ryetarded

Pro

I had a circuit short on me early last season it melted my grip and glove and then went cold ...about a month later my other grip failed and left both hand s cold but the thumb warmer "worked" Lucky i was riding a week long ride in minus 30 C

Crewchief47

Lifetime Member

- Joined

- Jan 16, 2006

- Messages

- 2,830

- Location

- McGregor, ON Canada

- Country

- Canada

- Snowmobile

- 2008 Nytro MTX 45th

Just some musing I've had.

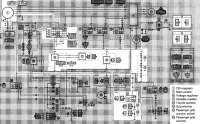

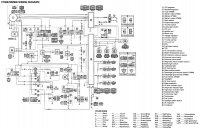

I was out in the garage last night and had a look over the old smoker grip warmers. The grips were in series at around 7.5 ohms and the variable resistor went from 0.5 ohms(low) to .5 Kohms(high.

Now if I understand the schematic, the variable is wired in parallel? Is there any way this could work? The resistor was around $35 on Ports fiche. Perhaps adding the resistor on a seperate circuit and fooling the ECU with resistors to eliminate the error code?

I was out in the garage last night and had a look over the old smoker grip warmers. The grips were in series at around 7.5 ohms and the variable resistor went from 0.5 ohms(low) to .5 Kohms(high.

Now if I understand the schematic, the variable is wired in parallel? Is there any way this could work? The resistor was around $35 on Ports fiche. Perhaps adding the resistor on a seperate circuit and fooling the ECU with resistors to eliminate the error code?

Attachments

BLUEBALLER

Expert

- Joined

- Jan 29, 2005

- Messages

- 420

Can you measure the resistance of your thumbwarmer for me?

Is the resistance of 7.5 ohms per grip or is that for both of them?

My warmers were in series on my SXR as well. I'm pretty sure the ol two smokes ran 13.8 - 14V off the voltage regulator.

Also - can you remove your kitchen tablecloth so I can see the whole schematic. kidding, lol

Is the resistance of 7.5 ohms per grip or is that for both of them?

My warmers were in series on my SXR as well. I'm pretty sure the ol two smokes ran 13.8 - 14V off the voltage regulator.

Also - can you remove your kitchen tablecloth so I can see the whole schematic. kidding, lol

Crewchief47

Lifetime Member

- Joined

- Jan 16, 2006

- Messages

- 2,830

- Location

- McGregor, ON Canada

- Country

- Canada

- Snowmobile

- 2008 Nytro MTX 45th

BLUEBALLER said:Can you measure the resistance of your thumbwarmer for me?

Is the resistance of 7.5 ohms per grip or is that for both of them?

My warmers were in series on my SXR as well. I'm pretty sure the ol two smokes ran 13.8 - 14V off the voltage regulator.

Also - can you remove your kitchen tablecloth so I can see the whole schematic. kidding, lol

Thumb warmer was 72 Ohms? (seemed a little high)

That was both grips in series. They meassured around 3.8 each if I recall.

I'll update the schematic, just for you! Thought you would like the table cloth.

Has anyone just wired the grips in parallel? I did that on my warrior and they were awesome! Sure you couldn't run them on full bars or you would blow the fuse, but you would only have to run 2-3 bars on the gauge and your hands were nice and toasty. Anyone try this on the Nytro? Thanks.

What about the possibility of using the power outlets power???

Nytro warmers are already in parallel.kkraus said:Has anyone just wired the grips in parallel? I did that on my warrior and they were awesome! Sure you couldn't run them on full bars or you would blow the fuse, but you would only have to run 2-3 bars on the gauge and your hands were nice and toasty. Anyone try this on the Nytro? Thanks.

doczap

Newbie

Man I can't believe that Yamaha has not done anything for this yet. Between this issue and the long list (not going to air here but I'm sure you all have a similar list) I decided to ditch mine. How ridiculous is it to spend over 10 grand on something that you have to do engineering work on? My kid loves his Phazer or I would send that thing down the road too just on principle. Good luck guys...

Rockmeister

TY Advertiser

- Joined

- Feb 7, 2007

- Messages

- 2,182

- Location

- NE Indiana

- Website

- www.yamaheater.com

- Country

- USA

- Snowmobile

- 2007 Attak - LOVE my sled!!!

Am a EE and have been working on a few things to help make warm hands a much simpler fix if possible.

With what I have seen, the target total resistance you want to shoot for on your sled for warm hands is 3 to 3.5 Ohms Total.

Meaning if you wire them in series the warmers should be 1.5 to 1.75 Ohms each for a total of 3.0 to 3.5 Ohms.

If you wire them in Parallel, you need a starting resistance of 6 to 7.5 ohms each warmer for a total of 3.0 to 3.5 Ohms.

With a total resistance or 3.0 or above, you are with-in factory load specs and are very unlikely to hurt the ECU, and still have warm hands!

Try to avoid using series resistors if possible, they will waste energy that is still used up from the charging circuit, but have no warming benefit to your hands.

You are much better off wiring them in a configuration that will not use a series resistor if possible, and will still have a total resistance of 3+ Ohms to protect the ECU.

Currently have the '06 updated Apex bars on my '05 Warrior/Rx-1.

'05 Warrior bars (Reasonably warm)

1.75 Ohms each

3.5 Ohms Wired in Series per factory

'06 Updated Apex Bars (Reasonably warm)

6.8 Ohms each

3.4 Ohms wired in Parallel with factory Apex update harness

Everyone that stated that the ECU output is a PWM signal is correct.

On my Warrior the warmer output sits at 10% Duty Cycle, at ANY setting above "off" until about 4000+ RPMs.

Above ~4000 RPMs, the output is changed roughly 10% Duty Cycle per step, up to near 100% on high.

This means at idle and slower speeds you only have 10% of the heat available to your hands NO MATTER WHAT THE HEAT IS SET TO!

If you take it easy on the trail, your hands will freeze!

This confirmed what I suspected, because the bars wouldn't warm well at Idle.

May have found a simple, cheap solution that doesn't involve changing your bars/warmers etc.

This is the factory waveform on low at Idle.

The Voltage per division(each line upward) is 5V.

Ground(0V) is the second line up from the bottom of the screen.

Was looking for a way to increase the output until the ECU does it itself with higher RPMS.

Thought of using a capacitor to help with this.

The capacitor charges(Stores energy) when possible (IE when the ECU output is on), and discharges(Gives back energy) when needed (When the ECU is off).

Tried multiple capacitor values and found about 1000 MFD(MicroFarad) 50V Capacitor(Cap) to work best.

Radio Shack Part number 272-1047 $2.59

This is an Electrolytic Capacitor and is Polarized.

The Cap MUST be connected + to positive and - to negative.

Wired the 1000 MFD in Parallel with the warmers.

This is the waveform with a 1000MFD Cap in Parallel with the warmers on low at Idle.

The volts per division is still 5V.

Ground is still 2 divisions up from the bottom.

The max voltage is approximately 13V at idle, the great thing is, the heaters are powered from the Capacitor when they are normally off.

The voltage eventually drops to about 4V minimum then the Cap starts charging again.

This makes a major difference at idle and at low speeds, the warmers actually warm pretty fast now!

Haven't been able to test on a trail yet, however my suspicion is that by having the heaters always on at least at a lowered level at idle and at lowered speeds, they will always tend to be much warmer.

I don't have an infared camera or thermometer so I am unable to give exact measurements.

Anyone with this equipment, could you please try adding a 1000 MFD cap and get some definable measurements for us?

With what I have seen, the target total resistance you want to shoot for on your sled for warm hands is 3 to 3.5 Ohms Total.

Meaning if you wire them in series the warmers should be 1.5 to 1.75 Ohms each for a total of 3.0 to 3.5 Ohms.

If you wire them in Parallel, you need a starting resistance of 6 to 7.5 ohms each warmer for a total of 3.0 to 3.5 Ohms.

With a total resistance or 3.0 or above, you are with-in factory load specs and are very unlikely to hurt the ECU, and still have warm hands!

Try to avoid using series resistors if possible, they will waste energy that is still used up from the charging circuit, but have no warming benefit to your hands.

You are much better off wiring them in a configuration that will not use a series resistor if possible, and will still have a total resistance of 3+ Ohms to protect the ECU.

Currently have the '06 updated Apex bars on my '05 Warrior/Rx-1.

'05 Warrior bars (Reasonably warm)

1.75 Ohms each

3.5 Ohms Wired in Series per factory

'06 Updated Apex Bars (Reasonably warm)

6.8 Ohms each

3.4 Ohms wired in Parallel with factory Apex update harness

Everyone that stated that the ECU output is a PWM signal is correct.

On my Warrior the warmer output sits at 10% Duty Cycle, at ANY setting above "off" until about 4000+ RPMs.

Above ~4000 RPMs, the output is changed roughly 10% Duty Cycle per step, up to near 100% on high.

This means at idle and slower speeds you only have 10% of the heat available to your hands NO MATTER WHAT THE HEAT IS SET TO!

If you take it easy on the trail, your hands will freeze!

This confirmed what I suspected, because the bars wouldn't warm well at Idle.

May have found a simple, cheap solution that doesn't involve changing your bars/warmers etc.

This is the factory waveform on low at Idle.

The Voltage per division(each line upward) is 5V.

Ground(0V) is the second line up from the bottom of the screen.

Was looking for a way to increase the output until the ECU does it itself with higher RPMS.

Thought of using a capacitor to help with this.

The capacitor charges(Stores energy) when possible (IE when the ECU output is on), and discharges(Gives back energy) when needed (When the ECU is off).

Tried multiple capacitor values and found about 1000 MFD(MicroFarad) 50V Capacitor(Cap) to work best.

Radio Shack Part number 272-1047 $2.59

This is an Electrolytic Capacitor and is Polarized.

The Cap MUST be connected + to positive and - to negative.

Wired the 1000 MFD in Parallel with the warmers.

This is the waveform with a 1000MFD Cap in Parallel with the warmers on low at Idle.

The volts per division is still 5V.

Ground is still 2 divisions up from the bottom.

The max voltage is approximately 13V at idle, the great thing is, the heaters are powered from the Capacitor when they are normally off.

The voltage eventually drops to about 4V minimum then the Cap starts charging again.

This makes a major difference at idle and at low speeds, the warmers actually warm pretty fast now!

Haven't been able to test on a trail yet, however my suspicion is that by having the heaters always on at least at a lowered level at idle and at lowered speeds, they will always tend to be much warmer.

I don't have an infared camera or thermometer so I am unable to give exact measurements.

Anyone with this equipment, could you please try adding a 1000 MFD cap and get some definable measurements for us?

NyTrOMaNIaC

TY 4 Stroke Master

NOW we're talkin !

Nice work, rockmeister Hopefully someone will be able to test your theory soon and report back with positive results

Hopefully someone will be able to test your theory soon and report back with positive results

Nice work, rockmeister

Hopefully someone will be able to test your theory soon and report back with positive results

Hopefully someone will be able to test your theory soon and report back with positive results

arteeex

TY 4 Stroke Master

You're about 15 pages late to the dance, but I can appreciate the input.

On the Nytro the 14V signal is interrupted to give something like a square wave. On HIGH and above 4500 RPM the signal is essentially constant at 14V as the time-off gaps close.

I get the idea for using the capacitor to provide "filler" voltage at lower settings and lower RPM, but with the charge and decay cycles is there actually a greater amount of energy (in Joules) expended per unit time? My guess would be that its pretty much the same if not lower, due to system loses.

Also, I think the contention is, even if you're running at 8000 RPM all day there simply isn't enough output from the stock heaters to do the job. Thus, the call for lower resistance heater elements that have been discussed.

I'd like to hear your opinion on this. Thanks.

On the Nytro the 14V signal is interrupted to give something like a square wave. On HIGH and above 4500 RPM the signal is essentially constant at 14V as the time-off gaps close.

I get the idea for using the capacitor to provide "filler" voltage at lower settings and lower RPM, but with the charge and decay cycles is there actually a greater amount of energy (in Joules) expended per unit time? My guess would be that its pretty much the same if not lower, due to system loses.

Also, I think the contention is, even if you're running at 8000 RPM all day there simply isn't enough output from the stock heaters to do the job. Thus, the call for lower resistance heater elements that have been discussed.

I'd like to hear your opinion on this. Thanks.

Rockmeister

TY Advertiser

- Joined

- Feb 7, 2007

- Messages

- 2,182

- Location

- NE Indiana

- Website

- www.yamaheater.com

- Country

- USA

- Snowmobile

- 2007 Attak - LOVE my sled!!!

arteeex said:You're about 15 pages late to the dance, but I can appreciate the input.

On the Nytro the 14V signal is interrupted to give something like a square wave. On HIGH and above 4500 RPM the signal is essentially constant at 14V as the time-off gaps close.

I get the idea for using the capacitor to provide "filler" voltage at lower settings and lower RPM, but with the charge and decay cycles is there actually a greater amount of energy (in Joules) expended per unit time? My guess would be that its pretty much the same if not lower, due to system loses.

Also, I think the contention is, even if you running at 8000 RPM all day there simply isn't enough output from the stock heaters to do the job. Thus, the call for lower resistance heater elements that have been discussed.

I'd like to hear your opinion on this. Thanks.

Actually the grips warm up MUCH faster at idle, so I know the amount of energy is greater, could take the time to calculate it but don't really want to. lol

You are correct above 1000MFD though, the cap will not fully charge with values above 1000 MFD.

My thinking is that the grips start out warmer from idle, being warmed much more throughout the RPM range and you don't have to wait until you are flying down the trail with cold fingers to wait for the warmers to finally kick in and try to keep up, let alone catch up when the wind chill and heat losses are at their greatest.

Actually the separate PWM box will do this also, but the cap is a much more cost effective thing to try.

Agree that lowering the resistance of the grips and raising the wattage is definitely effective.

Am just thinking this is worth a try without changing anything else.

BLUEBALLER

Expert

- Joined

- Jan 29, 2005

- Messages

- 420

I was high speed trail riding at -35C with Klim togwatee gloves, heat loc handguards and guantlets overtop. The engine rpms were over 5000 for miles on end. The stock grips DO NOT generate enough heat at those kinds of frigid temps. Hands were miserably cold.

Personally, the caps won't do what I need them to do. For southern riders that are riding in tight woods and are constantly on/off the gas and applying the brake frequently, then maybe. But up here in Canukistan, the trails are long & wide, the temps are bloody cold, and the handwarmers SUCK.

I'm not saying it won't work for the southern boys, I'm just saying it won't work for those that need it the most. my 0.02.

Personally, the caps won't do what I need them to do. For southern riders that are riding in tight woods and are constantly on/off the gas and applying the brake frequently, then maybe. But up here in Canukistan, the trails are long & wide, the temps are bloody cold, and the handwarmers SUCK.

I'm not saying it won't work for the southern boys, I'm just saying it won't work for those that need it the most. my 0.02.

jimmie d

TY 4 Stroke Master

Does anybody have a clue as to why Yamaha would have designed the circuit in this way must be a benefit somehow.

Jim

Jim

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.