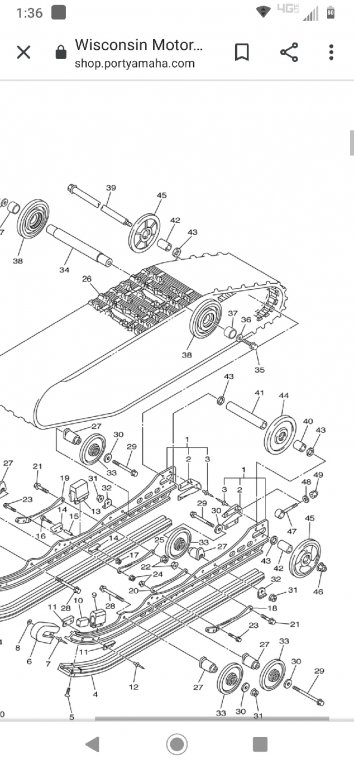

Here is the parts fiche

rkkoeb

Expert

Yep I think this is the way I have mine setup

RobX-1

VIP Member

- Joined

- Apr 13, 2003

- Messages

- 2,229

- Location

- Coldwater, OH

- Country

- USA

- Snowmobile

- 18 50th Apex XT-X, 08 40th Apex LTX GT, 08 40th Nytro RTX, & 03 RX-1

So from left to right (inside the rails) mine is setup as follows:

Adjustment bolt - Washer - Small sleeve - Bogie wheel - Large sleeve - washer - adjustment bolt

Rick

I have my skid out and just double checked and I believe that washer you have listed after the adjustment bolt is incorrect; it should be before the adjustment bolt so the order should be

Washer + Adjustment Bolt + Small Sleeve + Bogie Wheel + Large Sleeve + Adjustment Bolt + Washer

rkkoeb

Expert

There are 4 washers total. Two goes on the outside part of the skid and I think two inside

RobX-1

VIP Member

- Joined

- Apr 13, 2003

- Messages

- 2,229

- Location

- Coldwater, OH

- Country

- USA

- Snowmobile

- 18 50th Apex XT-X, 08 40th Apex LTX GT, 08 40th Nytro RTX, & 03 RX-1

Correct, I was only focusing on the inside of the rails. The two washers for the outer idler wheels go against the rail and before the small spacer and idler wheel.

I think what makes the microfiche misleading is that it appears to show the washer before the adjustment bolt. However, if you look closely, the line used to show the path of the rear axle bolt does not go through the adjustment bolt bracket which is where the rear axle bolt will go thru the loop on the adjustment bolt. This makes it appear the washer goes before the adjustment bolt bracket/adjustment bolt. When I went out and checked this, not only did I check this on my 08 Apex, but it is this way on my 18 Apex as well.

I think what makes the microfiche misleading is that it appears to show the washer before the adjustment bolt. However, if you look closely, the line used to show the path of the rear axle bolt does not go through the adjustment bolt bracket which is where the rear axle bolt will go thru the loop on the adjustment bolt. This makes it appear the washer goes before the adjustment bolt bracket/adjustment bolt. When I went out and checked this, not only did I check this on my 08 Apex, but it is this way on my 18 Apex as well.

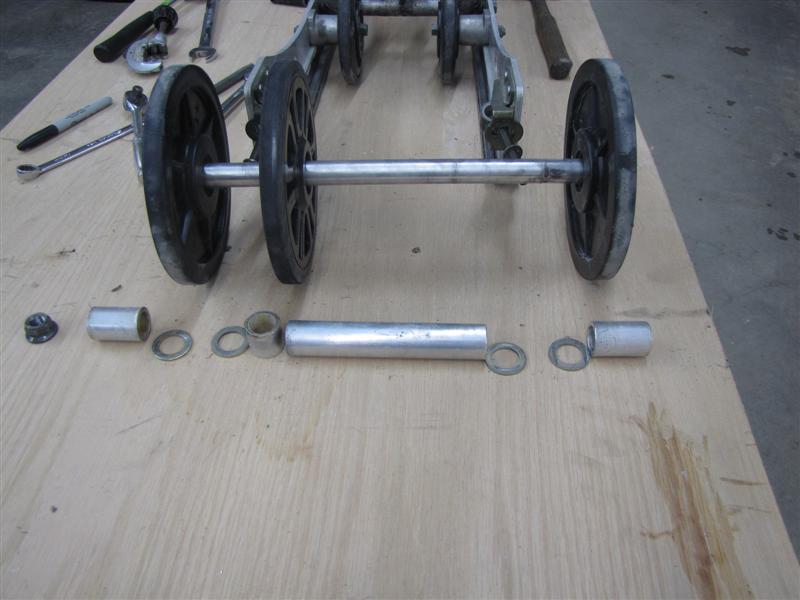

Here is the order of washers and spacers for the rear axle.

RobX-1

VIP Member

- Joined

- Apr 13, 2003

- Messages

- 2,229

- Location

- Coldwater, OH

- Country

- USA

- Snowmobile

- 18 50th Apex XT-X, 08 40th Apex LTX GT, 08 40th Nytro RTX, & 03 RX-1

Using Steiner's picture to help explain this, line #1 would be the driver side rail, line #2 would be the driver side adjustment bolt loop, line #3 would be the passenger side adjustment bolt loop and line #4 would be the passenger side rail.

rkkoeb

Expert

so based on this the washer would go up against the adjustment bolt loop

rkkoeb

Expert

Adjustment bolt loop - washer - small spacer - bogie wheel - large spacer - washer - adjustment bolt loop

RobX-1

VIP Member

- Joined

- Apr 13, 2003

- Messages

- 2,229

- Location

- Coldwater, OH

- Country

- USA

- Snowmobile

- 18 50th Apex XT-X, 08 40th Apex LTX GT, 08 40th Nytro RTX, & 03 RX-1

After posting my edited picture, I noticed I had my lines incorrectly drawn so corrected and updated the post.

It looks like the washers are there on each side of the slide frame to provide a flat surface for the aluminum collars(and adjusters) to butt up against, but your washers were still in the right sections so the spacing was OK, so it must be another reason for your track getting chewed.

Last edited:

rkkoeb

Expert

my original rear shaft was bad, had a spun bearing on it, so I picked up a complete used unit. Maybe it is the wrong size? Maybe the small spacer is the wrong size?

Washers go on the skid rails. This prevents the spacers from digging into the rails and allows the adjusters to slide on the rails when adjusting track tension.

rkkoeb

Expert

my adjuster sits in a channel so not sure if the washer would fit in this area

Similar threads

- Replies

- 3

- Views

- 810

- Replies

- 3

- Views

- 942

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.