stomper

TY 4 Stroke Master

I just did the jackshaft and driveshaft bearing repack that is here on my RX1 http://www.ty4stroke.com/viewtopic.php? ... t+bearings

I can't beleive how easy it was and I am glad I did it. The bearing are still in good condition but they did need a cleaning and new grease. I am mechanicly inclined and I do all my own maintenance and rebuilds on my sleds and atvs so it was realy straight forward, but even for someone that isn't that mechanicaly inclined it would be an easy thing to do for preventative maintenance. It just gives me a peice of mind knowing the condition of the bearings and now I can ride with out worring about them.

Thanks for the great tip ROCKERDAN

I can't beleive how easy it was and I am glad I did it. The bearing are still in good condition but they did need a cleaning and new grease. I am mechanicly inclined and I do all my own maintenance and rebuilds on my sleds and atvs so it was realy straight forward, but even for someone that isn't that mechanicaly inclined it would be an easy thing to do for preventative maintenance. It just gives me a peice of mind knowing the condition of the bearings and now I can ride with out worring about them.

Thanks for the great tip ROCKERDAN

Fourcam281

Expert

I did mine too and don't think they would have made it another season if I didn't. They were still in good shape but the bottom one didn't have much grease left in it.

Jeffz

VIP Member

- Joined

- Feb 3, 2010

- Messages

- 600

- Reaction score

- 8

- Points

- 1,013

- Location

- Cresco, Iowa

- Country

- USA

- Snowmobile

- 2008 Yamaha Nytro RTX 40th

2007 Phazer "RTX"

Just did them on my Brothers Phazer. Saves a lot of money!

NY AttakGT

TY 4 Stroke Guru

Jeffz said:Just did them on my Brothers Phazer. Saves a lot of money!

And headaches out on the trail during riding season. Better to do it now in a nice warm garage!

YAMAMISSILE

Extreme

Just did mine today. Like they said. . . Very easy to do. . . Even if you are not mechanically inclined.

stomper

TY 4 Stroke Master

Took me about 20 minutes. For those that are unsure, the secondary clutch bolt gets torqued to 46 ft pounds, on th 03 Rx1 anyways, according to the factory service manual.

kinger

VIP Member

- Joined

- Jan 17, 2005

- Messages

- 7,403

- Reaction score

- 1,539

- Points

- 1,963

- Location

- Clear Lake, IA

- Website

- www.piergenius.com

One thing I learned was to NOT pack it full all around only do about 1/3 to 1/2 way around then spin the assembly to spread it around.

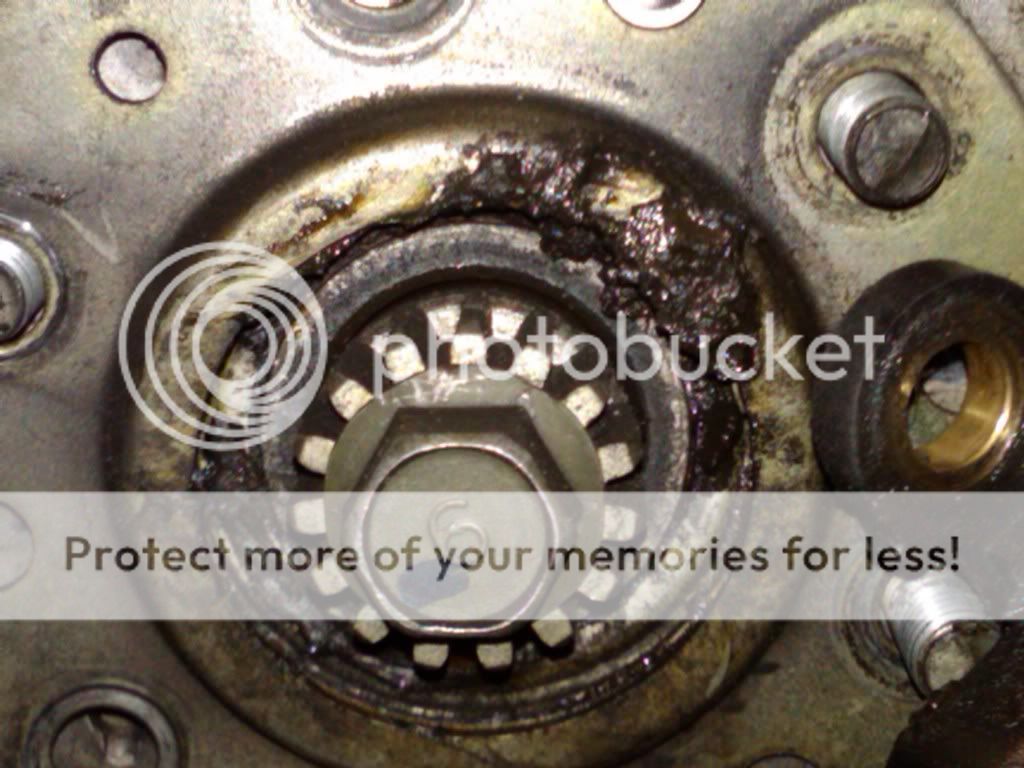

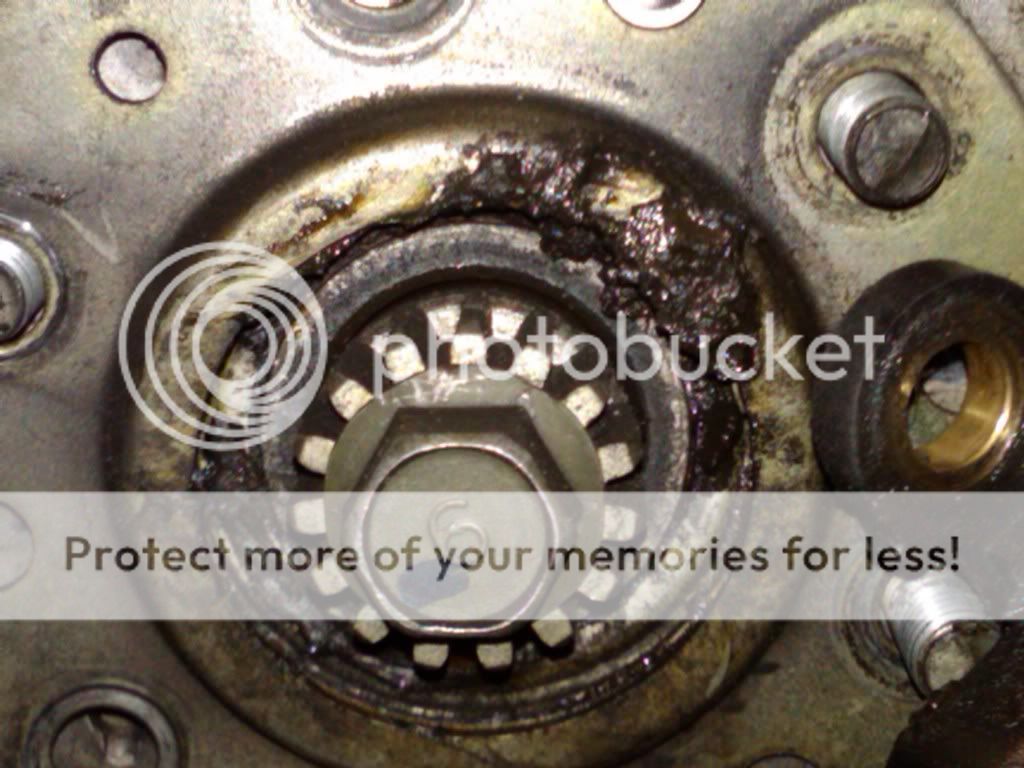

Otherwise you get this:

I validated that from the amsoil site:

"APPLICATION MAINTENANCE

Maintaining a clean work environment is important when equipment greasing is performed. Wipe grease fittings clean prior to injecting grease to prevent contaminant ingestion. Maintain bearing housings one-third to one-half full of grease. Do not over-grease, as excessive heat buildup can result.

Otherwise you get this:

I validated that from the amsoil site:

"APPLICATION MAINTENANCE

Maintaining a clean work environment is important when equipment greasing is performed. Wipe grease fittings clean prior to injecting grease to prevent contaminant ingestion. Maintain bearing housings one-third to one-half full of grease. Do not over-grease, as excessive heat buildup can result.

Irv

TY 4 Stroke God

- Joined

- Mar 23, 2005

- Messages

- 3,778

- Reaction score

- 43

- Points

- 1,233

- Location

- ONT. Canada

- Country

- Canada

- Snowmobile

- 2008 40th Anniversary Vector.

1995 XLT SP (Son's)

kinger said:One thing I learned was to NOT pack it full all around only do about 1/3 to 1/2 way around then spin the assembly to spread it around.

Otherwise you get this:

I validated that from the amsoil site:

"APPLICATION MAINTENANCE

Maintaining a clean work environment is important when equipment greasing is performed. Wipe grease fittings clean prior to injecting grease to prevent contaminant ingestion. Maintain bearing housings one-third to one-half full of grease. Do not over-grease, as excessive heat buildup can result.

Good tip for everyone Kinger, I learned that the hard way years ago, lucky for me it was just an idler wheel.

Not really picking up your pic all that good, hard to tell what is going on, but to me it looks like a lot of damage there, am I correct?

kinger

VIP Member

- Joined

- Jan 17, 2005

- Messages

- 7,403

- Reaction score

- 1,539

- Points

- 1,963

- Location

- Clear Lake, IA

- Website

- www.piergenius.com

Yeah the pict isn't the best no damage just grease EVERYWHERE. Bearing was ok just repacked it like this:

canadianhunter

TY 4 Stroke Junkie

I use the grease needle to repack. Just put the needle to one side of each ball, putting the grease between the far seal and the balls. That way the bearing ends up being approx. 1/2 full with grease all the way around.

I even remove the seal and do that on most new idler bearings, they have very little grease. I always use a good synthetic grease.

I even remove the seal and do that on most new idler bearings, they have very little grease. I always use a good synthetic grease.

Irv

TY 4 Stroke God

- Joined

- Mar 23, 2005

- Messages

- 3,778

- Reaction score

- 43

- Points

- 1,233

- Location

- ONT. Canada

- Country

- Canada

- Snowmobile

- 2008 40th Anniversary Vector.

1995 XLT SP (Son's)

Good thing Kinger, looked nasty imo.

Just curious what kind of grease you use?

I have been using Amsoil water proof/resistant grease for years and it seems to hold up well.

(I also use a needle applicator)

Just curious what kind of grease you use?

I have been using Amsoil water proof/resistant grease for years and it seems to hold up well.

(I also use a needle applicator)

stomper

TY 4 Stroke Master

Very good point and a good thing you brought it up because I think I may have put to much in. I left a bit of space for the expansion of the grease but I don't 1/3 to 1/2.

Thanks

Thanks

kinger

VIP Member

- Joined

- Jan 17, 2005

- Messages

- 7,403

- Reaction score

- 1,539

- Points

- 1,963

- Location

- Clear Lake, IA

- Website

- www.piergenius.com

IRv I use this:

http://www.amsoil.com/storefront/glb.aspx

Its important to get this EXACT model because if you look in the specs youll see this:

Low temperature torque, N*m - ASTM D 4693 (-40°C [-40°F]) 0.50 15.5 max

The value of 0.5 n-m to turn when the bearing is frozen means on those COLD mornings when the sled has been sitting outside the hotel the bearing will spin like its summer vs every other grease for wheels and stuff is 15 n-m to turn when froze. I put one in my freezer with this grease and the grease the new idler wheel came with I coudl barely turn the regular one, the one with this grease rotated like nothing happened.

I'm trying it this year hoping for better mpg. My first tank on a cold morning would get 6-7 mpg (supercharged remember) and last tank of the day would get 9-10mpg same conditions. Hoping its the grease that was holding me back but it may be doubtful it will stay at 9-10 all the time. Although in the morning I dont need a brake at ALL between the engine braking and the drag of the sled, in the afternoons it actually rolls up to a stop sign.

http://www.amsoil.com/storefront/glb.aspx

Its important to get this EXACT model because if you look in the specs youll see this:

Low temperature torque, N*m - ASTM D 4693 (-40°C [-40°F]) 0.50 15.5 max

The value of 0.5 n-m to turn when the bearing is frozen means on those COLD mornings when the sled has been sitting outside the hotel the bearing will spin like its summer vs every other grease for wheels and stuff is 15 n-m to turn when froze. I put one in my freezer with this grease and the grease the new idler wheel came with I coudl barely turn the regular one, the one with this grease rotated like nothing happened.

I'm trying it this year hoping for better mpg. My first tank on a cold morning would get 6-7 mpg (supercharged remember) and last tank of the day would get 9-10mpg same conditions. Hoping its the grease that was holding me back but it may be doubtful it will stay at 9-10 all the time. Although in the morning I dont need a brake at ALL between the engine braking and the drag of the sled, in the afternoons it actually rolls up to a stop sign.

Irv

TY 4 Stroke God

- Joined

- Mar 23, 2005

- Messages

- 3,778

- Reaction score

- 43

- Points

- 1,233

- Location

- ONT. Canada

- Country

- Canada

- Snowmobile

- 2008 40th Anniversary Vector.

1995 XLT SP (Son's)

kinger said:IRv I use this:

http://www.amsoil.com/storefront/glb.aspx

Its important to get this EXACT model because if you look in the specs youll see this:

Low temperature torque, N*m - ASTM D 4693 (-40°C [-40°F]) 0.50 15.5 max

The value of 0.5 n-m to turn when the bearing is frozen means on those COLD mornings when the sled has been sitting outside the hotel the bearing will spin like its summer vs every other grease for wheels and stuff is 15 n-m to turn when froze. I put one in my freezer with this grease and the grease the new idler wheel came with I coudl barely turn the regular one, the one with this grease rotated like nothing happened.

I'm trying it this year hoping for better mpg. My first tank on a cold morning would get 6-7 mpg (supercharged remember) and last tank of the day would get 9-10mpg same conditions. Hoping its the grease that was holding me back but it may be doubtful it will stay at 9-10 all the time. Although in the morning I dont need a brake at ALL between the engine braking and the drag of the sled, in the afternoons it actually rolls up to a stop sign.

Thanks Kinger, that is some good info!

I looked up the grease I use and my low temp number is 7.5, quite a bit higher than your's!!

Think I will be getting some of the stuff you posted pronto, especially after your freezer test report

Thanks

http://www.amsoil.com/storefront/gwr.aspx

thetruck454

TY 4 Stroke Junkie

Its a good thing I read this, I just did my brothers attak and my nytro and I packed the bearings as full as I could get them. looks like I'm going to be opening them back up and taking some grease out...

Also I just used a napa wheel bearing grease.

Also I just used a napa wheel bearing grease.

Similar threads

- Replies

- 2

- Views

- 796

- Replies

- 14

- Views

- 7K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.