brad4639

Extreme

uh oh

Here you can see that I narrowed to rear of the tunnel almost 2 inches from stock. The snowflap had to be cut to get into place.

I went to lift the rear end off the ground for the first time and quickly realized that there wasn't enough support on the rear of the tunnel. Back to the drawing board... I talked to one of the engineers I work with and came up with this fairly simple fix. Extruded Alum angle iron does not have much flex at all and doesn't add too much weight. Its riveted on the underside and helped drastically.

Here you can see that I narrowed to rear of the tunnel almost 2 inches from stock. The snowflap had to be cut to get into place.

I went to lift the rear end off the ground for the first time and quickly realized that there wasn't enough support on the rear of the tunnel. Back to the drawing board... I talked to one of the engineers I work with and came up with this fairly simple fix. Extruded Alum angle iron does not have much flex at all and doesn't add too much weight. Its riveted on the underside and helped drastically.

brad4639

Extreme

Gauges

Installed the boost guage, wideband air/fuel ratio, and digital water temp. Went pretty well but took a while to run the wires right and as clean as possible. I used single pods and mounted them with GoPro mounts. I debated with myself about putting them on the bars like most others but lets face it, I know the sled will be upside down more than a few times and I dont want to break them off.

Key on. They work! Here you can see the installed tether. Fits perfectly in the bar risers and almost looks factory.

Installed the boost guage, wideband air/fuel ratio, and digital water temp. Went pretty well but took a while to run the wires right and as clean as possible. I used single pods and mounted them with GoPro mounts. I debated with myself about putting them on the bars like most others but lets face it, I know the sled will be upside down more than a few times and I dont want to break them off.

Key on. They work! Here you can see the installed tether. Fits perfectly in the bar risers and almost looks factory.

yooper1

Expert

That is the cats #*$&@ in da moon light! With all your skills have you thought about relocating the speedo gage cluster off your riser? That might be a clean set up not sure about being upside down would work.

Son you have talent, keep dreaming and damn sure keep building! You come up to Houghton Mi you looking me up and I’ll take you for a drink and introduce you to some very neat people that build like you.

Son you have talent, keep dreaming and damn sure keep building! You come up to Houghton Mi you looking me up and I’ll take you for a drink and introduce you to some very neat people that build like you.

brad4639

Extreme

Test Drive

Took it out to my friends field to figure out the fuel controller and dial in the clutching. We've only got about a 4 in base so as soon as boost hits, it was spinning on dirt. That made tuning pretty difficult but I learned a few things.

First off the turbo was set at 9PSI, I had the fuel controller maxed out under boost and there was just no way to get enough fuel to it. I turned it down to 8psi which is what the kit says you can run. Fat chance, still way to lean.

Ended at 6PSI and finally had somewhat safe air/fuel level but still a little more lean than I would like. Can anyone shed some light on what I can run at sea level and what I'll be able to run up in the mountains? I'd really like to stay with 91 octane so I can ride ditches and some trails in MN and MI.

Took it out to my friends field to figure out the fuel controller and dial in the clutching. We've only got about a 4 in base so as soon as boost hits, it was spinning on dirt. That made tuning pretty difficult but I learned a few things.

First off the turbo was set at 9PSI, I had the fuel controller maxed out under boost and there was just no way to get enough fuel to it. I turned it down to 8psi which is what the kit says you can run. Fat chance, still way to lean.

Ended at 6PSI and finally had somewhat safe air/fuel level but still a little more lean than I would like. Can anyone shed some light on what I can run at sea level and what I'll be able to run up in the mountains? I'd really like to stay with 91 octane so I can ride ditches and some trails in MN and MI.

brad4639

Extreme

yooper1 said:That is the cats #*$&@ in da moon light! With all your skills have you thought about relocating the speedo gage cluster off your riser? That might be a clean set up not sure about being upside down would work.

Son you have talent, keep dreaming and damn sure keep building! You come up to Houghton Mi you looking me up and I’ll take you for a drink and introduce you to some very neat people that build like you.

Thanks! I was planning on going to the UP this weekend but now me and my wife are just heading to Banning Junction in MN. Its only about 2 hours from me and I really don't want to drive 6 hours to Houghton with an untested sled. Once I have everything dialed in, I'll look you up. I usually stay in Ironwood a few weekends a year but I wouldn't mind going farther up.

brad4639

Extreme

Found another issue to address

When I got back from test driving it for the first time, I went through and checked over everything to make sure it was all holding up. Found out that my drop brackets were not. Guess I shouldn't have made the "windows" in them. One started to bend with very little abuse.

If I were to put new drop brackets in it would require me taking the running boards off and drilling out around 80 rivets! So, I weighed my options and put some thought into it and came up with this..

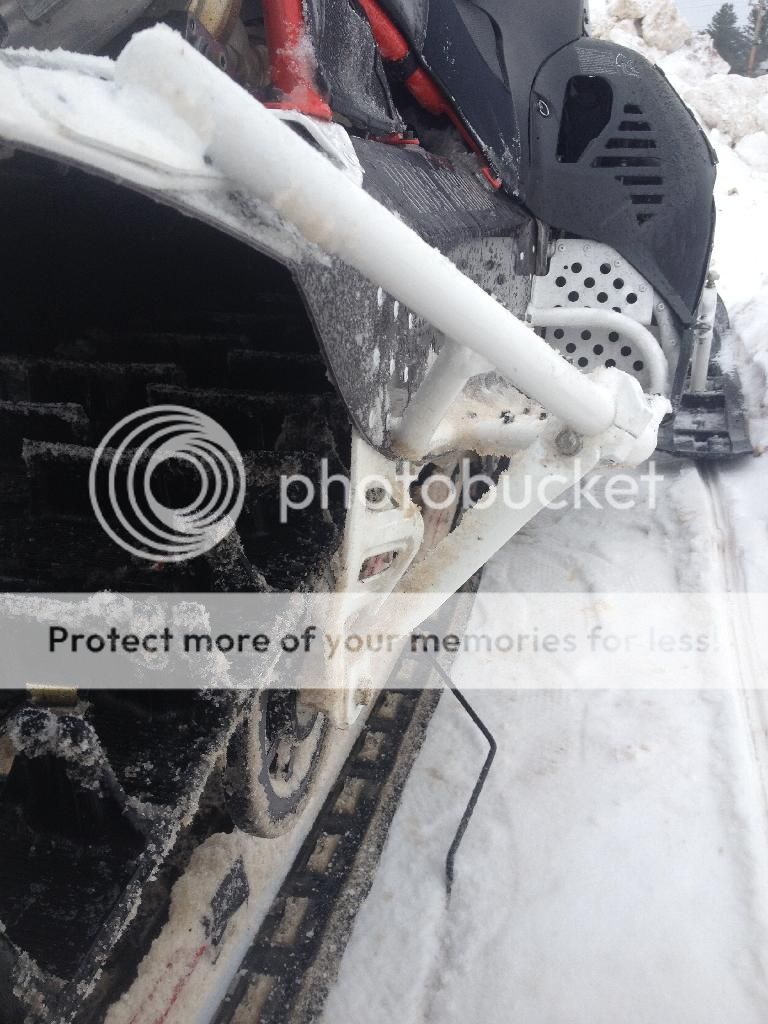

Here what the clamp looks like that hold it to the running board.

I think this should be strong enough, but I wont know til I get some miles on it.

When I got back from test driving it for the first time, I went through and checked over everything to make sure it was all holding up. Found out that my drop brackets were not. Guess I shouldn't have made the "windows" in them. One started to bend with very little abuse.

If I were to put new drop brackets in it would require me taking the running boards off and drilling out around 80 rivets! So, I weighed my options and put some thought into it and came up with this..

Here what the clamp looks like that hold it to the running board.

I think this should be strong enough, but I wont know til I get some miles on it.

yamaha1973

TY 4 Stroke Master

- Joined

- Nov 27, 2011

- Messages

- 1,288

- Location

- St. Peter Minnesota

- Country

- USA

- Snowmobile

- 2014 Viper XTX SE

Impressive! I love that you can see the polishing through the powder coat

brad4639

Extreme

brad4639

Extreme

updated drop brackets

Re-designed my drop brackets. I added some more material and bends. These ones should hold up but I'll put them to the test this weekend.

I also found I have an oil leak somewhere thats pretty bad. I couldnt quite pin point it yet but I'm thinking that it may be coming from the turbo oil feed line off the front of the head.

All the .5 holes are just for weight savings and will never be seen anyways.

Re-designed my drop brackets. I added some more material and bends. These ones should hold up but I'll put them to the test this weekend.

I also found I have an oil leak somewhere thats pretty bad. I couldnt quite pin point it yet but I'm thinking that it may be coming from the turbo oil feed line off the front of the head.

All the .5 holes are just for weight savings and will never be seen anyways.

brad4639

Extreme

Found my oil leak. The alum fitting that goes into the head and feeds oil to the turbo broke. This is the second one that failed on me. Its a 4AN to M8X1.25 and I can only find aluminum ones and no local places carry them.

I didnt want to wait for a week to get another crappy aluminum one that will probably break again so I made my own out of 303 stainless steel on a manual lathe. It took a couple hours but I dont have to worry about this one failing.

Finished comparison

I didnt want to wait for a week to get another crappy aluminum one that will probably break again so I made my own out of 303 stainless steel on a manual lathe. It took a couple hours but I dont have to worry about this one failing.

Finished comparison

This is some impressive fab and a machine work! Great job! It looks as if you have access to some nice equipment.

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,742

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

A masterpiece!

Too bad about the drop brackets. When the caved, glad they didnt wrinkle the tunnel.

Great job.

MS

Too bad about the drop brackets. When the caved, glad they didnt wrinkle the tunnel.

Great job.

MS

HartleRacing

Expert

fantastic work here! you have a real opportunity to begin selling product if you decide to go that route. figure out the bugs and small details, and post some of this up on the Snowest forum, i bet you get a pile of people wanting this setup

WolfOne

VIP Member

Very nice job

Straight_up_XTX

Pro

Man I knew I should have become a machinist!!

Great work!

Great work!

Similar threads

- Replies

- 4

- Views

- 4K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.