SeX Viper

Extreme

- Joined

- Mar 22, 2017

- Messages

- 52

- Reaction score

- 24

- Points

- 358

- Location

- Minnetonka, MN

- Country

- USA

- Snowmobile

- 2002 SX Viper

2014 SR Viper RTX

I have to imagine it goes on the tunnel side so you are pushing the grease in towards the brake rotor, that seems like a problem to me. Or is there a relief built into it so the old grease purges somewhere else?

twyztid

VIP Member

- Joined

- Feb 14, 2011

- Messages

- 1,034

- Reaction score

- 520

- Points

- 1,478

- Location

- Middleville, MI

- Country

- USA

- Snowmobile

- 2025 Sidewinder LTX LE EPS

2017 Sidewinder LTX SE

2012 Apex XTX

2012 RS Vector LTX

- LOCATION

- Middleville, MI

Be careful with that Greaser for the Procross chassis. I bought one at the Novi show last November without the bearing because I didn't want the China bearing (I used an NTN bearing that I put the grease holes in). I installed it without too much issue but removed it before ever riding with it. The foam used on the plate that is inside the tunnel is too thick (3/8") and doesn't allow you to properly torque the 3 bolts that thread into the caliper. It's kind of the same reason that you can't properly torque anything that has rubber sandwiched between it. I torqued all 3 bolts to the factory spec of 25 ft-lbs. The next day I checked them and they all need more to be torqued to 25 ft-lbs again. The following day, I checked it again and the same thing. At that point I removed the kit and put in a new NTN bearing in. If those bolts come loose, you will severely damage your tunnel from the slop.

I had inquired about having them made with thinner foam for the inside plate or, even better, having the foam cutout around the bolt holes. Was told they were going to look into it but I never heard back.

The bearing press works great... but that is all I will use from this kit. By cutting 2 zip ties loose, you can easily get enough brake line slack to be able to pull the caliper & rotor assembly without the need to split the caliper or remove the brake line. Because the press works so good, I will likely just replace the bearing every couple of seasons (I ride about 1500 miles per season)

I had inquired about having them made with thinner foam for the inside plate or, even better, having the foam cutout around the bolt holes. Was told they were going to look into it but I never heard back.

The bearing press works great... but that is all I will use from this kit. By cutting 2 zip ties loose, you can easily get enough brake line slack to be able to pull the caliper & rotor assembly without the need to split the caliper or remove the brake line. Because the press works so good, I will likely just replace the bearing every couple of seasons (I ride about 1500 miles per season)

YamaSpark

VIP Member

- Joined

- Sep 21, 2017

- Messages

- 120

- Reaction score

- 62

- Points

- 663

- Location

- Greenfield, Minnesota

- Country

- USA

- Snowmobile

- 2016 SR VIPER S-TX 137 DX

Yikes, that's not good.The foam used on the plate that is inside the tunnel is too thick (3/8") and doesn't allow you to properly torque the 3 bolts that thread into the caliper.

That must be the reason why most distributors no longer sell the Greaser for the Procross chassis, not even "thegreaser.net!

Rockmeister

TY Advertiser

- Joined

- Feb 7, 2007

- Messages

- 2,183

- Reaction score

- 209

- Points

- 1,383

- Location

- NE Indiana

- Website

- www.yamaheater.com

- Country

- USA

- Snowmobile

- 2007 Attak - LOVE my sled!!!

The seal mentioned was actually 1/4" thick, and per Kevins' & my conversation we made it 3/16" thick, just enough to actually seal the seal plate.

(Yours does look that thick, however 1/4 & now 3/16" is what we normally use)

Am sorry I hadn't had a chance to send you a new thinner one, was seriously swamped for the last few months & missed it.

The seal durometer is soft enough you can fully compress it between your fingers.

The mounting bolts easily compress it.

Myself & none of our testers had ever had the brake housing and/or bolts loosen and/or move at all.

Will do some additional testing with this in particular as we have NEVER seen this happen.

You can also easily cut the material off the seal near the bolts, that would eliminate any possible concerns.

The China produced bearing that was mentioned was actually tested for hardness & tolerance & did quite well!

Have one in my sled have put to very hard use for over 6000 miles & is still doing well, same with the seal mentioned, & the mounting bolts.

Have since replaced these bearings in the kits because of supply reasons, the quality was fine.

We must have a constant supply of quality parts to supply kits.

Unfortunately, using NTN/SKF etc becomes very problematic as many are popular to fake low quality bearings.

There is no guarantee you are getting what you think you are.

No matter what we sell, it needs to hold up, using a low quality bearing would be shooting ourselves in the foot.

Have seen many fake parts & they cause all kinds of problems, the last thing we want is a fake bearing causing an issue.

(Motion Industries, a major US bearing supplier was even sued for distributing fake bearings)

We would rather use a better one with better tolerances than stock, therefore we have been using ORS Bearings as they are good quality manufactured with KOYO equipment & less likely to be faked.

Have researched this heavily as I had myself run into fake SKF & MOOG bearings & wanted no issues with these in our products.

Invested quite a bit of time eliminating possible issues with the seals, bearings & installation.

Hope this helps!

RockMeister

PS Jerry with thegreaser.net simply hasn't had a chance to add the Grease It to his website. He does have & does sell them.

(Yours does look that thick, however 1/4 & now 3/16" is what we normally use)

Am sorry I hadn't had a chance to send you a new thinner one, was seriously swamped for the last few months & missed it.

The seal durometer is soft enough you can fully compress it between your fingers.

The mounting bolts easily compress it.

Myself & none of our testers had ever had the brake housing and/or bolts loosen and/or move at all.

Will do some additional testing with this in particular as we have NEVER seen this happen.

You can also easily cut the material off the seal near the bolts, that would eliminate any possible concerns.

The China produced bearing that was mentioned was actually tested for hardness & tolerance & did quite well!

Have one in my sled have put to very hard use for over 6000 miles & is still doing well, same with the seal mentioned, & the mounting bolts.

Have since replaced these bearings in the kits because of supply reasons, the quality was fine.

We must have a constant supply of quality parts to supply kits.

Unfortunately, using NTN/SKF etc becomes very problematic as many are popular to fake low quality bearings.

There is no guarantee you are getting what you think you are.

No matter what we sell, it needs to hold up, using a low quality bearing would be shooting ourselves in the foot.

Have seen many fake parts & they cause all kinds of problems, the last thing we want is a fake bearing causing an issue.

(Motion Industries, a major US bearing supplier was even sued for distributing fake bearings)

We would rather use a better one with better tolerances than stock, therefore we have been using ORS Bearings as they are good quality manufactured with KOYO equipment & less likely to be faked.

Have researched this heavily as I had myself run into fake SKF & MOOG bearings & wanted no issues with these in our products.

Invested quite a bit of time eliminating possible issues with the seals, bearings & installation.

Hope this helps!

RockMeister

PS Jerry with thegreaser.net simply hasn't had a chance to add the Grease It to his website. He does have & does sell them.

YamaSpark

VIP Member

- Joined

- Sep 21, 2017

- Messages

- 120

- Reaction score

- 62

- Points

- 663

- Location

- Greenfield, Minnesota

- Country

- USA

- Snowmobile

- 2016 SR VIPER S-TX 137 DX

Thanks Rock.The seal mentioned was actually 1/4" thick, and per Kevins' & my conversation we made it 3/16" thick, just enough to actually seal the seal plate.

(Yours does look that thick, however 1/4 & now 3/16" is what we normally use)

Am sorry I hadn't had a chance to send you a new thinner one, was seriously swamped for the last few months & missed it.

The seal durometer is soft enough you can fully compress it between your fingers.

The mounting bolts easily compress it.

Myself & none of our testers had ever had the brake housing and/or bolts loosen and/or move at all.

Will do some additional testing with this in particular as we have NEVER seen this happen.

You can also easily cut the material off the seal near the bolts, that would eliminate any possible concerns.

The China produced bearing that was mentioned was actually tested for hardness & tolerance & did quite well!

Have one in my sled have put to very hard use for over 6000 miles & is still doing well, same with the seal mentioned, & the mounting bolts.

Have since replaced these bearings in the kits because of supply reasons, the quality was fine.

We must have a constant supply of quality parts to supply kits.

Unfortunately, using NTN/SKF etc becomes very problematic as many are popular to fake low quality bearings.

There is no guarantee you are getting what you think you are.

No matter what we sell, it needs to hold up, using a low quality bearing would be shooting ourselves in the foot.

Have seen many fake parts & they cause all kinds of problems, the last thing we want is a fake bearing causing an issue.

(Motion Industries, a major US bearing supplier was even sued for distributing fake bearings)

We would rather use a better one with better tolerances than stock, therefore we have been using ORS Bearings as they are good quality manufactured with KOYO equipment & less likely to be faked.

Have researched this heavily as I had myself run into fake SKF & MOOG bearings & wanted no issues with these in our products.

Invested quite a bit of time eliminating possible issues with the seals, bearings & installation.

Hope this helps!

RockMeister

PS Jerry with thegreaser.net simply hasn't had a chance to add the Grease It to his website. He does have & does sell them.

I assume that installation of the Greaser requires removal of the driveshaft?

I'm still not clear on how this works on the procross. Do you have any pictures or installation instructions?

Thanks!

Rockmeister

TY Advertiser

- Joined

- Feb 7, 2007

- Messages

- 2,183

- Reaction score

- 209

- Points

- 1,383

- Location

- NE Indiana

- Website

- www.yamaheater.com

- Country

- USA

- Snowmobile

- 2007 Attak - LOVE my sled!!!

Thanks Rock.

I assume that installation of the Greaser requires removal of the driveshaft?

I'm still not clear on how this works on the procross. Do you have any pictures or installation instructions?

Thanks!

You are welcome!

No, you do not have to remove the driveshaft.

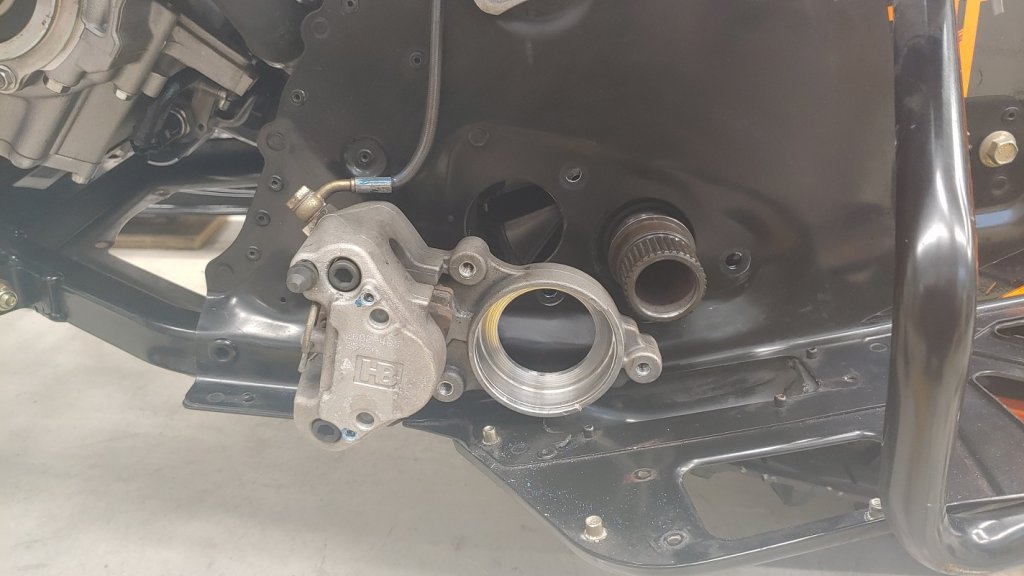

You basically remove the items around the brake:

The Secondary clutch, Footwell guard, etc.

Then remove the Brake Housing, Rotor Etc.

Do suggest loosening your track so it is not pulling back on your driveshaft as you work with it.

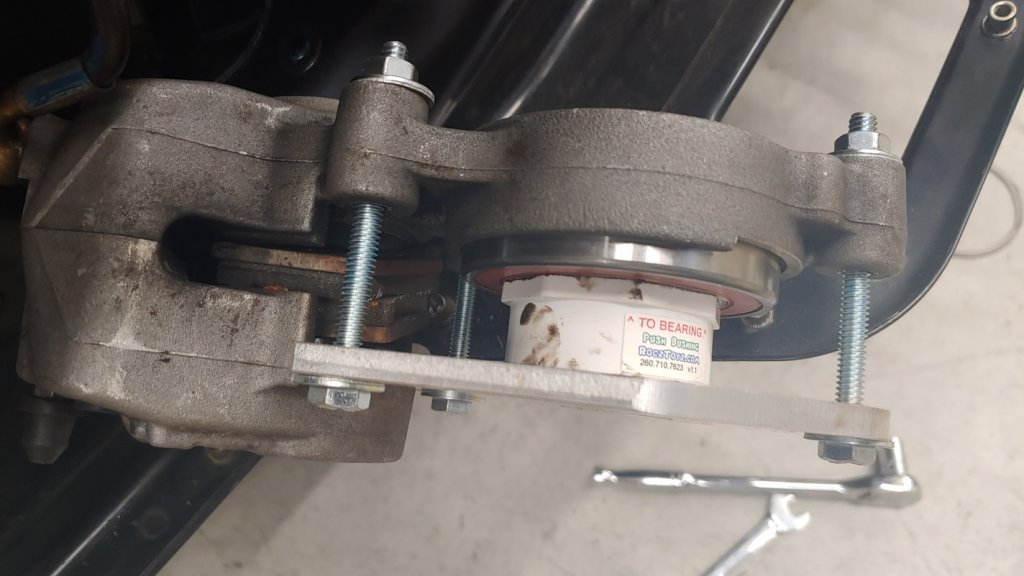

Use the included Bearing press to remove the existing bearing & Install the new one.

You do NOT have to break the seal on your brake system.

That way you have no mess with the brake fluid & you do not have to purge/bleed your brakes.

Re-assemble in the reverse order & you are on your way!

Can send me a PM or email & will send you a copy of the directions.

Hope this helps!

Rock

Kkurz

Expert

- Joined

- Nov 1, 2016

- Messages

- 394

- Reaction score

- 161

- Points

- 388

- Location

- Peterborough On.

- Country

- Canada

- Snowmobile

- 2014 XF7000 Sno-Pro Limited

(Yamaha powered)

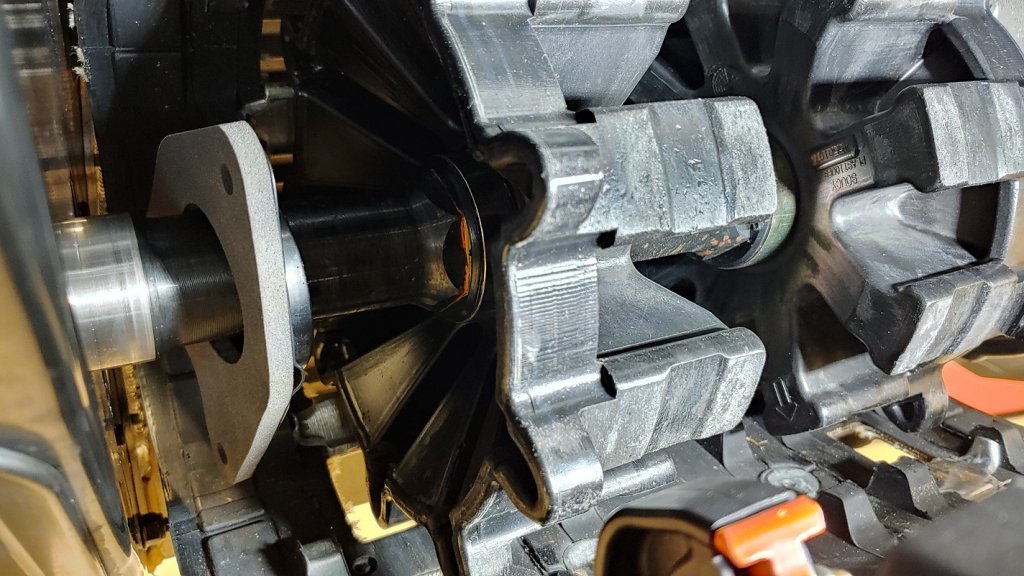

That's what I did, I slid a piece of threaded rod into the shaft and used the to shove it all on. It went very slick. I was even able to get the rod out of the shaft without cutting it.It’s best to install a bearing on shaft by only pushing on inner race. Could use puller and piece of pipe over shaft to do this nicely if heated bearing isn’t enough.

I had access to a lathe, so I could make a piece of pipe to shove on the inner race.

Upon further inspection, I see my shaft had been built up with weld and the inner race doesn't move on it. I'll take that all day.

Kkurz

Expert

- Joined

- Nov 1, 2016

- Messages

- 394

- Reaction score

- 161

- Points

- 388

- Location

- Peterborough On.

- Country

- Canada

- Snowmobile

- 2014 XF7000 Sno-Pro Limited

(Yamaha powered)

It's a great kit!!!You are welcome!

No, you do not have to remove the driveshaft.

You basically remove the items around the brake:

The Secondary clutch, Footwell guard, etc.

Then remove the Brake Housing, Rotor Etc.

Do suggest loosening your track so it is not pulling back on your driveshaft as you work with it.

Use the included Bearing press to remove the existing bearing & Install the new one.

You do NOT have to break the seal on your brake system.

That way you have no mess with the brake fluid & you do not have to purge/bleed your brakes.

Re-assemble in the reverse order & you are on your way!

Can send me a PM or email & will send you a copy of the directions.

Hope this helps!

Rock

srvfan

Expert

- Joined

- Nov 9, 2004

- Messages

- 487

- Reaction score

- 83

- Points

- 888

I just installed this kit today mine was different Fromm the pics above it did not have the inner seal just a tube of RTV for that .

Evrything went together well. The bearing press worked great.

Exscuse my ignorance but I don’t Understand how the grease will get into the bearing? The bearing that comes with the kit has a seal on the inside . I would think that it just fills the rear cup area around the shaft with grease and locks out moisture ?.

Evrything went together well. The bearing press worked great.

Exscuse my ignorance but I don’t Understand how the grease will get into the bearing? The bearing that comes with the kit has a seal on the inside . I would think that it just fills the rear cup area around the shaft with grease and locks out moisture ?.

Rockmeister

TY Advertiser

- Joined

- Feb 7, 2007

- Messages

- 2,183

- Reaction score

- 209

- Points

- 1,383

- Location

- NE Indiana

- Website

- www.yamaheater.com

- Country

- USA

- Snowmobile

- 2007 Attak - LOVE my sled!!!

Sorry, just saw this posting, so am replying now.

Yes, we changed the inner seal to an RTV seal & included Blue Loctite for the bolts.

That way the Mounting bolts clamp on the factory surfaces.

(We also have an update kit for anyone that purchased one WITH the inner seal, contact me & will get you taken care of.)

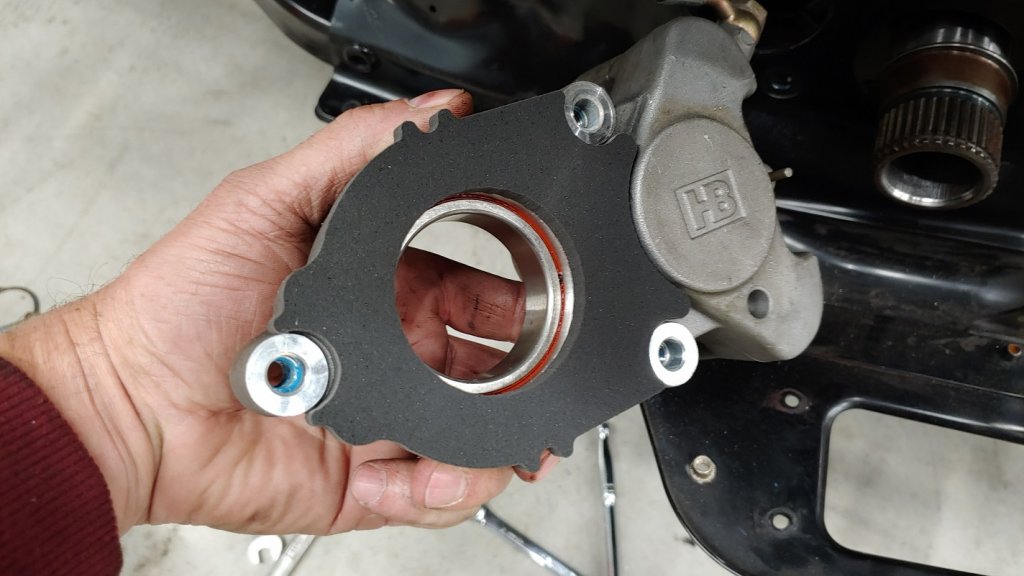

The inner seal on the bearing has Red Marks and tiny grease metering holes in it.

They are very small and towards the inner race.

This is why you must install the Red Marked side of the bearing towards the tunnel.

You do NOT want to remove the inner grease seal.

Rock

Yes, we changed the inner seal to an RTV seal & included Blue Loctite for the bolts.

That way the Mounting bolts clamp on the factory surfaces.

(We also have an update kit for anyone that purchased one WITH the inner seal, contact me & will get you taken care of.)

The inner seal on the bearing has Red Marks and tiny grease metering holes in it.

They are very small and towards the inner race.

This is why you must install the Red Marked side of the bearing towards the tunnel.

You do NOT want to remove the inner grease seal.

Rock

Similar threads

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.