baggs66

VIP Member

- Joined

- Nov 18, 2007

- Messages

- 392

- Reaction score

- 104

- Points

- 1,058

- Location

- chautuaqua co. n.y.

- Country

- USA

- Snowmobile

- 06 apex gt

When i installed my protecters today i put a screw thru the heat exchanger, i can't believe they would make screws long enough to hit, unbelievable. First one i put on was back about half inch and wouldn't slide forward, next two worked fine put screw in and they slid forward, then i saw a drip from first one backed out screw some and it slid forward, now coolant running out, just don't know what to say but be careful when you put on.

Crossfire12

TY 4 Stroke Guru

- Joined

- Feb 13, 2017

- Messages

- 884

- Reaction score

- 542

- Points

- 858

- Location

- New York Adirondacks

- Country

- USA

- Snowmobile

- 2010 Z1 Turbo ,2017 zr9000, F1100 turbo, 700 srx

- LOCATION

- Sacandaga reservoir

I glued mine on Aerctic cat ones.

baggs66

VIP Member

- Joined

- Nov 18, 2007

- Messages

- 392

- Reaction score

- 104

- Points

- 1,058

- Location

- chautuaqua co. n.y.

- Country

- USA

- Snowmobile

- 06 apex gt

These were yamaha ones that glue on then you put screw in so they cant slide out if glue doesn't hold.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Not sure how screw can go thru....they are not in the slot.

Here is my writeup..

https://ty4stroke.com/threads/my-rtx-le-50th-build-thread-rockerdan.149801/#post-1384038

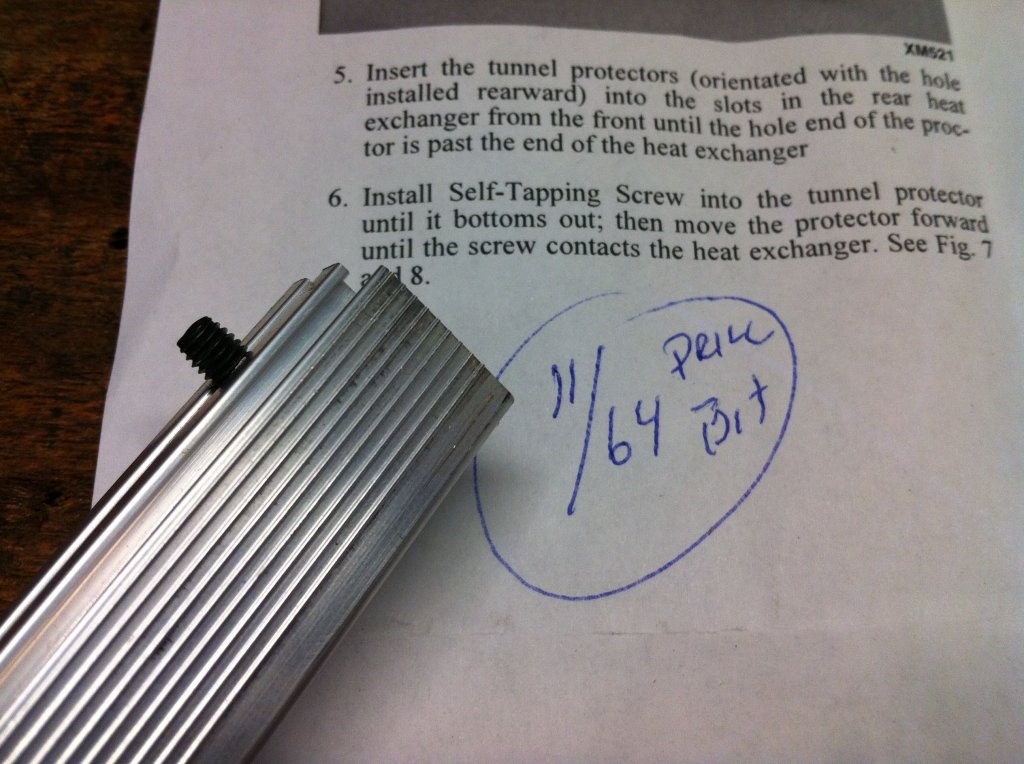

I gave a heads up in writeup to drill out holes larger, pre-thread in on bench, so then when installing they thread in easily.

Dan

Screws are behind exchanger as shown here

Here is my writeup..

https://ty4stroke.com/threads/my-rtx-le-50th-build-thread-rockerdan.149801/#post-1384038

I gave a heads up in writeup to drill out holes larger, pre-thread in on bench, so then when installing they thread in easily.

Dan

Screws are behind exchanger as shown here

Last edited:

baggs66

VIP Member

- Joined

- Nov 18, 2007

- Messages

- 392

- Reaction score

- 104

- Points

- 1,058

- Location

- chautuaqua co. n.y.

- Country

- USA

- Snowmobile

- 06 apex gt

I have to look tommorow, i was so mad that i had to just step away, it was in slot, i installed with electric driver so not sure if i pushed up enough to let it bite but it did.

NYTurbo

TY 4 Stroke God

- Joined

- Sep 26, 2017

- Messages

- 1,567

- Reaction score

- 1,372

- Points

- 958

- Location

- Ottawa

- Country

- Canada

- Snowmobile

- Sidewinder

Screws are not meant to touch heat exchanger. Only as a precaution in case glue doesn't hold to stop them from flying forward. The adhesive they use is pretty much permanent , it isn't going any where.

Motorhead

TY 4 Stroke God

- Joined

- Apr 20, 2003

- Messages

- 2,112

- Reaction score

- 995

- Points

- 1,583

- Location

- Augusta, Maine

- Country

- USA

- Snowmobile

- 2017 SW LTX-LE

- LOCATION

- Augusta ME

When i installed my protecters today i put a screw thru the heat exchanger, i can't believe they would make screws long enough to hit, unbelievable. First one i put on was back about half inch and wouldn't slide forward, next two worked fine put screw in and they slid forward, then i saw a drip from first one backed out screw some and it slid forward, now coolant running out, just don't know what to say but be careful when you put on.

Yeah that really sucks!

Probably had the protector a bit too high on the cooler when you sunk the screw huh?

If the protector was in it’s proper spot, the screw should catch on the very end of the cooler to hold it from sliding forward.

Oh well, we all screw up. Repair it correctly and move on because winter is approaching!

baggs66

VIP Member

- Joined

- Nov 18, 2007

- Messages

- 392

- Reaction score

- 104

- Points

- 1,058

- Location

- chautuaqua co. n.y.

- Country

- USA

- Snowmobile

- 06 apex gt

Not sure where to look on fiche but so far can't find it to replace with new so will probably get it welded, really sucks don't even have a mile on it yet lol

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Ahhh Yeah I see what happened.....Likely was in slot and not behind it.I have to look tommorow, i was so mad that i had to just step away, it was in slot, i installed with electric driver so not sure if i pushed up enough to let it bite but it did.

I mentioned in my build thread how the screws were too tight for factory holes in protectors, and to drill the holes out to 11/64'' and then screw them in up on bench, then remove them. So now when you install them under sled, you use a screwdriver and they go in nicely, and so you would feel if you were not far enough back.

That just sucks, first person I heard this to happen.....Would be very hard to do by hand but with a gun it can happen fast.

Is the Epoxy glue on that one already? if not you should be able to remove it, and have it welded up since it will be a small hole only. Might be harder if its already glued in place.

Dan

Stormbringer

Extreme

- Joined

- Jun 5, 2018

- Messages

- 109

- Reaction score

- 96

- Points

- 253

- Location

- Valparaiso Indiana

- Country

- USA

- Snowmobile

- 18 sidewinder rtx 15 viper rtx

I just put mine on last week and thought the same thing. As I was installing the screws I thought I put one in to far, I panicked and backed it off but It was okay! You are right the screws are to long!!!When I installed my protecters today i put a screw thru the heat exchanger, i can't believe they would make screws long enough to hit, unbelievable. First one i put on was back about half inch and wouldn't slide forward, next two worked fine put screw in and they slid forward, then i saw a drip from first one backed out screw some and it slid forward, now coolant running out, just don't know what to say but be careful when you put on.

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,496

- Reaction score

- 3,609

- Points

- 2,003

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Not sure how screw can hit anything, as long as you have protector back far enough. The screw is behind coolers.

baggs66

VIP Member

- Joined

- Nov 18, 2007

- Messages

- 392

- Reaction score

- 104

- Points

- 1,058

- Location

- chautuaqua co. n.y.

- Country

- USA

- Snowmobile

- 06 apex gt

Here is a pick of holes, didn't think they would hit so didn't pay attention and it got me big time.

PowderFalcon

Pinnin' it!

- Joined

- Jan 29, 2007

- Messages

- 990

- Reaction score

- 511

- Points

- 1,358

- Location

- Drumbo, ON

- Country

- Canada

- Snowmobile

- 2021 Sidewinder SRX

Baggs!!!

Omg man, I feel your pain. I did the Exact same thing on my brand new winder last year! Zero miles and I’ve got coolant all over the floor. I was losing my #*$&@!!!

Kind of a bone head move not checking before sending that cap screw, but would have been nice for a nice big bold warning on the install instructions to look out for that type of thing!!!

I’m usually more careful than that. Threw up in my mouth when I saw what I had done!

Lucky a buddy has a tig welder and we fixed it up. But kinda fukd having to weld your brand new sled!

Lesson learned for the next one!

Omg man, I feel your pain. I did the Exact same thing on my brand new winder last year! Zero miles and I’ve got coolant all over the floor. I was losing my #*$&@!!!

Kind of a bone head move not checking before sending that cap screw, but would have been nice for a nice big bold warning on the install instructions to look out for that type of thing!!!

I’m usually more careful than that. Threw up in my mouth when I saw what I had done!

Lucky a buddy has a tig welder and we fixed it up. But kinda fukd having to weld your brand new sled!

Lesson learned for the next one!

baggs66

VIP Member

- Joined

- Nov 18, 2007

- Messages

- 392

- Reaction score

- 104

- Points

- 1,058

- Location

- chautuaqua co. n.y.

- Country

- USA

- Snowmobile

- 06 apex gt

baggs66

VIP Member

- Joined

- Nov 18, 2007

- Messages

- 392

- Reaction score

- 104

- Points

- 1,058

- Location

- chautuaqua co. n.y.

- Country

- USA

- Snowmobile

- 06 apex gt

Where is the best place to drain the coolant so i can get welded?

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.