Is it possible to check the coolint flow on a Apex motor without running the engine using an external electric water pump? I have an Apex motor that had cooling issues that caused a blown head gasket and after decking the head which warped when the cylinder head gasket failed I want to make sure that the coolint is circulating properly before firing up the new motor. Have this motor in a side by side which has dual radiators and I was planning to add a external water pump to insure that cooling system is able to handle the amount of plumbing involved with dual radiators

Bueller...Bueller...

Not sure what you are asking. You want to know if you can check the flow of the system or just the engine? If just the engine then I would pour fluid in the top hose and let gravity flow it out the bottom. If input equals output I would have to say the flow would be good. If you concerned that you have a blocked passage way within the block then I think the only way to find that is complete and thorough inspection of a disassembled engine.

checking the coolent flow of the system using an electric water pump so that i can check to see if the system is flowing properly before firing up the motor and to see if there is any blockage in the system, as i said in my first thread the motor is installed in a RZR SXS with 2 radiator as i run this in tight slow trails along with open 2 tracks trails. I added an electric water pump because of the extra strain the dual radiators and position of the second radiator which is above the motor and the length of the cooling lines from the rear engine position all the way up to the front of the SXS then back to the second radiator that is 3 feet above the front radiator lines and 18 inches above the motor...that is what i have...so can i get the system to flow using only the electric pump without running the motor?

here are some pics to get a clearer idea of the system...

you can see the radiator is above the motor in the rear and the front radiator is at the same level as the motor

this shows the return lines from the front radiator going up to the rear radiator

you can see the radiator is above the motor in the rear and the front radiator is at the same level as the motor

this shows the return lines from the front radiator going up to the rear radiator

have one more pic showing the overflow tank

Sasquatch

Lifetime Member

- Joined

- Apr 17, 2004

- Messages

- 3,699

- Location

- North Western Ontario

- Website

- www.dptc.com

- Country

- Canada

- Snowmobile

- Yamaha's

My thoughts are two pumps could mean that the flow is as fast as the slowest pump. If you are trying to increase flow using two pumps it may not do that. I don't know what the volume of flow is for the stock motor pump or the secondary pump you added but I would start there. It may be hard to push water through a pump that is not running fudging any results so checking flow that way might not work.

Secondly the electric pump is running top speed while the engine pump is not if you are running slow speeds in the twistys. Removing the impeller from the engine pump if possible may give you the flow you possibly need at low rpms!

Secondly the electric pump is running top speed while the engine pump is not if you are running slow speeds in the twistys. Removing the impeller from the engine pump if possible may give you the flow you possibly need at low rpms!

kinger

VIP Member

What size radiators are you using? Yes you could remove the impeller but the rest of the WP needs to stay intact as it also drives the oil pump.

Sent from my iPad using Tapatalk

Sent from my iPad using Tapatalk

I agree with Sasquatch about not using a second water pump. I'm pretty sure the stock pump will be up to the task of getting sufficient water through the system. I would remove the thermostat from the housing and start it up. Water will flow through the whole system right away and you should be able to tell by touching the hoses and rads if the coolant is flowing properly. You might be able to see water moving in the top rad with the cap off. I would be worried about air in the system with the complexity of the routing. A trick I have used in the past to make sure the system is bled is to loosen each hose clamp one at a time and insert a small screwdriver blade under the hose. I let some coolant and air if any escape then tighten back up. I would start with the ones on the head and work my way upward.Is it possible to check the coolint flow on a Apex motor without running the engine using an external electric water pump? I have an Apex motor that had cooling issues that caused a blown head gasket and after decking the head which warped when the cylinder head gasket failed I want to make sure that the coolint is circulating properly before firing up the new motor. Have this motor in a side by side which has dual radiators and I was planning to add a external water pump to insure that cooling system is able to handle the amount of plumbing involved with dual radiators

1320

Extreme

I think you should run electric pumps and try it can't hurt anything without the motor running the only other way to see if the passages are blocked as a complete tear downchecking the coolent flow of the system using an electric water pump so that i can check to see if the system is flowing properly before firing up the motor and to see if there is any blockage in the system, as i said in my first thread the motor is installed in a RZR SXS with 2 radiator as i run this in tight slow trails along with open 2 tracks trails. I added an electric water pump because of the extra strain the dual radiators and position of the second radiator which is above the motor and the length of the cooling lines from the rear engine position all the way up to the front of the SXS then back to the second radiator that is 3 feet above the front radiator lines and 18 inches above the motor...that is what i have...so can i get the system to flow using only the electric pump without running the motor?

1320

Extreme

That's one heck of a plumbing system I'm impressedI think you should run electric pumps and try it can't hurt anything without the motor running the only other way to see if the passages are blocked as a complete tear down

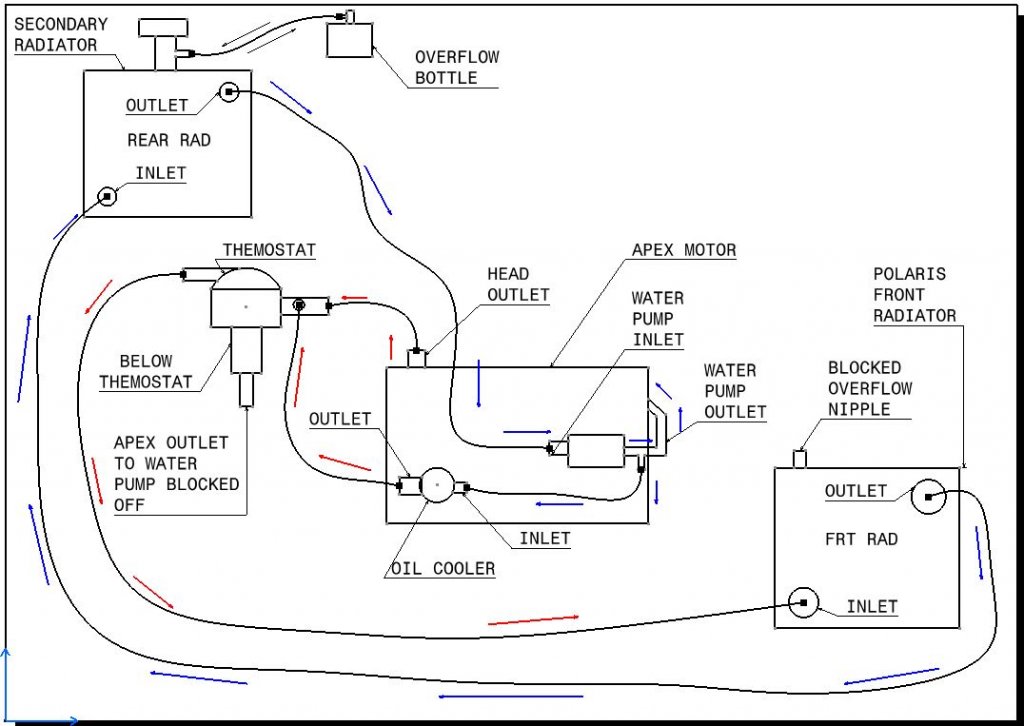

only thing in this diagram that is wrong is the flow of oil pump cooling is reversed, meaning output is input and input is output for the oil cooler after cooling flows out of the water pump it goes to the head and also to the oil cooler...

OK HERE IS THE CORRECT DIAGRAM OF THE COOLING SYSTEM...

Sasquatch

Lifetime Member

- Joined

- Apr 17, 2004

- Messages

- 3,699

- Location

- North Western Ontario

- Website

- www.dptc.com

- Country

- Canada

- Snowmobile

- Yamaha's

I think I got the gist of it but why would your rad outlets be at the top? Usually they are at the bottom of the rad to eliminate possibility of air into the system, the closed rad with no overflow should be good as it can be purged of air but the top one leaves a way for air to get into the system.

thor452

Because I can

- Joined

- Jan 5, 2010

- Messages

- 3,029

- Location

- Shawano,WI 54166

- Country

- USA

- Snowmobile

- 2012 Apex XTX 2017 Sidewinder LTX-LE

agreed switch inlet for outlet on the rads and you may be in business. if the way you show is the way you have it you could lose flow just from a small air gap. you need to pump in the top and flow out the bottom. may also be why you need so much cooling? maybe not but just a thought.

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 0

- Views

- 445

- Replies

- 17

- Views

- 3K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.