Hello all, is anyone running the TD large Gap turbo with all supporting mods ? (Cams, tapp clutch, injectors, header, intercooler, gap flasher, closed loop, etc).

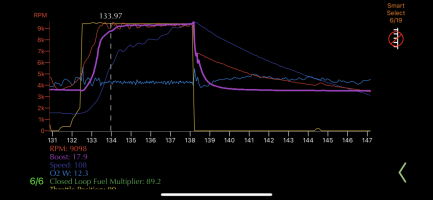

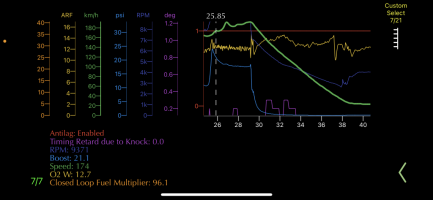

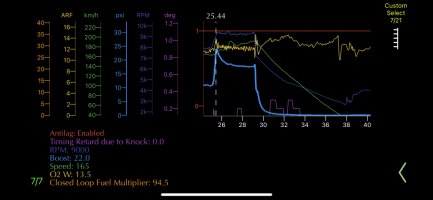

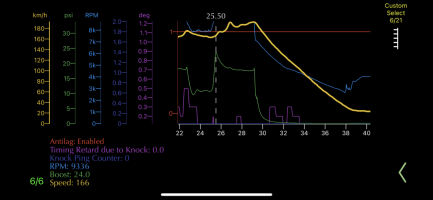

-anyone know what the target AFR should be on these ? How lean is too lean? I have attached some screenshots of my datalogs.

-has anyone run an external wastegate on these sleds ? With my current setup of the cams and large turbo with free flowing muffler , boost will sometimes creep to around 24-25 psi and the stock internal gate can not keep up. As 25 psi is not 91 octane friendly , I am going to install a small 38mm external gate to remedy this. I would set it up on a switch so wastegate pressure of 14 psi could be run (bypassing the stock ecu solinoid). Flipping the switch would allow the factory ecu boost setting to take control. This would be accomplished with 2 mac valves on the wastegate pressure lines. Thoughts? You can see the creep in the logs.

-I was sent 3 tunes, a 17,20, and 23 race tune. However I notice when I load the race tune the amount of variables That can be logged are dropped by 2. (21 down to 19) (Knock and timing dissapear from the selection of logged values) has anyone else experienced this before with the gap logger / dash display.

I have about 100 miles on the tune running vp110 only. I went for a short 5 mile journey and shut the sled off. When I fired it back up it would sputter in boost , it wouldn’t want to go above 10 psi you could hear the motor missing and not running right when boost was applied. Took it back into the shop and compression showed 30,130,130. (Warm). Pulled it apart to check the internals yet everything seeems ok???? Pictures of pistons and valves attached.

Reinstalled with a new head gasket and compression is now 130 across the board cold. Leakdown also checked out good.( Did I not screw the gauge in properly the first time). I am not sure what was causing the sled to run poorly, I thought a piston ring land broke after the compression check. Also checked valve clearances and while one was just out of spec for being tight, it still has clearance as to allow the valve to close fully (I thought that could also be a cause for the low compression)

I did do a boost leak check and that was good also. Is it common for these sleds to foul the plugs often and quickly on the race fuel? I guess the next step is to put it back together with new plugs and see how it runs. I have also removed the race tune as the others will allow me to log knock.

If anyone has any thoughts or experience on this it would be great. I have also asked for feedback from TD but have not heard back yet. Thanks and let me know.

View attachment 164540

-anyone know what the target AFR should be on these ? How lean is too lean? I have attached some screenshots of my datalogs.

-has anyone run an external wastegate on these sleds ? With my current setup of the cams and large turbo with free flowing muffler , boost will sometimes creep to around 24-25 psi and the stock internal gate can not keep up. As 25 psi is not 91 octane friendly , I am going to install a small 38mm external gate to remedy this. I would set it up on a switch so wastegate pressure of 14 psi could be run (bypassing the stock ecu solinoid). Flipping the switch would allow the factory ecu boost setting to take control. This would be accomplished with 2 mac valves on the wastegate pressure lines. Thoughts? You can see the creep in the logs.

-I was sent 3 tunes, a 17,20, and 23 race tune. However I notice when I load the race tune the amount of variables That can be logged are dropped by 2. (21 down to 19) (Knock and timing dissapear from the selection of logged values) has anyone else experienced this before with the gap logger / dash display.

I have about 100 miles on the tune running vp110 only. I went for a short 5 mile journey and shut the sled off. When I fired it back up it would sputter in boost , it wouldn’t want to go above 10 psi you could hear the motor missing and not running right when boost was applied. Took it back into the shop and compression showed 30,130,130. (Warm). Pulled it apart to check the internals yet everything seeems ok???? Pictures of pistons and valves attached.

Reinstalled with a new head gasket and compression is now 130 across the board cold. Leakdown also checked out good.( Did I not screw the gauge in properly the first time). I am not sure what was causing the sled to run poorly, I thought a piston ring land broke after the compression check. Also checked valve clearances and while one was just out of spec for being tight, it still has clearance as to allow the valve to close fully (I thought that could also be a cause for the low compression)

I did do a boost leak check and that was good also. Is it common for these sleds to foul the plugs often and quickly on the race fuel? I guess the next step is to put it back together with new plugs and see how it runs. I have also removed the race tune as the others will allow me to log knock.

If anyone has any thoughts or experience on this it would be great. I have also asked for feedback from TD but have not heard back yet. Thanks and let me know.

View attachment 164540

Attachments

max rolph

Expert

- Joined

- Feb 10, 2021

- Messages

- 447

- Age

- 60

- Location

- horse shoe valley

- Country

- Canada

- Snowmobile

- 998 turbo

12.3 is lean, should be 11.7-11.9

Big_Phil

TY 4 Stroke Master

- Joined

- Feb 5, 2014

- Messages

- 1,182

- Location

- Wasaga Beach, Ontario

- Country

- Canada

- Snowmobile

- Sidewinder RTX LE

Is Your head is 0-ringed? If not, that’s why you blew a head gasket at 25psi.

NYTurbo

TY 4 Stroke God

Ran 30 pounds of boost lots with stock head gasket and bolts .

I am running td super high boost arp studs and the td HD head gasket.

The gasket removed from the sled visually looks ok. If the head gasket went wouldn’t I see coolant in that piston ?

The gasket removed from the sled visually looks ok. If the head gasket went wouldn’t I see coolant in that piston ?

NYTurbo

TY 4 Stroke God

No , not usuallyI am running td super high boost arp studs and the td HD head gasket.

The gasket removed from the sled visually looks ok. If the head gasket went wouldn’t I see coolant in that piston ?

Fords4life

Expert

- Joined

- Dec 7, 2021

- Messages

- 319

- Age

- 57

- Location

- South Dakota

- Country

- USA

- Snowmobile

- 2021 riot 9000 & 2017 sw rtx

Farmerz24 you stated that you had a tight clearnce on a valve, that in deed when there is heat in the motor could cause a valve to hand a little off the valve seat.I dont have experience with a 998 turbo valve lashing, but experience with v8 race motors, and when valve lash is tight it causes run issues like you discrbe, and loss of compression, did you take a straight edge and feeler gauge to head and block to check for warpadge?

RK Performance

Newbie

AFR's should be under 12 for sure. What is your wastegate crack pressure? You should have gotten 2 springs with the turbo kit. It looks from your logs that you are getting a pretty big boost spike and then boost is falling off as you continue the run. If you are running 25psi boost make sure plugs are gaped around .18ish. Im running a similar setup but with pump gas for about 1000 miles and has been awesome. I believe on the race 23 tune knock is disabled because its for racing only and you dont want timing being pulled for false knock so it is disabled. I do not know that for fact, but if I'm racing I want knock protection off and most racers have it disabled.

NYTurbo

TY 4 Stroke God

Race 23 tune is supposed to 23 psi ?

Hp is what ?

Hp is what ?

I did get 2 springs but installed only 1 for a 8psi crack pressure. With both springs installed the gate would barely move until like 17 psi and I felt this is too high but was told it was correct. (I have removed the internal gate and am going to external gate for Better boost control)AFR's should be under 12 for sure. What is your wastegate crack pressure? You should have gotten 2 springs with the turbo kit. It looks from your logs that you are getting a pretty big boost spike and then boost is falling off as you continue the run. If you are running 25psi boost make sure plugs are gaped around .18ish. Im running a similar setup but with pump gas for about 1000 miles and has been awesome. I believe on the race 23 tune knock is disabled because its for racing only and you dont want timing being pulled for false knock so it is disabled. I do not know that for fact, but if I'm racing I want knock protection off and most racers have it disabled.

Makes sence about the knock, but you should still be able to log it to know IF you are knocking during the run.

Boost is definitely spiking which I was told is a phenomenon of the super high flowing cams and exhaust. Since this spike requires race fuel, I will install an external gate to miragate this and allow pump fuel to be run. I could still up the boost on race fuel when needed for race days ….

I read on this forum thst the valve clearance increases when warm, but I can’t verify this.Farmerz24 you stated that you had a tight clearnce on a valve, that in deed when there is heat in the motor could cause a valve to hand a little off the valve seat.I dont have experience with a 998 turbo valve lashing, but experience with v8 race motors, and when valve lash is tight it causes run issues like you discrbe, and loss of compression, did you take a straight edge and feeler gauge to head and block to check for warpadge?

No I did not check for warpage but in hindsight should have.

I believe so yes. Hp is around the 400 markRace 23 tune is supposed to 23 psi ?

Hp is what ?

Big_Phil

TY 4 Stroke Master

- Joined

- Feb 5, 2014

- Messages

- 1,182

- Location

- Wasaga Beach, Ontario

- Country

- Canada

- Snowmobile

- Sidewinder RTX LE

If you’re running c-16 or import, you can run 35+psi with no knock. So no need for knock control on the race tune. I’m not one to tell you what to do with your sled, but the only way to know for sure that all is working like it should is to have the sled on the dyno to confirm. It’s easier said than done to make 450+ Horse on these sleds and have no issues and have them run hard for a whole season.I did get 2 springs but installed only 1 for a 8psi crack pressure. With both springs installed the gate would barely move until like 17 psi and I felt this is too high but was told it was correct. (I have removed the internal gate and am going to external gate for Better boost control)

Makes sence about the knock, but you should still be able to log it to know IF you are knocking during the run.

Boost is definitely spiking which I was told is a phenomenon of the super high flowing cams and exhaust. Since this spike requires race fuel, I will install an external gate to miragate this and allow pump fuel to be run. I could still up the boost on race fuel when needed for race days ….

NYTurbo

TY 4 Stroke God

I’ve read all through this thread and your comments/statements. I’m probably one of the first to run the GAP big turbo and in my third season . I highly suggest you talk to your tuner and get your issues worked out . With the big turbo #*$&@ can go bad quickly especially with boost creep .

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.