Jd2859

Extreme

- Joined

- Dec 2, 2019

- Messages

- 59

- Reaction score

- 12

- Points

- 218

- Location

- La Crosse,Wisconsin

- Country

- USA

- Snowmobile

- 2020 sidewinder LTX GT

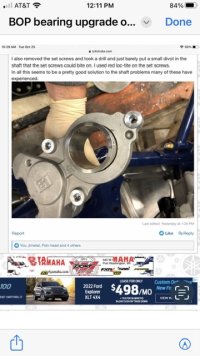

finally got around to taking the skid out and checking the drive shaft bearing.. sled is a 2020 with 1800 miles all stock for the first 800 miles then did a 240 tune for the rest of the miles but I have been building this thing all summer and now have around 350hp so I figured it’s a good time to really inspect this thing drive shaft shows little to no wear I measured the drive shaft and I’m getting 1.764 and the inner race is 1.765 but the back of the rotor tells me that the shaft has been spinning from seeing previous posts but maybe it just started I can’t Quiet catch the groove with my finger nail what you guys think I did get a Bop shaft saver so that will be going in