grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,116

- Reaction score

- 968

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

I just finished changing another bad cam chain tensioner in a 06 Vector. I've done several of these successfully without removing the valve cover to expose the timing marks. Unfortunately when I got this one back together it didn't idle properly. I pulled the valve cover and discovered that the exhaust cam had jumped time. After resetting the cams it ran much better. If I do another one of these I'll definitely pull the valve cover and tie strap the chain to the gears before removing the tensioner. Removing the cover only takes a few extra minutes and it's much easier than removing the tensioner twice.

Out of the tensioner I've replaced only a couple have actually been bad. I'm not sure how many of the 05 to 07 tensioners will eventually fail but at least be aware that some of them are failing. If anyone plans on changing theirs and have questions feel free to contact me. I'm always willing to help.

Out of the tensioner I've replaced only a couple have actually been bad. I'm not sure how many of the 05 to 07 tensioners will eventually fail but at least be aware that some of them are failing. If anyone plans on changing theirs and have questions feel free to contact me. I'm always willing to help.

Phantom

Expert

- Joined

- Apr 2, 2004

- Messages

- 451

- Reaction score

- 1

- Points

- 721

My tensioner started making noise at the end of last season (05 Rage 14,000 miles) I have the tensioner ordered.

What needs to be removed to rotate the engine forward for access? I'm sure I can figure it out but maybe a few tricks you have found will speed things up a bit.

Thanks!

BTW I plan on photo documenting the entire process for a how to guide.

What needs to be removed to rotate the engine forward for access? I'm sure I can figure it out but maybe a few tricks you have found will speed things up a bit.

Thanks!

BTW I plan on photo documenting the entire process for a how to guide.

what kind of noise do I listen for?

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,116

- Reaction score

- 968

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

Parts:

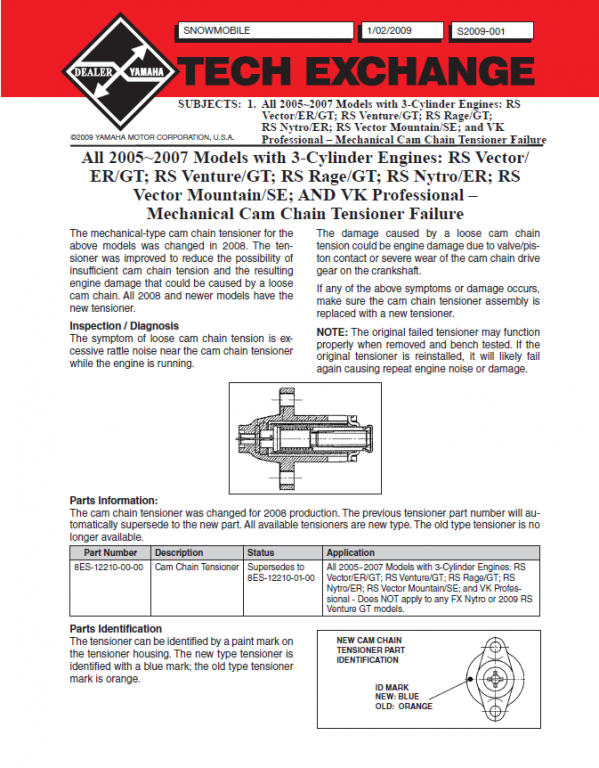

8ES-12210-01-00..........(1) TENSIONER ASSY (blue dot)

4FM-12213-00-00..........(1) GASKET, TENSIOER

93210-26006-00............(1) O-RING, VALVE COVER COOLANT PIPE (Recommended)

8FA-14623-00-00...........(3) GASKET, EXHAUST DONUTS (Recommended)

50/50 AUTOMOTIVE COOLANT (Optional)

1) remove side panels

2) remove seat and gas tank (gas tank cover and handlebars can be moved off to the side)

3) unbolt exhaust system and slide back a few inches (4 muffler bolts, 2 hanger bolts under platic plugs and 3 manifold clamps) http://www.ty4stroke.com/viewtopic.php?t=90978

4) remove steering column (unbolt the 2 bearing holders and swing it out of the way)

5) remove secondary clutch (don't lose shims on the back side of clutch)

6) remove air breather/ battery/ battery try and then loosen the 2 front engine mount bolts

7) drain the oil tank and remove it, drain the coolant by removing the lower cooler hose

8) remove the upper coolant pipe on top of the valve cover then remove the valve cover (The tube is held in by a cap screw and seals with an o-ring. Clear the head of the cap screw of any debris then use a 6mm allen socket to remove it. I've had to tap on the allen socket with a hammer to loosen the screw.)

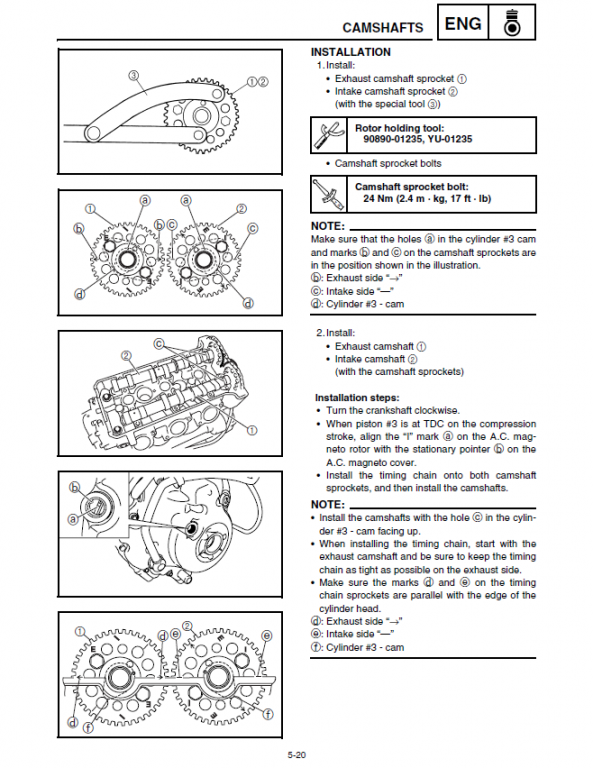

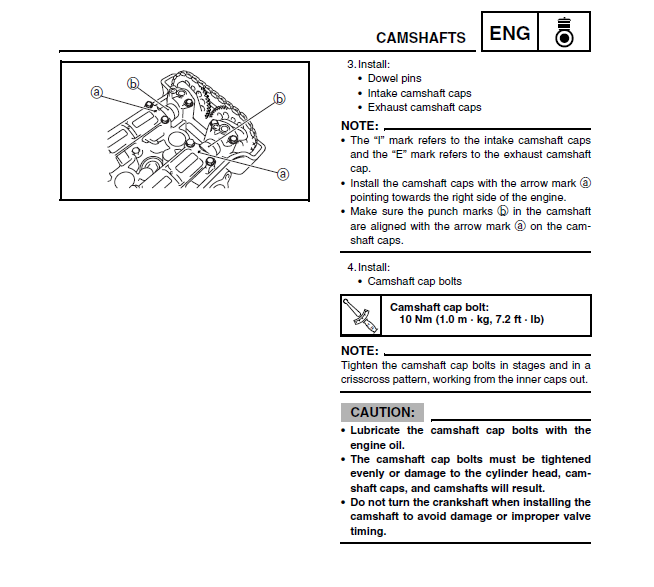

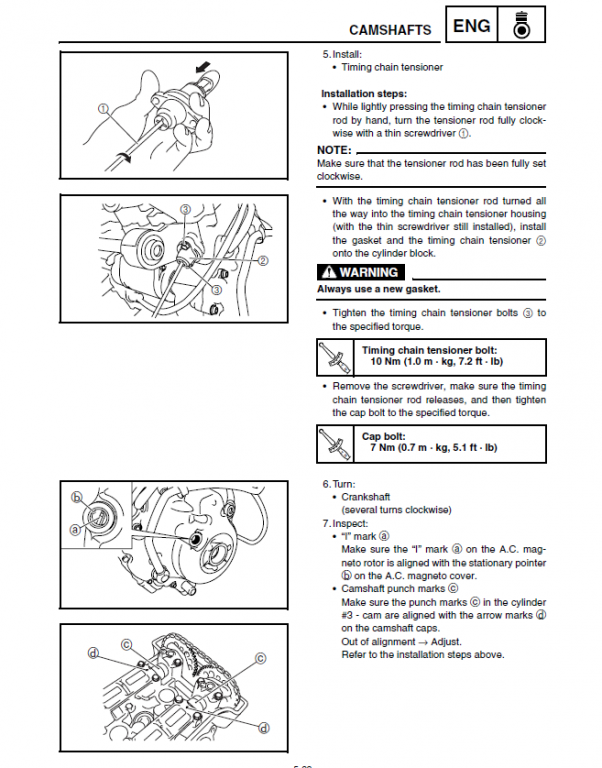

9) set the #3 cylinder on TDC. To do this remove the inspection plugs in the stator cover and rotate the engine CW until you pass a single "I" stopping at the "II" mark. The #3 cam lobes should be pointing down and away from each other (7 and 5 o'clock, #3 lobes are closest to the cam gears). If they are not rotate the engine one revolution CW (never rotate CCW). The cam timing marks should also be aligned at this point (exhaust ---> ----- intake).

10) use tie straps or wire ties to secure the timing chain to each gear. Cover the valve area with a rag to prevent anything from falling into the motor.

11) unbolt the long rear engine mount bolt and remove it. Remove the engine spacer with the special socket by turning it CW. The engine will have to be rocked up from the rear to get it out. (be careful not to damage the spacer or aluminum side plate threads)

12) with the engine rocked up unbolt the old (orange dot) tensioner and remove it. Clean the gasket area and install the new gasket and (blue dot) tensioner.

13) with the new tensioner bolted in pull the small tab to release it then install the new end plug. If there is slack in the chain between cam gears use a 10mm wrench on one of the rear cam gear bolts and rotate CCW just enough to take up the slack before releasing the tensioner. remove the ties on the cam, recheck all the timing marks then rotate the engine CW a few revolution then recheck the marks again at TDC. (when the new tensioner is released it doesn't always take all the slack out of the chain until the engine is rotated. I've had the chain jump the intake gear because of this so I position tie straps on the gear so that the engine can be rotated with the straps on. I reposition the tie straps several times as need until I make one revolution of the crank)

14) if all is OK put it back together.

Note: If you're replacing the exhaust donuts install them on the flex pipes before lower the engine.

Removing and reinstalling the lower cam tensioner bolt is difficult. A flexible 1/4" socket driver with a 8mm socket and a 1/4" drive 90 degree socket wrench helps. A magnet will also help getting the bolts in and out without dropping them. The special socket for removing the engine spacer was made from a 1/4" deep well 13mm socket. See special tools picture below.

http://s589.photobucket.com/albums/ss337/grizztracks/RS Yamaha Cam Chain Tensioner/

8ES-12210-01-00..........(1) TENSIONER ASSY (blue dot)

4FM-12213-00-00..........(1) GASKET, TENSIOER

93210-26006-00............(1) O-RING, VALVE COVER COOLANT PIPE (Recommended)

8FA-14623-00-00...........(3) GASKET, EXHAUST DONUTS (Recommended)

50/50 AUTOMOTIVE COOLANT (Optional)

1) remove side panels

2) remove seat and gas tank (gas tank cover and handlebars can be moved off to the side)

3) unbolt exhaust system and slide back a few inches (4 muffler bolts, 2 hanger bolts under platic plugs and 3 manifold clamps) http://www.ty4stroke.com/viewtopic.php?t=90978

4) remove steering column (unbolt the 2 bearing holders and swing it out of the way)

5) remove secondary clutch (don't lose shims on the back side of clutch)

6) remove air breather/ battery/ battery try and then loosen the 2 front engine mount bolts

7) drain the oil tank and remove it, drain the coolant by removing the lower cooler hose

8) remove the upper coolant pipe on top of the valve cover then remove the valve cover (The tube is held in by a cap screw and seals with an o-ring. Clear the head of the cap screw of any debris then use a 6mm allen socket to remove it. I've had to tap on the allen socket with a hammer to loosen the screw.)

9) set the #3 cylinder on TDC. To do this remove the inspection plugs in the stator cover and rotate the engine CW until you pass a single "I" stopping at the "II" mark. The #3 cam lobes should be pointing down and away from each other (7 and 5 o'clock, #3 lobes are closest to the cam gears). If they are not rotate the engine one revolution CW (never rotate CCW). The cam timing marks should also be aligned at this point (exhaust ---> ----- intake).

10) use tie straps or wire ties to secure the timing chain to each gear. Cover the valve area with a rag to prevent anything from falling into the motor.

11) unbolt the long rear engine mount bolt and remove it. Remove the engine spacer with the special socket by turning it CW. The engine will have to be rocked up from the rear to get it out. (be careful not to damage the spacer or aluminum side plate threads)

12) with the engine rocked up unbolt the old (orange dot) tensioner and remove it. Clean the gasket area and install the new gasket and (blue dot) tensioner.

13) with the new tensioner bolted in pull the small tab to release it then install the new end plug. If there is slack in the chain between cam gears use a 10mm wrench on one of the rear cam gear bolts and rotate CCW just enough to take up the slack before releasing the tensioner. remove the ties on the cam, recheck all the timing marks then rotate the engine CW a few revolution then recheck the marks again at TDC. (when the new tensioner is released it doesn't always take all the slack out of the chain until the engine is rotated. I've had the chain jump the intake gear because of this so I position tie straps on the gear so that the engine can be rotated with the straps on. I reposition the tie straps several times as need until I make one revolution of the crank)

14) if all is OK put it back together.

Note: If you're replacing the exhaust donuts install them on the flex pipes before lower the engine.

Removing and reinstalling the lower cam tensioner bolt is difficult. A flexible 1/4" socket driver with a 8mm socket and a 1/4" drive 90 degree socket wrench helps. A magnet will also help getting the bolts in and out without dropping them. The special socket for removing the engine spacer was made from a 1/4" deep well 13mm socket. See special tools picture below.

http://s589.photobucket.com/albums/ss337/grizztracks/RS Yamaha Cam Chain Tensioner/

Attachments

-

cam tensioner tools.jpg82.3 KB · Views: 2,668

cam tensioner tools.jpg82.3 KB · Views: 2,668 -

engine spacer socket.jpg38.4 KB · Views: 2,502

engine spacer socket.jpg38.4 KB · Views: 2,502 -

blue dot tensioner (new).jpg114 KB · Views: 2,577

blue dot tensioner (new).jpg114 KB · Views: 2,577 -

cam gears aligned.jpg68.5 KB · Views: 2,517

cam gears aligned.jpg68.5 KB · Views: 2,517 -

cam gears.jpg86.9 KB · Views: 3,899

cam gears.jpg86.9 KB · Views: 3,899 -

rotate engine.jpg124.9 KB · Views: 2,646

rotate engine.jpg124.9 KB · Views: 2,646 -

valve cover removal.jpg69.6 KB · Views: 2,352

valve cover removal.jpg69.6 KB · Views: 2,352 -

engine spacer.jpg83.6 KB · Views: 2,316

engine spacer.jpg83.6 KB · Views: 2,316 -

spacer.jpg72.6 KB · Views: 2,333

spacer.jpg72.6 KB · Views: 2,333 -

secondary clutch removed.jpg107.2 KB · Views: 2,787

secondary clutch removed.jpg107.2 KB · Views: 2,787 -

shaft removal.jpg116.4 KB · Views: 3,072

shaft removal.jpg116.4 KB · Views: 3,072 -

battery bracket removed.jpg71.9 KB · Views: 2,768

battery bracket removed.jpg71.9 KB · Views: 2,768 -

orange dot tensioner (old).jpg106.1 KB · Views: 2,844

orange dot tensioner (old).jpg106.1 KB · Views: 2,844 -

Cam Chain Tensioner Failure.pdf128.5 KB · Views: 505

Last edited:

Phantom

Expert

- Joined

- Apr 2, 2004

- Messages

- 451

- Reaction score

- 1

- Points

- 721

Thanks...

When I do mine I'll take pics pertaining to the steps you have outlined. I'll forward them to you and let you insert them into you written guide if you would like.

When I do mine I'll take pics pertaining to the steps you have outlined. I'll forward them to you and let you insert them into you written guide if you would like.

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,116

- Reaction score

- 968

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

I found a right angle bit driver at Lowe's that makes removing the tensioner bolts much easier. All you need is the 1/4" drive end of the ratchet instead of an 8mm wrench or socket.

Kobalt Right Angle Bit Driver #0338358

Kobalt Right Angle Bit Driver #0338358

Last edited:

towing

Expert

First of all, thank you very much grizztracks for this detailed procedure and tricks

Just a question, do you reuse the same valve cover gasket or we should put a new one???

Alain

Just a question, do you reuse the same valve cover gasket or we should put a new one???

Alain

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,116

- Reaction score

- 968

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

The valve cover gasket is a thick rubber seal and is reusable. I'll add a parts list to the procedure.

jamesc

Pro

real nice writeup Fran and thanks again. little tip that may help some doing this job. being i already had the oil filter access plate off i just put a bottle jack with a piece of wood on top under the oil pan to jack the engine up/forward, worked out pretty nice.

Doomsday_sled

Newbie

I'm in the market for a Vec' and will consider the earlier models with this in mind. How much will it cost for me to have this done a dealer if I settle on a pre-2008 model?

jamesc

Pro

i'm new to sledding, a tightwad and do my own work so take it for what it's worth. i wouldn't be surprised if a dealer wanted $400-500+ for the job. list on the parts if you replace the ones shown on this thread (which you should) is probably at least $200. if you shop around you can get them shipped for around $140. if you have mechanical skills and decent toolset you can do it yourself following the info posted here. barring that you might get someone that does sidework to knock it out for you. going to a dealer is going to be the most expensive option and regardless i wouldn't want to run the sled without replacing the tensioner. you might never have any problems or it might destroy the engine.

Crewchief47

Lifetime Member

- Joined

- Jan 16, 2006

- Messages

- 2,830

- Reaction score

- 32

- Points

- 1,333

- Location

- McGregor, ON Canada

- Country

- Canada

- Snowmobile

- 2008 Nytro MTX 45th

Jamesc, Please take the time to update your location in your profile, Thanks!

vogelm1

Pro

Excellent instructions Grizz, and thank you. I just did my '07 Vec as a preventative - figured it was cheap insurance to keep riding worry free. I would HIGHLY recommend taking the extra few minutes and remove the valve cover. That way you can double check the timing marks after new tensioner is in. When taking the old tensioner out, I heard a "click" and sure enough, the exhaust cam had rotated a little and chain jumped time a tooth or two. Had I not taken the time to double check timing marks, I may have had to do the whole job twice.

Also, save the little tab you pull out of the new tensioner after installation...may need it again in case you have to take out the tensioner and reset it, if timing is off.

Also, save the little tab you pull out of the new tensioner after installation...may need it again in case you have to take out the tensioner and reset it, if timing is off.

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,116

- Reaction score

- 968

- Points

- 1,753

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

good call on the tab  It's easily lost so when you pull it don't just set it down. I keep a couple in my tool box now.

It's easily lost so when you pull it don't just set it down. I keep a couple in my tool box now.

It's easily lost so when you pull it don't just set it down. I keep a couple in my tool box now.

It's easily lost so when you pull it don't just set it down. I keep a couple in my tool box now.jamesc

Pro

parts came in for my brothers sled last night and i installed them. one thing that might throw some people and i thought i'd seen it mentioned before is the timing marks. the instructions in the manual page above tell you to use the "I" mark which is not TDC. as Fran points out in his instructions you want the "ll" mark which is TDC.

what little tab, you mean you don't use a screwdriver like it shows in the manual ;-)

what little tab, you mean you don't use a screwdriver like it shows in the manual ;-)

Similar threads

- Replies

- 11

- Views

- 2K

- Replies

- 80

- Views

- 29K

- Replies

- 43

- Views

- 21K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.