Shootis

Newbie

- Joined

- Feb 2, 2016

- Messages

- 20

- Age

- 61

- Location

- Dedham,Me

- Country

- USA

- Snowmobile

- 2008 Vector LTX GT

2005 Rs Vector

The tool is en route to Canada to help another member!

SRX Maine

Extreme

Could you post the manual instructions again? I can't view them for some reason

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,110

- Age

- 60

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

Could you post the manual instructions again? I can't view them for some reason

I made changes to the photos on the first page so they're no longer linked to photobucket if that's what you're referring to.

Last edited:

SRX Maine

Extreme

Yeah, that’s what I’m looking for.I made changes to the photos on the first page so they're nolonger linked to photobucket if that's what you're refering to.

I’m doing my tensioner and was curious to read the Yamaha manual.

SRX Maine

Extreme

My exhaust cam seems to be just a tad behind when the pointer is on the IIYeah, that’s what I’m looking for.

I’m doing my tensioner and was curious to read the Yamaha manual.

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,110

- Age

- 60

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

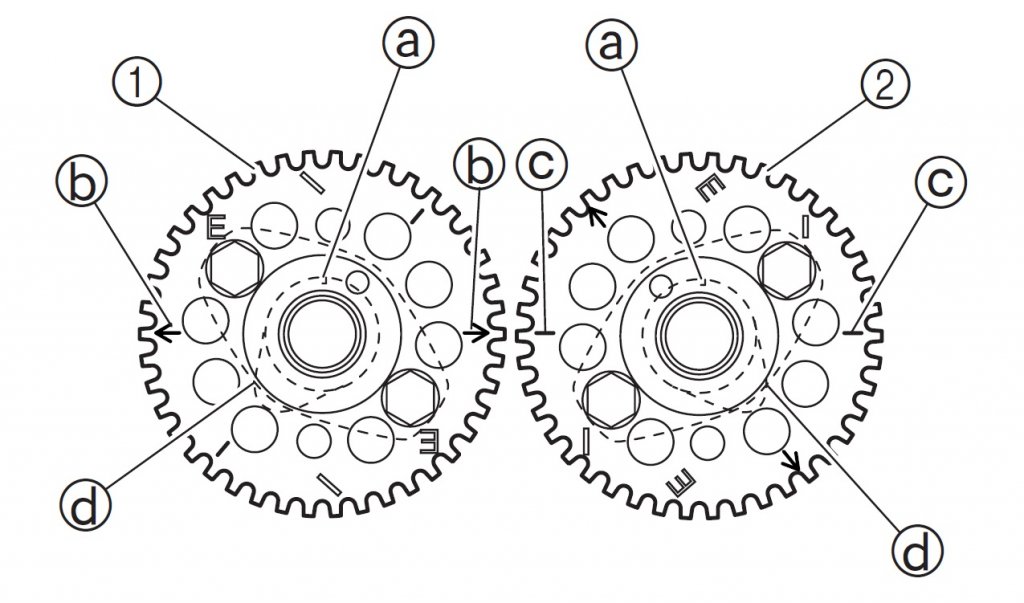

The marks on the both gears need to be aligned and the II mark on flywheel just close. The exhaust cam will want to rotate CW toward the intake cam because it's coming off the #3 exhaust lobe so it usually needs held in place while setting the chain. With the cams aligned if the chain is off by one tooth one the crank gear you won't see the II marks in the stator cover window.

SRX Maine

Extreme

The marks on the both gears need to be aligned and the II mark on flywheel just close. The exhaust cam will want to rotate CW toward the intake cam because it's coming off the #3 exhaust lobe so it usually needs held in place while setting the chain. With the cams aligned if the chain is off by one tooth one the crank gear you won't see the II marks in the stator cover window.

So in theory, the arrow on the exhaust gear should point directly at the line on the intake gear?

Mine looks like the pic in your photobucket

Let me ask you this. Why isn't this done at TDC of the firing stroke?

The lines and arrows appear to be in the same position, and the cam lobes are at 11 and 1

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,110

- Age

- 60

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

#3 cylinder (stator side) lobes should be at 7 and 5.

"d" shows #3 cylinder cam lobe position when setting timing.

"d" shows #3 cylinder cam lobe position when setting timing.

SRX Maine

Extreme

#3 cylinder (stator side) lobes should be at 7 and 5.

"d" shows #3 cylinder cam lobe position when setting timing.

View attachment 153743

That's what I thought

If I line it up like that, I'm a good 1/16th inch past the II

This is exactly how it was after ripping it apart

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,110

- Age

- 60

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

Like I said, as long as the cams align after rotating the engine several times and the II mark is visible in the window you are good. One tooth off and the II mark won't be in the window opening. The slight misalignment is due to worn guides and a stretched chain.

MEL

Veteran

- Joined

- Feb 22, 2021

- Messages

- 28

- Location

- Leslie Mi

- Country

- USA

- Snowmobile

- 2005 vector

2002 sxviper

1979 exciter

Hey Griz do I remember right the spacer tool was a 13mm deep 1/4 socket? Also how deep and wide are the cuts?

I am about to try this myself. If I lived near you I'd ask you to do it

Thanks

I am about to try this myself. If I lived near you I'd ask you to do it

Thanks

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,110

- Age

- 60

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

Hey Griz do I remember right the spacer tool was a 13mm deep 1/4 socket? Also how deep and wide are the cuts?

I am about to try this myself. If I lived near you I'd ask you to do it

Thanks

13mm, 1/4" drive deep well socket works. Notch it out leaving two tabs maybe 1/4" wide and 1/4" tall.

MEL

Veteran

- Joined

- Feb 22, 2021

- Messages

- 28

- Location

- Leslie Mi

- Country

- USA

- Snowmobile

- 2005 vector

2002 sxviper

1979 exciter

Sorry about the delayed response but thanks much!!!!!

Hopefully I wont bother you when I start this mission. Just putting together my Kodiak front diff locker kit. The vector is next.

Hopefully I wont bother you when I start this mission. Just putting together my Kodiak front diff locker kit. The vector is next.

MEL

Veteran

- Joined

- Feb 22, 2021

- Messages

- 28

- Location

- Leslie Mi

- Country

- USA

- Snowmobile

- 2005 vector

2002 sxviper

1979 exciter

Hey Grizz, Ive been trying not to bother you further with my adventure here but I have run in to a snag. Tool worked great by the way. when trying to install the new tensioner it stops abut 1/2 inch short of going all the way in. Now when I removed the old one it did snap back quite a bit but I didn't think much of that. I had the cables ties on the gears to timing wouldn't jump but when it released the tensioner I got slack in the chain which I know you take out with the exhaust cam ccw but should I try to do that and then try to install the tensioner? Have you ever had this happen?13mm, 1/4" drive deep well socket works. Notch it out leaving two tabs maybe 1/4" wide and 1/4" tall.

View attachment 161578

grizztracks

Tech Advisor

- Joined

- Feb 24, 2005

- Messages

- 3,110

- Age

- 60

- Location

- Scio, NY

- Country

- USA

- Snowmobile

- FX Nytro RTX, RS Vector, SR Viper RTX SE

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.