Soupy

Expert

- Joined

- Jan 10, 2017

- Messages

- 359

- Age

- 50

- Location

- West Michigan

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX-LE

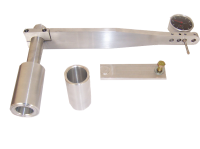

Wondering if parallelism is my problem. Other straightedge measurements say yes.

Is this an accepted way to measure it? Bushings, gauge fixturing and engine are tight.

Is this an accepted way to measure it? Bushings, gauge fixturing and engine are tight.

What does the belt look like before it goes and when it goes does it go in pieces are snap in half? What speed or circumstances..

Are your clutches completely stock?

Have you added any power?

Do you ride off trail in deeper?

I seriously doubt lack of parallelism... And you'd have a insurmountable issue if it was...

Are your clutches completely stock?

Have you added any power?

Do you ride off trail in deeper?

I seriously doubt lack of parallelism... And you'd have a insurmountable issue if it was...

Also where do you set your belt height at... And 8jp belt?

Soupy

Expert

- Joined

- Jan 10, 2017

- Messages

- 359

- Age

- 50

- Location

- West Michigan

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX-LE

PiecesWhat does the belt look like before it goes and when it goes does it go in pieces are snap in half? What speed or circumstances..

Are your clutches completely stock?

Have you added any power?

Do you ride off trail in deeper?

I seriously doubt lack of parallelism... And you'd have a insurmountable issue if it was...

Hot clutches

Problems with both stock clutches and with tuning bits added

No added power

Both on and off trail

I understand but I believe that i have the means to check it so I figured I would

Belt height usually as high as possible without creep or squealing, I learned this could be too tight

8jp

Joe ltx-le

TY 4 Stroke God

- Joined

- Mar 26, 2015

- Messages

- 1,524

- Age

- 37

- Location

- Beaverbank-ns

- Country

- Canada

- Snowmobile

- 2017 sidewinder ltx-dx

Ultimax! I'm telling ya

Soupy

Expert

- Joined

- Jan 10, 2017

- Messages

- 359

- Age

- 50

- Location

- West Michigan

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX-LE

It's on my to do listUltimax! I'm telling ya

Trussman

JAFO

- Joined

- Mar 18, 2007

- Messages

- 251

- Location

- WI

- Country

- USA

- Snowmobile

- 2004 Viper S

2017 'Winder

2022 SRX

I've been thinking about the same thing. For those blowing belts, are the clutches parallel? Offset is only 1 of the measurements to worry about.....

Joe ltx-le

TY 4 Stroke God

- Joined

- Mar 26, 2015

- Messages

- 1,524

- Age

- 37

- Location

- Beaverbank-ns

- Country

- Canada

- Snowmobile

- 2017 sidewinder ltx-dx

My clutches where always bang on and still blowing belts. Until I changed the belt and helix.

Also like mentioned before you don't want the belt too high in the clutch. Flush

Also like mentioned before you don't want the belt too high in the clutch. Flush

shagman

Vendor

- Joined

- Feb 18, 2014

- Messages

- 1,059

- Age

- 59

- Location

- Cedarville Michigan

- Country

- USA

- Snowmobile

- 2017 Sidewinder BTX LE

2014 SR Viper XTX SE (Sold)

Pieces

Hot clutches

Problems with both stock clutches and with tuning bits added

No added power

Both on and off trail

I understand but I believe that i have the means to check it so I figured I would

Belt height usually as high as possible without creep or squealing, I learned this could be too tight

8jp

Don’t go any tighter than top of sheaves. Especially with gates carbon.

Sent from my iPhone using Tapatalk

Soupy

Expert

- Joined

- Jan 10, 2017

- Messages

- 359

- Age

- 50

- Location

- West Michigan

- Country

- USA

- Snowmobile

- 2017 Sidewinder LTX-LE

Thanks fellas

beat me to it...too high of belt...longer and lower belt easier on belt..

replace secondary spring, too weak....dry cycle secondary to verify no casting flash hang up with sec sheaves...verify clutch rollers are not flat spotted...

seal belly pan with silicone (extremely important if off trail)........run stock gears or lower...

dry cycle primary to verify smooth moveable on pin movement....verify slider puck condition...replace primary spring ...

look on underside of clutch guard for witness (skid) marks from belt...

replace secondary spring, too weak....dry cycle secondary to verify no casting flash hang up with sec sheaves...verify clutch rollers are not flat spotted...

seal belly pan with silicone (extremely important if off trail)........run stock gears or lower...

dry cycle primary to verify smooth moveable on pin movement....verify slider puck condition...replace primary spring ...

look on underside of clutch guard for witness (skid) marks from belt...

Similar threads

- Replies

- 1

- Views

- 659

- Replies

- 0

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.