Torquezilla

Newbie

Td multi map, the electronics will bring boost down to where it needs to be but you will see that spike your after.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,682

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

You do this on pump gas (91)? I see you also have a waste gate "lock"? Looks like one from PEFI that I use but I would never use it on pump gas. I pump out all pump gas and switch to C16. Use lock shimmed to .030". Boost is about 28-29 psi. PEFI Stage 3R. Takes 92 grams per arm to hold 8600-8650 RPM.View attachment 174114this is how I achieve more boost by adding an external spring to the waste gate arm, unconventional but does work

0degC

Expert

- Joined

- Jun 5, 2009

- Messages

- 214

- Location

- Sudbury, Ontario

- Country

- Canada

- Snowmobile

- 2023 SRX, 2017 XF 9000

Yes it would seem your waist gate spring is on the weak side. They can very quite a bit sled to sled. Even if you had race tune you likely would not go more than 20. You could shim the waist gate a touch or install a different waist gate.

max rolph

Expert

- Joined

- Feb 10, 2021

- Messages

- 455

- Age

- 61

- Location

- horse shoe valley

- Country

- Canada

- Snowmobile

- 998 turbo

i have the aftermarket TD timer and actuator, using the good aluminum mity vac, im at 11 for it to move rod but it doesnt hold pressure.... it very slowly leeks dwn.... is this normal? i have plugged the pump and it will hold presure.... so somewhere in the actuator is loosing presure. is this very detrimental... it very slow leek dwn

0degC

Expert

- Joined

- Jun 5, 2009

- Messages

- 214

- Location

- Sudbury, Ontario

- Country

- Canada

- Snowmobile

- 2023 SRX, 2017 XF 9000

Don’t think should leak down? But under operation don’t think would have any effect if just a slow leak.i have the aftermarket TD timer and actuator, using the good aluminum mity vac, im at 11 for it to move rod but it doesnt hold pressure.... it very slowly leeks dwn.... is this normal? i have plugged the pump and it will hold presure.... so somewhere in the actuator is loosing presure. is this very detrimental... it very slow leek dwn

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,835

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Would be nice if someone had a sled from the earlier years sitting next to a brand new one and could tested both with the same tester.

Or even if anyone has a wastegate from an earlier sidewinder sitting on the self id buy just to test against mine.

Wanted to get back to you that I have checked my 23 crack pressure this week, and it has same 9 lb crack pressure as my 17, so no change there.

Jondmdp

Veteran

- Joined

- Mar 28, 2021

- Messages

- 25

- Age

- 33

- Location

- Pennsylvania

- Country

- USA

- Snowmobile

- 02 Mach Z

22 SRX

25 SRX

Thanks for doing so! I haven’t messed with it lately, once we see some snow fly I’ll get back to tinkering on it. Gonna test crack pressure with another gauge or 2 to verify my numbers are accurate. I will report back whenever I get around to doing soWanted to get back to you that I have checked my 23 crack pressure this week, and it has same 9 lb crack pressure as my 17, so no change there.

Doc Harley

TY 4 Stroke God

- Joined

- Oct 17, 2016

- Messages

- 3,711

- Age

- 56

- Location

- Here & there

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX SE

Would someone be so kind as to explaining the why & how to check crack pressure. .

Lack of snow keeps me tinkering.

Lack of snow keeps me tinkering.

Last edited:

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,835

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

Put air pressure on the wastegate port with a gauge attached to see the moment it starts to crack open as you raise the pressure slowly using a pressure regulator. I use a dial indicator on the very end of the actuator rod to make sure its exact and perfect.Would someone be so kind as to explaining the why & how to check crack pressure. .

Lack of snow keeps me tinkering.

Why do it? No reason if you don't know what you are doing or wanting to doo with the information.... In other words, only need to check it if you suspect a problem or want to do some custom tuning stuff or playing with boost levels and/or when the boost hits. The tune in the ECU controls the boost anyway and any playing could and probably will lead to hitting the boost cut for the average tune. You need to know what you are doing and the repercussions when you start playing, It's more for the advanced tuner when you start playing with tunes and waste gates. Usually not a problem with canned tunes unless it's a leaking diaphragm and cracking open too early or at too low of boost.

Doc Harley

TY 4 Stroke God

- Joined

- Oct 17, 2016

- Messages

- 3,711

- Age

- 56

- Location

- Here & there

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX SE

Right on......Put air pressure on the wastegate port with a gauge attached to see the moment it starts to crack open as you raise the pressure slowly using a pressure regulator. I use a dial indicator on the very end of the actuator rod to make sure its exact and perfect.

Why do it? No reason if you don't know what you are doing or wanting to doo with the information.... In other words, only need to check it if you suspect a problem or want to do some custom tuning stuff or playing with boost levels and/or when the boost hits. The tune in the ECU controls the boost anyway and any playing could and probably will lead to hitting the boost cut for the average tune. You need to know what you are doing and the repercussions when you start playing, It's more for the advanced tuner when you start playing with tunes and waste gates. Usually not a problem with canned tunes unless it's a leaking diaphragm and cracking open too early or at too low of boost.

Jondmdp

Veteran

- Joined

- Mar 28, 2021

- Messages

- 25

- Age

- 33

- Location

- Pennsylvania

- Country

- USA

- Snowmobile

- 02 Mach Z

22 SRX

25 SRX

Back with an update. I bought another new “mightyvac” brand pump to back up results of my testing with my old matco pump.Wanted to get back to you that I have checked my 23 crack pressure this week, and it has same 9 lb crack pressure as my 17, so no change there.

I’m still seeing 7psi crack pressure.

7psi- wastegate arm moves .005 inch. So I’m considering that to be “cracked”

I take it up to 9psi, wastegate arm moves .085 inch.

I know I saw a post where you said you used a dial indicator to be precise, what are you considering “crack point” to be?

I’m thinking I’m going to shim the actuator mount slightly till I see 9psi at .005 travel, put some VP in it, and log some runs. Starting on low tune to compare boost

Attachments

KnappAttack

24X ISR World Drag Racing Champion

- Joined

- Feb 19, 2004

- Messages

- 4,835

- Location

- Welch MN

- Country

- USA

- Snowmobile

- 2023 Sidewinder LTX-LE

2017 Sidewinder LTX-LE

I see .002" to be crack pressure, just a bit more pressure moves the arm many thousands and movement that really move the arm.

Sounds like you are doing it accurately, so I'd say you are spot on. I've never seen crack that low before.

Sounds like you are doing it accurately, so I'd say you are spot on. I've never seen crack that low before.

Jondmdp

Veteran

- Joined

- Mar 28, 2021

- Messages

- 25

- Age

- 33

- Location

- Pennsylvania

- Country

- USA

- Snowmobile

- 02 Mach Z

22 SRX

25 SRX

I’ll report back when i get a minute to shim it up and do some test blastsI see .002" to be crack pressure, just a bit more pressure moves the arm many thousands and movement that really move the arm.

Sounds like you are doing it accurately, so I'd say you are spot on. I've never seen crack that low before.

Jondmdp

Veteran

- Joined

- Mar 28, 2021

- Messages

- 25

- Age

- 33

- Location

- Pennsylvania

- Country

- USA

- Snowmobile

- 02 Mach Z

22 SRX

25 SRX

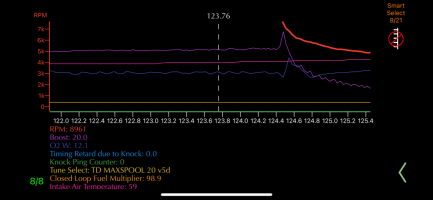

Update- I shimmed wastegate actuator .110 inch (2 washers I had) crack pressure now at 9.5psi. Ecotrail tune settled into 14psi like before. Max spool 20 tune made 19.7 to 20.3 (very short passes). Still no spike at the beginning of the run like I hear others say they see. AFR and fuel multiplier look all to be in check. Before I would struggle to see 19 on a long pass. I’ll get it out this evening and make some long smooth passes and do some more logs, But finally found that missing boost!I see .002" to be crack pressure, just a bit more pressure moves the arm many thousands and movement that really move the arm.

Sounds like you are doing it accurately, so I'd say you are spot on. I've never seen crack that low before.

Attachments

Simplespeed

TY 4 Stroke Junkie

- Joined

- Jan 8, 2022

- Messages

- 606

- Age

- 66

- Location

- 1191 Sauk Lane , Saginaw, Mi. 48638

- Country

- USA

- Snowmobile

- 2006 Apex , 2017 Sidewinder LTX -LE

How much increased performance are you experiencing after adding washers…

Similar threads

- Replies

- 12

- Views

- 4K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.