jetpilot785

Pro

- Joined

- Feb 8, 2014

- Messages

- 131

Very crazy stuff. Not sure it matters at all, but I'm boosted with TD eco trail. Can't imagine why it would matter. I've pounded my sled hundreds of times in 4K miles and it's only fell on its face maybe 3-5 times. This is very troubling symptom for Yamaha motors

It is crazy stuff. No real obvious indicators. If I put 4K miles on my sled and it fell flat momentarily 3-5 times the whole time during that 4K miles, I could live with that but try riding it limited to 30-35 mph for miles and have it stall at most road crossings and intersections. It did restart each time but it shouldn’t be shutting down in the first place and it should be indicating an issue of some sort to justify the shut down. This continuous stalling with no code or any lead on what’s causing the shut down is just stupid in my book. I’m out of patience and ideas. It’s ruined 2 trips so far and the weather forecast doesn’t look good so the year was almost a waste and 30k in new sleds that don’t run half the time and the other half they run like gangbusters. I believe they have bipolar disorder and need to be medicated.

ronzx9

Pro

- Joined

- Jan 11, 2017

- Messages

- 139

- Age

- 61

- Location

- Ohio

- Country

- USA

- Snowmobile

- 2017 Sidewinder L-TX-LE, 2016 Grand Touring SE 1200

When I took my sled in for this issue the dealer said there was close to 8oz of water and oil mix in the intercooler. He is thinking snow ingestion starts the issues. I had a ford ecoboost that had misfire issues under load. Those are known to get water and oil into the intercooler as well.

I haven't looked but do these sleds have mass flow meters? Oil on the wires of a mass flow meter reaps havoc with how motors run.

Sent from my SM-G900V using Tapatalk

I haven't looked but do these sleds have mass flow meters? Oil on the wires of a mass flow meter reaps havoc with how motors run.

Sent from my SM-G900V using Tapatalk

jetpilot785

Pro

- Joined

- Feb 8, 2014

- Messages

- 131

When I took my sled in for this issue the dealer said there was close to 8oz of water and oil mix in the intercooler. He is thinking snow ingestion starts the issues. I had a ford ecoboost that had misfire issues under load. Those are known to get water and oil into the intercooler as well.

I haven't looked but do these sleds have mass flow meters? Oil on the wires of a mass flow meter reaps havoc with how motors run.

Sent from my SM-G900V using Tapatalk

Took my intercoolers off yesterday and no sign of water whatsoever. There was a little bit of oil in the cooler but that’s pretty normal on forced inducted setups but the oil was the normal yellowish coloring and not grey or milky looking typical of oil and water mixing so not convinced it’s water in the intake system. I realize compressing air especially humid air can create some moisture in the intake but it usually burns it off in the combustion process. I have turbo charged Yamaha watercraft with all stock sensors intact and flashed to work like stock and have 2 full seasons on it pushing 400+ horsepower and that’s running in water in humid conditions and never encountered any issues like this. I’m also leading all the time so I don’t see the snow dust hardly at all. Funny thing when mine started to run a little better and could go 60-65, I kicked up more dust and my girls sled decided to run better and she passed me taped doing 100+ and she said the only difference between earlier when hers was acting up and that moment was I was kicking up more dust. Probably a coincidence but it appears snow dust isn’t really an issue.

upnumber6

Extreme

- Joined

- Jan 3, 2016

- Messages

- 102

- Age

- 35

- Location

- Winnipeg

- Country

- Canada

- Snowmobile

- 2007 apex rtx, 2011 apex se

I’ve been trying to figure it out too. When mine acts up, it don’t matter if I’m out front on hard packed trail or back of the pack, breaking fresh trail, intercooler iced over or clear, trying to get it hot and trying to cool it off

Fresh 89 with ethanol, fresh 91,fresh 91 with sea foam and fresh 91 with torco octane boost.right out of a hot shop or sitting outside at the cabin for days. stock muffler or aftermarket can (not as noticeable with the can tho) sometimes code 26 most times no code. It’s done it to me atleast once in every scenario. No matter what I’ve tried.

Fresh 89 with ethanol, fresh 91,fresh 91 with sea foam and fresh 91 with torco octane boost.right out of a hot shop or sitting outside at the cabin for days. stock muffler or aftermarket can (not as noticeable with the can tho) sometimes code 26 most times no code. It’s done it to me atleast once in every scenario. No matter what I’ve tried.

jetpilot785

Pro

- Joined

- Feb 8, 2014

- Messages

- 131

I’ve been trying to figure it out too. When mine acts up, it don’t matter if I’m out front on hard packed trail or back of the pack, breaking fresh trail, intercooler iced over or clear, trying to get it hot and trying to cool it off

Fresh 89 with ethanol, fresh 91,fresh 91 with sea foam and fresh 91 with torco octane boost.right out of a hot shop or sitting outside at the cabin for days. stock muffler or aftermarket can (not as noticeable with the can tho) sometimes code 26 most times no code. It’s done it to me atleast once in every scenario. No matter what I’ve tried.

Same here brother. It’s done it enough times now where there is no pattern. Like you, mine has done it in a variety of temps, conditions, fuel sources with various fuel additives. I did talk to the dealer I bought it from and they said to bring it in and they will hook it up to the YDS and see what’s going on. They told me that they talked to some guys at Yamaha and they said that even if it doesn’t pop a code on the screen, the ecu records the misfires, how many times, at what rpm etc. They also said they would run it on their track dyno to see if they can get it to replicate the issue for them under load and see if they can’t figure it out. I hope they find something as I like the sleds when they are running right but I’m not going to continue to battle with it into next season when no one really knows the root of the problem with no fix in sight. Based on what I’m feeling and what others have said about similar issues, if I was a gambling man, I would say it’s in the fuel delivery category as the bogs and backfires act like a lean condition. Now whether it’s the fuel pump, regulator, tank venting or what, I don’t know but I’m not spending $400-600 per sled to replace that stuff on my dime when I have a 5 year warranty on both but Yamaha already said that if the dealer can’t find the issue or duplicate it, there is no problem and they won’t just replace stuff for the hell of it so where do you go with it? Waiting to see what the 2019’s look like and if there is something I like that’s not forced inducted, I may just drop these off at the dealer and say I’ll be back in October to pick up my new rides lol.

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,205

- Age

- 50

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

This sucks for you guys. It's something I have had in 4700 miles now. BUT not like any thing you guys are describing. Sure hope it's figured out.

DennyTuna

RIP-Logan-Dylan-Never forgotten!

- Joined

- Jan 28, 2017

- Messages

- 740

- Age

- 62

- Location

- Ohio

- Country

- USA

- Snowmobile

- 18 Winder LTX 50th

16 SR Viper RTX (red)

02 SX Viper ER (red)

97 SX Vmax 600 (red)

Any updates on this issue? My buddies 18 started this falling flat on its face, sled has 9,000 miles, backfired and now wont go over 7,000 RPMS.

upnumber6

Extreme

- Joined

- Jan 3, 2016

- Messages

- 102

- Age

- 35

- Location

- Winnipeg

- Country

- Canada

- Snowmobile

- 2007 apex rtx, 2011 apex se

What I did and haven’t had the issue since….pulled my charge cooler and set it up to let it drain out over night( in a warm shop) and I got about a cup worth maybe of oil and water out of it , puddle on the floor was bigger then the cooler. Same time I also marked all the hoses for the sensors (map,baro and what ever the third one is) set the hoses up to kinda drain out and set the sensors where they can drain out aswell. Next day I gently blew out the lines and the sensors, put it back together

Hope it solves your issue

Hope it solves your issue

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,327

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Mount a temporary fuel pressure guage on it so that you can observe the fuel pressure as you're riding.Any updates on this issue? My buddies 18 started this falling flat on its face, sled has 9,000 miles, backfired and now wont go over 7,000 RPMS.

rev them up

Pro

- Joined

- Apr 3, 2006

- Messages

- 175

- Age

- 52

- Location

- Prince Edward Island, Canada

- Country

- Canada

- Snowmobile

- 2011 Nytro XTX, Hurricane Exhaust, K&N, Pcv, Autotune, Pod300, Star Suspension,

2018 Sidewinder, TD Max Spool 17, CAI, TD 3 Inch Stock Muffler Mod, 3Bar, BOV

- LOCATION

- Prince Edward Island, Canada

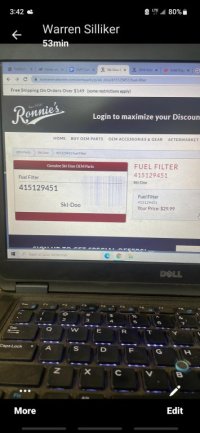

Guys check the fuel sock on the pump. Mine did this at wfo also had a spirt 500 miles before doing it at random times, fall on its face and backfire, also when it didn't do that had no power, boost was correct rpm down 300, my nytro ran 91 in 660ft my ms17 winder went 95, done by draggy, no lights or codes. Made 2 runs then it started all over again. Took pump out cleaned the fuel sock with brake cleaner then blew out with air. Sled runs perfect now. very mild heavy going nytro ran 84 and winder went 98. Cant get a fuel sock from yammie only comes with new pump, ordered a new filter from kimpex, ski doo fuel sock.

rev them up

Pro

- Joined

- Apr 3, 2006

- Messages

- 175

- Age

- 52

- Location

- Prince Edward Island, Canada

- Country

- Canada

- Snowmobile

- 2011 Nytro XTX, Hurricane Exhaust, K&N, Pcv, Autotune, Pod300, Star Suspension,

2018 Sidewinder, TD Max Spool 17, CAI, TD 3 Inch Stock Muffler Mod, 3Bar, BOV

- LOCATION

- Prince Edward Island, Canada

Part Number/Link?Cant get a fuel sock from yammie only comes with new pump, ordered a new filter from kimpex, ski doo fuel sock.

rev them up

Pro

- Joined

- Apr 3, 2006

- Messages

- 175

- Age

- 52

- Location

- Prince Edward Island, Canada

- Country

- Canada

- Snowmobile

- 2011 Nytro XTX, Hurricane Exhaust, K&N, Pcv, Autotune, Pod300, Star Suspension,

2018 Sidewinder, TD Max Spool 17, CAI, TD 3 Inch Stock Muffler Mod, 3Bar, BOV

- LOCATION

- Prince Edward Island, Canada

Fords4life

Expert

- Joined

- Dec 7, 2021

- Messages

- 342

- Age

- 58

- Location

- South Dakota

- Country

- USA

- Snowmobile

- 2021 riot 9000 & 2017 sw rtx

Turbo flash also awhile back had a sock part number from o'rileys i believe.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,619

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

It's part number S14005. It needs to be cut shorter on end opposite the connection. Just lay it along side the pump, cut to length with a good industrial scissors, then use a couple of zip ties around pump to seal off the end. Works much better than stock strainer. It's bigger and does not get kinked at the connection to pump. It has a right angle connector vs. the stock strainer is straight so strainer needs to be folded over end of the pump to be installed. Bad design IMO.

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.