fxnytroxtx

Guest

Which boost controller is that?

Like x3

mbarryracing

TY 4 Stroke God

- Joined

- Aug 31, 2007

- Messages

- 1,923

- Reaction score

- 192

- Points

- 1,078

- Location

- Springville NY

- Country

- USA

- Snowmobile

- 2006 Yamaha Attak Turbo

2015 SR Viper RTX-DX

1996 Vmax 600XT

ANTI LAG 2-STEP STUTTER

The MoTeC 2-step anti-lag works very well.

Now you have to understand the dynamics that occurs when you are on the 2-step. There are so many variables in the system that influence the results, including the design of the exhaust system (length, volume, shape) and the turbo characteristics, the engine, the fuel. Unlike an MSD Launch Master that you can only adjust the RPM, with the MoTeC you can adjust the fuel and ignition to tailor the results you want.

I didn't spend a whole lot of time refining my 2-step program table after I got it close enough, as I don't use it every day. It's been very repeatable in most instances, with the exception once when it was really warm out and the sled was heat soaked. The AFR was too rich and it "put the fire out", per say. That could be tuned with more time devoted, as well, or I should have let the intercooler fans run before hand.

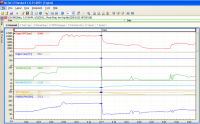

Here is a data log of playing with the 2-step stutter. It's building around 43 Kpa (6 psi) at just under clutch engagement. It's literally breathing fire.

Note that the MAP is in absolute pressure, so need to subtract the barometric pressure to talk boost pressure.

I did have a video at night blowing flames out the FPP dual outlet muffler, but I haven't located the file. If I find it I'll post at a later time.

The MoTeC 2-step anti-lag works very well.

Now you have to understand the dynamics that occurs when you are on the 2-step. There are so many variables in the system that influence the results, including the design of the exhaust system (length, volume, shape) and the turbo characteristics, the engine, the fuel. Unlike an MSD Launch Master that you can only adjust the RPM, with the MoTeC you can adjust the fuel and ignition to tailor the results you want.

I didn't spend a whole lot of time refining my 2-step program table after I got it close enough, as I don't use it every day. It's been very repeatable in most instances, with the exception once when it was really warm out and the sled was heat soaked. The AFR was too rich and it "put the fire out", per say. That could be tuned with more time devoted, as well, or I should have let the intercooler fans run before hand.

Here is a data log of playing with the 2-step stutter. It's building around 43 Kpa (6 psi) at just under clutch engagement. It's literally breathing fire.

Note that the MAP is in absolute pressure, so need to subtract the barometric pressure to talk boost pressure.

I did have a video at night blowing flames out the FPP dual outlet muffler, but I haven't located the file. If I find it I'll post at a later time.

Attachments

mbarryracing

TY 4 Stroke God

- Joined

- Aug 31, 2007

- Messages

- 1,923

- Reaction score

- 192

- Points

- 1,078

- Location

- Springville NY

- Country

- USA

- Snowmobile

- 2006 Yamaha Attak Turbo

2015 SR Viper RTX-DX

1996 Vmax 600XT

INTERMITTENT CUT-OUT

The shop gremlins continued to wreak havoc on my machine as it sat quiet at night.

One PITA that started to occur when I was track dyno testing was an occasional intermittent cut-out when at full throttle. Once in a while the machine just seemed to shut off for a brief second, like an over-boost or RPM limit was tripped and all the injectors shut off then turned back on again... It was such an instant cut, it wasn't a fuel pump or misfire.

Of course I had phone conversations late at night with Martin until early hours of the morning. Checked all the parameter limits, and even raised them to the moon in an attempt to make the gremlin go away. Under normal trail riding or short WOT blasts it wouldn't cut out, just seemed like when it was really loaded.

The big clue and a break in the case was when I tied to start my sled last December to pull it into the shop to prep for the season, it wouldn't start. I also couldn't get the ECU to communicate with the laptop. Again Martin saved the day and guided me towards low battery voltage that the ECU wouldn't operate on. Hmmm...

So it's known that the Yamaha PWC's have a volt drop through the wiring harness, so the ECU sees lower voltage then what battery voltage actually is. Theory is because the volt drop caused by the diode that is in the harness to protect the precious electronics from the ever so clever idiots who hook their battery up backwards. The stock ECU is designed to accomodate this lower voltage operation, when the MoTeC is not so much...

Well the Yamaha Apex has the same volt drop, and it varies from machine to machine. Mine just happens to be more then others, just like my odd stock fuel injectors. I observed more then 1 volt difference comparing the voltage at the battery terminals with a multi-meter and the battery voltage reading on the ECU screen. Maybe a sign of something degrading in the wiring as the sled gets older? I didn't find any corrosion or burnt ground connections at the junction lugs, which has also been discussed in threads there on this awsome TY.

Darn shop gremlins were out-smarting me.

So throw on the helmet and go out and log some runs with my unlimited data logging!!! Interesting that when the boost comes up (and so does the fuel pressure accordingly due to the stock rising rate FPR on the rail) the battery voltage drops correspondingly??? My theory is that as my secondary supplimental Walbro GSL392 fuel pump became loaded, this in turn caused more amp draw, and along with all the other electronic load on the sled (grip warmers, microwave, curling iron, etc) resulted is a drop in voltage seen at the ECU. Geez, what if I had the load of a water-meth injection pump too???

Of course this was all theory after a mass consumption of liquid fermented potatos, because like a watched pot of water that will never boil I could not ever get the sled to cut-out during a data logging run. HAHA.

because like a watched pot of water that will never boil I could not ever get the sled to cut-out during a data logging run. HAHA.

Didn't matter, the data that was logged showed the voltage drop that I would indeed get rectified.

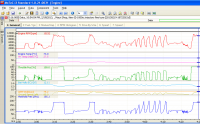

Here is a data log showing how much the voltage drops as the boost & fuel pressure comes up on a short blast. Guess what happens if the voltage gets too low after a longer run? Sounds like my symptom.

The shop gremlins continued to wreak havoc on my machine as it sat quiet at night.

One PITA that started to occur when I was track dyno testing was an occasional intermittent cut-out when at full throttle. Once in a while the machine just seemed to shut off for a brief second, like an over-boost or RPM limit was tripped and all the injectors shut off then turned back on again... It was such an instant cut, it wasn't a fuel pump or misfire.

Of course I had phone conversations late at night with Martin until early hours of the morning. Checked all the parameter limits, and even raised them to the moon in an attempt to make the gremlin go away. Under normal trail riding or short WOT blasts it wouldn't cut out, just seemed like when it was really loaded.

The big clue and a break in the case was when I tied to start my sled last December to pull it into the shop to prep for the season, it wouldn't start. I also couldn't get the ECU to communicate with the laptop. Again Martin saved the day and guided me towards low battery voltage that the ECU wouldn't operate on. Hmmm...

So it's known that the Yamaha PWC's have a volt drop through the wiring harness, so the ECU sees lower voltage then what battery voltage actually is. Theory is because the volt drop caused by the diode that is in the harness to protect the precious electronics from the ever so clever idiots who hook their battery up backwards. The stock ECU is designed to accomodate this lower voltage operation, when the MoTeC is not so much...

Well the Yamaha Apex has the same volt drop, and it varies from machine to machine. Mine just happens to be more then others, just like my odd stock fuel injectors. I observed more then 1 volt difference comparing the voltage at the battery terminals with a multi-meter and the battery voltage reading on the ECU screen. Maybe a sign of something degrading in the wiring as the sled gets older? I didn't find any corrosion or burnt ground connections at the junction lugs, which has also been discussed in threads there on this awsome TY.

Darn shop gremlins were out-smarting me.

So throw on the helmet and go out and log some runs with my unlimited data logging!!! Interesting that when the boost comes up (and so does the fuel pressure accordingly due to the stock rising rate FPR on the rail) the battery voltage drops correspondingly??? My theory is that as my secondary supplimental Walbro GSL392 fuel pump became loaded, this in turn caused more amp draw, and along with all the other electronic load on the sled (grip warmers, microwave, curling iron, etc) resulted is a drop in voltage seen at the ECU. Geez, what if I had the load of a water-meth injection pump too???

Of course this was all theory after a mass consumption of liquid fermented potatos,

because like a watched pot of water that will never boil I could not ever get the sled to cut-out during a data logging run. HAHA.

because like a watched pot of water that will never boil I could not ever get the sled to cut-out during a data logging run. HAHA. Didn't matter, the data that was logged showed the voltage drop that I would indeed get rectified.

Here is a data log showing how much the voltage drops as the boost & fuel pressure comes up on a short blast. Guess what happens if the voltage gets too low after a longer run? Sounds like my symptom.

Attachments

mbarryracing

TY 4 Stroke God

- Joined

- Aug 31, 2007

- Messages

- 1,923

- Reaction score

- 192

- Points

- 1,078

- Location

- Springville NY

- Country

- USA

- Snowmobile

- 2006 Yamaha Attak Turbo

2015 SR Viper RTX-DX

1996 Vmax 600XT

WIRIING ECU SUPPLY VOLTAGE DIRECT TO BATTERY

To eliminate my volt drop issue, it was recommended to supply the MoTeC ECU with direct battery voltage.

We already have a method of feeding battery voltage to the supplimental fuel pump and turbo oil scavenge pump via individual relays that are energized with keyed on power, so as they are never starved of power. Intermittent fuel pumps under boost result in bad rattling, and intermittent oil scavenge pumps cause bad smoke screens.

I simply spliced into the battery voltage red wire in the harness going to A26 terminal at the ECU connector and used that "keyed / switched" power to trigger a separate 3rd relay, which then in turn feeds fused power direct from the battery back to that A26 battery terminal at the ECU connector. The relay is way more resiliant to any voltage variation.

That cut-out gremlin got SPANKED, hasn't been back since.

To eliminate my volt drop issue, it was recommended to supply the MoTeC ECU with direct battery voltage.

We already have a method of feeding battery voltage to the supplimental fuel pump and turbo oil scavenge pump via individual relays that are energized with keyed on power, so as they are never starved of power. Intermittent fuel pumps under boost result in bad rattling, and intermittent oil scavenge pumps cause bad smoke screens.

I simply spliced into the battery voltage red wire in the harness going to A26 terminal at the ECU connector and used that "keyed / switched" power to trigger a separate 3rd relay, which then in turn feeds fused power direct from the battery back to that A26 battery terminal at the ECU connector. The relay is way more resiliant to any voltage variation.

That cut-out gremlin got SPANKED, hasn't been back since.

Attachments

mbarryracing

TY 4 Stroke God

- Joined

- Aug 31, 2007

- Messages

- 1,923

- Reaction score

- 192

- Points

- 1,078

- Location

- Springville NY

- Country

- USA

- Snowmobile

- 2006 Yamaha Attak Turbo

2015 SR Viper RTX-DX

1996 Vmax 600XT

BOILING FUEL IN GAS TANK

Since I put the original turbo kit on this sled, WAY BEFORE THE MOTEC, I had been fighting this unique patience testing phenomenon in which occasionally the sled would just sputter & die.

Happened the first time in the middle of a road crossing with my then 9 year old boy on the back and a state plow truck rolling towards us. It just shut off and when trying to restart it caught my attention that neither fuel pump would whine like they normally do when you first cycle the key on. It would eventually start after it cooled down and would run the rest of the ride?

The next time it happened I opened the gas cap to listen if the in-tank pump was cycling and noticed not only was it NOT, but I could hear the fuel at a rolling boil at the bottom of the tank. Yes, that's right... the fuel in the gas tank actually boiling and No... that's not good.

So it all started to make sense that this phenomenon seemed to occur when the fuel level was getting low, 3/8 tank or less, and the tunnel got heat soaked from the hot exhaust after driving slow or in low to no snow dust conditions. What was happening was the exhaust headers in the tunnel would radiate enough heat into the tunnel and into the gas tank to raise the temperature of the fuel to the point it would start to boil. This heat build-up amplified the issue that my factory in-tank fuel pump was weak and failing, as it would stop operating all together when it reached a certain temp (which was fuel boiling temp...) and certain resistance, since resistance rises with temp.

Who knows if it wasn't also fading out and losing pressure or volume before it quit, and wasn't feeding my secondary pump sufficiently either.

A fuel pressure gauge would be in the future, as would an attempt to keep the heat out of the tank...

There is no effective way to get the heat OUT of the fuel in the tank once it's in there. The fuel is getting circulated through the fuel rail where it is getting heated and returned into the plastic gas tank that is acting like a thermos. I've always observed the AFR's drift leaner & leaner as the fuel gets warmer and warmer and the specific gravity gets lighter and lighter... The whole reason I was always stopping to change the settings on my piggyback controller through out the ride until I filled the gas tank with cold fresh fuel, then changing the setting back. Duh?

Guess what? We've since seen this fuel boiling on a stock Apex, as well, so it's not a boosted sled only problem... just that apparently the stock sleds AFR's aren't as sensitive to hot & thinner fuel as a boosted application...

Another bad side effect is that heating the fuel also boils off the light ends in the fuel that help prevent detonation. So when your gas tank vent is whistling, that is basically your octane rating vaporizing away too!!!!

Since I put the original turbo kit on this sled, WAY BEFORE THE MOTEC, I had been fighting this unique patience testing phenomenon in which occasionally the sled would just sputter & die.

Happened the first time in the middle of a road crossing with my then 9 year old boy on the back and a state plow truck rolling towards us. It just shut off and when trying to restart it caught my attention that neither fuel pump would whine like they normally do when you first cycle the key on. It would eventually start after it cooled down and would run the rest of the ride?

The next time it happened I opened the gas cap to listen if the in-tank pump was cycling and noticed not only was it NOT, but I could hear the fuel at a rolling boil at the bottom of the tank. Yes, that's right... the fuel in the gas tank actually boiling and No... that's not good.

So it all started to make sense that this phenomenon seemed to occur when the fuel level was getting low, 3/8 tank or less, and the tunnel got heat soaked from the hot exhaust after driving slow or in low to no snow dust conditions. What was happening was the exhaust headers in the tunnel would radiate enough heat into the tunnel and into the gas tank to raise the temperature of the fuel to the point it would start to boil. This heat build-up amplified the issue that my factory in-tank fuel pump was weak and failing, as it would stop operating all together when it reached a certain temp (which was fuel boiling temp...) and certain resistance, since resistance rises with temp.

Who knows if it wasn't also fading out and losing pressure or volume before it quit, and wasn't feeding my secondary pump sufficiently either.

A fuel pressure gauge would be in the future, as would an attempt to keep the heat out of the tank...

There is no effective way to get the heat OUT of the fuel in the tank once it's in there. The fuel is getting circulated through the fuel rail where it is getting heated and returned into the plastic gas tank that is acting like a thermos. I've always observed the AFR's drift leaner & leaner as the fuel gets warmer and warmer and the specific gravity gets lighter and lighter... The whole reason I was always stopping to change the settings on my piggyback controller through out the ride until I filled the gas tank with cold fresh fuel, then changing the setting back. Duh?

Guess what? We've since seen this fuel boiling on a stock Apex, as well, so it's not a boosted sled only problem... just that apparently the stock sleds AFR's aren't as sensitive to hot & thinner fuel as a boosted application...

Another bad side effect is that heating the fuel also boils off the light ends in the fuel that help prevent detonation. So when your gas tank vent is whistling, that is basically your octane rating vaporizing away too!!!!

Attachments

mbarryracing

TY 4 Stroke God

- Joined

- Aug 31, 2007

- Messages

- 1,923

- Reaction score

- 192

- Points

- 1,078

- Location

- Springville NY

- Country

- USA

- Snowmobile

- 2006 Yamaha Attak Turbo

2015 SR Viper RTX-DX

1996 Vmax 600XT

When I took the fuel tank out to install heat shields, this is what I found. Charred...

Does it make sense why the fuel was boiling in the tank?

Do you think my exhaust was getting hot enough in the tunnel?

This was the result of slow riding along roadsides in Old Forge jumping from lake to lake, and then running marginal snow covered lakes WFO for long distances.

You'll never see this with a stock NA sled, because a stock NA sled doesn't make HP like this one and also doesn't have a turbo stuck on the end of the exhaust either.

Understandable now why some of the original front mount turbo kits, with all the red hot exhaust & turbo crammed right next to gas tank, had burned to the ground... Atleast here the aluminum tunnel was somewhat of a barrier. Phew...

No visible damage or deformation to the bottom of the plastic gas tank, didn't get hot enough to melt.

HP makes heat, and heat is what drives a turbo. This setup sure does breath fire though, (literally, LOL) probably the reason it responds to good, almost electric motor like. A big contributor to the great response and driveability is as a rear mount it uses the stock exhaust headers and the designed-in tuned length, etc.

I'll take the heat as a trade-off for how darn good this sled runs, and will just fix the next weakest link...

Does it make sense why the fuel was boiling in the tank?

Do you think my exhaust was getting hot enough in the tunnel?

This was the result of slow riding along roadsides in Old Forge jumping from lake to lake, and then running marginal snow covered lakes WFO for long distances.

You'll never see this with a stock NA sled, because a stock NA sled doesn't make HP like this one and also doesn't have a turbo stuck on the end of the exhaust either.

Understandable now why some of the original front mount turbo kits, with all the red hot exhaust & turbo crammed right next to gas tank, had burned to the ground... Atleast here the aluminum tunnel was somewhat of a barrier. Phew...

No visible damage or deformation to the bottom of the plastic gas tank, didn't get hot enough to melt.

HP makes heat, and heat is what drives a turbo. This setup sure does breath fire though, (literally, LOL) probably the reason it responds to good, almost electric motor like. A big contributor to the great response and driveability is as a rear mount it uses the stock exhaust headers and the designed-in tuned length, etc.

I'll take the heat as a trade-off for how darn good this sled runs, and will just fix the next weakest link...

Attachments

mbarryracing

TY 4 Stroke God

- Joined

- Aug 31, 2007

- Messages

- 1,923

- Reaction score

- 192

- Points

- 1,078

- Location

- Springville NY

- Country

- USA

- Snowmobile

- 2006 Yamaha Attak Turbo

2015 SR Viper RTX-DX

1996 Vmax 600XT

STAINLESS HEAT SHIELDS

I did some reaearch and installed InfernoShield 1800 degF stainless & ceramic heat shields, made by Heat Shield Products, in between the exhaust headers and the tunnel.

They can be cut to size and rivetted in place...

Since I had to remove the headers anyways, perfect time to install the copper exhaust donuts, too.

I also placed one of their ThermaFlect 1100 degF ceramic heat shield pads between the top of the tunnel and the bottom of the gas tank, as added protection. I dont ever want to deal with this again... and so far this thermal management initiative has proven to be very very effective.

I did some reaearch and installed InfernoShield 1800 degF stainless & ceramic heat shields, made by Heat Shield Products, in between the exhaust headers and the tunnel.

They can be cut to size and rivetted in place...

Since I had to remove the headers anyways, perfect time to install the copper exhaust donuts, too.

I also placed one of their ThermaFlect 1100 degF ceramic heat shield pads between the top of the tunnel and the bottom of the gas tank, as added protection. I dont ever want to deal with this again... and so far this thermal management initiative has proven to be very very effective.

Attachments

mbarryracing

TY 4 Stroke God

- Joined

- Aug 31, 2007

- Messages

- 1,923

- Reaction score

- 192

- Points

- 1,078

- Location

- Springville NY

- Country

- USA

- Snowmobile

- 2006 Yamaha Attak Turbo

2015 SR Viper RTX-DX

1996 Vmax 600XT

INJECTOR DYNAMICS 1000cc INJECTORS

This past year I pulled the trigger on installing a set of Injector Dynamics ID1000cc injectors, MoTeC recommends them and so does Precision Sports.

The stock injectors were pretty much maxed out of pulse width at 14 lbs boost, which is great for trail riding on pump gas but limits my ability to occasionally crank up the boost and utilize the full power potenial of the sled. I did some more horse-trading to procure an un-used set for the Yamaha Apex (p/n 1000.27.02.48.11.4) with the Denso plug-and-play adapters. These are specially machined to fit the Apex fuel rail and throttle bodies.

They are indeed longer then the stock injectors, about 9mm or so, which requires machining up some fuel rail spacers and using longer bolts to fasten it to the throttle bodies.

The nozzle end o-rings were more stiff and therefore took some finess to get them seated into the throttle bodies. I just lubed them up with some motor oil and was careful not to rip any, and also to make sure the injectors get seated all the way into the throttle body ports. Dont use the fuel rail bolts to draw them in, you'll just bend the fuel rail tabs...

The plug-and-play adapters were the way to go. Just plug into the stock injector plugs and then into the ID1000 injectors. Nice and clean.

This past year I pulled the trigger on installing a set of Injector Dynamics ID1000cc injectors, MoTeC recommends them and so does Precision Sports.

The stock injectors were pretty much maxed out of pulse width at 14 lbs boost, which is great for trail riding on pump gas but limits my ability to occasionally crank up the boost and utilize the full power potenial of the sled. I did some more horse-trading to procure an un-used set for the Yamaha Apex (p/n 1000.27.02.48.11.4) with the Denso plug-and-play adapters. These are specially machined to fit the Apex fuel rail and throttle bodies.

They are indeed longer then the stock injectors, about 9mm or so, which requires machining up some fuel rail spacers and using longer bolts to fasten it to the throttle bodies.

The nozzle end o-rings were more stiff and therefore took some finess to get them seated into the throttle bodies. I just lubed them up with some motor oil and was careful not to rip any, and also to make sure the injectors get seated all the way into the throttle body ports. Dont use the fuel rail bolts to draw them in, you'll just bend the fuel rail tabs...

The plug-and-play adapters were the way to go. Just plug into the stock injector plugs and then into the ID1000 injectors. Nice and clean.

Attachments

mbarryracing

TY 4 Stroke God

- Joined

- Aug 31, 2007

- Messages

- 1,923

- Reaction score

- 192

- Points

- 1,078

- Location

- Springville NY

- Country

- USA

- Snowmobile

- 2006 Yamaha Attak Turbo

2015 SR Viper RTX-DX

1996 Vmax 600XT

BOSCH 044 FUEL PUMP

Since I was installing the larger injectors, it was also time to upgrade the fuel supply system too.

After all the issues I had with the stock in-tank fuel pump, instead of replacing it decided to eliminate the FPP "lift-pump" setup (stock pump feeding a secondary external inline pump) all together and use just one large pump mounted external to the tank.

There are two benefits to the two pump setup that FPP uses. First is simplicity of not having to mess with the in-tank system, and second is that when using the in-tank pump as a "lift-pump" to feed a secondary high pressure pump that secondary pump also then gains output capacity at higher pressures (fuel pressure rises 1:1 with boost).

I picked the Bosch 044 fuel pump to use because of it's rated capacity with higher volume at higher pressures (enough for 600+ HP) so alone it's already more capacity then my original in-tank and secondary inline Walbro GSL392 high pressure pumps running together...

I mounted it in the nose of the sled on the plate that I had made previously that the MoTeC is mounted under. Mostly because of available room because that pump is so big that I would have trouble fitting it up under the cowlings where the slim Walbro resided.

Also added a real automotive fuel filter to the system to protect the injectors from any pump shrapnel in case of a failure.

I had gotten an Apex stock pump delete kit from Dave at Hurricane Performance, a nice & simple aluminum plate that replaces the stock sending unit. Just take the in-tank sock filter off the stock pump pick-up and clamp it to the pick-up hose on the plate. Installing this was probably the easiest part of the whole project.

WIRING : The previous secondary supplimental fuel pump relay was triggered by splicing into the stock in-tank fuel pump pigtail, so it turned on when the stock pump turned on. Well I no longer have the stock pump so instead of having the stock fuel pump relay operate a second relay in series, I decided to eliminate that additional potential fail mode and trigger the new fuel pump relay in parallel instead, directly by the same trigger from the ECU that energizes the stock relay.

Confused?

Why not just power the new single fuel pump with the stock relay, you ask? I dont trust that the stock relay (that is rated to handle the draw of a wimpy stock fuel pump) has enough rating to handle a huge big amp draw fuel pump like the Bosch. Also I still wanted to power the new fuel pump directly from the battery.

Why not eliminate the stock relay all together and just use one, you ask? Because the stock relay also powers the injectors. The injector wiring has a constant positive voltage and the ECU cycles them by switching the ground.

So I spliced into the harness wire for the fuel pump relay and used the same ECU ground trigger that activates he stock relay to also activate the bigger relay.

That was probably as clear as mud... Ha

Check out my new billet BOV's that I got from FPP, too. No diaghrams to bulge out under high boost pressure and then get pinched when the valve closes, like the Bosch BOV's are prone to.

Since I was installing the larger injectors, it was also time to upgrade the fuel supply system too.

After all the issues I had with the stock in-tank fuel pump, instead of replacing it decided to eliminate the FPP "lift-pump" setup (stock pump feeding a secondary external inline pump) all together and use just one large pump mounted external to the tank.

There are two benefits to the two pump setup that FPP uses. First is simplicity of not having to mess with the in-tank system, and second is that when using the in-tank pump as a "lift-pump" to feed a secondary high pressure pump that secondary pump also then gains output capacity at higher pressures (fuel pressure rises 1:1 with boost).

I picked the Bosch 044 fuel pump to use because of it's rated capacity with higher volume at higher pressures (enough for 600+ HP) so alone it's already more capacity then my original in-tank and secondary inline Walbro GSL392 high pressure pumps running together...

I mounted it in the nose of the sled on the plate that I had made previously that the MoTeC is mounted under. Mostly because of available room because that pump is so big that I would have trouble fitting it up under the cowlings where the slim Walbro resided.

Also added a real automotive fuel filter to the system to protect the injectors from any pump shrapnel in case of a failure.

I had gotten an Apex stock pump delete kit from Dave at Hurricane Performance, a nice & simple aluminum plate that replaces the stock sending unit. Just take the in-tank sock filter off the stock pump pick-up and clamp it to the pick-up hose on the plate. Installing this was probably the easiest part of the whole project.

WIRING : The previous secondary supplimental fuel pump relay was triggered by splicing into the stock in-tank fuel pump pigtail, so it turned on when the stock pump turned on. Well I no longer have the stock pump so instead of having the stock fuel pump relay operate a second relay in series, I decided to eliminate that additional potential fail mode and trigger the new fuel pump relay in parallel instead, directly by the same trigger from the ECU that energizes the stock relay.

Confused?

Why not just power the new single fuel pump with the stock relay, you ask? I dont trust that the stock relay (that is rated to handle the draw of a wimpy stock fuel pump) has enough rating to handle a huge big amp draw fuel pump like the Bosch. Also I still wanted to power the new fuel pump directly from the battery.

Why not eliminate the stock relay all together and just use one, you ask? Because the stock relay also powers the injectors. The injector wiring has a constant positive voltage and the ECU cycles them by switching the ground.

So I spliced into the harness wire for the fuel pump relay and used the same ECU ground trigger that activates he stock relay to also activate the bigger relay.

That was probably as clear as mud... Ha

Check out my new billet BOV's that I got from FPP, too. No diaghrams to bulge out under high boost pressure and then get pinched when the valve closes, like the Bosch BOV's are prone to.

Attachments

mbarryracing

TY 4 Stroke God

- Joined

- Aug 31, 2007

- Messages

- 1,923

- Reaction score

- 192

- Points

- 1,078

- Location

- Springville NY

- Country

- USA

- Snowmobile

- 2006 Yamaha Attak Turbo

2015 SR Viper RTX-DX

1996 Vmax 600XT

1000CC INJECTOR INITIAL STARTUP ISSUES

So just like when I first started the sled after installing my MoTeC for the first time and it was super rich, well it was doing the same darn thing. WTF

I had downloaded the 1000cc injector calibration that Martin had kindly provided me, and that he had been using successfully on everything else. The MoTeC will self adjust the maps to any injector that you enter the specs for, but mine didn't run right once again.

Now I was smarter then I was the first time, I started looking for what was diffeent with my unique machine.The high pressure Bosch Fuel Pump... Time for that fuel pressure gage I had been talking about.

Ordered one up from JEGs and after installing it, it showed that my base fuel pressure was WAY too high, over 50 psi... No wonder it was running too rich.

Some more trouble shooting on my part narrowed it down to the stock FPR fuel pressure regulator on the fuel rail that was no longer pulling fuel pressure away when vacuum was applied. It stays closed and the higher volume of my new super-hetrodyne fuel pump caused the fuel pressure to get jacked up. TADA!

Fuel pressure and battery voltage really does affect the flow of injectors, more then I thought... There is a reason injector manufacturers provide you with a Flow Data Chart with fow rate and injector dead times according to base fuel pressure and battery voltage.

Fuel pressure is something EVERYONE should double check on a boosted application because it's actually quite common to have fuel pressure variation from sled to sled, and have it all out of wack because of a waxed-out pump, etc.

Just read some of the Dyno Tech Research blogs and articles...

You just end up chasing your tail trying to tune around it, wasting time and money on a wild goose chase.

So just like when I first started the sled after installing my MoTeC for the first time and it was super rich, well it was doing the same darn thing. WTF

I had downloaded the 1000cc injector calibration that Martin had kindly provided me, and that he had been using successfully on everything else. The MoTeC will self adjust the maps to any injector that you enter the specs for, but mine didn't run right once again.

Now I was smarter then I was the first time, I started looking for what was diffeent with my unique machine.The high pressure Bosch Fuel Pump... Time for that fuel pressure gage I had been talking about.

Ordered one up from JEGs and after installing it, it showed that my base fuel pressure was WAY too high, over 50 psi... No wonder it was running too rich.

Some more trouble shooting on my part narrowed it down to the stock FPR fuel pressure regulator on the fuel rail that was no longer pulling fuel pressure away when vacuum was applied. It stays closed and the higher volume of my new super-hetrodyne fuel pump caused the fuel pressure to get jacked up. TADA!

Fuel pressure and battery voltage really does affect the flow of injectors, more then I thought... There is a reason injector manufacturers provide you with a Flow Data Chart with fow rate and injector dead times according to base fuel pressure and battery voltage.

Fuel pressure is something EVERYONE should double check on a boosted application because it's actually quite common to have fuel pressure variation from sled to sled, and have it all out of wack because of a waxed-out pump, etc.

Just read some of the Dyno Tech Research blogs and articles...

You just end up chasing your tail trying to tune around it, wasting time and money on a wild goose chase.

Attachments

mbarryracing

TY 4 Stroke God

- Joined

- Aug 31, 2007

- Messages

- 1,923

- Reaction score

- 192

- Points

- 1,078

- Location

- Springville NY

- Country

- USA

- Snowmobile

- 2006 Yamaha Attak Turbo

2015 SR Viper RTX-DX

1996 Vmax 600XT

TOMEI ADJUSTABLE FUEL PRESSURE REGULATOR INSTALL

The replacement cost of the stock FPR wasn't worth it when it wasn't even adjustable. So after some more research on TY, I purchased a nice compact boost referenced FPR from Tomei that was adjustable for base pressure from 28psi to 113 psi.

Tomei Fuel Pressure Regulator Type S, p/n 185001

Also had to remove and eliminate the stock FPR off the fuel rail. Read in another TY thread about an adapter also made by Tomei. Has an 1/8" NPT and 40mm slotted mounting holes that fit the stock fuel rail.

Tomei Fuel Pressure Regulator Adapter, p/n 185106

Mounted the new adjustable FPR off the headlight bracket usng the provided mounting plate with the regulator. I used my own brass elbows and plumbed the fuel lines up and away from the heat. Ran the manifold pressure line to the same port that the stock FPR used.

Started it up and set the base fuel pressure to 43 psi. TADA, ran awesome and ran it all last season without touching anything, FINALLY!!!!

They weren't lying about these 1000cc injectors, the machine idles and transitions nice. No complaints from the mbarryracing shop.

The replacement cost of the stock FPR wasn't worth it when it wasn't even adjustable. So after some more research on TY, I purchased a nice compact boost referenced FPR from Tomei that was adjustable for base pressure from 28psi to 113 psi.

Tomei Fuel Pressure Regulator Type S, p/n 185001

Also had to remove and eliminate the stock FPR off the fuel rail. Read in another TY thread about an adapter also made by Tomei. Has an 1/8" NPT and 40mm slotted mounting holes that fit the stock fuel rail.

Tomei Fuel Pressure Regulator Adapter, p/n 185106

Mounted the new adjustable FPR off the headlight bracket usng the provided mounting plate with the regulator. I used my own brass elbows and plumbed the fuel lines up and away from the heat. Ran the manifold pressure line to the same port that the stock FPR used.

Started it up and set the base fuel pressure to 43 psi. TADA, ran awesome and ran it all last season without touching anything, FINALLY!!!!

They weren't lying about these 1000cc injectors, the machine idles and transitions nice. No complaints from the mbarryracing shop.

Attachments

mbarryracing

TY 4 Stroke God

- Joined

- Aug 31, 2007

- Messages

- 1,923

- Reaction score

- 192

- Points

- 1,078

- Location

- Springville NY

- Country

- USA

- Snowmobile

- 2006 Yamaha Attak Turbo

2015 SR Viper RTX-DX

1996 Vmax 600XT

DATA LOG FROM 1000CC INJECTOR RUN

Here is a logged data run from an aggressive trail ride in Old Forge NY with the new 1000cc injectors in warm 30 deg F weather.

Notice how stable the intake air temperature stays, even after beating on it pretty good for a long time there aren't any visible spikes. Never saw any air temps over 28 deg C (82 deg F) at anytime on the display during riding that day.

This is a result of the combination of the FPP tunnel snow intercooler and air-to-air intercooler with fans, and my cold air box around the turbo intake. When you can keep your intake air temps in check, you can push the threshold before detonation that much further.

Here is a logged data run from an aggressive trail ride in Old Forge NY with the new 1000cc injectors in warm 30 deg F weather.

Notice how stable the intake air temperature stays, even after beating on it pretty good for a long time there aren't any visible spikes. Never saw any air temps over 28 deg C (82 deg F) at anytime on the display during riding that day.

This is a result of the combination of the FPP tunnel snow intercooler and air-to-air intercooler with fans, and my cold air box around the turbo intake. When you can keep your intake air temps in check, you can push the threshold before detonation that much further.

Attachments

mbarryracing

TY 4 Stroke God

- Joined

- Aug 31, 2007

- Messages

- 1,923

- Reaction score

- 192

- Points

- 1,078

- Location

- Springville NY

- Country

- USA

- Snowmobile

- 2006 Yamaha Attak Turbo

2015 SR Viper RTX-DX

1996 Vmax 600XT

RIGIDONE

TY 4 Stroke Master

- Joined

- Jan 5, 2009

- Messages

- 1,300

- Reaction score

- 81

- Points

- 738

- Location

- SYRACUSE, NY

- Country

- USA

- Snowmobile

- Pro S Switchback

like button!!!!!!!!!!!!!!!!where r u my friend!?!?!? great thread!!!awesome detail..

Similar threads

- Replies

- 11

- Views

- 3K

- Replies

- 21

- Views

- 4K

- Replies

- 3

- Views

- 1K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.