Mtnviper

Vendor

- Joined

- Aug 19, 2003

- Messages

- 1,476

- Reaction score

- 340

- Points

- 1,288

- Location

- Burlington Wa.

- Website

- fourstrokesolutionsllc.com

Tom,

You might try Dustin at Outlaw Motorsports, he built a Boondocker Phazer for a buddy a few years ago and may still have a source for some of the items you need.

Originally my buddy was running stock internals but blew it up due to combination of not enough octane and to much boost. He then had Dustin rebuild it with custom pistons and I think rods. Not sure what the compression ratio was though.

Bill

You might try Dustin at Outlaw Motorsports, he built a Boondocker Phazer for a buddy a few years ago and may still have a source for some of the items you need.

Originally my buddy was running stock internals but blew it up due to combination of not enough octane and to much boost. He then had Dustin rebuild it with custom pistons and I think rods. Not sure what the compression ratio was though.

Bill

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

@cannondale27 - I emailed @HURRICANE Dave, but I am not gonna hold my breath on having something in stock. I assume he would have to go through the same 5 week wait?

@Mtnviper - I actually spoke with Dustin at Outlaw earlier today because they used custom JE pistons in their shop phazer project and I was told by JE that if I could get the Job Number from that order, it would save me from having to calculate/figure out everything myself. He is going to try and dig, but he doesnt think they have anything on that one anymore since it was like 10 years ago.

Edit: Dave replied (seriously, does that guy ever stop working? ) Nothing in stock, he offered to call Cp to check tho

) Nothing in stock, he offered to call Cp to check tho

@Mtnviper - I actually spoke with Dustin at Outlaw earlier today because they used custom JE pistons in their shop phazer project and I was told by JE that if I could get the Job Number from that order, it would save me from having to calculate/figure out everything myself. He is going to try and dig, but he doesnt think they have anything on that one anymore since it was like 10 years ago.

Edit: Dave replied (seriously, does that guy ever stop working?

Last edited:

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

Did you check CP pistons? I had nothing but bad luck with JE pistons in quads. CP never had a failure and they last forever.

Can you elaborate on the bad luck with JE in quads? I really dont want to drop $550 on pistons only to have 'bad luck'!

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

CP has a 4 piece minimum order. Wiseco has a 12 piece minimum order. It would appear JE is the only option at 3 times the cost of 'shelf' Wiseco pistons.

I have seen Phazers that say they have an ARP head stud kit in them but I cannot find any. It feels like all aftermarket support for the Phazer has just completely dried up. According to the OEM part number the YXZ uses the same head bolts as the Phazer, and there are kits for the YXZ that I have found, but they are $200 and come with 8 bolts where as the phazer only needs 6.

This is getting quite frustrating.

I have seen Phazers that say they have an ARP head stud kit in them but I cannot find any. It feels like all aftermarket support for the Phazer has just completely dried up. According to the OEM part number the YXZ uses the same head bolts as the Phazer, and there are kits for the YXZ that I have found, but they are $200 and come with 8 bolts where as the phazer only needs 6.

This is getting quite frustrating.

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

I actually called all three places and spoke with someone as their websites all had conflicting information on turn around time and minimum orders:

- JE Custom Pistons

- 4 - 5 weeks after they get sample and payment

- Need a sample piston sent in

- Two pistons are about $250 each ($500)

- Four pistons are about $185 each ($370)

- CP/Carrillo

- 4-5 weeks after the get sample and payment

- Need a sample piston sent in

- Two pistons are about $375 each ($750)

- Four pistons are about $283 each ($566)

- Wiseco

- 6-8 weeks after they get payment

- No sample needed, they have specs on hand

- Two pistons are about $--- each ($---) - They will not do 2 pistons

- Four pistons are about $160 each ($320)

Last edited:

kallholmen

Pro

125'ish both sides cold, poured a little oil in and got 175 and 155. The 155 side would slowly loose pressure as well. One plug (from the 155 side) was oil fouled and the plug from the 175 side looked like hell from what I assume was pre-ignition or detonation. When I bought it the PO ran pump gas so I ASSumed it had the headshim. I did a bunch of digging and managed to find the first owner of this sled. He never installed the head shim and ran 100 octane. The sled was sold to the guy I bought it from with 1200 miles on it running great. He put 600 miles on it with pump gas and that was the outcome.

I planned to build the '08 motor some time in the future. Now it looks like I will be swapping them around and building the 2010 motor sometime in the future.

You can't do an accurate test because of the decompression pin (springloaded, until you get rpm). You need to take valve cover of to deactivate it.

I have the art# for the headshim somewhere if you are interested? Otherwise I know that MCX in Sweden have the headshim in stock. Built my own turbo Phazer a couple of years ago. A friend of mine just used two ordinary gaskets and ARP-bolts. Works fine.

Skickat från min iPhone med Tapatalk

Last edited:

kallholmen

Pro

CP has a 4 piece minimum order. Wiseco has a 12 piece minimum order. It would appear JE is the only option at 3 times the cost of 'shelf' Wiseco pistons.

I have seen Phazers that say they have an ARP head stud kit in them but I cannot find any. It feels like all aftermarket support for the Phazer has just completely dried up. According to the OEM part number the YXZ uses the same head bolts as the Phazer, and there are kits for the YXZ that I have found, but they are $200 and come with 8 bolts where as the phazer only needs 6.

This is getting quite frustrating.

Same bolts on Nytro.

Skickat från min iPhone med Tapatalk

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

You can't do an accurate test because of the decompression pin (springloaded, until you get rpm). You need to take valve cover of to deactivate it. I have the art# for the headshim somewhere if you are interested? Otherwise I know that MCX in Sweden have the headship in stock. Built my own turbo Phazer a couple of years ago. A friend of mine just used two ordinary gaskets and ARP-bolts. Works fine.

Yeah. my plan is to make my own Leakdown tester so I can actually see what is going on. I wanted to do that yesterday, but I ended up working sun-up to sun-down. Hoping to do that tonight. If anyone happens to know off hand what pressure I should set it to, that would be great. Otherwise I'll try and search tonight.

Either way I think I am going to order pistons. I'll plan on putting them in the 2010 motor. While I am waiting for them, I will work on the 08 motor so I can use that if the pistons don't show up in time. I'll just need to figure out what to do about that one. They have MCX shims in stock here in the states, but they are $250, which is just silly. The shim is .060 with the stock .018 gasket split in half around it for a total of .078 which lowers the compression down to 9.7. Two stacked OEM headgaskets are .036, which lowers it down to 11.5. I'm kinda toying with having my buddy cut one or two in different thicknesses on the waterjet he has access to now that I know its just a sheet of metal with the gasket split around it. Anyone know what material they are made of?

kallholmen

Pro

That cant be accurate? As I remembered it two original headgaskets were a match, or maybe even a bit thicker?

Skickat från min iPhone med Tapatalk

Skickat från min iPhone med Tapatalk

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

Thats what MCX told me when I asked him how big the shim was:

"I’m not sure what it lowers it to, but the shim itself is .060 and has the stock gasket split around it. Which I believe gives a total of .080”

The stock gasket is .018", so .078"

"I’m not sure what it lowers it to, but the shim itself is .060 and has the stock gasket split around it. Which I believe gives a total of .080”

The stock gasket is .018", so .078"

kallholmen

Pro

Thats what MCX told me when I asked him how big the shim was:

"I’m not sure what it lowers it to, but the shim itself is .060 and has the stock gasket split around it. Which I believe gives a total of .080”

The stock gasket is .018", so .078"

Ok. I might remember it wrong. The shim is 0,6 mm thicker than original, that's correct but it's not just a shim with two original gasket wrapped around it. And as I remember the original gasket that my friend used was way thicker than 0.18? But it might have been some other shims/gaskets that he had?

Btw MCX in Sweden sold the head shim for 1000 sek, = $124.

My build (in Swedish): Phazer MTX "just good enough" turbo.

http://forum.snowmobile.se/showthread.php?t=67778

Skickat från min iPhone med Tapatalk

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

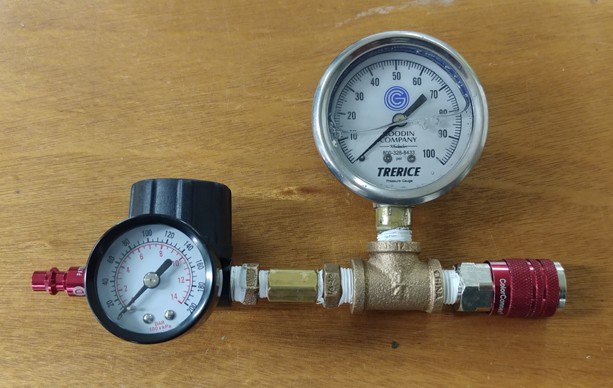

Today was kind of an exciting day. During the work day packages just kept arriving with parts, Including the new-to-me 151" track. As I was wrapping up work, I got a call from the powdercoater that my parts were ready for pick up. I zipped over there and grabbed them on my way to pick up some misc fittings to make my own leak down tester.

I already had a few 100 PSI gauges laying around from various household and garage plumbing projects, as well as some airline quick connections, so all I needed was a cheap regulator and a bunch of random fittings. I was in such a hurry to get my parts from powdercoating since they called me 20 minutes before they closed and they were 15 minutes away that I didnt really figure out exactly what fittings I would need, so I just grabbed a bunch of them. Part of making a DIY leakdown tester is that you have to create an orifice that is only .040 / 1mm, usually by filling it with epoxy and drilling it out. Thinking that the smaller the area filled with epoxy the better, I also grabbed some fittings to make a 1/4" to 1/8" reducer. When I got home I filled one of the 1/8" reducer fittings with JB Qwik.

While I was waiting for the JB weld to cure, I decided to tackle my steering stem slop issue as the OFT Racing billet steering black had finally arrived a month after I ordered it. The difference it made was substantial! I realize the vid clips are short but you get the idea.

Still wanting to wait as long as possible on the curing of the epoxy, I moved onto mounting the rear bumper and snow flap. I got that bolted up and riveted in with some more black rivets, and then installed the snow flap with some large-head black rivets. I also slipped the running board edges into place.

At that point I had waited several hours between having dinner, messing with the steering block, mounting the bumper, and tucking the kids into bed. I decided that the JB weld should be good enough to drill out by now. However, I couldn't find my small bits anywhere. I have a large drill bit organizer that came from a hardware store, but that only goes down to 1/16". For other various drill bits, drivers, screw bits, router bits, and hole saws I have a large tackle box. They were not in there either. I realized I that the local home-improvement store that was 15 mins away closed in 25 mins. I dropped everything and jumped in the truck to go pick up a 1mm bit because I just desperately wanted to know what was going on with both the motor from this sled, as well as the motor from the 08 I am parting out.

They only sold bits that small in a kit, so I grabbed the kit and some more roloc scotchbrite pads for taking off the powder on the rails where the hyfax mount, and returned home excited to get the tester done and see what was going on with these engines. Thats when I realized where ever my small bits were, my small-bit adapter chuck was with them and I had no way to chuck up a bit that small and the store was well past closed. I tried a few things after attempting to locate them once again that included a dremel collet, gorilla tape, and a countersink bit before I ended up using some heat shrink with adhesive around the bit in order to get it to hold in the drill chuck and was finally able to slap together a tester.

I went to test it out, and realized both of the gauges on it were inaccurate. I set my water filter/regulator on my airline from my compressor at 80 psi. Both the regulator and the gauge past the regulator (I have that because I have a by pass that allows me to run full unregulated pressure) were showing 80. The cheapo regulator on the tester was showing 82 or 83, and the liquid gauge was showing something in the upper 70's before I even connected it to a motor. At this point it was nearly midnight. I was exhausted and didnt want to deal with trying to get the motor to TDC on the compression stroke since the clutch wasnt even mounted or attempt any math on the differences between the known accurate pressure and the differences between what the regulator was showing and what the leak-side gauge was showing. I called it a night, and am excited to try it out tomorrow.

I already had a few 100 PSI gauges laying around from various household and garage plumbing projects, as well as some airline quick connections, so all I needed was a cheap regulator and a bunch of random fittings. I was in such a hurry to get my parts from powdercoating since they called me 20 minutes before they closed and they were 15 minutes away that I didnt really figure out exactly what fittings I would need, so I just grabbed a bunch of them. Part of making a DIY leakdown tester is that you have to create an orifice that is only .040 / 1mm, usually by filling it with epoxy and drilling it out. Thinking that the smaller the area filled with epoxy the better, I also grabbed some fittings to make a 1/4" to 1/8" reducer. When I got home I filled one of the 1/8" reducer fittings with JB Qwik.

While I was waiting for the JB weld to cure, I decided to tackle my steering stem slop issue as the OFT Racing billet steering black had finally arrived a month after I ordered it. The difference it made was substantial! I realize the vid clips are short but you get the idea.

Still wanting to wait as long as possible on the curing of the epoxy, I moved onto mounting the rear bumper and snow flap. I got that bolted up and riveted in with some more black rivets, and then installed the snow flap with some large-head black rivets. I also slipped the running board edges into place.

At that point I had waited several hours between having dinner, messing with the steering block, mounting the bumper, and tucking the kids into bed. I decided that the JB weld should be good enough to drill out by now. However, I couldn't find my small bits anywhere. I have a large drill bit organizer that came from a hardware store, but that only goes down to 1/16". For other various drill bits, drivers, screw bits, router bits, and hole saws I have a large tackle box. They were not in there either. I realized I that the local home-improvement store that was 15 mins away closed in 25 mins. I dropped everything and jumped in the truck to go pick up a 1mm bit because I just desperately wanted to know what was going on with both the motor from this sled, as well as the motor from the 08 I am parting out.

They only sold bits that small in a kit, so I grabbed the kit and some more roloc scotchbrite pads for taking off the powder on the rails where the hyfax mount, and returned home excited to get the tester done and see what was going on with these engines. Thats when I realized where ever my small bits were, my small-bit adapter chuck was with them and I had no way to chuck up a bit that small and the store was well past closed. I tried a few things after attempting to locate them once again that included a dremel collet, gorilla tape, and a countersink bit before I ended up using some heat shrink with adhesive around the bit in order to get it to hold in the drill chuck and was finally able to slap together a tester.

I went to test it out, and realized both of the gauges on it were inaccurate. I set my water filter/regulator on my airline from my compressor at 80 psi. Both the regulator and the gauge past the regulator (I have that because I have a by pass that allows me to run full unregulated pressure) were showing 80. The cheapo regulator on the tester was showing 82 or 83, and the liquid gauge was showing something in the upper 70's before I even connected it to a motor. At this point it was nearly midnight. I was exhausted and didnt want to deal with trying to get the motor to TDC on the compression stroke since the clutch wasnt even mounted or attempt any math on the differences between the known accurate pressure and the differences between what the regulator was showing and what the leak-side gauge was showing. I called it a night, and am excited to try it out tomorrow.

Last edited:

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

Ok. I might remember it wrong. The shim is 0,6 mm thicker than original, that's correct but it's not just a shim with two original gasket wrapped around it. And as I remember the original gasket that my friend used was way thicker than 0.18? But it might have been some other shims/gaskets that he had?

Btw MCX in Sweden sold the head shim for 1000 sek, = $124.

My build (in Swedish): Phazer MTX "just good enough" turbo.

http://forum.snowmobile.se/showthread.php?t=67778

Hmm. From what I had read and seen, they are all the OEM head gasket split in two with the shim slipped inside, and that is what Brad from MCX told me as well? Maybe its different here in the states from what you get in Sweden? I know the price of $249US is just silly, kinda wonder if its like @mysledblows said, stock/supply is low as well as demand so the jacked up the prices?

I know your sled, I have your build thread link as well as several of your posts bookmarked! I've said it before, and I will say it again: Your sled is sick!

kallholmen

Pro

Hmm. From what I had read and seen, they are all the OEM head gasket split in two with the shim slipped inside, and that is what Brad from MCX told me as well? Maybe its different here in the states from what you get in Sweden? I know the price of $249US is just silly, kinda wonder if its like @mysledblows said, stock/supply is low as well as demand so the jacked up the prices?

I know your sled, I have your build thread link as well as several of your posts bookmarked! I've said it before, and I will say it again: Your sled is sick!

Thanks I've moved down south and haven't even started it for two seasons.

Reading your stuff makes me wanna dig it out and go back north asap.

Usually things are a lot cheaper on your side of the pond? Give Erik a call or send him a mail. Guess you can order the part directly from Yamaha too (I have saved the Yamaha parts# somewhere).

MC Xpress AB

Norra Altervägen 821

945 92 Altersbruk

Sweden

Phone: +46 911 202 005 (14-16)

Fax: +46 911 202 008

E-mail: info@mcx.se

Skickat från min iPhone med Tapatalk

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

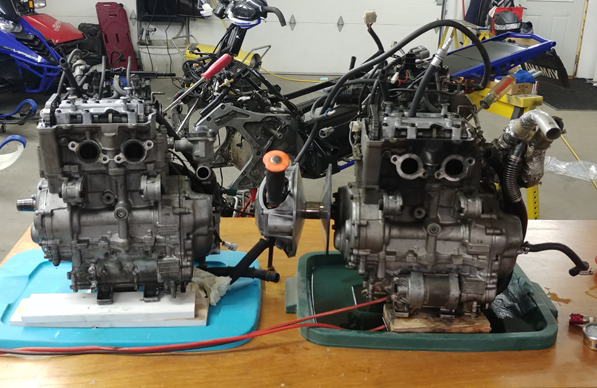

Let the battle of the blocks commence!

I skipped a rare group ride (had 8 of the 9 of our group going, which is rare for so many of us to all be able to go on the same night) just so I could figure this situation out.

I had a hell of a time with my first attempt(s) at leak down testing. The motors kept wanting to turn over at any PSI over 30 if I had them at exactly TDC on the compression stroke. I tried a bar through the clutch at first (pictured) before I learned that if I increased pressure too fast the clutch would move and almost knock the motor over! I ended up finding a steel rod that fit inside the holes in the cams and would keep them from turning that worked great.

Both motors were obviously tested cold, and both at the 80 psi standard. With 3-10% leakage being considered good, 11-20% being considered acceptable, and 20+ being time for rebuild

Just to satisfy my curiosity, I decided to test them both at 100 psi even tho that wouldn't give me standards to go off of.

I highly doubt JE will be able to get me pistons in time for the March trip. I am going to order four pistons regardless and see if I can't sell one set and hope they come in time. In case they dont I am going to try and get teh 08 engine in the sled to use for the trip. I just have to figure out if I want to get a shim for it, make a shim, or crank down the boost

I skipped a rare group ride (had 8 of the 9 of our group going, which is rare for so many of us to all be able to go on the same night) just so I could figure this situation out.

I had a hell of a time with my first attempt(s) at leak down testing. The motors kept wanting to turn over at any PSI over 30 if I had them at exactly TDC on the compression stroke. I tried a bar through the clutch at first (pictured) before I learned that if I increased pressure too fast the clutch would move and almost knock the motor over! I ended up finding a steel rod that fit inside the holes in the cams and would keep them from turning that worked great.

Both motors were obviously tested cold, and both at the 80 psi standard. With 3-10% leakage being considered good, 11-20% being considered acceptable, and 20+ being time for rebuild

- 2008 Phazer motor with 2200 miles (mods were intake, exhaust, 3* timing advance key & PCV)

- Right side 71 | 10% leakage | Heard in crankcase but also in intake

- Left/Clutch 75 | 6% Leakage | Only heard in crank case

- 2010 Phazer motor with 1800 miles (turbo with PO running too low of octane for 600 miles)

- Right Side 62 | 22 % leakage | Heard in crankcase

- Left/Clutch 31 | 61% leakage Crankcase & significantly at exhaust

Just to satisfy my curiosity, I decided to test them both at 100 psi even tho that wouldn't give me standards to go off of.

- 2008 Phazer motor

- Right side 83 | 17% leakage | Heard in crankcase but also significantly in intake

- Left/Clutch 87 | 13% Leakage | Only heard in crank case

- 2010 Phazer motor

- Right Side | I tried to test this, and the damn cam chain started skipping.

- Left/Clutch | see above

I highly doubt JE will be able to get me pistons in time for the March trip. I am going to order four pistons regardless and see if I can't sell one set and hope they come in time. In case they dont I am going to try and get teh 08 engine in the sled to use for the trip. I just have to figure out if I want to get a shim for it, make a shim, or crank down the boost

Last edited:

Similar threads

- Replies

- 2

- Views

- 979

- Replies

- 8

- Views

- 3K

- Replies

- 2

- Views

- 552

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.