rindtj

TY 4 Stroke Junkie

Well thanks for that Buzz Killington, Haha.

One of the best threads I have seen on TY in a long time, and I don't even own a Nytro! Someone of you guys are some pretty smart dudes.

You know what they say- "You can't make chicken soup, out of chicken poop."

One of the best threads I have seen on TY in a long time, and I don't even own a Nytro! Someone of you guys are some pretty smart dudes.

You know what they say- "You can't make chicken soup, out of chicken poop."

00-NUKE

Expert

rlcofmn said:Glad to see you picked up on the Laser glitch that Scott and I talked about the other night. So whats the verdict? Stock configuration how much bump steer and where's it at?

Good work!

And Trust me, there is no end of the road for playing with Nytro's

I think the laser light works OK for bump steer but 2 measurements from separate points are required. Example...

Remove the shock from one side.

What I did was Marked my first 3 laser points at 30" from the tip of the laser to the marker board with the laser mounted to the pivot point of the spindle. 1st point was lined up to a vertival line on the marker board with the suspension in the extended position. The next 2 points were marked at middle and fully compressed positions vearing outward on the marker board.

The second set of measurements were with the laser mounted at the toe of the carbide again 30" from tip of the laser to marker board. The starting point was lined up with the laser pointing at the same starting point as the spindles on the marker board with the suspension at fully extended position. Then points were marked again at midrange and fully compressed positions again vearing outward, but worse.

Conclusion: The distance between the spindle mark and the toe mark at midrange and fully compressed positions is bump steer. The distance between the spindle mark and the center line is scrub.

AKrider

TY 4 Stroke God

rindtj said:Well thanks for that Buzz Killington, Haha.

One of the best threads I have seen on TY in a long time, and I don't even own a Nytro! Someone of you guys are some pretty smart dudes.

You know what they say- "You can't make chicken soup, out of chicken poop."

Ha ha, I know, I'm currently pretty discouraged.

00-NUKE,

I think I must be forever the optimist.

What did you find with your measurements? Is there any hope? I completely agree with you about using two separate measurement points. We went about things differently. I first used a laser on the spindle shooting at cardboard about 43" in front of the laser. I then added two concrete blocks, parallel to the ski at the bottom of the stoke (shock installed) for a reference. This worked well but was very time consuming to record measurements throughout the stroke. I checked at 1" intervals of the stroke as the suspension was compressed. I also started my measurement at the bottom of the shock stroke, otherwise you measured stroke that didn't matter and it tended to have lots of toe out.

What did you find with your measurements? Is there any hope? I completely agree with you about using two separate measurement points. We went about things differently. I first used a laser on the spindle shooting at cardboard about 43" in front of the laser. I then added two concrete blocks, parallel to the ski at the bottom of the stoke (shock installed) for a reference. This worked well but was very time consuming to record measurements throughout the stroke. I checked at 1" intervals of the stroke as the suspension was compressed. I also started my measurement at the bottom of the shock stroke, otherwise you measured stroke that didn't matter and it tended to have lots of toe out.

This isn't rocket science (diagram courtesy of Ski-doo Race Manual, circa 1994), but a guy will chase his tail trying to get everything set up perfect. I kept thinking how nice it would be to have an alignment rack like a car repair shop would have.

I then decided to try using a similar version of the youtube video set-up. My photo gives an idea, but I then modified my rig so the laser shot directly back on itself and used a piece of vertical cardboard, taped onto laser to record the toe measurements. I set my mirror within 2-3" of the ski tip distance. This seemed to be a very accurate way to measure toe since the scrub was automatically built into the measurement thanks to the mirror. It took a bit of time to set up.

I was again very surprised by how much a single washer (maybe 1 mm in thickness) would change the toe and require realignment. This was discouraging because all of my other sleds (all trailing arm types) can have a ton of slop and still go down a trail way straighter and with more stability than my Nytro. I have a hard time believing the Nytro is so sensitive. Maybe it is? For a single 1mm washer to make that much difference in toe to effect the handling is ridiculous. If that is so than we are fk'd. No sled, even a brand new, right from the showroom floor, with 0 miles has no play in the steering or front end. My sled is not a good example to test on as it is closer to 4000 miles and the ski spindle bolts have a lot of play. I'm not saying this is okay, but I would like to know why this much play in the steering never made much of a difference on my 80's, early 90's Polaris sleds or my late 90's early 00's Ski-doo sleds?

Basically I've gone full circle. I started off this spring with the attitude that the Nytro is hopeless cause. I then did research and thought it could be fixed. I'm now pretty certain that the geometry is fk'd and there is minimal improvement that can be brought to the stock front end. I've bought enough skis and skags on race discounts to become very skeptical to claims that anything can be done to improve the handling of Nytro. I'm now thinking there is more at work here than just bump steer. I'm not convinced that the twisting and flex in the Nytro front end is not contributing to the unpredictable handling. We all know the Nytro handles like sh!t. What is the cause? I thought I knew but now I'm throwing my hands up.

:exc:

:exc:

00-NUKE

Expert

AKrider said:Got so carried away with thinking the tie rod needed to be parallel to the lower a-arm I forgot all about instant center. So, figuring that Yamaha built that in seeing as how the two a-arms and tie rod are all at different angles should be a simple matter of spacing the end of the tie rod up and down to the sweet spot.

I hate to admit it but I'm pretty convinced my racing buddy is right. It is a total waste of time and effort to try and do anything to improve the stock Nytro front end. Since the '09 geometry is only 30%-40% better than absolute garbage... in the end what do you have? A really nice engine wrapped in a POS chassis.

I'll reserve judgement on the aftermarket front ends that are on the market until I ride them or see convincing documentation that they work. Thanks to everyone for working together and brainstorming ideas. That was fun!

The "instant center" is why I moved the tie rod aft on the spindle. The tie rod either needs to be bent into an "S" shape at one point or it needs to have some sort of a bracket short of the outer ball joint mounted to it to in order to keep the mounting point on the spindle.

The up and down change of the tie rod mounting point on the spindle adds to proper toe but doesn't "maintain" proper toe throughout the transition, if that makes sense.

We need to find a way to keep the inside half of the tie rod back and have our outer ball joint mounting point forward of that to maintain proper toe and instant center with the a-arms along with vertical travel. The problem is putting an "S" in the tie rod will weaken it.

I promise that if no one else figures this thing out, "I WILL!"

AKrider

TY 4 Stroke God

I found this and the nytro seems to experience symptom #5.

http://www.longacreracing.com/articles/art.asp?ARTID=13

Problem is, Yamaha already shortened the tie rod with the '09 geometry. Maybe their shorter upper a-arms to create the 2 degree negitive camber is causing the toe out problems? I got better control when I went back to 0 degree camber but my '08 uses longer tie rods with the mounting tabs located on the outside edge of the spindle.

http://www.longacreracing.com/articles/art.asp?ARTID=13

Problem is, Yamaha already shortened the tie rod with the '09 geometry. Maybe their shorter upper a-arms to create the 2 degree negitive camber is causing the toe out problems? I got better control when I went back to 0 degree camber but my '08 uses longer tie rods with the mounting tabs located on the outside edge of the spindle.

00-NUKE

Expert

AKrider said:I found this and the nytro seems to experience symptom #5.

http://www.longacreracing.com/articles/art.asp?ARTID=13

Problem is, Yamaha already shortened the tie rod with the '09 geometry. Maybe their shorter upper a-arms to create the 2 degree negitive camber is causing the toe out problems? I got better control when I went back to 0 degree camber but my '08 uses longer tie rods with the mounting tabs located on the outside edge of the spindle.

I don't think it has anything to do with the shorter or longer tie rods. I think it has to do with the fact that the a-arms are pointing STRAIGHT out from the frame and the tie rod isn't, forcing the tie rod to have a less defined arc in it's up and down travel than the a-arms do. When I brought the mounting point behind the spindle, the tie rod is now facing perpendicular from the sled frame allowing it to maintain is true arc.

00-NUKE said:AKrider said:I found this and the nytro seems to experience symptom #5.

http://www.longacreracing.com/articles/art.asp?ARTID=13

Problem is, Yamaha already shortened the tie rod with the '09 geometry. Maybe their shorter upper a-arms to create the 2 degree negitive camber is causing the toe out problems? I got better control when I went back to 0 degree camber but my '08 uses longer tie rods with the mounting tabs located on the outside edge of the spindle.

I don't think it has anything to do with the shorter or longer tie rods. I think it has to do with the fact that the a-arms are pointing STRAIGHT out from the frame and the tie rod isn't, forcing the tie rod to have a less defined arc in it's up and down travel than the a-arms do. When I brought the mounting point behind the spindle, the tie rod is now facing perpendicular from the sled frame allowing it to maintain is true arc.

but you also doubled your steering ratio thus cutting any steering in half, including your bump steer. So now your 3/8" or less of factory bump steer is 3/16" so depending one how accurate your way of measuring is, errors could easily hide that. I think AK is right that there is a much bigger problem than "bump steer"

AKrider

TY 4 Stroke God

00-NUKE said:I don't think it has anything to do with the shorter or longer tie rods. I think it has to do with the fact that the a-arms are pointing STRAIGHT out from the frame and the tie rod isn't, forcing the tie rod to have a less defined arc in it's up and down travel than the a-arms do. When I brought the mounting point behind the spindle, the tie rod is now facing perpendicular from the sled frame allowing it to maintain is true arc.

I had a good discussion with rlcofmn today. What is needed in this thread are the bump steer measurements for the '09 geometry. The '08 front end is flawed and Yamaha made changes to correct for the bump steer. The significant changes they made to the front end included shorter toe rods, moving the tie rod mounts on the spindles to the inside, decreasing the caster angle and moving the ski bolt further back on the spindle to increase trail. These are all good changes.

00-Nuke, could you check how much your skis toe out or in on compression, all the way through the stroke on your front end switched back to the original stock configuration? I measured in 1" increments to give me a good idea of what was happening. Earlier in this thread I first I measured my toe change with the skis on the sled and it was 13/16". With the laser, removing the 2.5mm ball joint and shimming the tie rod I was able to cut it in half, but I also ended up with the skis toeing out and then in.

This was posted before but it gives an excellent visual of how too long of a tie rod pushes out on the spindle during compression causing toe out..

http://www.youtube.com/watch?v=gKJAukSZRT0

00-NUKE

Expert

AKrider said:00-NUKE said:I don't think it has anything to do with the shorter or longer tie rods. I think it has to do with the fact that the a-arms are pointing STRAIGHT out from the frame and the tie rod isn't, forcing the tie rod to have a less defined arc in it's up and down travel than the a-arms do. When I brought the mounting point behind the spindle, the tie rod is now facing perpendicular from the sled frame allowing it to maintain is true arc.

I had a good discussion with rlcofmn today. What is needed in this thread are the bump steer measurements for the '09 geometry. The '08 front end is flawed and Yamaha made changes to correct for the bump steer. The significant changes they made to the front end included shorter toe rods, moving the tie rod mounts on the spindles to the inside, decreasing the caster angle and moving the ski bolt further back on the spindle to increase trail. These are all good changes.

00-Nuke, could you check how much your skis toe out or in on compression, all the way through the stroke on your front end switched back to the original stock configuration? I measured in 1" increments to give me a good idea of what was happening. Earlier in this thread I first I measured my toe change with the skis on the sled and it was 13/16". With the laser, removing the 2.5mm ball joint and shimming the tie rod I was able to cut it in half, but I also ended up with the skis toeing out and then in.

This was posted before but it gives an excellent visual of how too long of a tie rod pushes out on the spindle during compression causing toe out..

http://www.youtube.com/watch?v=gKJAukSZRT0

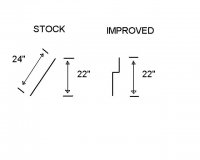

I don't think I'm explaining myself very well. I'm not saying to mount the tie rod aft of the spindle. I'm just saying that so far that position has shown the best results. My next testing will be with a tie rod that has a Z or S bend in it to check the changes. This will act as a shorter tie rod due to the angle of attack. The problem with this is the possible weakness of the tie rod. I'm using the example of a 24" tie rod because I can't remember the measurements at this moment in time. Sorry for the MS paint, it's all I have at the moment.

Attachments

AKrider

TY 4 Stroke God

Dang, I'm not able to view your attachment.

I don't believe adding a curve to the tie rod will make a difference. The tie rod just pushes or pulls on the spindle. To make an extreme example, the tie rod could look like a pretzel but it wouldn't matter because the only important measurement is the distance between the toe rod ends. I think the tie rod is too long on my '08. Making it shorter like an '09 won't work in my case because it would then be too short to attach to the spindle. I'd really like to try '09 spindles on my front end but I don't want to spend $400 on an experiment that may not yield any benefits.

I don't believe adding a curve to the tie rod will make a difference. The tie rod just pushes or pulls on the spindle. To make an extreme example, the tie rod could look like a pretzel but it wouldn't matter because the only important measurement is the distance between the toe rod ends. I think the tie rod is too long on my '08. Making it shorter like an '09 won't work in my case because it would then be too short to attach to the spindle. I'd really like to try '09 spindles on my front end but I don't want to spend $400 on an experiment that may not yield any benefits.

AKrider said:Dang, I'm not able to view your attachment.

I don't believe adding a curve to the tie rod will make a difference. The tie rod just pushes or pulls on the spindle. To make an extreme example, the tie rod could look like a pretzel but it wouldn't matter because the only important measurement is the distance between the toe rod ends. I think the tie rod is too long on my '08. Making it shorter like an '09 won't work in my case because it would then be too short to attach to the spindle. I'd really like to try '09 spindles on my front end but I don't want to spend $400 on an experiment that may not yield any benefits.

X2 but I liked my example better that you could spell out Yamaha and it would not make a difference.

It doesn't matter how you connect them Point A and B is all that matters. Sorry to say it Nuke but your chasing your tail here. :exc:

It doesn't matter how you connect them Point A and B is all that matters. Sorry to say it Nuke but your chasing your tail here. :exc:00-NUKE

Expert

rlcofmn said:AKrider said:Dang, I'm not able to view your attachment.

I don't believe adding a curve to the tie rod will make a difference. The tie rod just pushes or pulls on the spindle. To make an extreme example, the tie rod could look like a pretzel but it wouldn't matter because the only important measurement is the distance between the toe rod ends. I think the tie rod is too long on my '08. Making it shorter like an '09 won't work in my case because it would then be too short to attach to the spindle. I'd really like to try '09 spindles on my front end but I don't want to spend $400 on an experiment that may not yield any benefits.

X2 but I liked my example better that you could spell out Yamaha and it would not make a difference.It doesn't matter how you connect them Point A and B is all that matters. Sorry to say it Nuke but your chasing your tail here. :exc:

What you aren't seeing is that the tie rod is a little longer than your a-arms because it is coming in from way behind them at an angle. Because of this when they all hit the lateral axis the tie rod pulls back due to it having a less defined arc than the a-arms at mid-swing. This forces the tie rod to pull in on the spindle and this is why AK's stock suspension readings go from zero to toe out and back to zero throughout the transition. The tie rod's angle of attack has to match that of the a-arms for a consistant arc pattern.

arteeex

TY 4 Stroke Master

Putting a bend in the tie rod will not change the line of action of the force it transmits. Provided the link can support the loads required, the only thing that matters is the straight-line distance between the mounting points. The shape of the link is largely irrelevant.

AKrider

TY 4 Stroke God

rlcofmn,

Ha ha, I did modify your analogy a bit.

00-NUKE,

I can view your attachment now and I believe I understand where you are coming from. When I spoke with Rlcofmn, he was thinking the length of the tie rod could be creating the bump steer issue. He used the example of a Polaris steering linkage in which it uses short tie rods attached to a rack equipped with two bell cranks.

I don't think the angle is an issue because most every fourwheeler uses angled tie rods that run from the steering post flag to the back of the spindle. I'm pretty sure the Ski-doo XP runs the same type of set up.

Looking back at your original mod, I think the benefit you felt in the stutters was due to reducing the camber change throughout the travel which probably reduced the bump steer. It would be really good to establish just how much tow change the '09 geometry shows as the suspension strikes through its travel.

Ha ha, I did modify your analogy a bit.

00-NUKE,

I can view your attachment now and I believe I understand where you are coming from. When I spoke with Rlcofmn, he was thinking the length of the tie rod could be creating the bump steer issue. He used the example of a Polaris steering linkage in which it uses short tie rods attached to a rack equipped with two bell cranks.

I don't think the angle is an issue because most every fourwheeler uses angled tie rods that run from the steering post flag to the back of the spindle. I'm pretty sure the Ski-doo XP runs the same type of set up.

Looking back at your original mod, I think the benefit you felt in the stutters was due to reducing the camber change throughout the travel which probably reduced the bump steer. It would be really good to establish just how much tow change the '09 geometry shows as the suspension strikes through its travel.

Super Sled

Lifetime Member

- Joined

- Feb 25, 2009

- Messages

- 3,631

- Reaction score

- 6

- Points

- 1,218

- Location

- Riding on the North Shore, MN

- Country

- USA

- Snowmobile

- Summit X

AKrider said:rlcofmn,

Ha ha, I did modify your analogy a bit.

00-NUKE,

I can view your attachment now and I believe I understand where you are coming from. When I spoke with Rlcofmn, he was thinking the length of the tie rod could be creating the bump steer issue. He used the example of a Polaris steering linkage in which it uses short tie rods attached to a rack equipped with two bell cranks.

I don't think the angle is an issue because most every fourwheeler uses angled tie rods that run from the steering post flag to the back of the spindle. I'm pretty sure the Ski-doo XP runs the same type of set up.

Do you guys think maybe you all are over thinking this a tad? Every vehicle with a moving suspension has displacement during the stroke of the suspesion/ axle movement. And every sled out there does the exact thing as the Nytro. Now maybe the Nytro exaggerates it more than other sleds, but I'm not on board with calling the sled "flawed".

Similar threads

- Replies

- 13

- Views

- 4K

- Replies

- 6

- Views

- 2K

- Replies

- 3

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.