scooterwj

Pro

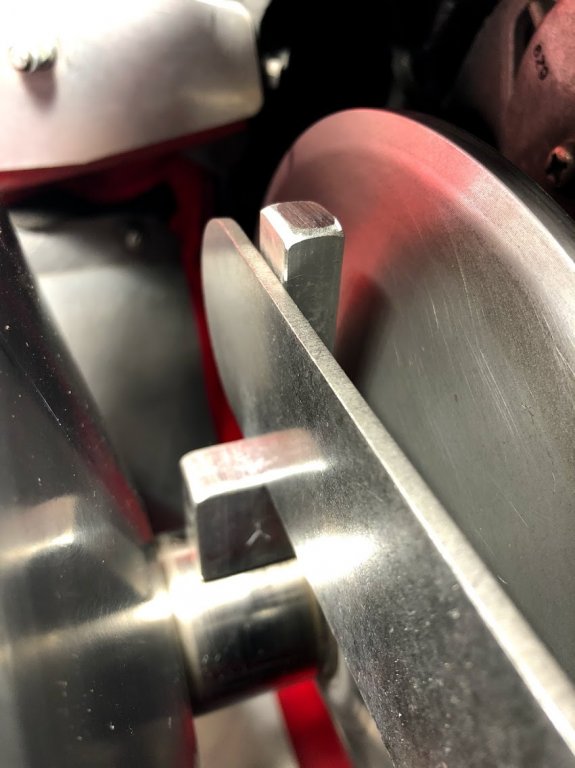

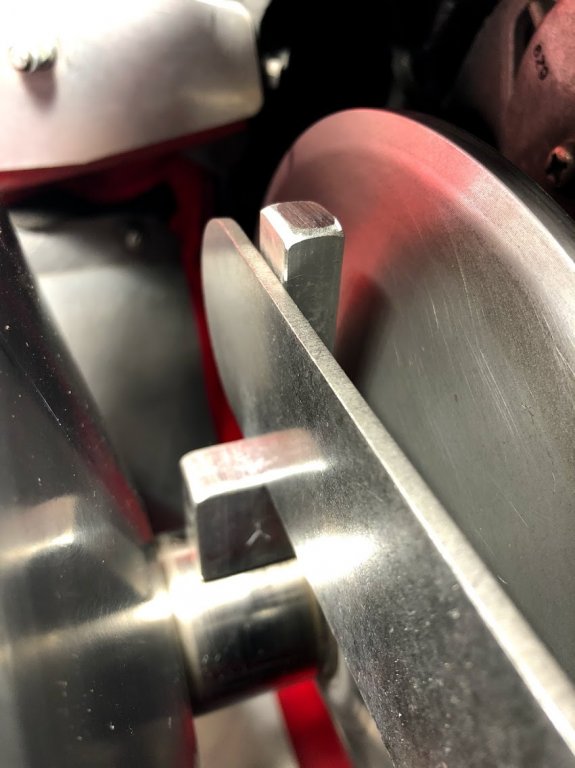

I know there is days of reading on this topic.... I have the Hurricane clutch alignment tool. I put the tool on and there is a little play, I put a one MM washer in there with the go-no-go part and that made it fit snug. So, is 1 MM of play there too much? I do not have any shims/washers on the back of my secondary. Is it worth it to have 1 MM machined off the back? Thanks!

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Where did you put the shim?

Reason I ask is....if you have play, that means you need to go back more with secondary to tighten up play between bar and gauge.....

Each sled is slightly diff I know.....I had to remove 4mm, and ALL shims to get mine set with the bar...

T0ns pics of this in my build thread.

https://ty4stroke.com/threads/my-rtx-le-50th-build-thread-rockerdan.149801/page-31#post-1446884

Dan

Reason I ask is....if you have play, that means you need to go back more with secondary to tighten up play between bar and gauge.....

Each sled is slightly diff I know.....I had to remove 4mm, and ALL shims to get mine set with the bar...

T0ns pics of this in my build thread.

https://ty4stroke.com/threads/my-rtx-le-50th-build-thread-rockerdan.149801/page-31#post-1446884

Dan

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Crazy how much diff from your sled to mine....I had to remove 4mm off hub, then remove ALL shims, to get bar fitting nicely....While it sounds like you are close with just needed to remove 1mm or so, if im understanding you?

I know most ive spoke to had to remove 3mm min.....

I believe my primary moved inward by approx 1 to 1.5mm total, when I snapped a belt and primary slams shut banging that large PTO bearing inward. So with 1mm loss, I would have had to still remove 3mm to and all shims removed to get aligned to hurricane bar specs.

What is interesting is, if this new lowered offset does indeed cure belt life as many claim, Will YAMAHA ever change their specs? Mine was right in spec with YAM when delivered.

Dan

I know most ive spoke to had to remove 3mm min.....

I believe my primary moved inward by approx 1 to 1.5mm total, when I snapped a belt and primary slams shut banging that large PTO bearing inward. So with 1mm loss, I would have had to still remove 3mm to and all shims removed to get aligned to hurricane bar specs.

What is interesting is, if this new lowered offset does indeed cure belt life as many claim, Will YAMAHA ever change their specs? Mine was right in spec with YAM when delivered.

Dan

scooterwj

Pro

Where did you put the shim?

Reason I ask is....if you have play, that means you need to go back more with secondary to tighten up play.....

Each sled is slightly diff I know.....I had to remove 4mm, and ALL shims to get mine set with the bar...

T0ns pics of this in my build thread.

https://ty4stroke.com/threads/my-rtx-le-50th-build-thread-rockerdan.149801/page-31#post-1446884

Dan

Hey Dan, thanks for the info. What I meant is that there is 1MM in gap between the "arm" on the go-no-go gauge and the flat-stock on the tool coming off the secondary. I see in Dave's video about the tool that it's ok to have some play/wiggle and I'm wondering if 1MM is ok or too much? Thanks!

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

So, if you had 1mm space....then you can remove 1mm shim, and it will be perfect. Is that how yours is?Hey Dan, thanks for the info. What I meant is that there is 1MM in gap between the "arm" on the go-no-go gauge and the flat-stock on the tool coming off the secondary. I see in Dave's video about the tool that it's ok to have some play/wiggle and I'm wondering if 1MM is ok or too much? Thanks!

That is way diff then mine then....

Dan

scooterwj

Pro

So, if you had 1mm space....then you can remove 1mm shim, and it will be perfect. Is that how yours is?

That is way diff then mine then....

Dan

No, I had no shims on the back of the secondary from the factory.... no adjustment :-(

ROCKERDAN

OCD Sledhead

- Joined

- Oct 8, 2005

- Messages

- 7,503

- Location

- Huntsville Ontario & Niagara NY

- Country

- Other

- Snowmobile

- '18 RTX 50th "Winder"

Gotcha.....So you got no shims, and have a 1mm space from bar to gauge then? So you could move back another 1mm to get perfect?No, I had no shims on the back of the secondary from the factory.... no adjustment :-(

That is certainly alot better then mine...I removed a full 4mm and with no shims is great on bar.

You could machine off 2mm, and then use a 1mm shim and should get you perfect. Not really a must, but I sure would like to have at least a 1mm shim in mine, and not against the circlip.

But for me, 4mm is already going a tad past flush at full shift....so really I dont recommend machining off more then 3mm max.

Dan

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,072

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Don't forget to check and make sure your alignment bar is straight.

if your're going to get it machined you might as well take the full 3mm off the shaft. That way there, if the primary moves in for some reason, you have the space to move the secondary in. The shims come in 1mm and 2mm sizes and they're cheap.

1mm Part # 8JP-RA448-00-00

2mm Part # 8JP-RA449-00-00

1mm Part # 8JP-RA448-00-00

2mm Part # 8JP-RA449-00-00

Chris Rose

Expert

- Joined

- Jul 29, 2016

- Messages

- 288

- Age

- 70

- Location

- Powassan ONT

- Country

- Canada

- Snowmobile

- 2017 sidewinder stx-DX with TD/Max 16 stock muffler

- WEBSITE

- chrisjrose2018@@gmail.com

Dave at Hurricane told me to use a shim between the clutch and the circlip. I took 4mm off mine and used a 2mm spacer. Only 2mm to be inline was required for mine.

Bigblue1

TY 4 Stroke Junkie

So Dan my belts weren't snapping. They were exploding into pieces......stock after 400 miles. So I did the rollers in secondary, rollers in primary (one of the bushings was sticking), and installed TP orange springs and TP belt adjuster. Now getting around 1,000 miles with one stint at 1,400, after TD Powertrail and Dalton weight set up. I could almost live with that but no, I want 2,000 miles out of a belt. My Apex never blows a belt past 3,000 miles. So naturally, viewing your videos and researching on this forum, I got the alignment tool after checking offset. It was off with no shims or screws on the back side so I machined 2mm off since putting me at 58.7mm. Your float post is interesting. I have been running TP adjuster backwards since the back of it is perfectly flat. We'll see what happens this winter.

stohlem

Extreme

- Joined

- Jan 11, 2015

- Messages

- 62

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX LE, 2014 Apex XTX

- LOCATION

- Illinois

Hey Dan, It may be not make a difference but when I measured mine with the gauge, I placed it with the thick side up per Dave's video. Just wondering if you get the same result with heel down.

scooterwj

Pro

Hey Dan, It may be not make a difference but when I measured mine with the gauge, I placed it with the thick side up per Dave's video. Just wondering if you get the same result with heel down.

I noticed that as well and checked mine both ways and got the same measurement

stohlem

Extreme

- Joined

- Jan 11, 2015

- Messages

- 62

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX LE, 2014 Apex XTX

- LOCATION

- Illinois

Ok, thanks for the reply.

JayM

Expert

- Joined

- Oct 29, 2018

- Messages

- 476

- Age

- 44

- Location

- Pickering, ON

- Country

- Canada

- Snowmobile

- 2017 Sidewinder R-TX SE

Anyone in the Toronto area have a Hurricane Clutch Alignment Tool? My sled is a new 2017 with 0km and I'm already changing primary/secondary rollers/spring/glide washer and I would like to check the alignment before the season starts. I'm all up for spending $$ but my sled mod budget is extremely in the negative so I would be willing to pay and "rent" one if someone has one?

Similar threads

- Replies

- 48

- Views

- 6K

- Replies

- 4

- Views

- 1K

- Replies

- 0

- Views

- 2K

- Replies

- 1

- Views

- 747

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.