Skeller1

Newbie

- Joined

- Feb 13, 2019

- Messages

- 4

- Age

- 44

- Location

- Toledo

- Country

- USA

- Snowmobile

- 2018 Yamaha sidewinder ltx-le

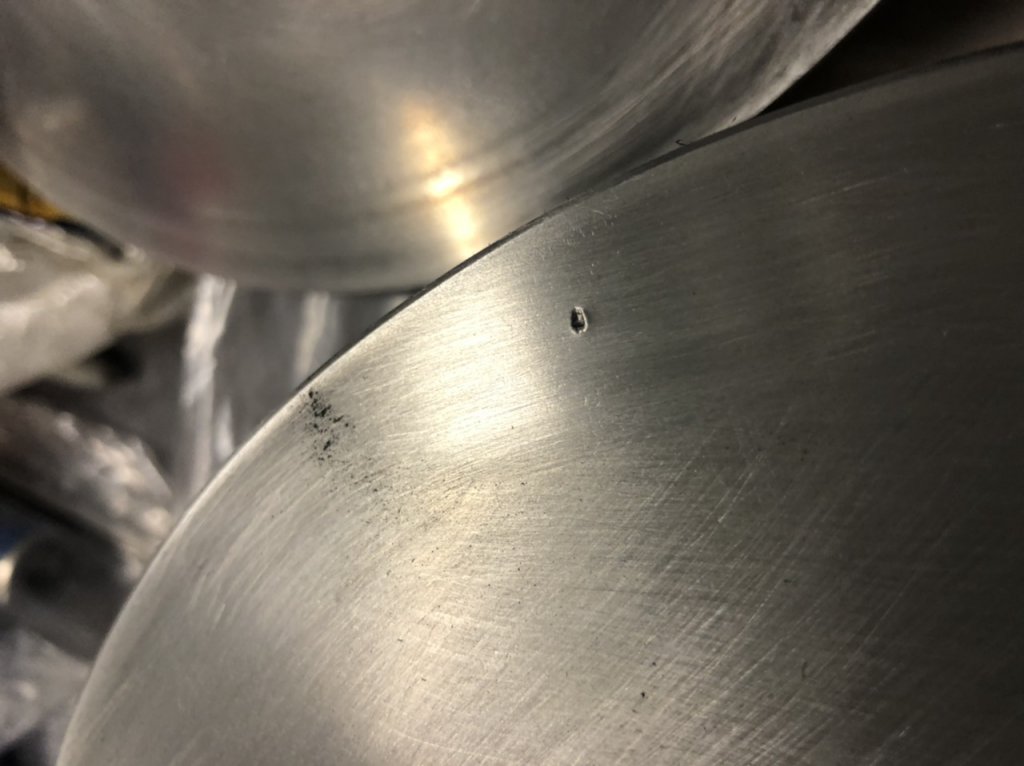

Good afternoon all. I just received my secondary sheave back from having 3mm machined off of the stub shaft and I see these two spots. Don’t know how they would have happened but clearly something went awry. What are your thoughts on a fix? I’m worried if I sand smooth it won’t be balanced, and if I order new I’ll probably have to have it machined again in order to align clutches. Any thoughts/opinions would be greatly appreciated. Thanks!

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Good afternoon all. I just received my secondary sheave back from having 3mm machined off of the stub shaft and I see these two spots. Don’t know how they would have happened but clearly something went awry. What are your thoughts on a fix? I’m worried if I sand smooth it won’t be balanced, and if I order new I’ll probably have to have it machined again in order to align clutches. Any thoughts/opinions would be greatly appreciated. Thanks!

View attachment 153135 View attachment 153136 View attachment 153137

The machine shop owes you a new sheave, don’t settle for less.

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Hard to find good help these days!

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

Actually when you picked it up you should have refused it and not paid.

Skeller1

Newbie

- Joined

- Feb 13, 2019

- Messages

- 4

- Age

- 44

- Location

- Toledo

- Country

- USA

- Snowmobile

- 2018 Yamaha sidewinder ltx-le

Thoughts on trying to sand down and smooth out till after season when I can replace?

Same exact thing happened to me, I took a fine flat file and made the surface flat. I doubt it's perfect but i have almost 500 miles since i did it and belt looks fine. We must have used the same machine shop.

Skeller1

Newbie

- Joined

- Feb 13, 2019

- Messages

- 4

- Age

- 44

- Location

- Toledo

- Country

- USA

- Snowmobile

- 2018 Yamaha sidewinder ltx-le

Thanks Jett, I’ll give that a go.Same exact thing happened to me, I took a fine flat file and made the surface flat. I doubt it's perfect but i have almost 500 miles since i did it and belt looks fine. We must have used the same machine shop.

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,103

- Age

- 49

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

Man that’s some seriously sh&$ work done

Crappy engineering, manufacturing and workmanship is such a drag. And worse when companies refuse to stand behind their business. Give them a chance to make it right then smear them across the world when they wont.

DooZ

TY 4 Stroke Junkie

I guess if you want to use it, try to get all the rough edges filed/smoothed out the best you can. In my opinion the mark at the top of the sheave isn't as important as the middle sheave. Most of your use is in the middle, so get that as smooth as possible so it doesn't eat belts. I totally agree with the other guys though, and wouldn't be accepting that $h!t work.

ClutchMaster

HUGE Member

- Joined

- Jan 18, 2016

- Messages

- 2,996

- Location

- tomahawk

- Country

- USA

- Snowmobile

- 2015 Viper 270 hurricane,

2002 Viper W/162 A.C. skid, SRX pipes &CDI, 780 BB

- LOCATION

- Wisconsin

It’s just stupid to run it, they owe you a new sheave. Buy the new part and fix it correctly. Take the old sheave and the receipt, get it replaced.

hman4

Extreme

- Joined

- Sep 22, 2014

- Messages

- 121

- Age

- 63

- Country

- USA

- Snowmobile

- 2010 Apex, 2002srx, 2000 srx

Sh*t happens, was it a machine shop you payed to have do it or one of your buddy's that offered to do it free. Most machine shops are not set up do any little job and they will not spend a lot of time to fixture and hold some pieces the way they would if they were doing 100's of them. If it's a real machine shop they can just add a little weld and recut the face, not a huge deal. you will not throw it out of balance by sanding on it a little to make sure the edges are smooth.

stevewithOCD

Yamaha, Make me Come Back

- Joined

- Jan 1, 2008

- Messages

- 3,360

- Age

- 56

- Location

- Live CT Ride MAINE

- Country

- USA

- Snowmobile

- 900 R

2006 Apex RTX

Order a new one.

File what you got for this upcoming trip.

When the new one arrives, take the old one back to the shop with the bill for the new one plus the machining bill.

If you can't get one right away, i have a new one sitting in the box.

File what you got for this upcoming trip.

When the new one arrives, take the old one back to the shop with the bill for the new one plus the machining bill.

If you can't get one right away, i have a new one sitting in the box.

Skeller1

Newbie

- Joined

- Feb 13, 2019

- Messages

- 4

- Age

- 44

- Location

- Toledo

- Country

- USA

- Snowmobile

- 2018 Yamaha sidewinder ltx-le

It was my father in law who did it for me. He told me right away that it slipped out of the jig he made to hold it while using a surface grinder. It was an honest mistake and not something I hold him responsible for. He doesn’t work in a machine shop but does have access to equipment at work so I asked him if he thought he could do it.Sh*t happens, was it a machine shop you payed to have do it or one of your buddy's that offered to do it free. Most machine shops are not set up do any little job and they will not spend a lot of time to fixture and hold some pieces the way they would if they were doing 100's of them. If it's a real machine shop they can just add a little weld and recut the face, not a huge deal. you will not throw it out of balance by sanding on it a little to make sure the edges are smooth.

I leave for UP Monday so I just wanted some thoughts on my options since replacing isn’t an option before I leave. I appreciate all the feedback. Thanks!

yamamarc

TY 4 Stroke God

- Joined

- Sep 29, 2013

- Messages

- 3,051

- Location

- Massey Ontario

- Country

- Canada

- Snowmobile

- 2019 zr9000 Ltd

File/sand it smooth and run it..imo keep an eye on it but I think it will be fine!!!!

Order a sheave in the meantime and replace in the off season

Order a sheave in the meantime and replace in the off season

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.