- Joined

- Jun 1, 2004

- Messages

- 7,848

- Reaction score

- 2,041

- Points

- 2,103

- Location

- sudbury on

- Country

- Canada

- Snowmobile

- 2016 apex xtx

2011 apex xtx

2009 phaser rtx/x

1997 et410t/r

1988 vk 540

that is good to hear!

Great work. Please keep us updated as I'm very interested in this swap!

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,875

- Reaction score

- 2,750

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

Great work. Please keep us updated as I'm very interested in this swap!

I will be able to offer them in either a 7 tooth or an 8 tooth driver in 2.52 pitch.

I've started a thread on the two stroke site on my progress.

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,875

- Reaction score

- 2,750

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

I've got a few sets made up now. Going to retail a pair of new 8 tooth drivers with adapter bushings installed for $95.

Price is right, but I have a couple questions. First, How are you ensuring that the square drive is centered within the hex driver? Second, What materials are you using? It looks like some type of plastic material (e.g., HDPE, UHMW, UHMWPE, nylon, delrin, etc.) with some sort of metal square drive insert (or maybe that's just a discoloration from where the driver has been pressed onto the shaft?). Either way, the plastic material appears to be pretty thin near the corners of the square drive, so I'm also wondering if in testing these, you have logged some real world miles (as opposed to installing a track and running it on a stand) to see how the drivers hold up?

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,875

- Reaction score

- 2,750

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

I don't make the drivers. They are an off the shelf driver I get from kimpex.

The bushing is a hex od to match the driver ID. It centers itself when you press it into the driver. The square is centered in the hex bushing.

Material of the bushing is 6061 Aluminum.

Bushing is 1.5" long and fully in cased inside the driver. Despite wall being thin in the corner, once its all assembled everything is under compression. There are metal band clamps on OD of driver too.

No trail time yet as I only began working on this over the summer. If I had any doubts I wouldn't be offering them for sale yet. Remember....this is an 18 hp motor....not 200hp sidewinder. Ha.

The bushing is a hex od to match the driver ID. It centers itself when you press it into the driver. The square is centered in the hex bushing.

Material of the bushing is 6061 Aluminum.

Bushing is 1.5" long and fully in cased inside the driver. Despite wall being thin in the corner, once its all assembled everything is under compression. There are metal band clamps on OD of driver too.

No trail time yet as I only began working on this over the summer. If I had any doubts I wouldn't be offering them for sale yet. Remember....this is an 18 hp motor....not 200hp sidewinder. Ha.

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,875

- Reaction score

- 2,750

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

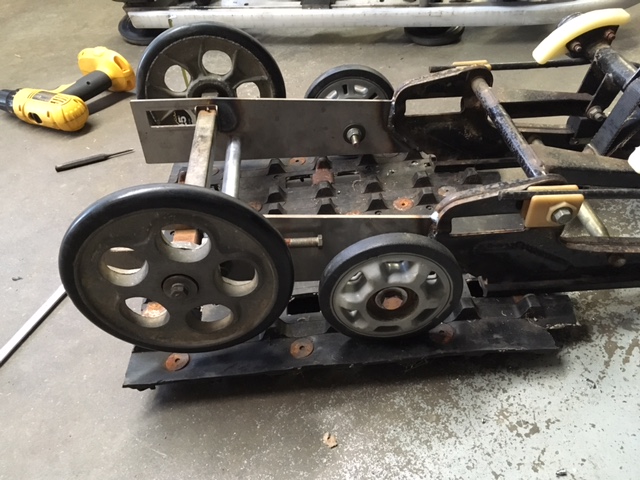

For those that don't want to do a skid swap to accommodate a 121" track I'm working on a rail extension kit. Extensions get welded to stock rails. Welded my test set up friday. Hoping to install this week to test fit then add set of wheels and weld nuts on for tension adj bolts.

1bad10tacoma

Veteran

- Joined

- Oct 20, 2015

- Messages

- 27

- Reaction score

- 0

- Points

- 201

- Location

- Maine

- Country

- USA

- Snowmobile

- 2007 Yamaha Phazer GT

1988 Yamaha Bravo LT

1986 Yamaha Bravo ST

SweetFor those that don't want to do a skid swap to accommodate a 121" track I'm working on a rail extension kit. Extensions get welded to stock rails. Welded my test set up friday. Hoping to install this week to test fit then add set of wheels and weld nuts on for tension adj bolts.

View attachment 121861

1bad10tacoma

Veteran

- Joined

- Oct 20, 2015

- Messages

- 27

- Reaction score

- 0

- Points

- 201

- Location

- Maine

- Country

- USA

- Snowmobile

- 2007 Yamaha Phazer GT

1988 Yamaha Bravo LT

1986 Yamaha Bravo ST

Anyone know how tight to set the track on a LT bravo? I put a used track on my sled and I can't seem to find any info on it. Thanks

thor452

Because I can

- Joined

- Jan 5, 2010

- Messages

- 3,029

- Reaction score

- 621

- Points

- 1,603

- Location

- Shawano,WI 54166

- Country

- USA

- Snowmobile

- 2012 Apex XTX 2017 Sidewinder LTX-LE

like a banjo lol

- Joined

- Jun 1, 2004

- Messages

- 7,848

- Reaction score

- 2,041

- Points

- 2,103

- Location

- sudbury on

- Country

- Canada

- Snowmobile

- 2016 apex xtx

2011 apex xtx

2009 phaser rtx/x

1997 et410t/r

1988 vk 540

usually just tight enough for it not to skip when it has good traction on the older air cools I still run.

YukonMP

TY 4 Stroke Guru

- Joined

- Dec 25, 2014

- Messages

- 859

- Reaction score

- 583

- Points

- 1,208

- Location

- Yukon Territory

- Country

- Canada

- Snowmobile

- 2014 Venture MultiPurpose 2020 VK Professional ll

Out of my 2011 manual.

40-50mm with 10 kg pull. Converted to American ... 1.57-1.97 inches with 22 pounds downforce.

My interpretation is that I want to be able to get a 2 by 2 in without too much trouble when the track is hanging slack under its own weight only. Seems to work, I have 5k miles on the original sliders and they are still 80 percent easy.

40-50mm with 10 kg pull. Converted to American ... 1.57-1.97 inches with 22 pounds downforce.

My interpretation is that I want to be able to get a 2 by 2 in without too much trouble when the track is hanging slack under its own weight only. Seems to work, I have 5k miles on the original sliders and they are still 80 percent easy.

1bad10tacoma

Veteran

- Joined

- Oct 20, 2015

- Messages

- 27

- Reaction score

- 0

- Points

- 201

- Location

- Maine

- Country

- USA

- Snowmobile

- 2007 Yamaha Phazer GT

1988 Yamaha Bravo LT

1986 Yamaha Bravo ST

Thanks a lot, that's a big help.Out of my 2011 manual.

40-50mm with 10 kg pull. Converted to American ... 1.57-1.97 inches with 22 pounds downforce.

My interpretation is that I want to be able to get a 2 by 2 in without too much trouble when the track is hanging slack under its own weight only. Seems to work, I have 5k miles on the original sliders and they are still 80 percent easy.

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,875

- Reaction score

- 2,750

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

Attached are some photos of my 121 rail extensions for the bravo. They are steel, so just get welded to the stock rails. Added a set of wheels, and a cross shaft in the rear. The assembled skid has my prototype extensions. Last pic shows the production extension profile. Nuts get welded on for track adjuster bolts. Will work up pricing for the rail extension kit soon.

1bad10tacoma

Veteran

- Joined

- Oct 20, 2015

- Messages

- 27

- Reaction score

- 0

- Points

- 201

- Location

- Maine

- Country

- USA

- Snowmobile

- 2007 Yamaha Phazer GT

1988 Yamaha Bravo LT

1986 Yamaha Bravo ST

Similar threads

- Replies

- 4

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.