Im having problems with my connection to the air intake sensor on the first cylinder. (dont seem to be the first?!)

First time one wire was teared apart, and one of the metal pins in the connector was missing, tried to repair it with a new metal pin and soldered the wire, it worked for a while, but now its broken again.

My yamaha dealer say that i only can buy the complete wiring harness.

And no one who sells used spareparts want to sell only that connection, only the complete harness.

So my question is, is there anyone who have seen just that connection with a bit of wires ?

Or maybe have used another connection from something else ?

First time one wire was teared apart, and one of the metal pins in the connector was missing, tried to repair it with a new metal pin and soldered the wire, it worked for a while, but now its broken again.

My yamaha dealer say that i only can buy the complete wiring harness.

And no one who sells used spareparts want to sell only that connection, only the complete harness.

So my question is, is there anyone who have seen just that connection with a bit of wires ?

Or maybe have used another connection from something else ?

Clay350

Extreme

- Joined

- Oct 29, 2010

- Messages

- 64

- Reaction score

- 0

- Points

- 106

- Location

- Minneapolis (just moved here)

- Website

- www.treetopsmedia.com

It has to be a standard connection of some kind. I would ltry to reference it if there is a # on it. It will probably be available through some company online. I would try Catalina like mouser or an automotive type electrical connector search.

PhazerSD

Newbie

- Joined

- Nov 17, 2019

- Messages

- 6

- Reaction score

- 3

- Points

- 33

- Location

- WestSide Canada

- Country

- Canada

- Snowmobile

- 2014 Yamaha Phazer

2011 Yamaha RS Venture

Going through this now.

Sensor on the Phazer airbox is the DENSO 5PS-82380-00. Had a broken wire inside the 3-way plug on the harness connector. Not enough slack to solder onto. tried to take it apart and repair this harness side plug but its a PITA. Sealed wire plugs and all that. doing more damage than good...

As for replacing the offending "Harness side" plug, I've researched it down to being a OEM Sumitomo Series: TS 090 Sealed Series

OEM P/N: 6189-0099. My connector has the number 10845 stamped on it.. seems to be a Toyota cross reference number to this part?!

Ordered this $3.57 connector kit that comes with new seals and connector ends: https://www.corsa-technic.com/item.php?item_id=774&category_id=157

Also ordered some 'color match' wires.

Will assemble / solder and seal it all together.

Sensor on the Phazer airbox is the DENSO 5PS-82380-00. Had a broken wire inside the 3-way plug on the harness connector. Not enough slack to solder onto. tried to take it apart and repair this harness side plug but its a PITA. Sealed wire plugs and all that. doing more damage than good...

As for replacing the offending "Harness side" plug, I've researched it down to being a OEM Sumitomo Series: TS 090 Sealed Series

OEM P/N: 6189-0099. My connector has the number 10845 stamped on it.. seems to be a Toyota cross reference number to this part?!

Ordered this $3.57 connector kit that comes with new seals and connector ends: https://www.corsa-technic.com/item.php?item_id=774&category_id=157

Also ordered some 'color match' wires.

Will assemble / solder and seal it all together.

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,498

- Reaction score

- 4,166

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Search on ebay under 'Yamaha wire harness' in the snowmobile category, there are all kinds of harness' for 10-30 bucks, just find one that has the 3 pin connector by looking at pictures. I think it is the same connector as many of the two strokes had for the TPS sensor.

PhazerSD

Newbie

- Joined

- Nov 17, 2019

- Messages

- 6

- Reaction score

- 3

- Points

- 33

- Location

- WestSide Canada

- Country

- Canada

- Snowmobile

- 2014 Yamaha Phazer

2011 Yamaha RS Venture

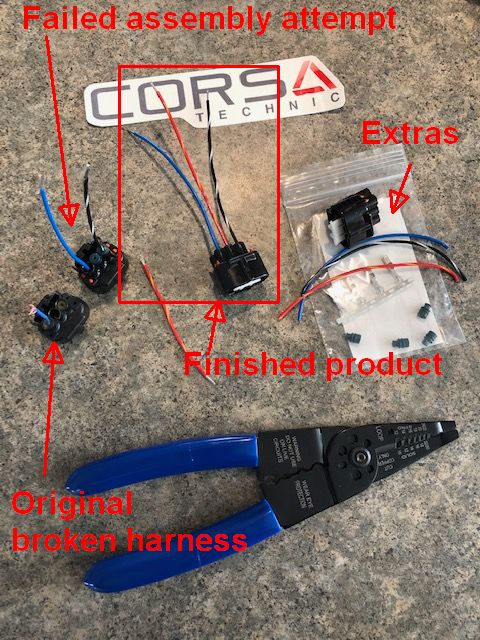

OK! My parts from Corsa Technic came in and it all worked perfectly. First, I mis-assembled a brand new connector, screwed it up twice since it was the first time ive ever done this.. the red wire pulled out once it was all assembled... Did not crimp it tight enough. I also did not crimp the rubber seal properly on the first blue wire.. I cannot figure out how to get these pins to release to rebuild/reassemble this...

Here is a video of 'proper' pin crimping.

I then assembled a brand new connector correctly! (ordered 3 since I knew one would be the training wheels)

Soldered it onto the Yammy end, sealed it using heat gun and shrink jackets. No more code! Running smooth and buttery.

Here is a video of 'proper' pin crimping.

I then assembled a brand new connector correctly! (ordered 3 since I knew one would be the training wheels)

Soldered it onto the Yammy end, sealed it using heat gun and shrink jackets. No more code! Running smooth and buttery.

Last edited:

saskybowhunter

Newbie

- Joined

- Dec 2, 2014

- Messages

- 20

- Reaction score

- 3

- Points

- 493

- Country

- Canada

- Snowmobile

- 2008 Venture Lite

Hey there I've ran into the exact same problem as you, just wondering what you selected for socket/wire size and insolation/seal size when you were ordering?

PhazerSD

Newbie

- Joined

- Nov 17, 2019

- Messages

- 6

- Reaction score

- 3

- Points

- 33

- Location

- WestSide Canada

- Country

- Canada

- Snowmobile

- 2014 Yamaha Phazer

2011 Yamaha RS Venture

This is the exact order invoice:

-------------------

Order Information

-------------------

3-Way Kit - TS 090 Sealed Series

https://www.corsa-technic.com/item.php?item_id=774

Quantity: 3.00

Price: $ 3.57

Extended Price: $ 10.71

Options:

Socket/Wire size .5-1.25 mm | 20-16 AWG (TS090-SKT2)Insulation/Seal size 2.0-2.5 mm | .079-.098 in (TS090-SL3)

18 AWG MIL-W-22759/16-18 Wire - Wire

https://www.corsa-technic.com/item.php?item_id=798

Quantity: 1.00

Price: $ 0.45

Extended Price: $ 0.45

Options:

Base Color, Stripe Color Black, WhiteBase Color, Stripe Color Red, YellowBase Color, Stripe Color Blue, *No Stripe*

Sub Total: $ 12.06

Shipping Method: USPS First Class Mail Int. (Up to 3 weeks)

Shipping: $13.00

Order Total: $ 25.06

-------------------

Order Information

-------------------

3-Way Kit - TS 090 Sealed Series

https://www.corsa-technic.com/item.php?item_id=774

Quantity: 3.00

Price: $ 3.57

Extended Price: $ 10.71

Options:

Socket/Wire size .5-1.25 mm | 20-16 AWG (TS090-SKT2)Insulation/Seal size 2.0-2.5 mm | .079-.098 in (TS090-SL3)

18 AWG MIL-W-22759/16-18 Wire - Wire

https://www.corsa-technic.com/item.php?item_id=798

Quantity: 1.00

Price: $ 0.45

Extended Price: $ 0.45

Options:

Base Color, Stripe Color Black, WhiteBase Color, Stripe Color Red, YellowBase Color, Stripe Color Blue, *No Stripe*

Sub Total: $ 12.06

Shipping Method: USPS First Class Mail Int. (Up to 3 weeks)

Shipping: $13.00

Order Total: $ 25.06

saskybowhunter

Newbie

- Joined

- Dec 2, 2014

- Messages

- 20

- Reaction score

- 3

- Points

- 493

- Country

- Canada

- Snowmobile

- 2008 Venture Lite

This is the exact order invoice:

-------------------

Order Information

-------------------

3-Way Kit - TS 090 Sealed Series

https://www.corsa-technic.com/item.php?item_id=774

Quantity: 3.00

Price: $ 3.57

Extended Price: $ 10.71

Options:

Socket/Wire size .5-1.25 mm | 20-16 AWG (TS090-SKT2)Insulation/Seal size 2.0-2.5 mm | .079-.098 in (TS090-SL3)

18 AWG MIL-W-22759/16-18 Wire - Wire

https://www.corsa-technic.com/item.php?item_id=798

Quantity: 1.00

Price: $ 0.45

Extended Price: $ 0.45

Options:

Base Color, Stripe Color Black, WhiteBase Color, Stripe Color Red, YellowBase Color, Stripe Color Blue, *No Stripe*

Sub Total: $ 12.06

Shipping Method: USPS First Class Mail Int. (Up to 3 weeks)

Shipping: $13.00

Order Total: $ 25.06

Thank you!! did you buy the special tool for crimping them is in the youtube video you posted? where did you find that? thanks for your help!

PhazerSD

Newbie

- Joined

- Nov 17, 2019

- Messages

- 6

- Reaction score

- 3

- Points

- 33

- Location

- WestSide Canada

- Country

- Canada

- Snowmobile

- 2014 Yamaha Phazer

2011 Yamaha RS Venture

Nope do not have the special crimp tool.. I'd imagine that would be the completely correct way to get perfect crimps.. BUT any regular small gauge hand tool should work - I used the blue one in the pic above sold as "Multi Tool Stripper, Cutter and Crimper"

I could have recovered the first harness I messed up, but I already pushed the mis-crimped red wire into the plug.. then pulled on it to see if it would hold.. and it didn't. There was no getting it out after that. Should have done some tensile 'pull-tests' on it before committing the wire/pin into the harness body.

Technically, you could recover your stock connector and just replace the single wire through a process like this video, with almost zero cost... I could not accomplish that process, and destroyed the stock harness.

This guy has it down.. has a different 'special tool' for harness re-pin processes

The connectors are quite fragile as its a very thin metal.. you could probably crimp with any plier. This is why I bought 3 sets of it all, 1 for practice 1 for the machine and 1 for insurance against failure. Plus, the shipping price was the same for 1 or 3 sets.. so might as well have some extras on hand.. the shipping was still half the invoice amount after I added three sets worth of this harness plug!

great write up on crimping:

https://www.jalopyjournal.com/forum/threads/the-right-crimper.1188584/

Princess Auto has more crimpers than a guy might need

https://www.princessauto.com/en/cutting-crimping-and-punching-tools/category/360-005-015-000

I could have recovered the first harness I messed up, but I already pushed the mis-crimped red wire into the plug.. then pulled on it to see if it would hold.. and it didn't. There was no getting it out after that. Should have done some tensile 'pull-tests' on it before committing the wire/pin into the harness body.

Technically, you could recover your stock connector and just replace the single wire through a process like this video, with almost zero cost... I could not accomplish that process, and destroyed the stock harness.

The connectors are quite fragile as its a very thin metal.. you could probably crimp with any plier. This is why I bought 3 sets of it all, 1 for practice 1 for the machine and 1 for insurance against failure. Plus, the shipping price was the same for 1 or 3 sets.. so might as well have some extras on hand.. the shipping was still half the invoice amount after I added three sets worth of this harness plug!

great write up on crimping:

https://www.jalopyjournal.com/forum/threads/the-right-crimper.1188584/

Princess Auto has more crimpers than a guy might need

https://www.princessauto.com/en/cutting-crimping-and-punching-tools/category/360-005-015-000

saskybowhunter

Newbie

- Joined

- Dec 2, 2014

- Messages

- 20

- Reaction score

- 3

- Points

- 493

- Country

- Canada

- Snowmobile

- 2008 Venture Lite

Nope do not have the special crimp tool.. I'd imagine that would be the completely correct way to get perfect crimps.. BUT any regular small gauge hand tool should work - I used the blue one in the pic above sold as "Multi Tool Stripper, Cutter and Crimper"

I could have recovered the first harness I messed up, but I already pushed the mis-crimped red wire into the plug.. then pulled on it to see if it would hold.. and it didn't. There was no getting it out after that. Should have done some tensile 'pull-tests' on it before committing the wire/pin into the harness body.

Technically, you could recover your stock connector and just replace the single wire through a process like this video, with almost zero cost... I could not accomplish that process, and destroyed the stock harness.

This guy has it down.. has a different 'special tool' for harness re-pin processes

The connectors are quite fragile as its a very thin metal.. you could probably crimp with any plier. This is why I bought 3 sets of it all, 1 for practice 1 for the machine and 1 for insurance against failure. Plus, the shipping price was the same for 1 or 3 sets.. so might as well have some extras on hand.. the shipping was still half the invoice amount after I added three sets worth of this harness plug!

great write up on crimping:

https://www.jalopyjournal.com/forum/threads/the-right-crimper.1188584/

Princess Auto has more crimpers than a guy might need

https://www.princessauto.com/en/cutting-crimping-and-punching-tools/category/360-005-015-000

Thanks for the replies! You were a lot of help! I was able to remove the pins from the connector on the wires that were broken using a safety pin(it was a not easy, i was very close to giving up). the wire broke right next the the seal so i removed the seal and stripped the wire right up to were it was crimped giving me about half and inch of wire to work with. I soldered a new wire to it and then soldered that wire to the existing harness. Only having half an inch to play with was tricky so i dont know how much i trust the joint BUT it did clear the code! To seal the connector I just pushed some silicon in there, it is setting up in the garage right now and ill take it for a test drive after work tomorrow but i did start it and it seemed okay. I plan on ordering 3 new plugs and wire like you did so i am ready when my solder eventually fails. Thanks again for your help it is greatly appreciated and im sure it will help many more guys!

Woody255

Extreme

- Joined

- Apr 19, 2016

- Messages

- 61

- Reaction score

- 13

- Points

- 438

- Location

- NW ON

- Country

- Canada

- Snowmobile

- Vmax4's

Was this code 13 by chance? My sons 2010 Phazer is flashing code 13, running rough intermittently. Thanks.

turbogts22

Pro

- Joined

- Jan 16, 2021

- Messages

- 136

- Reaction score

- 107

- Points

- 313

- Location

- Spooner, Wisconsin

- Country

- USA

- Snowmobile

- Two 2010 Phazer GT's

Code 13 is cylinder #1 pressure sensor open or short circuit. You possibly have a wire or connector issue with that sensor.

Similar threads

- Replies

- 4

- Views

- 1K

- Replies

- 10

- Views

- 3K

- Replies

- 8

- Views

- 4K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.