I am currently in the process of changing my SW engine oil and doing a chaincase inspection.

A few seasons ago I installed Scott Taylor 15 wide top and bottom forged gears as well as a thin spacer on the top gear to prevent side motion.

I use Red Line synthetic 75W90 gear oil

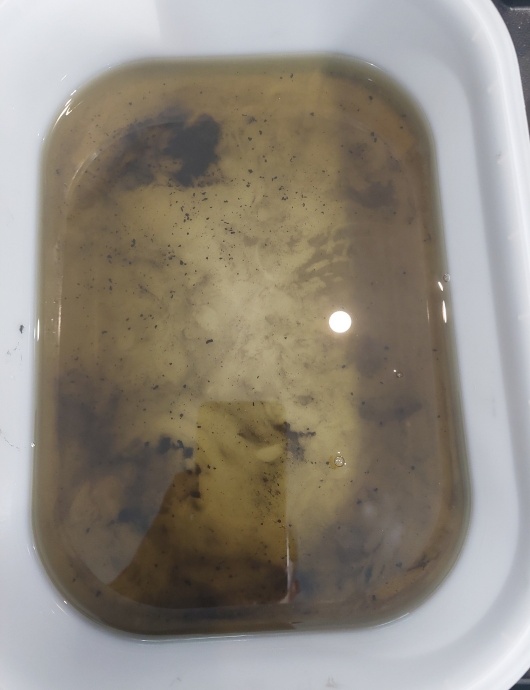

After a full season of riding I drained the oil and dismantled the chaincase for inspection.

Here's my findings:

-my chaincase oil was still relatively clean

-there were virtually no metal filings in the chaincase and oil and even the speedo magnets had very little sludge on them

-there was no detectable wear on the top gear bushing

I had always theorized that the OEM 13 wide bottom gear paired with the 15 wide top gear was allowing the chain to walk back and forth at a high frequency and due to the ability for the top gear to move laterally was causing bushing chatter and damage that eventually leads to the top gear wobbling on the shaft.

Last season I also occasionally intentionally reversed the sled for a short distance during my rides to ensure the top gear bushing rotated on the shaft to ensure it had lube.

As a side note....if you have found your chaincase gasket has stretched when reassembling the cover and bulges out of the cover and wont fit anymore, just put the gasket out in the snow or in the freezer foe a while and it should shrink enough to be reused.

Lol

I learned that trick 50 miles from home many seasons ago when I had to pull the heads on my 2002 700 SRX to retrieve a portion of a broken power valve from one of the cylinders. The head O rings had stretched on disassembly to the point that they would not fit in the cylinder grooves....15 mins with the O rings in the snow cured the problem and I got the engine back together and got home under my own steam.

All works for me!

A few seasons ago I installed Scott Taylor 15 wide top and bottom forged gears as well as a thin spacer on the top gear to prevent side motion.

I use Red Line synthetic 75W90 gear oil

After a full season of riding I drained the oil and dismantled the chaincase for inspection.

Here's my findings:

-my chaincase oil was still relatively clean

-there were virtually no metal filings in the chaincase and oil and even the speedo magnets had very little sludge on them

-there was no detectable wear on the top gear bushing

I had always theorized that the OEM 13 wide bottom gear paired with the 15 wide top gear was allowing the chain to walk back and forth at a high frequency and due to the ability for the top gear to move laterally was causing bushing chatter and damage that eventually leads to the top gear wobbling on the shaft.

Last season I also occasionally intentionally reversed the sled for a short distance during my rides to ensure the top gear bushing rotated on the shaft to ensure it had lube.

As a side note....if you have found your chaincase gasket has stretched when reassembling the cover and bulges out of the cover and wont fit anymore, just put the gasket out in the snow or in the freezer foe a while and it should shrink enough to be reused.

Lol

I learned that trick 50 miles from home many seasons ago when I had to pull the heads on my 2002 700 SRX to retrieve a portion of a broken power valve from one of the cylinders. The head O rings had stretched on disassembly to the point that they would not fit in the cylinder grooves....15 mins with the O rings in the snow cured the problem and I got the engine back together and got home under my own steam.

All works for me!

Kuzzy

Expert

- Joined

- Dec 6, 2020

- Messages

- 442

- Reaction score

- 234

- Points

- 408

- Location

- saskatchewan

- Country

- Canada

- Snowmobile

- 2020 yamaha sidewinder xtx se

2022 STX GT

2017 King Cat M9000

I was not as lucky as you. I need to do my to top bushing, very shot, full of sludge (was stock, ordered dmc), track shaft spun in bearing (stock, no saver installed), chain case oil was a bit milky and definately shiny (magnets were fuzzy) , not sure why oil was milky, I put green oil in there, it definately was mixing with something.

I have a long list of things to do before I ride yet lol.

I have a long list of things to do before I ride yet lol.

yamamarc

TY 4 Stroke God

- Joined

- Sep 29, 2013

- Messages

- 3,051

- Reaction score

- 2,848

- Points

- 1,583

- Location

- Massey Ontario

- Country

- Canada

- Snowmobile

- 2019 zr9000 Ltd

I got in the habit of soaking the gears and chains in wd-40 for a day and agitate periodically..

Crazy the crap that build up in the chain links

Crazy the crap that build up in the chain links

jonlafon1

Lifetime Member

- Joined

- Aug 18, 2014

- Messages

- 4,298

- Reaction score

- 3,345

- Points

- 1,603

- Country

- USA

- Snowmobile

- 2022 Sidewinder LTX_SE

2024 Catalyst RXC

2017 Sidewinder LTX-SE. 11750 miles (SOLD)

You got some moisture in your chaincase. That’s usually why it turns milky.I was not as lucky as you. I need to do my to top bushing, very shot, full of sludge (was stock, ordered dmc), track shaft spun in bearing (stock, no saver installed), chain case oil was a bit milky and definately shiny (magnets were fuzzy) , not sure why oil was milky, I put green oil in there, it definately was mixing with something.

I have a long list of things to do before I ride yet lol.

Crossfire12

TY 4 Stroke Guru

- Joined

- Feb 13, 2017

- Messages

- 884

- Reaction score

- 542

- Points

- 858

- Location

- New York Adirondacks

- Country

- USA

- Snowmobile

- 2010 Z1 Turbo ,2017 zr9000, F1100 turbo, 700 srx

- LOCATION

- Sacandaga reservoir

Condensation

Kuzzy

Expert

- Joined

- Dec 6, 2020

- Messages

- 442

- Reaction score

- 234

- Points

- 408

- Location

- saskatchewan

- Country

- Canada

- Snowmobile

- 2020 yamaha sidewinder xtx se

2022 STX GT

2017 King Cat M9000

Todd Beenen

Expert

- Joined

- Feb 16, 2020

- Messages

- 255

- Reaction score

- 176

- Points

- 328

- Location

- Michigan

- Country

- USA

- Snowmobile

- 2020 T-Cat

FWIW Scott recommend I use 15w-40 synthetic diesel oil in my chaincase.

I never asked him when I purchased his gears so I just ran the Red Line 75W90 that seems to have worked well. Scott Taylor did tell me that he feels the major contributing factor to the top gear bushing wear is the oil contamination from the sintered iron OEM gears and as I stated with his forged gears I had very little metal in my oil.FWIW Scott recommend I use 15w-40 synthetic diesel oil in my chaincase.

Similar threads

- Replies

- 11

- Views

- 1K

- Replies

- 9

- Views

- 3K