Bigblue1

TY 4 Stroke Junkie

- Joined

- Nov 29, 2007

- Messages

- 563

- Reaction score

- 272

- Points

- 1,108

- Location

- NY

- Country

- USA

- Snowmobile

- Sidewinder RTX-LE

Apex SE

I'll take a pic when I go through next month and send it.I want to see the pattern for the lack of rolling resistance.

Bigblue1

TY 4 Stroke Junkie

- Joined

- Nov 29, 2007

- Messages

- 563

- Reaction score

- 272

- Points

- 1,108

- Location

- NY

- Country

- USA

- Snowmobile

- Sidewinder RTX-LE

Apex SE

yes forget to mention.Trick is to the get the stud heads flush. In my opinion there's no way you can over tighten the tall nuts enough to strip them. Just don't over tighten them to over-compress the track. Even using the plastic backers you should have no trouble getting the stud heads flush even if you start with the tall nuts and change them out after the rubber has compressed when studding through the quiet pads on the track.

max rolph

Expert

- Joined

- Feb 10, 2021

- Messages

- 455

- Reaction score

- 277

- Points

- 408

- Location

- horse shoe valley

- Country

- Canada

- Snowmobile

- 998 turbo

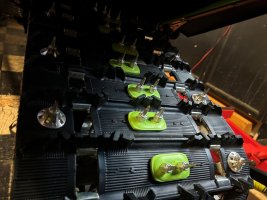

here are the pics, only 8 scratch marks ... but you only need more for drag racing, this works amazing for high speed and none go where wheels ride or drivers.... no noise and no resistance.... you can turn track by hand as if it had no studs. i usually never stud out side... but what i did was dremmeled a half moon out of the silent pads soo studs sunk flush with the stud stars on outer belt.

Attachments

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,319

- Reaction score

- 3,584

- Points

- 1,713

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2022 SIDEWINDER LTX GT

- LOCATION

- Vermont

Doesn't that pattern hit your center rear cooler protector?here are the pics, only 8 scratch marks ... but you only need more for drag racing, this works amazing for high speed and none go where wheels ride or drivers.... no noise and no resistance.... you can turn track by hand as if it had no studs. i usually never stud out side... but what i did was dremmeled a half moon out of the silent pads soo studs sunk flush with the stud stars on outer belt.

I had a Thundercat I bought to flip with studs in the center and the rear center cooler protector was torn up.

I usually try to stay out of the middle 1 1/2" of the track.......

Simplespeed

TY 4 Stroke Junkie

- Joined

- Jan 8, 2022

- Messages

- 619

- Reaction score

- 428

- Points

- 368

- Location

- 1191 Sauk Lane , Saginaw, Mi. 48638

- Country

- USA

- Snowmobile

- 2006 Apex , 2017 Sidewinder LTX -LE

Interesting way to stud a track and what length stud did you use… Iam sure its smooth and no noise…

max rolph

Expert

- Joined

- Feb 10, 2021

- Messages

- 455

- Reaction score

- 277

- Points

- 408

- Location

- horse shoe valley

- Country

- Canada

- Snowmobile

- 998 turbo

trigger studs, 3/8 above lugs. no noise.... since rarely drag race anyway.... perfect 3 per bar traction.

I used the Pro Lite double backers touching side by side up the middle and haven't hit the middle protector yet on 3 sleds Rich. That was with 1.575" Mega BitesDoesn't that pattern hit your center rear cooler protector?

I had a Thundercat I bought to flip with studs in the center and the rear center cooler protector was torn up.

I usually try to stay out of the middle 1 1/2" of the track.......

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,689

- Reaction score

- 2,744

- Points

- 1,053

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

To ensure all stud heads are flush to inside of track, including those in quiet track pads, I use a hole saw with a stop to control depth and drill the stud hole at the same time. Then, remove rubber inside the hole saw circle. Hole saw is exact size of stud head (15/16" for Megabites). When complete all stud heads are flush, no noise, no wear and tear on idler wheels, no vibration. Track runs very quiet even with 240 studs.

Attachments

Upstater57

Lifetime Member

- Joined

- Apr 25, 2021

- Messages

- 574

- Reaction score

- 563

- Points

- 738

- Location

- New York

- Country

- USA

- Snowmobile

- 2022 Tcat EPS,

2014 ZR9000 (sold)

1978,1979,1980 SRX (sold)

I run 5, 1.575studs per bar and end up replacing a wheel or two every year. A small price to pay for a good launch when you line up with your buddies. A few things I have noticed:

Careful installation of studs and re-torquing them every year helps a great deal.

Getting rid of the quiet pads also helps.

The ski doo wheels are cheap and also seem to help.

Overall, I have less trouble with wheels during years we have a lot of snow. Use more wheels during low snow seasons. Cost of doing business.

Careful installation of studs and re-torquing them every year helps a great deal.

Getting rid of the quiet pads also helps.

The ski doo wheels are cheap and also seem to help.

Overall, I have less trouble with wheels during years we have a lot of snow. Use more wheels during low snow seasons. Cost of doing business.

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.