemed to shift out nicely. I left the new primary with the stock calibration and the secondary stock at 3-3 wrap and stock spring. Bushings, slides and spring were all changed last year. I’ll be testing this setup over the weekend and will report back with the results and any calibration change considerations.

A couple of things worth noting: I swapped out the skid to a 136 Mono 2 and stretched it to 144". The track is a 1.22 Ice Attack and the gearing was changed from 21/40 to 22/40. I do a lot of big trails which is why I geared up a bit.

Something that I forgot to mention. The clutch "clack clack clack" has been reduced by about 90%! Having said that, any clutch with 40K KM is going to clack more than normal.

Clutch installed with new belt:

Clutch holding tool, extra weights and the M18 X 1.5 bolt for removing the old clutch:

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I think you're going to be a satisfied customer!

They're so easy to calibrate, so simple and basically no maintenance.

I've never had any form of radar confirmation, but these clutches pull hard once engaged. I can't comment on the big hp sleds running the trails, but for me; they just plain work for the way I ride.

Agreed on the 1/2" U.S. bolt supplied with the clutch. They work fine and I've not had any issues...and I've loosened and torqued each of mine at least a dozen times.

Please post your conclusion after you get some miles logged!

They're so easy to calibrate, so simple and basically no maintenance.

I've never had any form of radar confirmation, but these clutches pull hard once engaged. I can't comment on the big hp sleds running the trails, but for me; they just plain work for the way I ride.

Agreed on the 1/2" U.S. bolt supplied with the clutch. They work fine and I've not had any issues...and I've loosened and torqued each of mine at least a dozen times.

Please post your conclusion after you get some miles logged!

Last edited:

Bradford

Expert

Well, I did about 450 miles over the weekend in varying conditions and all I can say is these clutches are the real deal! I know my old clutch was past due but I was pleasantly surprised by the difference in performance. Engagement is smooth at just over 3000 RPM and full throttle is right at 8500 RPM. It pulls harder out of the hole than it did before and always seems to be in the right gear for the trail conditions and speed. I ran a couple of tests to see what the speed would be for different RPM's. Holding 7000 RPM, my speed was 65 ~ 70+ MPH depending on conditions. Holding just under 8000 RPM, my speed would creep up to 85 MPH (speedo, no GPS). I didn't have a chance to see what the top speed would be but if I can cruse at 85 MPH, I'm good with that.

I checked the clutch temperatures several times and even though I could hold my hand on either sheave, the inner one always seemed a bit hotter. I also noticed a different belt pattern on the two sheaves so I'll check my alignment next. Can someone tell me the best way to do that?:

I checked the clutch temperatures several times and even though I could hold my hand on either sheave, the inner one always seemed a bit hotter. I also noticed a different belt pattern on the two sheaves so I'll check my alignment next. Can someone tell me the best way to do that?:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

I ended up pulling one, 5.7 gram slug from each puck on my Vector. Whack the throttle, and she's singing @ 8700.

Last edited:

Fast

TY 4 Stroke Guru

- Joined

- Sep 25, 2018

- Messages

- 966

- Age

- 56

- Location

- Ontario

- Country

- Canada

- Snowmobile

- 2019 srx,2006 apex gt,96 storm hot to go

Where did you buy a PB80 for $500 canadian?Well, my original RS Nytro clutch finally hit 40K KM or about 24K miles. Basically, everything needs to be replaced and the shives are wearing so I decided to go with a new Power Bloc PB-80 model 1100-0222 primary clutch after reading Redbeard’s report on his Vec and Apex (thanks for that). The first thing that I noticed when ordering is that CV Tech has the same calibration for all 973 carbed motors regardless of the year or model of sled while Yamaha lists 3 or 4 different calibrations. However, the new clutch came with 9 extra weights to aid in fine tuning which was good to see. Price was $500 CDN plus $15 shipping. I also ordered the clutch holding tool which set me back another $29 and picked up a new OEM belt.

To remove the old clutch, I used the famed “water trick”. Essentially an M18 X 1.5 bolt with a few wraps of Teflon tape on the threads. After removing the primary bolt, I put the sled on its side and filled the bolt hole to within 1” of the clutch face with water, threaded in the M18 bolt and started cranking and POP, it came right off! It was a lot easier than what I was expecting. I used a cloth wrapped bar through the clutch openings to keep it from turning.

Installing the new clutch was dead simple using a 1/2" torque wrench and the CV Tech holding tool. Torque specs are Step 1: Tighten the CV Tech supplied bolt using the supplied crown washer to 85 ft-lb. Step 2: loosen the bolt and retighten to 43 ft-lb. It’s worth noting that the supplied bolt is not a metric bolt but is a standard ½” fine thread grade 8 bolt. I read some threads on here where people were concerned about this but personally I don’t think it’s an issue given how close these threads actually are over the length of thread that are actually used.

Testing the clutches on the stand looked good. Shifting was very smooth, back-shift was quick it seemed to shift out nicely. I left the new primary with the stock calibration and the secondary stock at 3-3 wrap and stock spring. Bushings, slides and spring were all changed last year. I’ll be testing this setup over the weekend and will report back with the results and any calibration change considerations.

A couple of things worth noting: I swapped out the skid to a 136 Mono 2 and stretched it to 144". The track is a 1.22 Ice Attack and the gearing was changed from 21/40 to 22/40. I do a lot of big trails which is why I geared up a bit.

Something that I forgot to mention. The clutch "clack clack clack" has been reduced by about 90%! Having said that, any clutch with 40K KM is going to clack more than normal.

Clutch installed with new belt:

View attachment 146803

View attachment 146805

Clutch holding tool, extra weights and the M18 X 1.5 bolt for removing the old clutch:

View attachment 146804

Bradford

Expert

G Bourque in Dieppe, NB. https://www.gbourque.com/Where did you buy a PB80 for $500 canadian?

twiz28

Expert

- Joined

- Nov 8, 2004

- Messages

- 236

- Age

- 53

- Location

- New Brunswick, CAN

- Country

- Canada

- Snowmobile

- 2017 Sidewinder BTX 1.75 Backcountry

2017 Sidewinder XTX 137

A friend has one on his fx nytro, seems to work well. I do his maintainence and have no experience with the pb, which puller is needed if this clutch has to come off? I assume the Yamaha puller doesn't fit? Or does it?

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,657

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

You need a puller specifically for the PB80. Stock Yamaha will not work.

(Picture)

Yamaha - top

PB80 - bottom

The only other way, would be to use the hydraulic method that Bradford used above. As far as the thread size and pitch of bolt needed; my old shop tool gauges the PB puller threads at M15 x 1.5 (or very close). I personally have never tried that method.

(Picture)

Yamaha - top

PB80 - bottom

The only other way, would be to use the hydraulic method that Bradford used above. As far as the thread size and pitch of bolt needed; my old shop tool gauges the PB puller threads at M15 x 1.5 (or very close). I personally have never tried that method.

Last edited:

Similar threads

- Replies

- 4

- Views

- 962