toolman11k

Veteran

I figured I would share something with everyone, because I assume others will have this problem as well. I have a 2008 Yamaha Apex with 4,600 miles on it. Here was the problem. I would go for a ride, sled would die, fuel pump would not run. Let it sit and fuel pump would run. Did my reading and figured it was a fuel pump relay, i switched all 3 relays around, and still same issues. Keep in mind this was intermittent. I checked the fuel pump relay, and it had 12V in, 12V ignition(fuel pump command), ground(which is another issue) and wire out to the fuel pump. With the fuel pump disconnected, i would have 3.8V out of the relay going to the pump. As soon as the pump was connected, 0V. I thought bad relay under power. I used a heavy duty automotive test relay, and the same issue. The relay was not the problem. After much messing around, i figured out I had a voltage drop to the input side of the relay. The relay would click, but the pump would not run. after tearing 1/2 the sled apart looking for bad wires, fuses, contacts, grounds, etc, etc. The following was the issue.

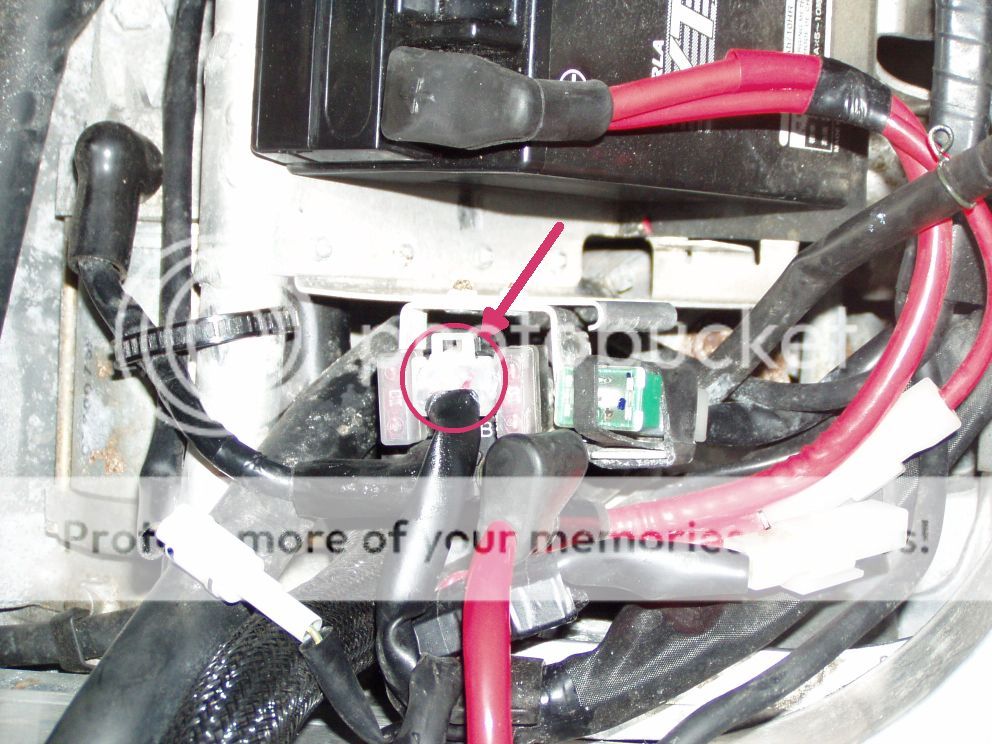

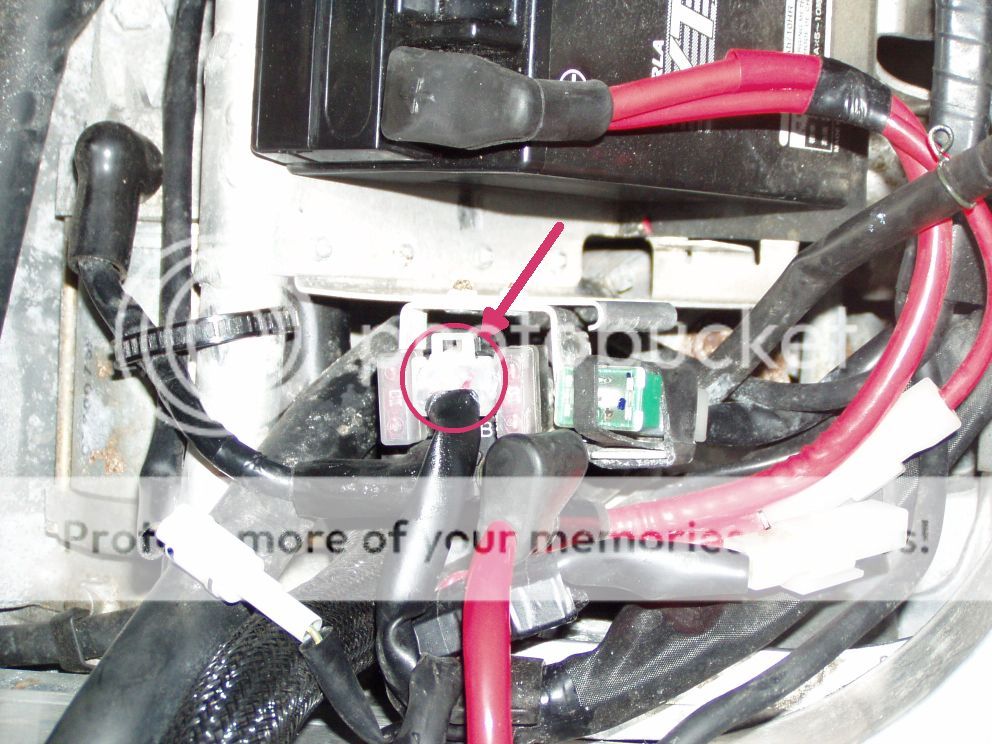

Next to the battery is a horse sh#! designed connector, THANKS YAMAHA. Here is why. This is a plastic connector with 3 spade terminals in it, however it is open on the back, and sort of sealed on the bottom, and it is pointing straight upwards. This causes snow to melt, and water to sit in this connector and corrode the female terminal inside the plastic connector. This was the source of the voltage drop causing the fuel pump issues. I removed the connector, removed the 1 heavily corroded female connector and replaced it with a new one. I then filled the connector with dielectric grease and re-installed. Filling the back of the connector with dielectric as well. No more voltage drop issues, pump runs fine.

This connector should have been a weather-pack connector like everything else on the sled, or at least mounted sideways so water could not sit it the connector.

Anyway enough rambling, I just thought if I could save 1 person the agony I had, or get stranded on the trail, next time you have your air box off, pull this connector, check for corrosion and fill it full of dielectric grease. Save your self trouble down the road.

Hope this helps someone.

Next to the battery is a horse sh#! designed connector, THANKS YAMAHA. Here is why. This is a plastic connector with 3 spade terminals in it, however it is open on the back, and sort of sealed on the bottom, and it is pointing straight upwards. This causes snow to melt, and water to sit in this connector and corrode the female terminal inside the plastic connector. This was the source of the voltage drop causing the fuel pump issues. I removed the connector, removed the 1 heavily corroded female connector and replaced it with a new one. I then filled the connector with dielectric grease and re-installed. Filling the back of the connector with dielectric as well. No more voltage drop issues, pump runs fine.

This connector should have been a weather-pack connector like everything else on the sled, or at least mounted sideways so water could not sit it the connector.

Anyway enough rambling, I just thought if I could save 1 person the agony I had, or get stranded on the trail, next time you have your air box off, pull this connector, check for corrosion and fill it full of dielectric grease. Save your self trouble down the road.

Hope this helps someone.

Hammer 1

Pro

Thanks for the info and pic.

Snowmobileaddict

TY 4 Stroke Junkie

I noticed this on my sled last offseason as well. It was nice and crustified. I did the same thing. Clean 'er up and pack with grease.

wcfpusher

Pro

great find and thanks for the heads up!

DoktorC

TY 4 Stroke Master

Well as luck would have it, today I went to move my sled out of my "office" and into my truck (sled day tomorrow with the boys) and...nothing....gauge is dead, fuel pump relay is clicking rapidly. I turn the key a few time and blink....everything works...pump and tach cycle. I start it and it quits. I do this a couple of times then it runs and stays running.

Now, I happened to read this thread today so it was in my head while diagnosing. I pulled the F/P relay and turned the key...sure enough the gauge stayed on...clearly the relay wasn't the problem. I went directly for the connector on the starter relay (after disassembling the sled....I miss the hood on my RX sometimes!!!!) and BINGO...green crustiness. Cleaned it up and she's fixed and ready to ride in the morning!

I know this is a long way of saying "thanks" but there ya go. You saved me hours of searching!!!

Now, I happened to read this thread today so it was in my head while diagnosing. I pulled the F/P relay and turned the key...sure enough the gauge stayed on...clearly the relay wasn't the problem. I went directly for the connector on the starter relay (after disassembling the sled....I miss the hood on my RX sometimes!!!!) and BINGO...green crustiness. Cleaned it up and she's fixed and ready to ride in the morning!

I know this is a long way of saying "thanks" but there ya go. You saved me hours of searching!!!

Hammer 1

Pro

THIS SITE ABSOLUTELY ROCKS!!!:

Thanks for the info, I know how hard it is to trace down electrical problems. Glad this is in my knoledge now!

Irv

TY 4 Stroke God

- Joined

- Mar 23, 2005

- Messages

- 3,778

- Age

- 59

- Location

- ONT. Canada

- Country

- Canada

- Snowmobile

- 2008 40th Anniversary Vector.

1995 XLT SP (Son's)

Excellent info, thanks for sharing!

Next time mine will be getting the same dielectric greas treatment, just wish I knew I this before I removed everthing twice already trying to hook up my E-shield!

3rd times a charm?

Next time mine will be getting the same dielectric greas treatment, just wish I knew I this before I removed everthing twice already trying to hook up my E-shield!

3rd times a charm?

unclearpine

Extreme

When I get back in that deep into my sled I will definitely do that bit of preventive maintenance.Thanks for this post Toolman.

Irv

TY 4 Stroke God

- Joined

- Mar 23, 2005

- Messages

- 3,778

- Age

- 59

- Location

- ONT. Canada

- Country

- Canada

- Snowmobile

- 2008 40th Anniversary Vector.

1995 XLT SP (Son's)

unclearpine said:When I get back in that deep into my sled I will definitely do that bit of preventive maintenance.Thanks for this post Toolman.

Just did mine recently when adjusting my toe-out, everything was clean with no hint of corrosion but once you have a good look at it while your in there, you can definitely see how easy it would be to get all corroded.

Thanks again Toolman

unclearpine

Extreme

This is one more place to keep a eye on.This is what failed on my sled this winter and let me down.The best part is it was a easy fix if you know what is wrong.And I was at a restaurant.

http://www.ty4stroke.com/viewtopic.php? ... highlight=

I still do not know what causes this ground terminal to fail,but its gone now.Whats next, I got over 16,000 Km on my sled now?

http://www.ty4stroke.com/viewtopic.php? ... highlight=

I still do not know what causes this ground terminal to fail,but its gone now.Whats next, I got over 16,000 Km on my sled now?

quebecmoutainrider

TY 4 Stroke Junkie

Thanks toolman11k....great post..

fast shee

Veteran

Just a FYI, yamaha has this problem on almost all their sleds and atv models. Had it on my grizzly, yfz450, nytro, phazer. Terrible design from yamaha.

Winderallday!

VIP Member

I went through this painful issue this past spring, and with the help from this post, tracked it down after looking at all ground blocks etc etc., I cleaned up the connector and the solenoid at the battery, good to go.

Thot I had it licked, but same gremlin returned this fall when I pulled it out of storage. Had the sled running a couple of times, then fuel pump quit. Tested relay and pump, both fine.

Long story short, I pulled the connnector at the solenoid again, looked 100%, but the spade connectors didn't seem to be fitting over the lugs very tight. Sure enough, wiggled the connector a bit and pump fires up! Tightened the "grip" on the curl of the spade connectors so they grabbed the lugs better, problem solved!

Something else to look at FWIW.

Cheers,

Thot I had it licked, but same gremlin returned this fall when I pulled it out of storage. Had the sled running a couple of times, then fuel pump quit. Tested relay and pump, both fine.

Long story short, I pulled the connnector at the solenoid again, looked 100%, but the spade connectors didn't seem to be fitting over the lugs very tight. Sure enough, wiggled the connector a bit and pump fires up! Tightened the "grip" on the curl of the spade connectors so they grabbed the lugs better, problem solved!

Something else to look at FWIW.

Cheers,

Similar threads

- Replies

- 24

- Views

- 2K

- Replies

- 4

- Views

- 1K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.