micaelaman

Veteran

- Joined

- Dec 3, 2014

- Messages

- 49

- Age

- 48

- Country

- Sweden

- Snowmobile

- Sidewinder MTX 162, Arctic Cat M800 HCR

Hello,

When I replaced the track I noticed that the rail tips where shot so I replace them as well. Now after like 200 km the rail trips are shot again. When I go over high bumps I can hear a strange vibration and I suspect that when the front shock is fully extended and the rear shock is fully compressed the angle of the rails make the tips hits the rack hard.

It is a Sidewinder 2017 MTX 162"

Have anyone else seen this problem?

ATB

Micael Åman

When I replaced the track I noticed that the rail tips where shot so I replace them as well. Now after like 200 km the rail trips are shot again. When I go over high bumps I can hear a strange vibration and I suspect that when the front shock is fully extended and the rear shock is fully compressed the angle of the rails make the tips hits the rack hard.

It is a Sidewinder 2017 MTX 162"

Have anyone else seen this problem?

ATB

Micael Åman

Mtnviper

Vendor

Does your sled have anti-stab wheels at the front of the rails? If not, then adding them will help a lot with reducing the rail tip wear.

If you already have anti-stab wheels, then you may want to shorten the limiter strap by one or two holes. This will help reduce the pressure on the rail tip as well as reduce the track approach angle for less trenching in deep snow.

If you already have anti-stab wheels, then you may want to shorten the limiter strap by one or two holes. This will help reduce the pressure on the rail tip as well as reduce the track approach angle for less trenching in deep snow.

micaelaman

Veteran

- Joined

- Dec 3, 2014

- Messages

- 49

- Age

- 48

- Country

- Sweden

- Snowmobile

- Sidewinder MTX 162, Arctic Cat M800 HCR

Mtnviper

Vendor

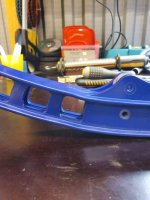

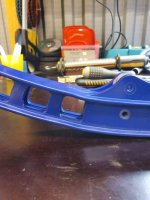

Wow those are chewed up pretty good. I wonder if the track tension might be loose? While under load, that would be the slack side of the track and it's possible that the track could be "looping up" before it gets to the rails.

You could drop the rear of the skid, the draw back is it may reduce weight transfer and make the front end feel more heavy.

You could drop the rear of the skid, the draw back is it may reduce weight transfer and make the front end feel more heavy.

micaelaman

Veteran

- Joined

- Dec 3, 2014

- Messages

- 49

- Age

- 48

- Country

- Sweden

- Snowmobile

- Sidewinder MTX 162, Arctic Cat M800 HCR

Yes, something is wrong here, but i can't find out what it is. I have found a couple of threads here that suggest that the rail-tips are hitting the drivers. But i don't think is't the case.

Somehow the track is wearing on the slides and rail-tips. The drivers are pretty worn as well and might not "release" the track in time and create a "looping up".

I will take it apart to see if i can find anything bent or wrecked.

Somehow the track is wearing on the slides and rail-tips. The drivers are pretty worn as well and might not "release" the track in time and create a "looping up".

I will take it apart to see if i can find anything bent or wrecked.

rla1

Extreme

- Joined

- Jan 4, 2015

- Messages

- 113

- Location

- saskatchewan

- Country

- Canada

- Snowmobile

- 2017 sidewinder btx le

If you have a 162 inch skid with a 3" track on trail and your track is loose running high speeds I can see this happening.

micaelaman

Veteran

- Joined

- Dec 3, 2014

- Messages

- 49

- Age

- 48

- Country

- Sweden

- Snowmobile

- Sidewinder MTX 162, Arctic Cat M800 HCR

After the last pictures i mounted new rail-tips, shortened the limiter strap, adjusted the track tension to spec, loose the centre spring.

This is what I found after two days of riding in deep snow.

Both rails where bent

One rail is cracked

Booth drivers are severely worn

The track (which is new) is missing a lot of clips.

The anti-stab axle had a track-clip jammed on it. Between the rail and wheel.

The slides are badly worn in the front. Even the screws are worn

The rail tips are, once again shoot.

I don't know if this is the root cause or it is the result of an other problem.

The rail was not cracked when i replaced the track. However when i replaced the track the old track was also missing clips and the rail tips where damaged. So the problem did appear before i replaced the track and before the rail was cracked.

This is what I found after two days of riding in deep snow.

Both rails where bent

One rail is cracked

Booth drivers are severely worn

The track (which is new) is missing a lot of clips.

The anti-stab axle had a track-clip jammed on it. Between the rail and wheel.

The slides are badly worn in the front. Even the screws are worn

The rail tips are, once again shoot.

I don't know if this is the root cause or it is the result of an other problem.

The rail was not cracked when i replaced the track. However when i replaced the track the old track was also missing clips and the rail tips where damaged. So the problem did appear before i replaced the track and before the rail was cracked.

micaelaman

Veteran

- Joined

- Dec 3, 2014

- Messages

- 49

- Age

- 48

- Country

- Sweden

- Snowmobile

- Sidewinder MTX 162, Arctic Cat M800 HCR

dustin

Veteran

- Joined

- Dec 24, 2006

- Messages

- 26

- Age

- 39

- Location

- Meadowlands, MN

- Country

- USA

- Snowmobile

- 17 sidewinder btx se

Yikes I'm going to have to give my driver's a closer look.

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,229

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

You have any pics of the front torque arm? Something seems wrong in that area, as the suspension is somehow moving forward.

If the drivers are stock, I don't think they are the issue.

Have any mods been done to the rear suspension?

If the drivers are stock, I don't think they are the issue.

Have any mods been done to the rear suspension?

Mtnviper

Vendor

I think this is the root cause. The drivers are not straight. This may cause the track to "stick" on the drivers and crerate a loop that wears the railtips down.....

View attachment 152898 View attachment 152899

Yeah, I could definitely see how that would cause the track to hang up on the drivers and cause the loop effect. Basically with the driver's that badly worn and not straight, it effectively puts them out of time with each other as well.

To be that badly worn, there may have been a fair amount of heat generated. Do you use ice scratchers or do a lot of high speed running?

micaelaman

Veteran

- Joined

- Dec 3, 2014

- Messages

- 49

- Age

- 48

- Country

- Sweden

- Snowmobile

- Sidewinder MTX 162, Arctic Cat M800 HCR

Yes, I always use the ice scratchers when i'm not in the pow. I have a pair of brp scratches that I will mount as well.

The torque arm is straight, as far as I can measure (cross measure, etc).

The sled has Maptun 270 hp kit and it might be to much for the drivers.

However, I order new drivers, rails, tips, anti stab axle, slides, etc. I can tell you, these things aren't cheep here in Sweden

The torque arm is straight, as far as I can measure (cross measure, etc).

The sled has Maptun 270 hp kit and it might be to much for the drivers.

However, I order new drivers, rails, tips, anti stab axle, slides, etc. I can tell you, these things aren't cheep here in Sweden

micaelaman

Veteran

- Joined

- Dec 3, 2014

- Messages

- 49

- Age

- 48

- Country

- Sweden

- Snowmobile

- Sidewinder MTX 162, Arctic Cat M800 HCR

I drove like 200 km this weekend and all seems good now. I have replaced: Rails, slides, railtips, antistab axle incl wheels, drivers.

Also, I had to mount 23 new track clips as they had vanished.

I can't see any wear on the tips or slides.

Also, I had to mount 23 new track clips as they had vanished.

I can't see any wear on the tips or slides.

Mtnviper

Vendor

I drove like 200 km this weekend and all seems good now. I have replaced: Rails, slides, railtips, antistab axle incl wheels, drivers.

Also, I had to mount 23 new track clips as they had vanished.

I can't see any wear on the tips or slides.

Bill

rxwhopper

TY 4 Stroke Guru

shouldnt the rear suspension be mounted on bottom hole? i thought had to match front hole

Similar threads

- Replies

- 25

- Views

- 4K

- Replies

- 4

- Views

- 880

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.