Snowmobileaddict

TY 4 Stroke Junkie

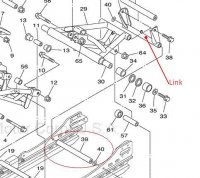

I am putting my rear skid back together and I am noticing a bit too much slop in the fitment of the aluminum shaft #39 in the photo below to the steel suspension link tube also shown in the photo below.

I find it strange that yamaha didn't use any nylon bushings at this location. It looks like after 6,000 miles, the aluminum cross shaft has worn out-of-round a bit. It just fits a bit loose (I.D. to O.D.) for my taste.

The good news is that the shaft is only a $20 part. Can anyone comment on how this shaft fits the suspension link tube when brand new?

I did a bit of forum searching and it seems when brand-new, folks had a difficult time injecting grease at this location because the fitment was snug and some miles had to go on for the shaft to wear-in a bit and allow for the assembly to readily accept grease. If that is the case, a new aluminum shaft will be just the ticket for me.

Thanks!

I find it strange that yamaha didn't use any nylon bushings at this location. It looks like after 6,000 miles, the aluminum cross shaft has worn out-of-round a bit. It just fits a bit loose (I.D. to O.D.) for my taste.

The good news is that the shaft is only a $20 part. Can anyone comment on how this shaft fits the suspension link tube when brand new?

I did a bit of forum searching and it seems when brand-new, folks had a difficult time injecting grease at this location because the fitment was snug and some miles had to go on for the shaft to wear-in a bit and allow for the assembly to readily accept grease. If that is the case, a new aluminum shaft will be just the ticket for me.

Thanks!

Attachments

Winderallday!

VIP Member

- Joined

- Dec 4, 2007

- Messages

- 588

- Reaction score

- 167

- Points

- 1,058

- Location

- SW, Ontario

- Country

- Canada

- Snowmobile

- 2018 Sidewinder DX

I agree it's curious why there are no bushings to take the wear, however, if a new shaft is only $20, it's likely the same cost as a pair of bushings. At least here in Canada, some suspension bushing are $12 each!

I believe by design there is likely close to 1mm diameter difference to allow grease to fill the void and reach the ends, but there will always be a spot where grease won't go due to the crosslink sitting on one side of the aluminum shaft, and that spot is likely where the grease fitting is so it's hard to pump grease in there. I always clean and re-apply generous amount of grease on the shaft and in the crosslink prior to re-installing into the skid, then give it a shot of grease once assembled.

I have turned the aluminum shaft down in a lathe slightly for about 1" on either side of center in order to create a larger void to make it easier to fill and retain grease in this location. Seems to work well.

Cheers!

I believe by design there is likely close to 1mm diameter difference to allow grease to fill the void and reach the ends, but there will always be a spot where grease won't go due to the crosslink sitting on one side of the aluminum shaft, and that spot is likely where the grease fitting is so it's hard to pump grease in there. I always clean and re-apply generous amount of grease on the shaft and in the crosslink prior to re-installing into the skid, then give it a shot of grease once assembled.

I have turned the aluminum shaft down in a lathe slightly for about 1" on either side of center in order to create a larger void to make it easier to fill and retain grease in this location. Seems to work well.

Cheers!

Honk

TY 4 Stroke Master

make sure to install the two washers on the inside, when I installed them it tighten it right up.

Snowmobileaddict

TY 4 Stroke Junkie

I have excessive play between the ID of the tube vs the OD of the shaft.

The washers are just there so the rails seat against the shaft and not the tube.

The washers are just there so the rails seat against the shaft and not the tube.

woolyviper

TY 4 Stroke Master

- Joined

- Mar 24, 2006

- Messages

- 1,151

- Reaction score

- 2

- Points

- 841

- Location

- hibbing,mn

- Country

- USA

- Snowmobile

- 2009 Yamaha Phazer RTX

you need some space in the shaft to accept grease from the zurk fitting - its a pivot point and not a weight bearing point.

Maxout01

VIP Member

woolyviper said:you need some space in the shaft to accept grease from the zurk fitting - its a pivot point and not a weight bearing point.

Hows is it not a weight bearing point? The arm is the sole point where the rear arm attaches to the rails. Its holding alot of weight. Especially while riding.

kinger

VIP Member

- Joined

- Jan 17, 2005

- Messages

- 7,414

- Reaction score

- 1,553

- Points

- 1,963

- Location

- Clear Lake, IA

- Website

- www.piergenius.com

The shock holds the weight.

Snowmobileaddict

TY 4 Stroke Junkie

Some folks seem to have the understanding that shaft (#39) is not exposed to any radial forces or loading. I have to disagree.

Maxout1 gets it, that shaft is what connects the rear arm to the rails.

Maxout1 gets it, that shaft is what connects the rear arm to the rails.

Maxout01

VIP Member

Snowmobileaddict said:Some folks seem to have the understanding that shaft (#39) is not exposed to any radial forces or loading. I have to disagree.

Maxout1 gets it, that shaft is what connects the rear arm to the rails.

Thanks for the back-up!

You guys have to understand the load the shock is under is alot more thats true, but the piece connects the rear of the suspension to the rails. So all forces/weight have to travel through that point to even make it to the shock and then the shock does its thing and absorbs that. Its like saying the shackle of a pickup leaf spring pack isnt under weight, but yet the springs are. They are in fact both under load and work with one another.

Similar threads

- Replies

- 23

- Views

- 5K

- Replies

- 60

- Views

- 14K

- Replies

- 1

- Views

- 735

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.