ALEXR

Newbie

- Joined

- Mar 16, 2023

- Messages

- 17

- Location

- Toronto/Bracebridge, Ontario,

- Country

- Canada

- Snowmobile

- 2021 Yamaha Sidewinder LTX LE

Good day. Would a spun drive shaft bearing cause this on the upper idler wheel? It's only on the left side. It appears to be hitting the rear skid bolt nut. My bearing has clearly spun & getting it welded & turned down. Already have a new brake disc, bearing, PEFI shaft wedge, & upper wheel. My track is properly aligned & track tension is good.

Thanks in advance, Alex.

Thanks in advance, Alex.

Attachments

Sevey

TY 4 Stroke God

- Joined

- Feb 15, 2011

- Messages

- 1,748

- Location

- Collingwood, ON

- Website

- www.ty4stroke.com

- Country

- Canada

- Snowmobile

- 2018 Sidewinder RTX

My ten cents - these are two separate issues and not result of the shaft spinning.

For your drive shaft - Look into the new bearing with locking collar from Barn of Parts.

MS

For your drive shaft - Look into the new bearing with locking collar from Barn of Parts.

MS

ALEXR

Newbie

- Joined

- Mar 16, 2023

- Messages

- 17

- Location

- Toronto/Bracebridge, Ontario,

- Country

- Canada

- Snowmobile

- 2021 Yamaha Sidewinder LTX LE

Yaaa. Have no idea what caused it. Track tension & alignment were good. Thought about the BOP bearing, but prefer the drive shaft being welded & drive shaft wedge from nenew. Thx, Alex.

ALEXR

Newbie

- Joined

- Mar 16, 2023

- Messages

- 17

- Location

- Toronto/Bracebridge, Ontario,

- Country

- Canada

- Snowmobile

- 2021 Yamaha Sidewinder LTX LE

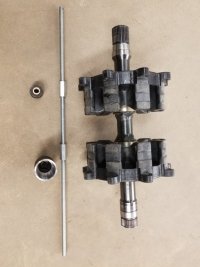

Here's a pic with the skid out. It certainly appears to be hitting the corner of the "nut" that holds the rear skid bolt through the torsion arm. Skid must be flexing to the left side somehow on acceleration or deceleration & gouging the idler wheel. Skid itself is in great shape with the Hurricane upper cross shaft & center shock shaft, skid bolts & track are tight & aligned. Thought perhaps the spun bearing is allowing the drive shaft to move just that much on accel or decel to make contact. Thx.

Attachments

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,486

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

For what it's worth, long ago I had my driveshaft welded, then turned and ground on center to facilitate pressing the bearings on. Since then, subjected to annual inspection, it has worked perfectly. Zero issues. I did not use a driveshaft saver of any kind. Shaft can't spin on shaft because it's pressed on. It has never moved. No need for shaft saver. BTW - my chain case side bearing is also pressed on. The shaft can (and does) spin in that bearing but never wears it out because it's submerged in oil.Yaaa. Have no idea what caused it. Track tension & alignment were good. Thought about the BOP bearing, but prefer the drive shaft being welded & drive shaft wedge from nenew. Thx, Alex.

ALEXR

Newbie

- Joined

- Mar 16, 2023

- Messages

- 17

- Location

- Toronto/Bracebridge, Ontario,

- Country

- Canada

- Snowmobile

- 2021 Yamaha Sidewinder LTX LE

Thank you for the reply Turboflash.

I've read about the chaincase bearing, but being bathed in oil is not an issue. As for the caliper side, should that bearing be an interferance fit once welded & ground down, or a press fit? I would imagine the wedge would just be insurance. Plus I already have it. Once the new bearing is in the caliper housing & placed on the drive shaft splines, should I lightly tap it in, then use the 3 mounting bolts to slowly seat it? That's what I did last season, but was easier to do with a spun bearing.

Also....any idea what caused the upper wheel gouging?

Thx again, Alex.

I've read about the chaincase bearing, but being bathed in oil is not an issue. As for the caliper side, should that bearing be an interferance fit once welded & ground down, or a press fit? I would imagine the wedge would just be insurance. Plus I already have it. Once the new bearing is in the caliper housing & placed on the drive shaft splines, should I lightly tap it in, then use the 3 mounting bolts to slowly seat it? That's what I did last season, but was easier to do with a spun bearing.

Also....any idea what caused the upper wheel gouging?

Thx again, Alex.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,486

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

I had my shaft journals ground in accordance with AFBMA (anti-friction bearing manufacturers association) specs.

To AFBMA, press fit and interference fit mean the same thing. In this case, the shaft diameter is slightly larger than the ID of the bearing.

For this size of bearing, AFBMA specs an interference of .0005 to .00075 between the shaft dia and bearing ID. That might not sound like much (or enough) but it is. My bearings have never moved on shaft. Keep in mind when one uses interference fit, the bearing internal clearance has to correct (in our case, C3 bearing clearance is specified in parts book as the oem bearing). When the bearing is pressed onto shaft, the force expands the bearing inner race a tiny bit and thereby reduces space between outer race and inner race. Of course the balls remain constant size. If the press fit uses up all internal clearance, there will be radial preload and the bearing will in minutes.

I built a special press tool to press bearings on. It's basically a multi-segment threaded rod with a special size deep socket that only pushes on inner race of bearing. I put the bearing into the caliper, then start assy onto shaft, then assy press tool through shaft (3 sections that thread into each other), then simply just tighten a hex nut with a thick washer under it that presses against back of the deep socket. I tighten nut, which presses caliper assy onto the journal on shaft until the caliper just touches side of tunnel. Stop, put the 3 bolts in. The idea is not axially load bearing either way (meaning bearing is in neutral position - not in too far, not out too far). When the 3 bolts are tightened, the caliper assy shouldn't move. If it does, assy wasn't pressed on tight enough.

Yes, the wedge would be just insurance but not needed.

As far as wheel rouges, without a closer inspection. IDK. Any chance you have or had a rivet in tunnel that was too long (might be broke off now)? The suspension moves up and down (in and out of tunnel). Something obviously hit it.

To AFBMA, press fit and interference fit mean the same thing. In this case, the shaft diameter is slightly larger than the ID of the bearing.

For this size of bearing, AFBMA specs an interference of .0005 to .00075 between the shaft dia and bearing ID. That might not sound like much (or enough) but it is. My bearings have never moved on shaft. Keep in mind when one uses interference fit, the bearing internal clearance has to correct (in our case, C3 bearing clearance is specified in parts book as the oem bearing). When the bearing is pressed onto shaft, the force expands the bearing inner race a tiny bit and thereby reduces space between outer race and inner race. Of course the balls remain constant size. If the press fit uses up all internal clearance, there will be radial preload and the bearing will in minutes.

I built a special press tool to press bearings on. It's basically a multi-segment threaded rod with a special size deep socket that only pushes on inner race of bearing. I put the bearing into the caliper, then start assy onto shaft, then assy press tool through shaft (3 sections that thread into each other), then simply just tighten a hex nut with a thick washer under it that presses against back of the deep socket. I tighten nut, which presses caliper assy onto the journal on shaft until the caliper just touches side of tunnel. Stop, put the 3 bolts in. The idea is not axially load bearing either way (meaning bearing is in neutral position - not in too far, not out too far). When the 3 bolts are tightened, the caliper assy shouldn't move. If it does, assy wasn't pressed on tight enough.

Yes, the wedge would be just insurance but not needed.

As far as wheel rouges, without a closer inspection. IDK. Any chance you have or had a rivet in tunnel that was too long (might be broke off now)? The suspension moves up and down (in and out of tunnel). Something obviously hit it.

Attachments

ALEXR

Newbie

- Joined

- Mar 16, 2023

- Messages

- 17

- Location

- Toronto/Bracebridge, Ontario,

- Country

- Canada

- Snowmobile

- 2021 Yamaha Sidewinder LTX LE

Appreciate your insight & experience Turboflash. I am familiar with axial bearing load. Local machinest/shop near me (Peak Performance) does the drive shaft machining & shock rebuilds, so he has experience with the ProCross chassis & what tolerance to turn it down to. I may have to make a similar jig to seat the assembly on the shaft. Hopefully it will go smooth.....

No rivets or anything else sticking out of the tunnel. If you look at the photo of the skid out, only thing I can see hitting, is the rear skid through nut. I ground down a 3/4"(?....can't remember exact size) wrench to fit on the nut between the upper wheel & torsion arm when tightening the bolt. It appears to match perfectly. Upper wheel spins & catches the corner of the nut. This is the second set of wheels that it has happened to. Thought my spun bearing was allowing the drive shaft to move just that much & allowing the skid to shift. Don't believe it's ice buildup as the right side is fine & the ice would chip off. Dunno.

No rivets or anything else sticking out of the tunnel. If you look at the photo of the skid out, only thing I can see hitting, is the rear skid through nut. I ground down a 3/4"(?....can't remember exact size) wrench to fit on the nut between the upper wheel & torsion arm when tightening the bolt. It appears to match perfectly. Upper wheel spins & catches the corner of the nut. This is the second set of wheels that it has happened to. Thought my spun bearing was allowing the drive shaft to move just that much & allowing the skid to shift. Don't believe it's ice buildup as the right side is fine & the ice would chip off. Dunno.

ALEXR

Newbie

- Joined

- Mar 16, 2023

- Messages

- 17

- Location

- Toronto/Bracebridge, Ontario,

- Country

- Canada

- Snowmobile

- 2021 Yamaha Sidewinder LTX LE

Upstater57

Lifetime Member

- Joined

- Apr 25, 2021

- Messages

- 542

- Age

- 66

- Location

- New York

- Country

- USA

- Snowmobile

- 2022 Tcat EPS,

2014 ZR9000 (sold)

1978,1979,1980 SRX (sold)

Makes me wonder if the wheel is not pressed on all the way and possibly hitting the track clips?Wheel is hitting this. Gouges seem to line up with it.

ALEXR

Newbie

- Joined

- Mar 16, 2023

- Messages

- 17

- Location

- Toronto/Bracebridge, Ontario,

- Country

- Canada

- Snowmobile

- 2021 Yamaha Sidewinder LTX LE

I see what you're saying Upstarter. I've changed that upper idler wheel on many AC sleds. Never had an issue. But....always a first time. So if its hitting the track clips, it's forcing the wheel over. It's a possibility. Here's the right side (no gouges) & both sides.

Attachments

Upstater57

Lifetime Member

- Joined

- Apr 25, 2021

- Messages

- 542

- Age

- 66

- Location

- New York

- Country

- USA

- Snowmobile

- 2022 Tcat EPS,

2014 ZR9000 (sold)

1978,1979,1980 SRX (sold)

Normally those wheels are almost a press fit and usually require a puller to take them off. Replacing the axle mount piece is a good idea. Normally once that is tightly installed it never moves. These sleds sometimes remind me of old big blocks. They find ways to break things. LOL

ALEXR

Newbie

- Joined

- Mar 16, 2023

- Messages

- 17

- Location

- Toronto/Bracebridge, Ontario,

- Country

- Canada

- Snowmobile

- 2021 Yamaha Sidewinder LTX LE

They are a pain to get off. Sled is at the cottage. Going to look when I get there. Appreciate the help. Thx, Alex.

Upstater57

Lifetime Member

- Joined

- Apr 25, 2021

- Messages

- 542

- Age

- 66

- Location

- New York

- Country

- USA

- Snowmobile

- 2022 Tcat EPS,

2014 ZR9000 (sold)

1978,1979,1980 SRX (sold)

Try to borrow a cat wheel puller if you can. The paint on the shaft makes it an interference fit. Good luck

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,062

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Use air hammer on inside bearing race after and wheel will be off in 3 seconds.

Similar threads

- Replies

- 21

- Views

- 35K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.