SumpBuster

TY 4 Stroke God

- Joined

- Jul 18, 2003

- Messages

- 2,353

- Location

- Carlisle, NY .

- Country

- USA

- Snowmobile

- 18 sidewinder; 06 Apex RTX

I had a Cosworth Vega with bucket tappets and shims in the recess, but Chevy had a 'fork', and you would rotate the cams so the tappet you are working on was pressed down and then the tool would hold it down while you removed the shim and put the correct amount back in.You adjust gap by changing shims? You can't just turn a nut onto of the valve and tighten it down? That's how my friend and I did it on his diesel marine generator. Do you have to pull the cam to adjust? Or is that something else, and I'm not connecting the dots here?

musselman

Pro

- Joined

- Apr 17, 2009

- Messages

- 167

- Location

- Fenelon Falls, Ontario

- Country

- Canada

- Snowmobile

- 2019 Ren XRS 900T, 2010 Nytro RTX

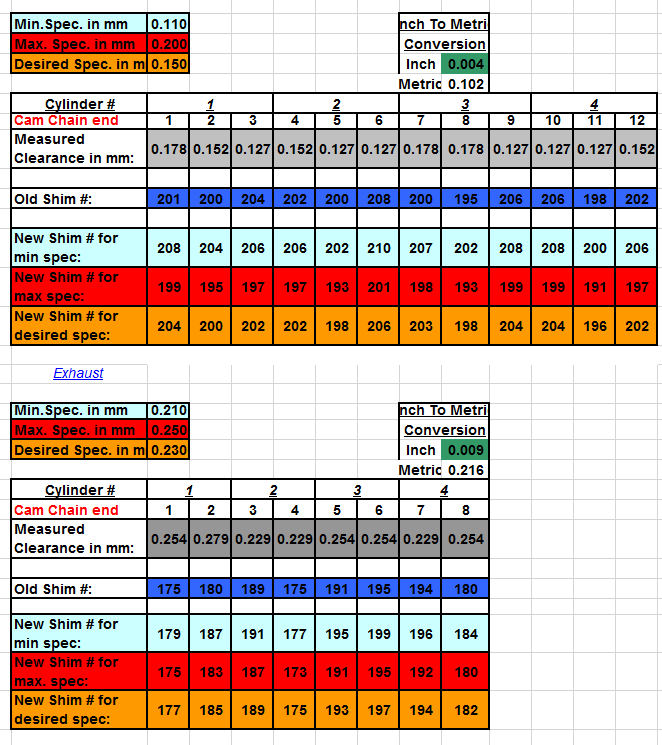

Yes unfortunately the cams need to come out to change shims, this is new territory for me so it may take some time. I have attached the excel sheet I used to record all of my valve clearances for reference. I still need to update it with the current shims to figure out what new shims are required.

Attachments

steveg_nh

TY 4 Stroke Junkie

So the shims just wear out over time? Too bad they just weren't adjustable.

musselman

Pro

- Joined

- Apr 17, 2009

- Messages

- 167

- Location

- Fenelon Falls, Ontario

- Country

- Canada

- Snowmobile

- 2019 Ren XRS 900T, 2010 Nytro RTX

No the shims don't really wear at all, the valve and seat wear causing the valve to protrude further into the head which reduces the clearance between the cam and bucket.

SumpBuster

TY 4 Stroke God

- Joined

- Jul 18, 2003

- Messages

- 2,353

- Location

- Carlisle, NY .

- Country

- USA

- Snowmobile

- 18 sidewinder; 06 Apex RTX

Yeah, the cosworth shims were pretty hard!No the shims don't really wear at all, the valve and seat wear causing the valve to protrude further into the head which reduces the clearance between the cam and bucket.

steveg_nh

TY 4 Stroke Junkie

Ah I see. Thanks for explaining that!

musselman

Pro

- Joined

- Apr 17, 2009

- Messages

- 167

- Location

- Fenelon Falls, Ontario

- Country

- Canada

- Snowmobile

- 2019 Ren XRS 900T, 2010 Nytro RTX

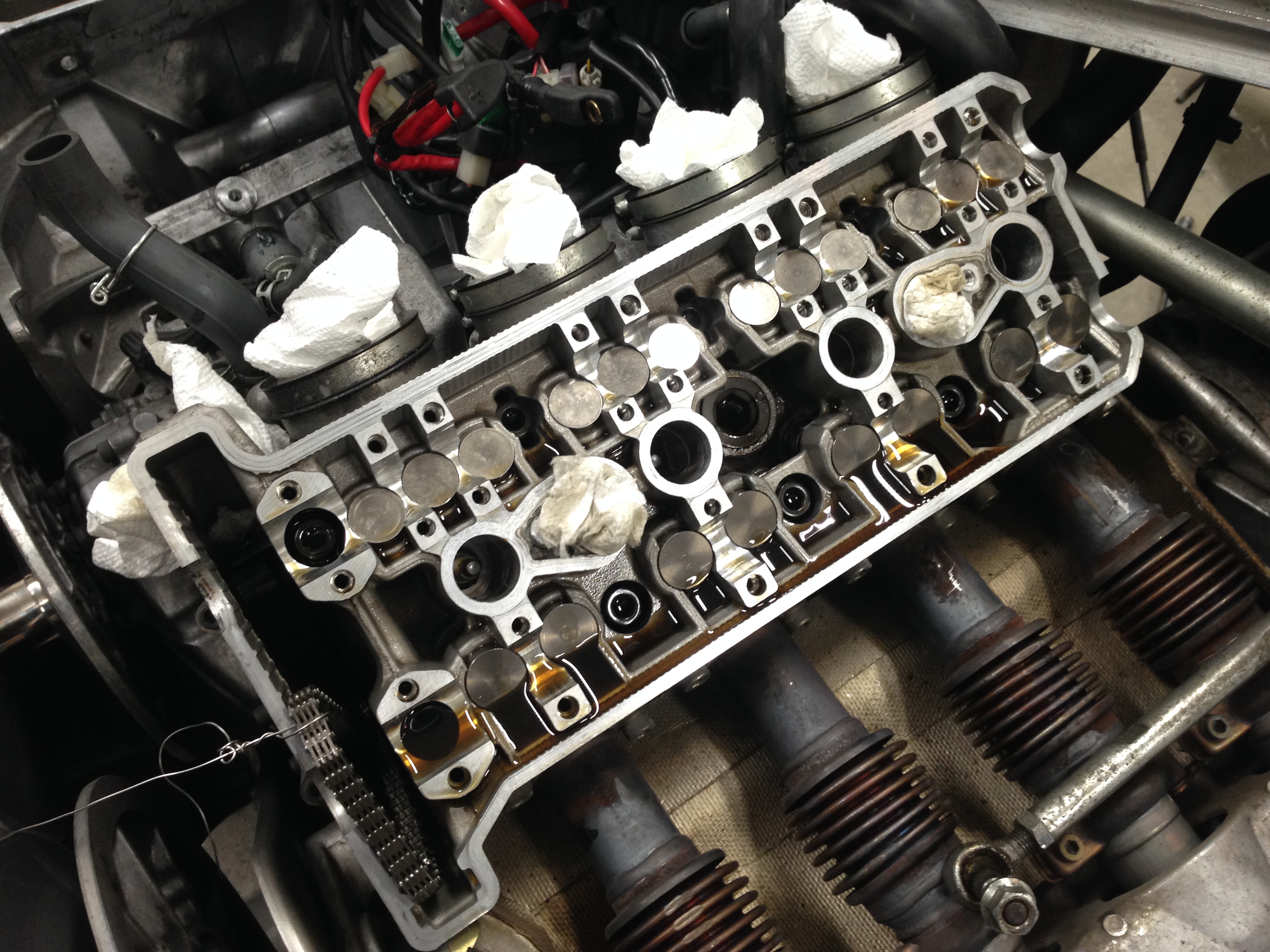

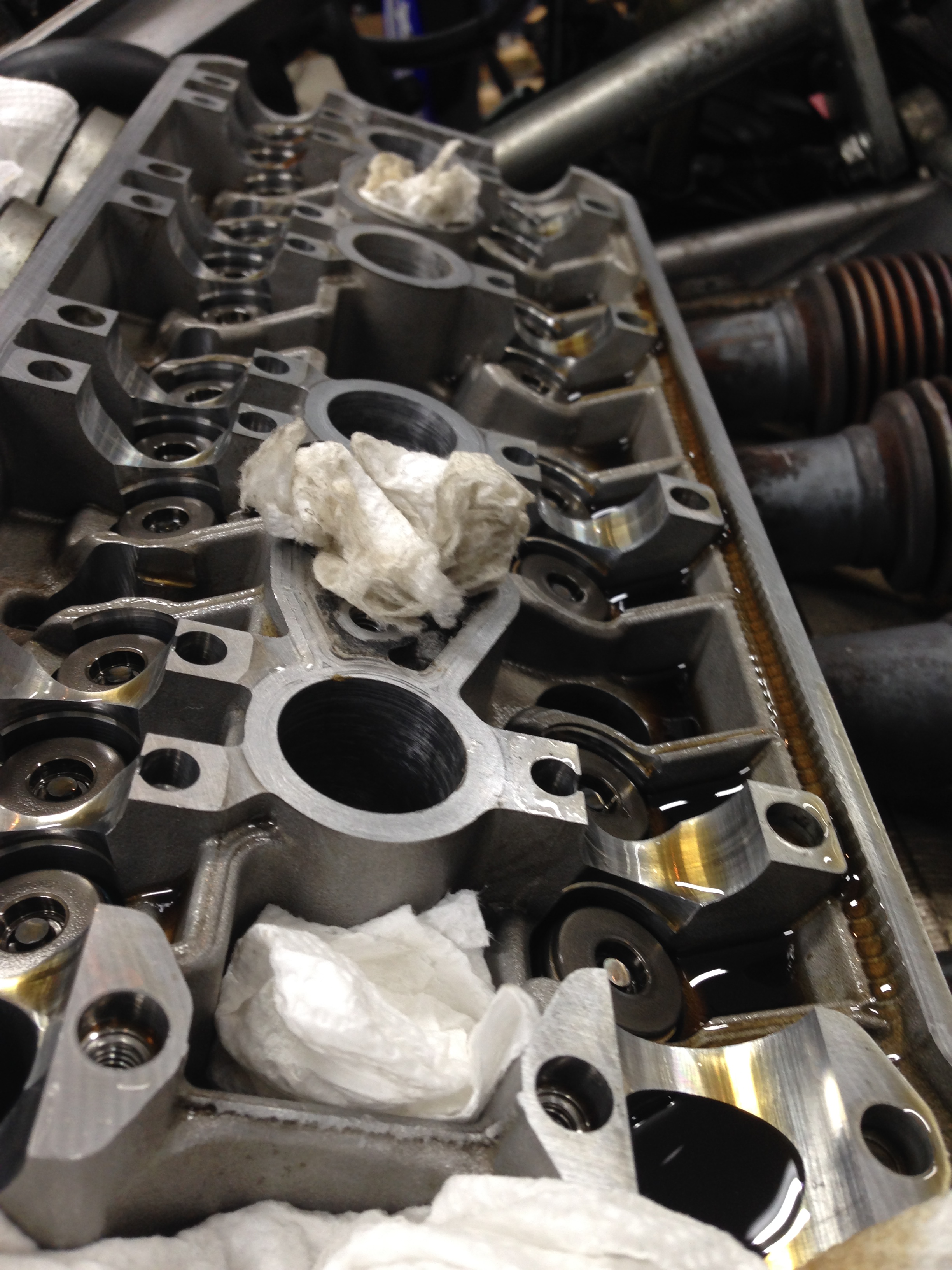

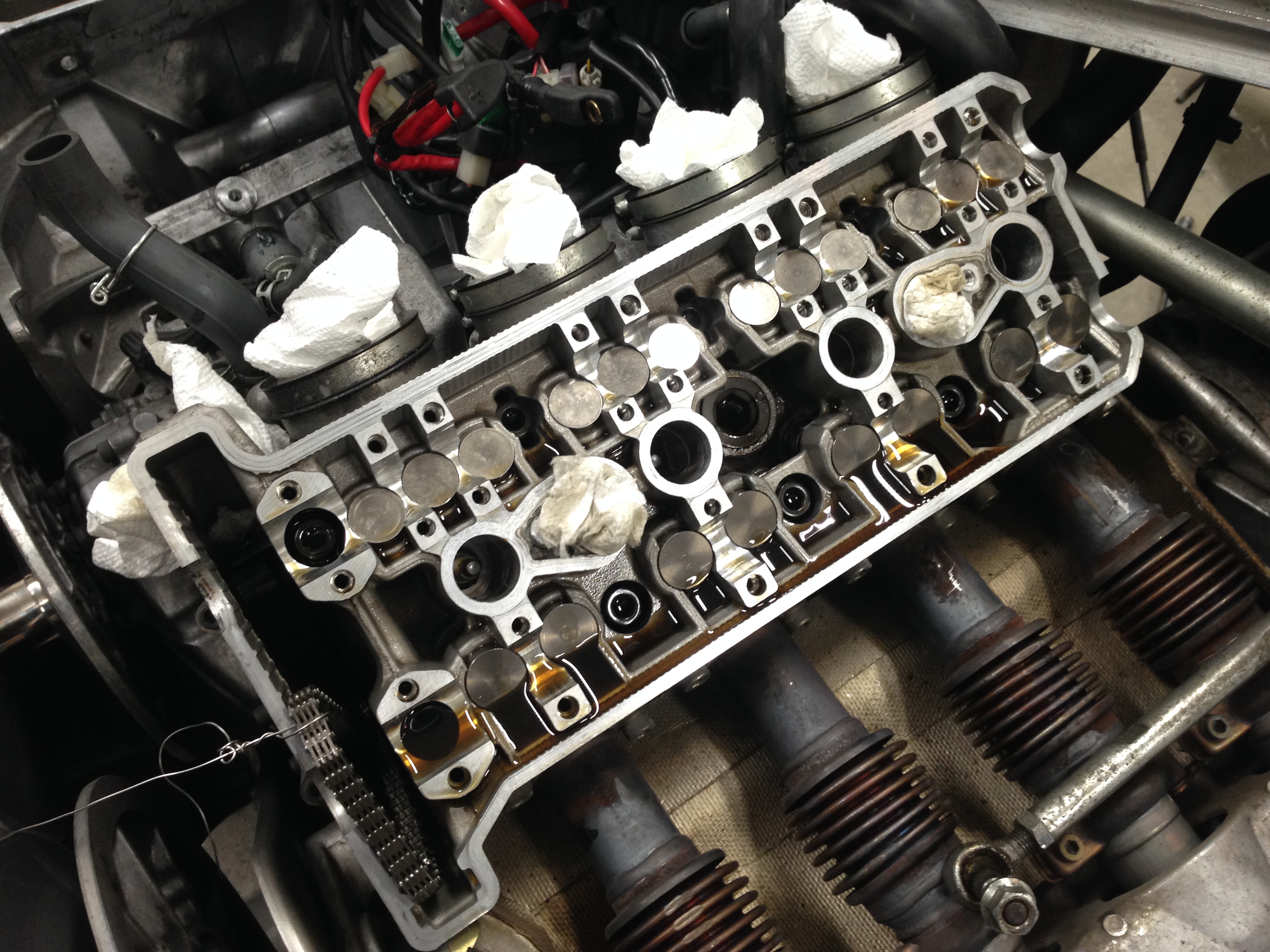

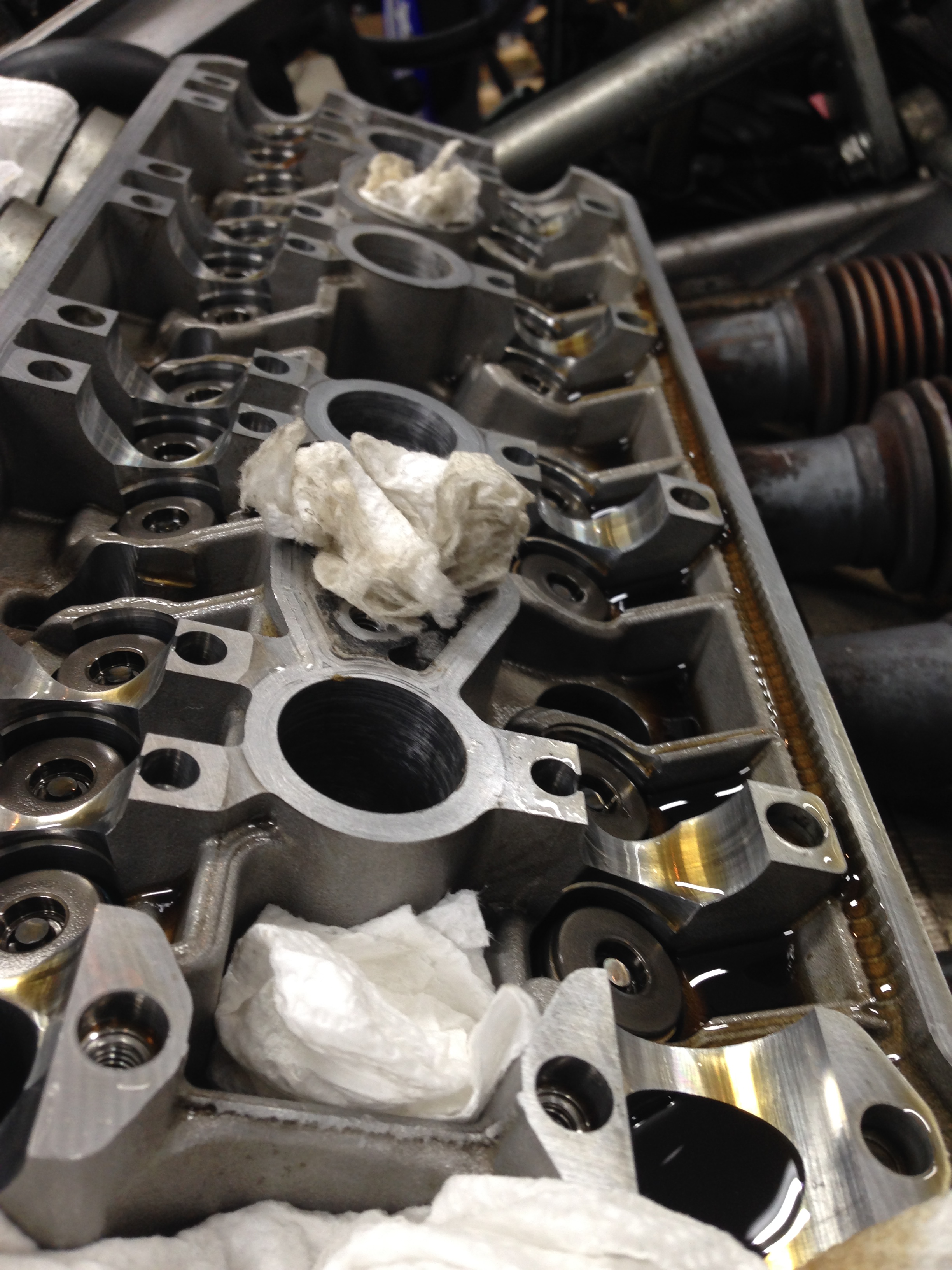

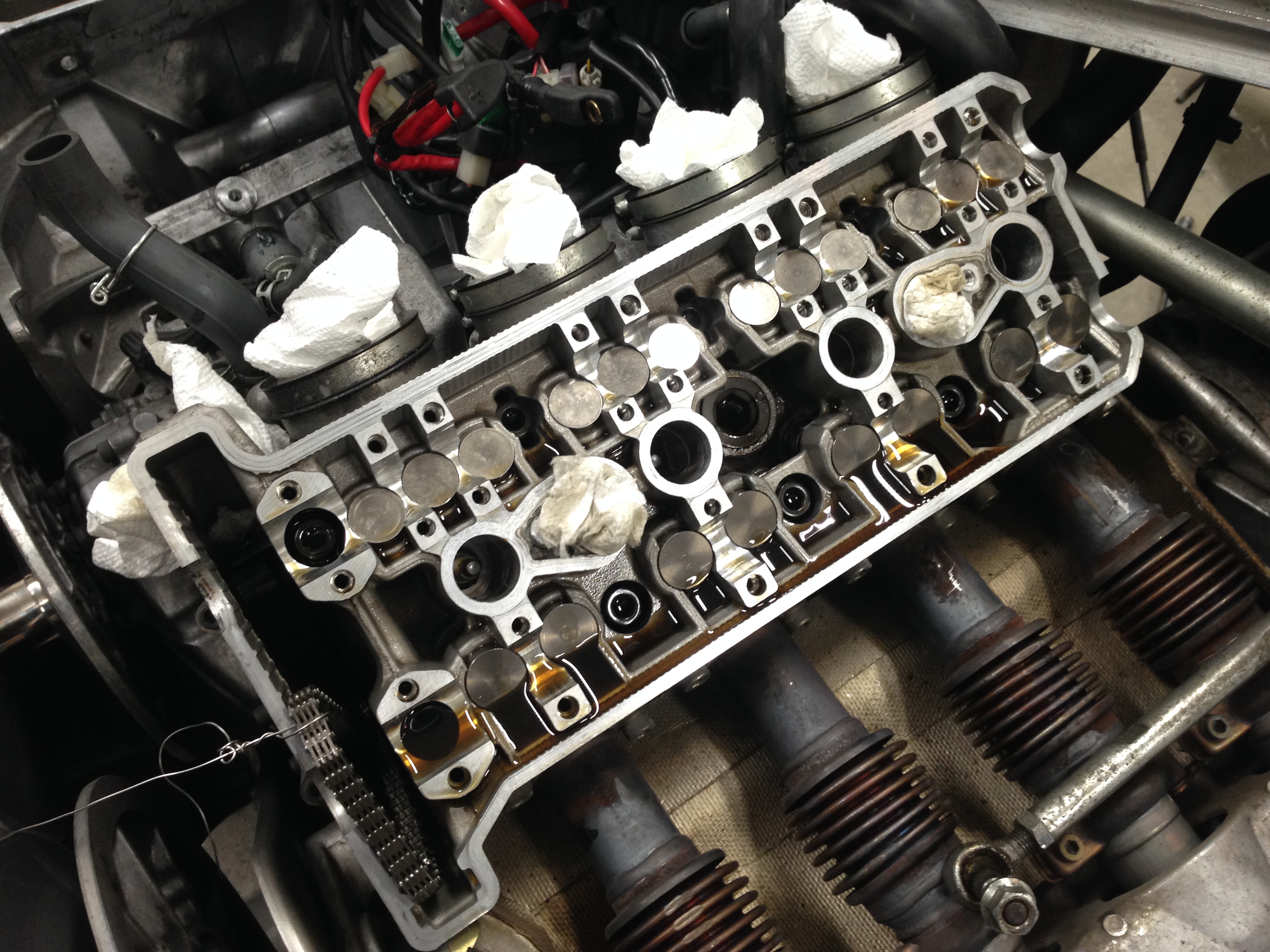

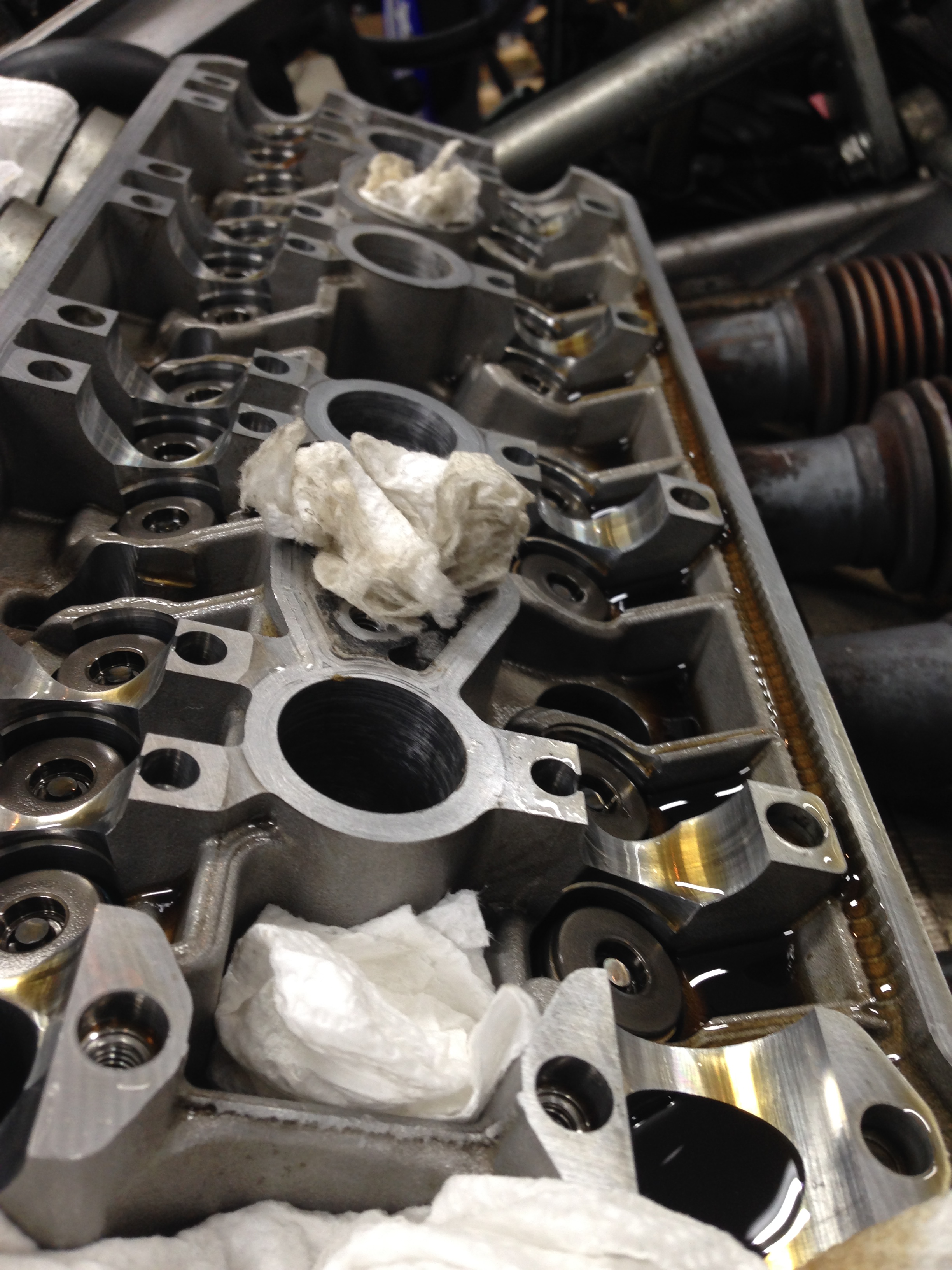

Got the cams out and removed the buckets and shims. Should I measure the shims that were in there or do they not wear? It's going to be tricky to get within spec on some valves since the replacement shims only come in 0.05mm increments.

steveg_nh

TY 4 Stroke Junkie

Holy crap that is surgery!

SumpBuster

TY 4 Stroke God

- Joined

- Jul 18, 2003

- Messages

- 2,353

- Location

- Carlisle, NY .

- Country

- USA

- Snowmobile

- 18 sidewinder; 06 Apex RTX

Got the cams out and removed the buckets and shims. Should I measure the shims that were in there or do they not wear? It's going to be tricky to get within spec on some valves since the replacement shims only come in 0.05mm increments

Absolutely mic them, especially where they made contact and adjust according to what you measured.Got the cams out and removed the buckets and shims. Should I measure the shims that were in there or do they not wear? It's going to be tricky to get within spec on some valves since the replacement shims only come in 0.05mm increments.

SumpBuster

TY 4 Stroke God

- Joined

- Jul 18, 2003

- Messages

- 2,353

- Location

- Carlisle, NY .

- Country

- USA

- Snowmobile

- 18 sidewinder; 06 Apex RTX

A work of art!Holy crap that is surgery!

steveg_nh

TY 4 Stroke Junkie

Very satisfying too!

musselman

Pro

- Joined

- Apr 17, 2009

- Messages

- 167

- Location

- Fenelon Falls, Ontario

- Country

- Canada

- Snowmobile

- 2019 Ren XRS 900T, 2010 Nytro RTX

musselman

Pro

- Joined

- Apr 17, 2009

- Messages

- 167

- Location

- Fenelon Falls, Ontario

- Country

- Canada

- Snowmobile

- 2019 Ren XRS 900T, 2010 Nytro RTX

Added a picture to view the measurements easier.

TBay Sledhead

TY 4 Stroke Master

- Joined

- Jan 16, 2005

- Messages

- 1,129

- Age

- 72

- Location

- Thunder Bay, Ontario.Ca

- Country

- Canada

- Snowmobile

- 06 Attak

01 SXR Long Track

I'm having a little trouble interpreting your data. What are the no represent in the old shim new shim columns, is that standard or metric or some kind of part no.

musselman

Pro

- Joined

- Apr 17, 2009

- Messages

- 167

- Location

- Fenelon Falls, Ontario

- Country

- Canada

- Snowmobile

- 2019 Ren XRS 900T, 2010 Nytro RTX

The shim measurements are shown in hundredths of a mm, this is the format that is shown on the shim itself, for example a 175 shim will measure 1.75 mm.

Similar threads

- Replies

- 2

- Views

- 856

- Replies

- 13

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.