TPAY243

Lifetime Member

- Joined

- Apr 14, 2013

- Messages

- 834

- Age

- 57

- Location

- Northern Wis

- Country

- USA

- Snowmobile

- 2020 Yamaha Sidewinder LTX SE

where is this test facility you speak of, I only know of one and they are well aware of the problem.hi guys this Arctic cat is bad but the problem is Yamaha Testing don't here of these problems i was talking to one of the engineer's that work at the test center and they don't know anything about front drive axle so i sent them and the top gear in the chain case. but what get me is these sleds are 16k plus and they are not worth in and it is a shame Yamaha even put there name on. when you YAMAHA it meant that you had the best. wonder if that will happen again can only hope.

DMCTurbo

VIP Member

- Joined

- Nov 12, 2005

- Messages

- 2,775

- Age

- 51

- Location

- Val Caron, Ontario

- Country

- Canada

- Snowmobile

- 2017 Sidewinder XTX LE 137

New bearing

Old bearing

Unworn area of shaft

Worn area of shaft

Old bearing

Unworn area of shaft

Worn area of shaft

shop around if you get a high price, it doesnt require anything special or extensive and can be done in about an hour. Good Luck!I have a machine shop lined up tomorrow to give me a price. Thanks.

DMCTurbo

VIP Member

- Joined

- Nov 12, 2005

- Messages

- 2,775

- Age

- 51

- Location

- Val Caron, Ontario

- Country

- Canada

- Snowmobile

- 2017 Sidewinder XTX LE 137

Thanks for the adviceshop around if you get a high price, it doesnt require anything special or extensive and can be done in about an hour. Good Luck!

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,567

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

DMC, how far in was your wedge?

DMCTurbo

VIP Member

- Joined

- Nov 12, 2005

- Messages

- 2,775

- Age

- 51

- Location

- Val Caron, Ontario

- Country

- Canada

- Snowmobile

- 2017 Sidewinder XTX LE 137

I tapped it in once it dug in so the bolt head was flush with the end of the shaft.DMC, how far in was your wedge?

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,567

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

If you have a few days to spare , grab yourself a new quality bearing and bring your shaft over to a machine shop and have it welded up and turned down so the bearing requires some motivation to fit on shaft. I think I only paid $50 to get this done to mine and now I dont need loctite or dimples or wedges to hold it. Youll be done with it forever, only way mine is spinning is if it seizes solid.

I had my old shaft metalized (spray welded) and ground down a few months ago. I created a press fit (interference fit) per the ISO recommended tables. For this 6009 bearing for a heavy shock load that's about .0005 - .0007". I ended up with the shaft this much bigger than the ID of the bearing. This is how most electric motors are engineered. Important to use C3 bearing because when you press it together, when the bearing goes onto the shaft journal essentially the ID of the bearing will get "stretched" bigger using up some of the internal clearance of the bearing .If you have a few days to spare , grab yourself a new quality bearing and bring your shaft over to a machine shop and have it welded up and turned down so the bearing requires some motivation to fit on shaft. I think I only paid $50 to get this done to mine and now I dont need loctite or dimples or wedges to hold it. Youll be done with it forever, only way mine is spinning is if it seizes solid.

I didn't choose to try to freeze the track shaft and heat up the bearings. Wasn't sure how to do that since I did this interference fit on both sides of the shaft. I had to build a press mechanism to press the bearings on. Time will tell if this is a "permanent solution."

As we all know, this Cat design is an absolute disaster and just plain doesn't work.

You can read this post I put up after I got done. https://ty4stroke.com/threads/new-drive-shaft-axle.160253/page-3 Post #41.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,567

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

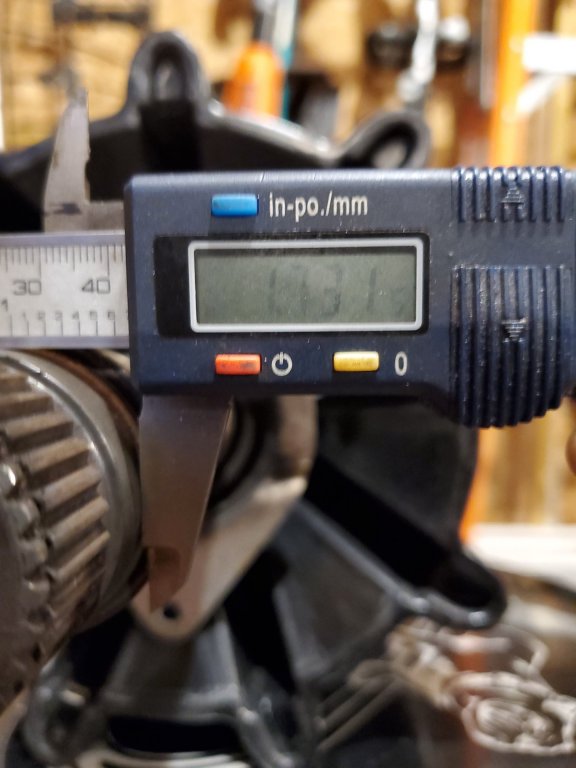

So you have a minimum of .006" clearance between a brand new bearing and the unworn area of shaft. That won't work.New bearing

View attachment 155519

Old bearing

View attachment 155520

Unworn area of shaft

View attachment 155521

Worn area of shaft

View attachment 155522

On worn area, you have over .047" clearance between old bearing ID. Yikes.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,567

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

Has anyone heard of any issues with conventional welding on the journals on the track shaft? I'm referring to shaft becoming brittle due to the extreme heat. When I had my shaft spray-welded (which doesn't use much heat) the shop doing usually does electric motor armatures and shafts where bearing has spun. They told me they do not use wire-feed, TIG, or arc on shafts like this because too much heat is needed and that makes the shaft get brittle potentially causing it to break at some future point. Anyone had any experiences like that? Spray-welding costs more due to it being more time consuming. It's faster to use one of other welding techniques.If you have a few days to spare , grab yourself a new quality bearing and bring your shaft over to a machine shop and have it welded up and turned down so the bearing requires some motivation to fit on shaft. I think I only paid $50 to get this done to mine and now I dont need loctite or dimples or wedges to hold it. Youll be done with it forever, only way mine is spinning is if it seizes solid.

The dealer just next door to me has several done every fall as this is a problem on the cat 2 strokes as well. He said once done they never have an issue again when inspecting them during fall service. The welder can keep the heat to a minimum by welding in quick bursts and not much penetration is needed since its just a surface buildup. My shaft showed zero signs of heat or discoloration in the circlip groove or edge of where bearing rides on opposite side of shaft. Im sure it can be done wrong in the wrong hands for sure, like most things. They have had great luck getting these done with mig welder, several have posted on facebook sidewinder groups getting this repaired the same way as well. I am not aware of anyone in our area that does spray welding so thats the only option we have.Has anyone heard of any issues with conventional welding on the journals on the track shaft? I'm referring to shaft becoming brittle due to the extreme heat. When I had my shaft spray-welded (which doesn't use much heat) the shop doing usually does electric motor armatures and shafts where bearing has spun. They told me they do not use wire-feed, TIG, or arc on shafts like this because too much heat is needed and that makes the shaft get brittle potentially causing it to break at some future point. Anyone had any experiences like that? Spray-welding costs more due to it being more time consuming. It's faster to use one of other welding techniques.

Yes good call mentioning the c3 bearing, I went with the koyo c3. They are readily available just about everywhere for a fair price.I had my old shaft metalized (spray welded) and ground down a few months ago. I created a press fit (interference fit) per the ISO recommended tables. For this 6009 bearing for a heavy shock load that's about .0005 - .0007". I ended up with the shaft this much bigger than the ID of the bearing. This is how most electric motors are engineered. Important to use C3 bearing because when you press it together, when the bearing goes onto the shaft journal essentially the ID of the bearing will get "stretched" bigger using up some of the internal clearance of the bearing .

I didn't choose to try to freeze the track shaft and heat up the bearings. Wasn't sure how to do that since I did this interference fit on both sides of the shaft. I had to build a press mechanism to press the bearings on. Time will tell if this is a "permanent solution."

As we all know, this Cat design is an absolute disaster and just plain doesn't work.

You can read this post I put up after I got done. https://ty4stroke.com/threads/new-drive-shaft-axle.160253/page-3 Post #41.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,567

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

C3 shouldn't cost any more. It's just a process of selecting the right inner ring, outer ring, and ball size when the bearing is put together. It's all done automatically by instruments capable of measuring into the millionths!

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,236

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2022 SIDEWINDER LTX GT

- LOCATION

- Vermont

coolingI didn't choose to try to freeze the track shaft and heat up the bearings.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,567

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

Neat! Never seen those tricks before. Thanks.

Chain case side bearing has to be put into chain case by itself (which I did by freezing bearing and heating case around where it goes in). And, brake side bearing in usually is put into caliper housing prior to install which is what I did. Now how to heat bearing ID and cool track shaft to get them on before they lock up (press fit). Not sure if you could cool track shaft where the bearing journal is enough to get it to go into chain case side bearing (remember that bearing is already in case so how do you heat that bearing short of using a small torch or inductive device?) before it locks up? Maybe. Then on brake side, you'd have to heat up the whole caliper housing to get bearing hot? At same time again trying to freeze the track shaft enough to get it to slip on before it locks up? Maybe it could be done.

I just built my install cup to just barely slide over track shaft (and press on bearing ID only) and then ran my threaded rod through track shaft to the other side and used a couple washers and nuts to just press them on. It was easy.

I also have a puller to get them off shaft if/when I need to.

Chain case side bearing has to be put into chain case by itself (which I did by freezing bearing and heating case around where it goes in). And, brake side bearing in usually is put into caliper housing prior to install which is what I did. Now how to heat bearing ID and cool track shaft to get them on before they lock up (press fit). Not sure if you could cool track shaft where the bearing journal is enough to get it to go into chain case side bearing (remember that bearing is already in case so how do you heat that bearing short of using a small torch or inductive device?) before it locks up? Maybe. Then on brake side, you'd have to heat up the whole caliper housing to get bearing hot? At same time again trying to freeze the track shaft enough to get it to slip on before it locks up? Maybe it could be done.

I just built my install cup to just barely slide over track shaft (and press on bearing ID only) and then ran my threaded rod through track shaft to the other side and used a couple washers and nuts to just press them on. It was easy.

I also have a puller to get them off shaft if/when I need to.

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,236

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2022 SIDEWINDER LTX GT

- LOCATION

- Vermont

It is easy to cool the shaft, they are hollow. Spray the inside....

yamamarc

TY 4 Stroke God

- Joined

- Sep 29, 2013

- Messages

- 3,051

- Location

- Massey Ontario

- Country

- Canada

- Snowmobile

- 2019 zr9000 Ltd

Another option would be to stuff dry ice in hollow shaft!!It is easy to cool the shaft, they are hollow. Spray the inside....

We use it all the time for interference fits at work!!

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.