Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,659

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Here I wanted to show you guys a behind the scenes picture of the tunnel extension just before I shot it with the first coat of powder...

The photo doesn't look like much, but it took me over an hour just to hang the extension from the rack as shown. All I have is an old kitchen range to cook parts, so before I bake anything important, I practice placing the part in the oven so that it will fit without bumping the sides; that involves hanging and re-hanging the part several times to get it right. I know I'm into my 4th month of building this project, but it's little things like this that consume an enormous amount of time.

The photo doesn't look like much, but it took me over an hour just to hang the extension from the rack as shown. All I have is an old kitchen range to cook parts, so before I bake anything important, I practice placing the part in the oven so that it will fit without bumping the sides; that involves hanging and re-hanging the part several times to get it right. I know I'm into my 4th month of building this project, but it's little things like this that consume an enormous amount of time.

Last edited:

- Joined

- Apr 13, 2003

- Messages

- 21,486

- Age

- 54

- Location

- Schofield, WI

- Website

- www.totallyamaha.com

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

Here I wanted to show you guys a behind the scenes picture of the tunnel extension just before i shot it with the first coat of powder...

The photo doesn't look like much, but it took me over an hour just to hang the extension from the rack as shown. All I have is an old kitchen range to cook parts, so before I bake anything important, I practice placing the part in the oven so that it will fit without bumping anything and screwing up the finish. That involves hanging and re-hanging the part several times to get it right. I know I'm into my 4th month of building this project, but it's little things like this that consume an enormous amount of time.

View attachment 120509

It not about the time, its more about the fun of the build and the learning curve along with custom design and fabrications that does it for me.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,659

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Mark, are you coming to the Giveaway ride this winter? It's usually around the end of January. As soon as Tom posts the date this fall, I'm on it!...hope to see this winter.

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,659

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

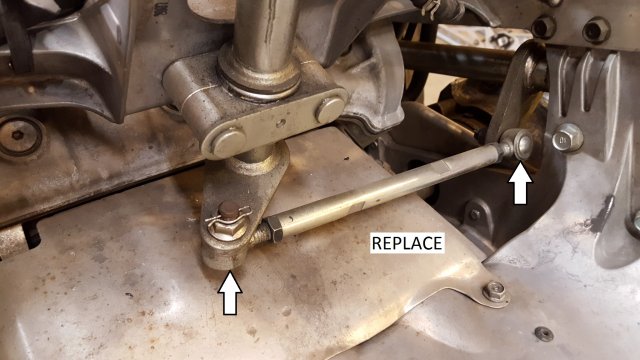

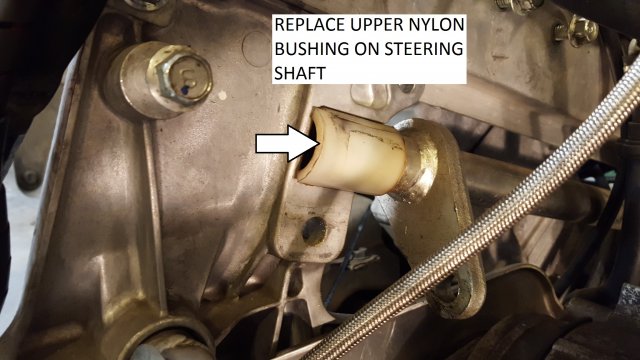

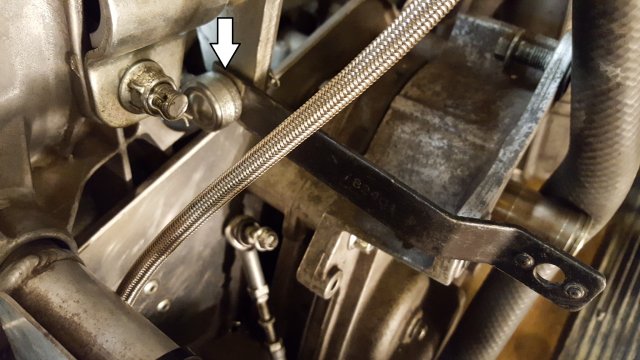

I have been swamped with work at home lately, so progress on the sled is moving really slow! I finished running all the air lines, except for the ski shocks. I'll run those lines once I get the shocks back from getting a rebuild at fast. I also installed Weather Pak connectors on the air solenoid coils and replaced a torn tie rod boot. With the exception of a few other knick knacks, the sled is ready to be set back on the floor. Once there, I'm going to replace the tie rod ends above the exhaust header, then all the body panels can be re-installed.

The next big task will be the wiring.

The next big task will be the wiring.

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,659

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

It's on the floor! I temporarily placed the seat and tail light assembly on to get a full preview.

My goal is to have the body panels fully assembled by mid-week; it's time to shut 'er down and go to work.

My goal is to have the body panels fully assembled by mid-week; it's time to shut 'er down and go to work.

yamadoo

Yamadoo is a snowmobile ' aholic'.

- Joined

- Jun 3, 2003

- Messages

- 3,645

- Country

- USA

- Snowmobile

- 15 Viper STX DX red/white- GPS and KING AIR suspension 4kmiles

13 Apex XTX 45 anniversary RED/WHITE/BLACK 3K miles

10 Vector LTX Blue 9kmiles

11 Venture GT 4k miles

86 SnoScoot(2) for grand kids

Mark, are you coming to the Giveaway ride this winter? It's usually around the end of January. As soon as Tom posts the date this fall, I'm on it!

My schedule isn't out yet but will try to do at least one muni try ride. Last year did the March ride worked well. The give away ride is close to the Manitoba ride and I really enjoy that as well. Lots of great problems to have

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,659

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

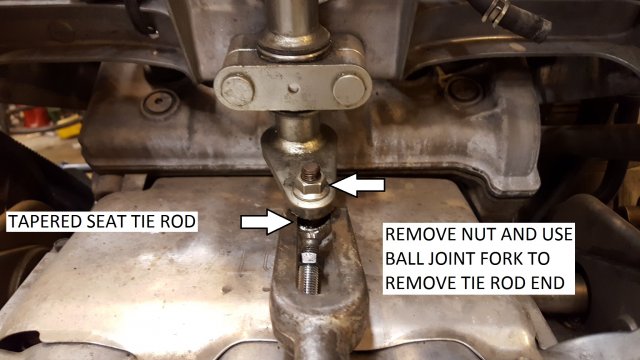

Tie rod ends above the exhaust header are replaced! I find it odd that these ends were sloppy and the outer tie rod ends for each ski are still good!?  I'm guessing it's related to heat and the design of the joint. I'd like to note that wrenches used for tightening wheels on an angle grinder work nicely for keeping tie rods locked in position when tightening jam nuts. Minor grinding involved, and I can still use them for my grinders...lol!

I'm guessing it's related to heat and the design of the joint. I'd like to note that wrenches used for tightening wheels on an angle grinder work nicely for keeping tie rods locked in position when tightening jam nuts. Minor grinding involved, and I can still use them for my grinders...lol!

The engine coolant is looking past its sell by date, so time to drain 'er down and replace with new. This will give me a good opportunity to run the sled and align the track while I'm at it!

The engine coolant is looking past its sell by date, so time to drain 'er down and replace with new. This will give me a good opportunity to run the sled and align the track while I'm at it!

Last edited:

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,659

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Engine coolant is replaced and the cooling system is bled down. I primed the carbs with gas, hit the key and she lit instantly!

OK, I attempted to align the track while the sled was running, but had limited success...it just wouldn't align...at the front of the track! Hmm...I had the same issue on this exact sled 6 years ago when it was converted to a 151" track. I ultimately had to shift the extrovert drivers 1/8" to the left on the drive shaft to square everything up. This time, they need to go back 1/8" to the right!??? I'm not sure what gives here, other than different skids and tracks??

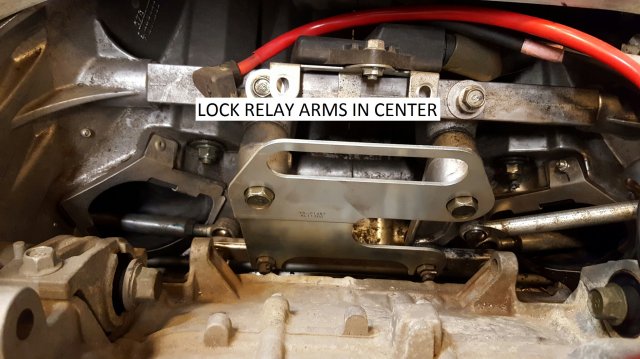

So, instead of pulling the skid back out, dismantling the chain case, etc...etc...I enlisted the help of my custom driver relocation tool, for the second time! It's made from an old hex collar that was once used to keep the original factory drivers from walking back and forth. I split the collar and made it into a two-piece clamp that fastens around the drive shaft. There are two pusher bolts that push against a collar, which puts force on the driver and moves it.

20 minutes later, the track is now aligned!

OK, I attempted to align the track while the sled was running, but had limited success...it just wouldn't align...at the front of the track! Hmm...I had the same issue on this exact sled 6 years ago when it was converted to a 151" track. I ultimately had to shift the extrovert drivers 1/8" to the left on the drive shaft to square everything up. This time, they need to go back 1/8" to the right!??? I'm not sure what gives here, other than different skids and tracks??

So, instead of pulling the skid back out, dismantling the chain case, etc...etc...I enlisted the help of my custom driver relocation tool, for the second time! It's made from an old hex collar that was once used to keep the original factory drivers from walking back and forth. I split the collar and made it into a two-piece clamp that fastens around the drive shaft. There are two pusher bolts that push against a collar, which puts force on the driver and moves it.

20 minutes later, the track is now aligned!

Last edited:

- Joined

- Apr 13, 2003

- Messages

- 21,486

- Age

- 54

- Location

- Schofield, WI

- Website

- www.totallyamaha.com

- Country

- USA

- Snowmobile

- 2020 Sidewinder SRX

Engine coolant is replaced and the cooling system is bled down. I primed the carbs with gas, hit the key and she lit instantly!

OK, I attempted to align the track while the sled was running, but had limited success...it just wouldn't align...at the front of the track! Hmm...I had the same issue on this exact sled 6 years ago when it originally got converted to a 151" track. I ultimately had to shift the extrovert drivers 1/8" to the left on the drive shaft to square everything up. This time, they need to go back 1/8" to the right!??? I'm not sure what gives here, other than different skids and tracks??

So, instead of pulling the skid back out, dismantling the chain case, etc...etc...I enlisted the help of my custom driver relocation tool, for the second time! It's made from an old hex collar that was once used to keep the original factory drivers from walking back and forth on the drive shaft. I split the collar in two and use bolts / welded nuts to clamp it around an installed drive shaft. There are two pusher bolts that push against a collar, which puts force on the driver and moves it.

20 minutes later, the track is now aligned!

View attachment 120593 View attachment 120594 View attachment 120595 View attachment 120596 View attachment 120597 View attachment 120598

That is one trick little tool!! Nice!

DranttelSS

TY Advertiser

- Joined

- Oct 9, 2014

- Messages

- 924

- Age

- 58

- Location

- St. Peter MN

- Country

- USA

- Snowmobile

- 2007 Yamaha Attak

- WEBSITE

- www.dranttelsalesandservice.com

Your builds are nothing short of impressive! Thanks for sharing!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

thor452

Because I can

- Joined

- Jan 5, 2010

- Messages

- 3,029

- Location

- Shawano,WI 54166

- Country

- USA

- Snowmobile

- 2012 Apex XTX 2017 Sidewinder LTX-LE

awesome the things people think of. I would have torn down the whole thing cursing the whole time.

yamadoo

Yamadoo is a snowmobile ' aholic'.

- Joined

- Jun 3, 2003

- Messages

- 3,645

- Country

- USA

- Snowmobile

- 15 Viper STX DX red/white- GPS and KING AIR suspension 4kmiles

13 Apex XTX 45 anniversary RED/WHITE/BLACK 3K miles

10 Vector LTX Blue 9kmiles

11 Venture GT 4k miles

86 SnoScoot(2) for grand kids

I love the way you think these things through than execute the plans making it all seem simple. Wow. Great. Again!!!!!

Redbeard

Lifetime Member

- Joined

- Oct 14, 2011

- Messages

- 1,659

- Location

- IN

- Country

- USA

- Snowmobile

- 2012 Apex, 136 M20, PB80

2008 Vector, 136 M20, PB80

Well, my friends...I wish I had new progress to report, but I do not. My livelihood is calling and I have to shut down my sled projects and focus on work 100%.

Hopefully I'll be able to report back before Thanksgiving.

Hopefully I'll be able to report back before Thanksgiving.

yamadoo

Yamadoo is a snowmobile ' aholic'.

- Joined

- Jun 3, 2003

- Messages

- 3,645

- Country

- USA

- Snowmobile

- 15 Viper STX DX red/white- GPS and KING AIR suspension 4kmiles

13 Apex XTX 45 anniversary RED/WHITE/BLACK 3K miles

10 Vector LTX Blue 9kmiles

11 Venture GT 4k miles

86 SnoScoot(2) for grand kids

Well, my friends...I wish I had new progress to report, but I do not. My livelihood is calling and I have to shut down my sled projects and focus on work 100%.

Hopefully I'll be able to report back before Thanksgiving.

Be safe working the long harvest hours

DGZRT

VIP Member

- Joined

- Feb 23, 2006

- Messages

- 1,181

- Location

- Stevens Point Wisconsin

- Country

- USA

- Snowmobile

- 2008 Vector shorty, 17 Shitdoo 1200X, 2000- pullmyass-340 for Grandkids

Nice work!!! You have some MAD SKILLS ...

Similar threads

- Replies

- 2

- Views

- 439

- Replies

- 46

- Views

- 148K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.