kallholmen

Pro

Ouch.

My first thought when I saw the slow motion film (cams) was that the chain behaved strange. It kind of jumped a bit on the first cam. Looked lose or as it had a bad link. Didn't comment on that, sorry.

You have the adjuster on the front of the engine.

If that film was on the same engine?

But now that it skipped, it's head shim for you! Half way there already. Depending on how thick the head shim is you have to change the timing by grinding the holes on the camdrivers back (mine is 0,4 mm).

And: you have an engine to compare with! Easy.

Skickat från min iPhone med Tapatalk

My first thought when I saw the slow motion film (cams) was that the chain behaved strange. It kind of jumped a bit on the first cam. Looked lose or as it had a bad link. Didn't comment on that, sorry.

You have the adjuster on the front of the engine.

If that film was on the same engine?

But now that it skipped, it's head shim for you! Half way there already. Depending on how thick the head shim is you have to change the timing by grinding the holes on the camdrivers back (mine is 0,4 mm).

And: you have an engine to compare with! Easy.

Skickat från min iPhone med Tapatalk

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

That film was from the 2010 / same motor. I've watched it a few dozen times now and I think you are right, it seems to jump a bit on the intake cam gear a few different times.

I contacted MXC again. Its $249 CAD, or $198 USD with the stock gasket included. Its $125 USD without the gasket. I asked if I could just buy the head shim for $125. If so, I'll pull the head on the 08, find out what is up with the valves, replace the timing key with stock, and then shim it to use while I do the low-comp pistons in the 2010

Edit: I called powderlites and they still have a few head shims in stock. $49 bucks! I ordered it!

I contacted MXC again. Its $249 CAD, or $198 USD with the stock gasket included. Its $125 USD without the gasket. I asked if I could just buy the head shim for $125. If so, I'll pull the head on the 08, find out what is up with the valves, replace the timing key with stock, and then shim it to use while I do the low-comp pistons in the 2010

Edit: I called powderlites and they still have a few head shims in stock. $49 bucks! I ordered it!

Last edited:

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

I am really struggling with what to do about the 2008 motor. Head shim and change the cam timing, or just double stack Cometic head gaskets and leave the cams alone. I ordered the shim, and am going to order two more head gaskets (I have one for the 2010 motor already).

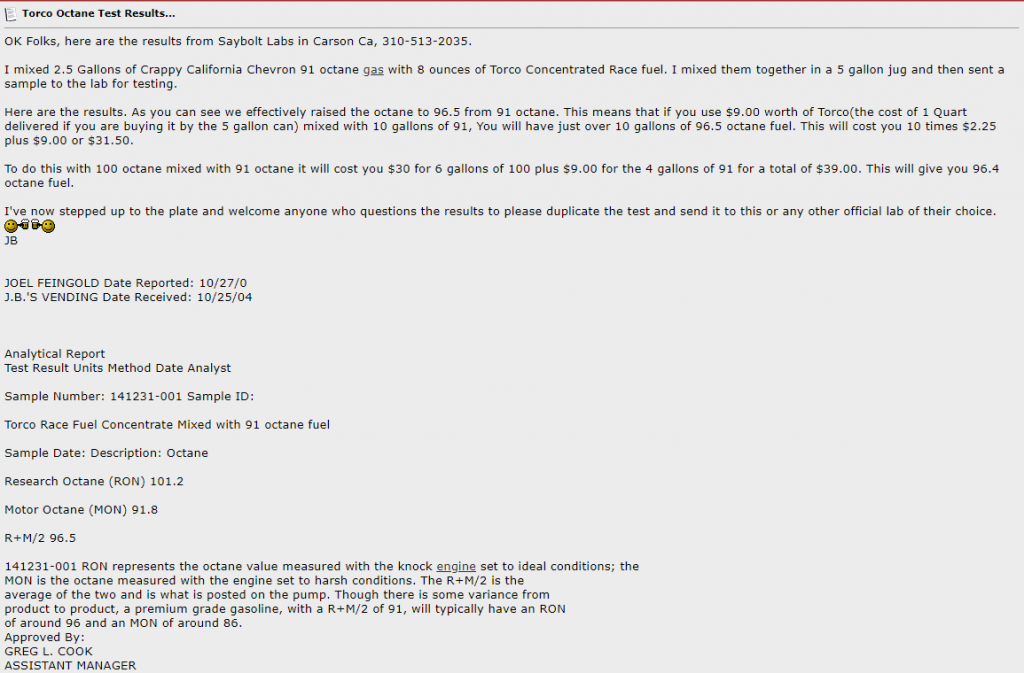

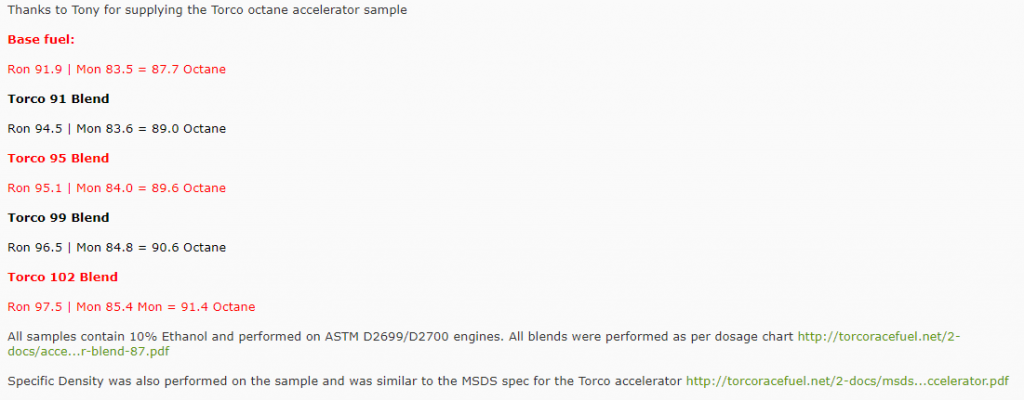

My goal is to be running 96 octane which is ~5 gallons of 91 and ~2 gallons of 110. I could also run 7 gallons of 91 with 24 ounces of Torco in a pinch as that has been independently lab tested as the amount you need to actually obtain 96 octane (torco's mix charts claim only 11.2)

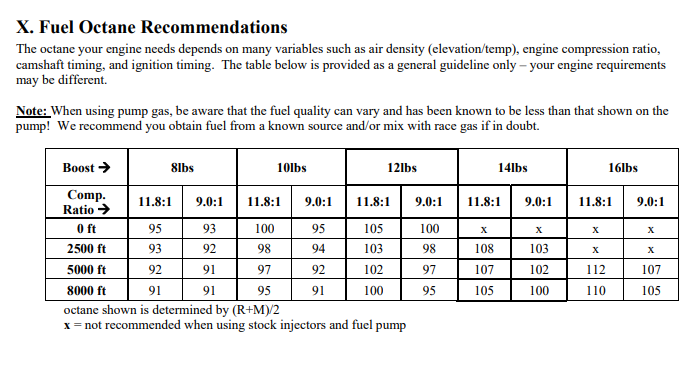

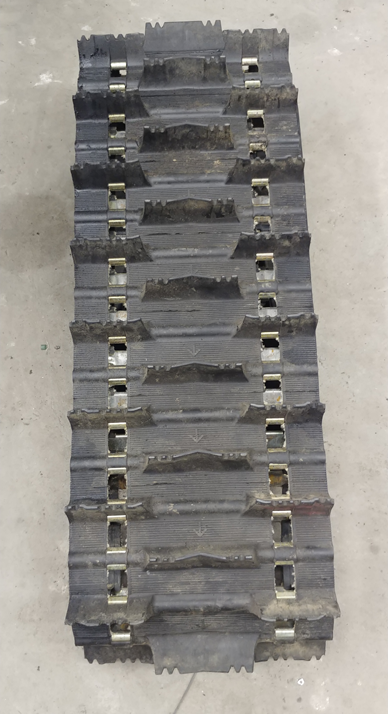

Looking at the octane recommendations from Boondocker, and considering the compression ratio with 2x head gaskets is 11.5, and with the shim is 9.6, this is pretty close to 11.8 and 9.0

With the double stacked head gaskets, I could run 8 psi here for testing and 10 psi out west as every where we go is 7500' or above . With the shim, I could run 10 psi here for testing, and 12 psi out west. I have read numerous posts where users were either removing the head shim completely or not installing them, not touching the timing, and running 10-12 psi on 91-100ll at 10,000'

I would think at 96 octane with a double stacked gasket (11.5 cr) at 7500 or above, I would be fine. Thoughts?

My goal is to be running 96 octane which is ~5 gallons of 91 and ~2 gallons of 110. I could also run 7 gallons of 91 with 24 ounces of Torco in a pinch as that has been independently lab tested as the amount you need to actually obtain 96 octane (torco's mix charts claim only 11.2)

Looking at the octane recommendations from Boondocker, and considering the compression ratio with 2x head gaskets is 11.5, and with the shim is 9.6, this is pretty close to 11.8 and 9.0

With the double stacked head gaskets, I could run 8 psi here for testing and 10 psi out west as every where we go is 7500' or above . With the shim, I could run 10 psi here for testing, and 12 psi out west. I have read numerous posts where users were either removing the head shim completely or not installing them, not touching the timing, and running 10-12 psi on 91-100ll at 10,000'

I would think at 96 octane with a double stacked gasket (11.5 cr) at 7500 or above, I would be fine. Thoughts?

Last edited:

kallholmen

Pro

I am really struggling with what to do about the 2008 motor. Head shim and change the cam timing, or just double stack Cometic head gaskets and leave the cams alone. I ordered the shim, and am going to order two more head gaskets (I have one for the 2010 motor already).

My goal is to be running 96 octane which is ~5 gallons of 91 and ~2 gallons of 110. I could also run 7 gallons of 91 with 24 ounces of Torco in a pinch as that has been independently lab tested as the amount you need to actually obtain 96 octane (torco's mix charts claim only 11.2)

Looking at the octane recommendations from Boondocker, and considering the compression ratio with 2x head gaskets is 11.5, and with the shim is 9.6, this is pretty close to 11.8 and 9.0

With the double stacked head gaskets, I could run 8 psi here for testing and 10 psi out west as every where we go is 7500' or above . With the shim, I could run 10 psi here for testing, and 12 psi out west. I have read numerous posts where users were either removing the head shim completely or not installing them, not touching the timing, and running 10-12 psi on 91-100ll at 10,000'

I would think at 96 octane with a double stacked gasket (9.6 cr) at 7500 or above, I would be fine. Thoughts?

Boost is cool. My system is a bit different from yours and I don't know what turbo etc that you'll be running. But if its the fear of lag that's stopping you from lowering the compression rate you should think again. The little 500 cc produces a lot of heat (a lot!) and the turbo likes heat. And by moving the dump as close to the inlet as possible - well, the turbo keeps spinning and gives you immediate response.

If you pm me your email I can send you install instructions for MCX, its a bit different from yours but I'm sure you'll find it useful.

Do you have a service manual?

Skickat från min iPhone med Tapatalk

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

From what I understand, the head shim is great at lower elevations, at higher elevations it produces a lot of bog and a muddy feel to the low end response. The only time I am going to ride this sled other than testing around here is at elevation. Its not so much the turbo lag I am concerned about, its the overwhelming number of people who do not run a shim when at elevation, most of which run 10 psi and pump gas (91 octane). I do have the manual for the MCX kit just for reference. Thanks for the offer tho! I also have a service manual., but I am thinking of picking up a printed version as well.

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

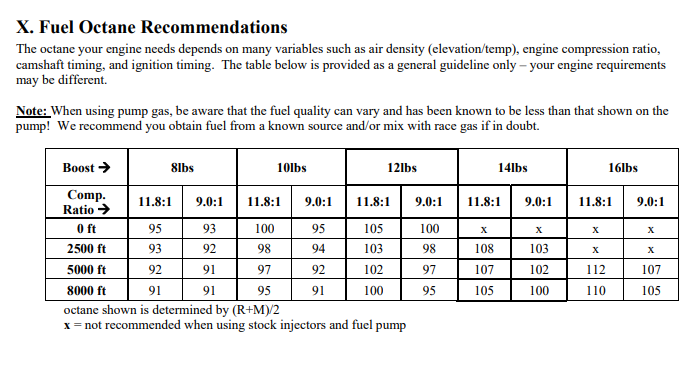

I got the track cut today with the help of a friend. That was a mess. If I ever have to do that again I learned a lot of lessons tho! The biggest take away is that fine toothed blades are NOT the way to go! If I do this again I will be picking up a multi-pack of cheap low-tooth count blades! I killed both of my nice 80 tooth and 60 tooth blades and smoked the hell out of my garage! No in-progress pix, sorry.

This was after I cleaned things up a bit!

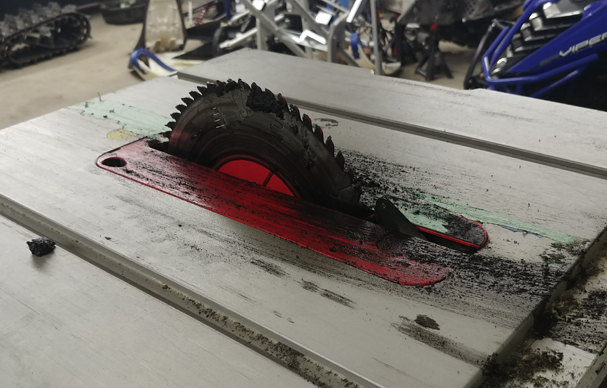

I now have a 151" x 14" x 2" Camoplast Challenger track!

This was after I cleaned things up a bit!

I now have a 151" x 14" x 2" Camoplast Challenger track!

kallholmen

Pro

Ok, but that's why you have a PCV (pressure control valve). It raises the boost due to elevation.

Skickat från min iPhone med Tapatalk

Skickat från min iPhone med Tapatalk

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

I dont have an MCX kit, its a boondockers kit. It doesnt do that.

kallholmen

Pro

Ok, but that's why you have a PCV (pressure control valve). It raises the boost due to elevation.

Skickat från min iPhone med Tapatalk

Edit: I just realised that your gas is different from ours. I run 98 and STP octane booster (stp is probably overkill).

We measure in RoN. America in both Ron an MoN.

Skickat från min iPhone med Tapatalk

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

The last week has been one of those fun weeks where packages just keep showing up! Some of the first to arrive were the Gates Carbon/Kevlar belt and a case of Torco. I assume some of you of you are familiar with the Gates Kevlar belts. I always made a habit of sticking with OEM belts after many trial and error attempts with aftermarket belts in my quad/ATV days, but after trying one of these in the 8DN version in my Viper because the stock belt wouldn't last and there was an insane amount of belt dust everywhere, I am completely sold!

I did an absolutely ridiculous amount of research on octane boosters. None of them do what they claim, not a single one. However, Torco has been in been independently proven to boost octane ratings 3-6 points depending on the fuel you start with, but not at the mixtures they state, and it is not linear, there is a point where you just cant boost your baseline fuel any more despite what they claim. Plus, they rate their boost numbers on RON only. In the US we rate our fuel on (RON + MON / 2) so their numbers do not correlate to what we see at the pumps.

Having said that my ultimate goal is to never have to haul gallons and gallons of fuel around. I am going to plan on running 96 octane, which on a 7 gallon tank is 5 gallons of 91 non-oxy/non-ethanol plus two gallons of 110 or 24 ounces of Torco. If none of those are an option I can run 100ll/AvGas but I will either have to up the boost a bit or loose hp (too much octane isnt better, you can actually loose power) If at all possible, I want to go to Torco route over mixing 91 and 110 as 110 is leaded and will decrease the life span of my wide band 02.

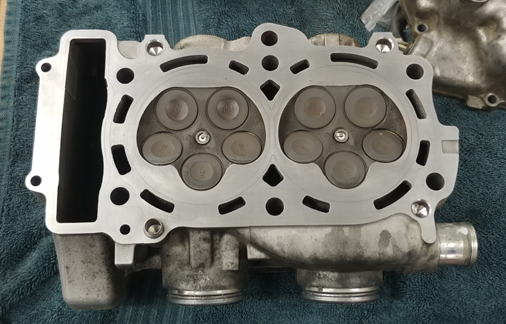

Last night I was able to get back out to the garage to do some wrenching. One of the other items that arrived this week was the ARP head stud kit from @HURRICANE Performance. They didn't actually offer a kit for the Phazer, but since the Phazer & the Nytro/Viper all share the same head studs, just minus two, they put together a "kit" for the Phazer for me. If anyone is interested in buying a Phazer kit for $150 instead of a Nytro/Viper kit for $200 and just not using two of the studs, contact Dave at Hurricane and he will get you squared away. I got the head surfaces on the 08 motor cleaned up and installed the studs. I did notice something slightly concerning on the head. It seems there was an issue at some point in this heads life that wanted to leave its mark.

I also swapped over the Turbo oil supply line from the 2010 motor. It took everything I had not to order a new braided stainless supply line and a different M10x1.0 Tee to clean that whole connection up. I have already spent so much on the project that I have yet to even try, so I told myself that will have to wait. The return line fitting would not come off the 2010 block. Its an aluminum replacement for the plastic plug that is on the stator cover. For now I am just going to swap covers. Eventually I will make my own more durable return line fitting. I already found a source on M32 hex plugs, which I can just add some brass fittings to (everything has to be non-magnetic there)

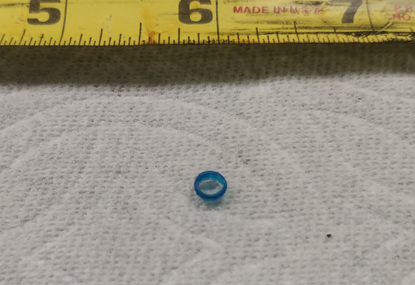

My curiosity about the 2010 engine was killing me, so I decided to pull the head off of it to see what I was dealing with. The valves looked fine, so I assume the leak-down results showing leaking from the exhaust valve on the clutch side are due to a cracked/leaking valve stem seal. The piston on that side however was a different story. Obviously the rings are shot over there as the edges of the piston are washed. What was really strange is that I found this goofy plastic thing laying on the piston. Its not burned or melted, so it couldn't have been there before hand, but I have absolutely no idea where the eff it could have came from!

While I was waiting for parts to arrive this week I did a bunch of re-edumacting myself on tuning. 15+ years ago I built my own turbo 'kit' and engine management system for my project car (using flashable e-proms and soldering a ziff socket into the ECU to burn fuel/ignition maps to). I used to know enough to be dangerous, but most of that has long since been forgotten and now I just remember enough to be really dangerous.

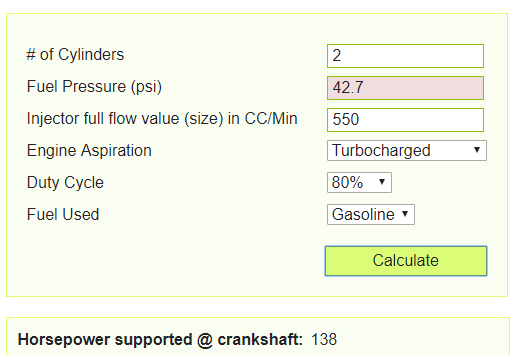

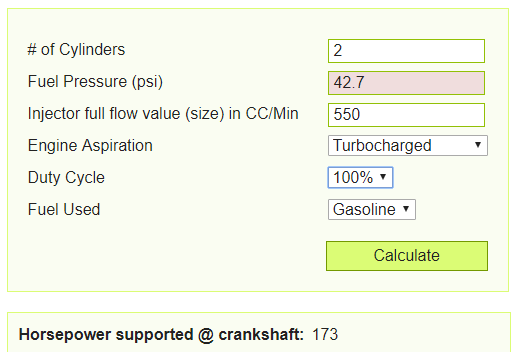

I started with fuel issues, as I never understood how the Boondocker kit seemed to use stock injectors with only a piggy-back fuel programmer vs the MCX kit which included two more injectors on top of the OEM ones. It turns out that the Phazer stock injectors are the same as the Nytro/Viper at 324cc (but only running 42.7psi vs 46 for the Nytro). These injectors support a maximum hp of 98 at 80% duty cycle for non-FI. With a turbo they drop to 82hp. It turns out that Boondockers piggyback does nothing more than push these injectors well over 100% to support their kit, which is a recipe for disaster. From what I do remember, not only does this significantly reduce the lifespan of an injector, there is also no padding for error.

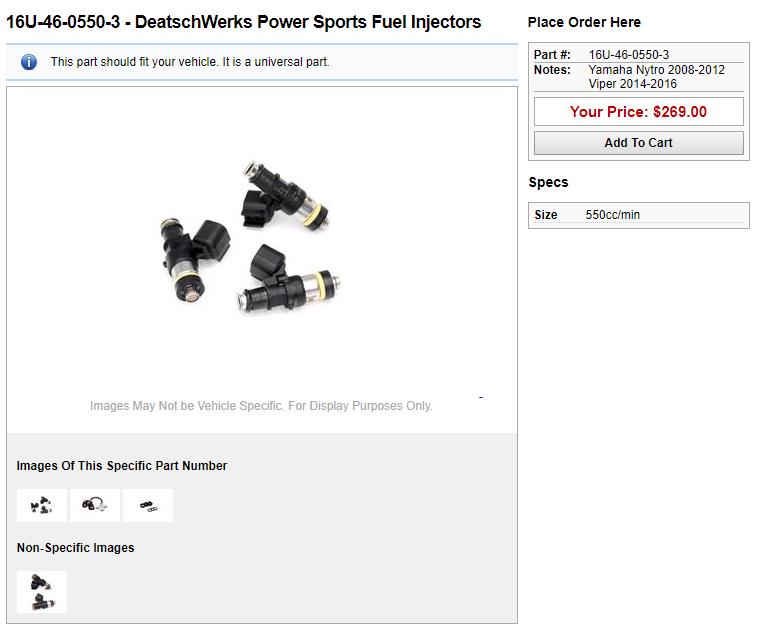

Someday I hope to build the 2010 block for boost with low-comp pistons and stronger rods to really see what we can pull out of these already tweaked 500's. With that in-mind, and knowing that those poor 324's were already being taxed to their limits, I set out to determine what would be needed and how affordable it would be. Could a person go cheap and use some Apex 380cc injectors or would more be needed? Could larger injectors even be added without massive tuning headaches? Has anyone tried this already?

The phazer has a stock fuel pressure of 42.7psi, which is actually quite low. That's a good thing as far as injector life span is considered.Keeping the 80% rule in mind, and shooting for a target hp of at the very least 120, with the potential for 150+ if I build the 2010 block, it would appear that a minimum of a 450cc injectors would be required. After doing a silly amount of google searches, it appears that DeatschWerks makes injector kits for the Nytro and Viper in 550cc. I contacted them and they sold me a 2 injector version of the kit for $179, and will be adding the phazer and this kit to their product line up under the part number 16U-46-0550-2. If anyone is interested in these, contact james@deatschwerks.com or 405-217-0167

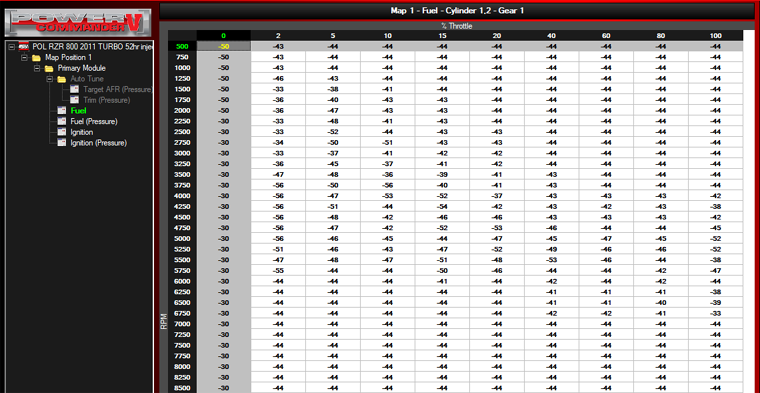

Needing a much better way to manage the tuning for this machine than the Boondocker piggy back box, I started digging into engine management solutions. You can use a map sensor with the standard Power Commander 5 by utilizing the 5v accessory port, however a person would really need the ignition module as well. Power Commander came out with a PCV VTI unit that has fuel, ignition and boost all in one unit which was very appealing. These units are about $500 however. That is when dumb luck struck. I found a brand new unit on clearance at 75% off. A complete engine management solution for $130 bucks is definitely something I can get excited about!

I called and spoke to someone at straightline performance about their chassis dyno since they are basically right down the road from me. I was told that even though their website advertises they offer the dyno and tuning services, they no longer do. Their dyno is reserved for their own R&D purposes for testing of their products. They did say they could make an exception and perhaps get my sled in there for some tuning, but it would be an absolute minimum of $600, and most likely around the $1000 mark. Thats a bit too much for my tastes considering most people pay 400-500 for this. He also said there was no way I was going to be able to get 550cc injectors to run because the PCV fuel mapping is based off of duty cycle, so even setting it at -100 would be -100 of a 324cc injector, leaving the 550 still dumping too much fuel.

I was really bummed out at this point, and feeling like every one who as questioned why the hell I am doing all this to a phazer when I could just get a N/A Nytro and have the same HP was right. I ended up calling Bikeman performance and speaking to their dyno guy since they are just a short drive away as well. I was told they also stopped offering their engine dyno to the public, and use it exclusively for testing of their own parts. However, he was extremely knowledgeable and helpful. Not only did he clarify that I will have no issues getting 550's to run with a PCV, he also talked with me at length about tuning it, and sent me a sample map from a RZR showing fuel & ignition tables (including boost) for going from 330cc to 550cc. He took it a step beyond and told me please dont hesitate to call for any help getting it tuned, and to keep him updated on how it all turns out.

Considering the 2010 only has a 7 gallon fuel tank and all my riding buddies are most likely going to have longer ranges on their fuel, I knew I needed some way to carry extra fuel with me. The giant koplin fuel caddie the sled came with was a bit too much for my tastes. If 96 octane was my goal, something in the 2 gallon size would be perfect as that is how much 110 I would need to mix with 91. A while back I was staring at the Phazer one night thinking about storage/fuel caddies when I realized that the angle under the cut-down seat was very close to that of my Viper. I grabbed the small tail bag from my viper to check. It was damn near perfect. I then remembered reading that the expandable tail bag for the viper fit a 2 gallon rotopax tank perfectly. With the help of some fellow TY Viper owners I was able to determine that it would in fact fit. I got a very lightly used expandable bag from @cannondale27 and a 2 gallon rotopax from Amazon.

I did an absolutely ridiculous amount of research on octane boosters. None of them do what they claim, not a single one. However, Torco has been in been independently proven to boost octane ratings 3-6 points depending on the fuel you start with, but not at the mixtures they state, and it is not linear, there is a point where you just cant boost your baseline fuel any more despite what they claim. Plus, they rate their boost numbers on RON only. In the US we rate our fuel on (RON + MON / 2) so their numbers do not correlate to what we see at the pumps.

Having said that my ultimate goal is to never have to haul gallons and gallons of fuel around. I am going to plan on running 96 octane, which on a 7 gallon tank is 5 gallons of 91 non-oxy/non-ethanol plus two gallons of 110 or 24 ounces of Torco. If none of those are an option I can run 100ll/AvGas but I will either have to up the boost a bit or loose hp (too much octane isnt better, you can actually loose power) If at all possible, I want to go to Torco route over mixing 91 and 110 as 110 is leaded and will decrease the life span of my wide band 02.

Last night I was able to get back out to the garage to do some wrenching. One of the other items that arrived this week was the ARP head stud kit from @HURRICANE Performance. They didn't actually offer a kit for the Phazer, but since the Phazer & the Nytro/Viper all share the same head studs, just minus two, they put together a "kit" for the Phazer for me. If anyone is interested in buying a Phazer kit for $150 instead of a Nytro/Viper kit for $200 and just not using two of the studs, contact Dave at Hurricane and he will get you squared away. I got the head surfaces on the 08 motor cleaned up and installed the studs. I did notice something slightly concerning on the head. It seems there was an issue at some point in this heads life that wanted to leave its mark.

I also swapped over the Turbo oil supply line from the 2010 motor. It took everything I had not to order a new braided stainless supply line and a different M10x1.0 Tee to clean that whole connection up. I have already spent so much on the project that I have yet to even try, so I told myself that will have to wait. The return line fitting would not come off the 2010 block. Its an aluminum replacement for the plastic plug that is on the stator cover. For now I am just going to swap covers. Eventually I will make my own more durable return line fitting. I already found a source on M32 hex plugs, which I can just add some brass fittings to (everything has to be non-magnetic there)

My curiosity about the 2010 engine was killing me, so I decided to pull the head off of it to see what I was dealing with. The valves looked fine, so I assume the leak-down results showing leaking from the exhaust valve on the clutch side are due to a cracked/leaking valve stem seal. The piston on that side however was a different story. Obviously the rings are shot over there as the edges of the piston are washed. What was really strange is that I found this goofy plastic thing laying on the piston. Its not burned or melted, so it couldn't have been there before hand, but I have absolutely no idea where the eff it could have came from!

While I was waiting for parts to arrive this week I did a bunch of re-edumacting myself on tuning. 15+ years ago I built my own turbo 'kit' and engine management system for my project car (using flashable e-proms and soldering a ziff socket into the ECU to burn fuel/ignition maps to). I used to know enough to be dangerous, but most of that has long since been forgotten and now I just remember enough to be really dangerous.

I started with fuel issues, as I never understood how the Boondocker kit seemed to use stock injectors with only a piggy-back fuel programmer vs the MCX kit which included two more injectors on top of the OEM ones. It turns out that the Phazer stock injectors are the same as the Nytro/Viper at 324cc (but only running 42.7psi vs 46 for the Nytro). These injectors support a maximum hp of 98 at 80% duty cycle for non-FI. With a turbo they drop to 82hp. It turns out that Boondockers piggyback does nothing more than push these injectors well over 100% to support their kit, which is a recipe for disaster. From what I do remember, not only does this significantly reduce the lifespan of an injector, there is also no padding for error.

Someday I hope to build the 2010 block for boost with low-comp pistons and stronger rods to really see what we can pull out of these already tweaked 500's. With that in-mind, and knowing that those poor 324's were already being taxed to their limits, I set out to determine what would be needed and how affordable it would be. Could a person go cheap and use some Apex 380cc injectors or would more be needed? Could larger injectors even be added without massive tuning headaches? Has anyone tried this already?

The phazer has a stock fuel pressure of 42.7psi, which is actually quite low. That's a good thing as far as injector life span is considered.Keeping the 80% rule in mind, and shooting for a target hp of at the very least 120, with the potential for 150+ if I build the 2010 block, it would appear that a minimum of a 450cc injectors would be required. After doing a silly amount of google searches, it appears that DeatschWerks makes injector kits for the Nytro and Viper in 550cc. I contacted them and they sold me a 2 injector version of the kit for $179, and will be adding the phazer and this kit to their product line up under the part number 16U-46-0550-2. If anyone is interested in these, contact james@deatschwerks.com or 405-217-0167

Needing a much better way to manage the tuning for this machine than the Boondocker piggy back box, I started digging into engine management solutions. You can use a map sensor with the standard Power Commander 5 by utilizing the 5v accessory port, however a person would really need the ignition module as well. Power Commander came out with a PCV VTI unit that has fuel, ignition and boost all in one unit which was very appealing. These units are about $500 however. That is when dumb luck struck. I found a brand new unit on clearance at 75% off. A complete engine management solution for $130 bucks is definitely something I can get excited about!

I called and spoke to someone at straightline performance about their chassis dyno since they are basically right down the road from me. I was told that even though their website advertises they offer the dyno and tuning services, they no longer do. Their dyno is reserved for their own R&D purposes for testing of their products. They did say they could make an exception and perhaps get my sled in there for some tuning, but it would be an absolute minimum of $600, and most likely around the $1000 mark. Thats a bit too much for my tastes considering most people pay 400-500 for this. He also said there was no way I was going to be able to get 550cc injectors to run because the PCV fuel mapping is based off of duty cycle, so even setting it at -100 would be -100 of a 324cc injector, leaving the 550 still dumping too much fuel.

I was really bummed out at this point, and feeling like every one who as questioned why the hell I am doing all this to a phazer when I could just get a N/A Nytro and have the same HP was right. I ended up calling Bikeman performance and speaking to their dyno guy since they are just a short drive away as well. I was told they also stopped offering their engine dyno to the public, and use it exclusively for testing of their own parts. However, he was extremely knowledgeable and helpful. Not only did he clarify that I will have no issues getting 550's to run with a PCV, he also talked with me at length about tuning it, and sent me a sample map from a RZR showing fuel & ignition tables (including boost) for going from 330cc to 550cc. He took it a step beyond and told me please dont hesitate to call for any help getting it tuned, and to keep him updated on how it all turns out.

Considering the 2010 only has a 7 gallon fuel tank and all my riding buddies are most likely going to have longer ranges on their fuel, I knew I needed some way to carry extra fuel with me. The giant koplin fuel caddie the sled came with was a bit too much for my tastes. If 96 octane was my goal, something in the 2 gallon size would be perfect as that is how much 110 I would need to mix with 91. A while back I was staring at the Phazer one night thinking about storage/fuel caddies when I realized that the angle under the cut-down seat was very close to that of my Viper. I grabbed the small tail bag from my viper to check. It was damn near perfect. I then remembered reading that the expandable tail bag for the viper fit a 2 gallon rotopax tank perfectly. With the help of some fellow TY Viper owners I was able to determine that it would in fact fit. I got a very lightly used expandable bag from @cannondale27 and a 2 gallon rotopax from Amazon.

Last edited:

This is Awesome Digital! I hope to do a similar build in next few years. Anyone who needs to ask why a Phazer has never ridden one!

Keep in mind these motors have steel intake valves and they rust when sitting. Would not surprise me if that is cause of lower readings in first one. When they run problem corrects itself.Let the battle of the blocks commence!

I skipped a rare group ride (had 8 of the 9 of our group going, which is rare for so many of us to all be able to go on the same night) just so I could figure this situation out.

View attachment 137692

I had a hell of a time with my first attempt(s) at leak down testing. The motors kept wanting to turn over at any PSI over 30 if I had them at exactly TDC on the compression stroke. I tried a bar through the clutch at first (pictured) before I learned that if I increased pressure too fast the clutch would move and almost knock the motor over! I ended up finding a rod steel rod that fit inside the holes in the cams and would keep them from turning that worked great.

Both motors were obviously tested cold, and both at the 80 psi standard. With 3-10% leakage being considered good, 11-20% being considered acceptable, and 20+ being time for rebuild

- 2008 Phazer motor with 2200 miles (mods were intake, exhaust, 3* timing advance key & PCV)

- Right side 71 | 10% leakage | Heard in crankcase but also significantly in intake

- Left/Clutch 75 | 6% Leakage | Only heard in crank case

The results speak for themselves. The 2010 motor needs new rings and appears to have burned/dropped an exhaust valve on one side. I'm very interested to see just how bad it is when I strip it down. The 2008 motor seems to just need some head work, either a valve adjustment (seems unlikely at 2200 miles) or some intake valve work.

- 2010 Phazer motor with 1800 miles (turbo with PO running too low of octane for 600 miles)

- Right Side 62 | 22 % leakage | Heard in crankcase

- Left/Clutch 31 | 61% leakage Crankcase & significantly at exhaust

Just to satisfy my curiosity, I decided to test them both at 100 psi even tho that wouldn't give me standards to go off of.

- 2008 Phazer motor

- Right side 83 | 17% leakage | Heard in crankcase but also significantly in intake

- Left/Clutch 87 | 13% Leakage | Only heard in crank case

So I knew the 2010 needed to be rebuilt regardless. Now its all outta whack. I grabbed the airline and ripped it off as fast as I could but it skipped I-don't-even-know-how-many teeth. I'm starting to wonder if that chain is weak. The 08 had no issues with the exact same setup.

- 2010 Phazer motor

- Right Side | I tried to test this, and the damn cam chain started skipping.

- Left/Clutch | see above

I highly doubt JE will be able to get me pistons in time for the March trip. I am going to order four pistons regardless and see if I can't sell one set and hope they come in time. In case they dont I am going to try and get teh 08 engine in the sled to use for the trip. I just have to figure out if I want to get a shim for it, make a shim, or crank down the boost

The JE's we had made were soft. Piston Pin would wear right into them,some just broke and the rings also wore very fast. CP last forever and very strong design with Web under piston. Rings lasted forever. I believe Wiseco copied the CP Web design. Have heard of many that had good luck with them but I never had luck with their rings. Digital why are you using a head shim if you are changing pistons?

DigitalFusion

VIP Member

- Joined

- Jan 19, 2011

- Messages

- 1,152

- Reaction score

- 123

- Points

- 988

- Location

- Chisago City, MN

- Country

- USA

- Snowmobile

- 14 Viper LTX, 10 Turbo Phazer MTX, 08 Phazer, 88 SnoScoot

Keep in mind these motors have steel intake valves and they rust when sitting. Would not surprise me if that is cause of lower readings in first one. When they run problem corrects itself.

That would explain a LOT. The valves from the 08 look perfect and it seems so unlikely that a seal was cracked. Its been sitting for a few years now.

The JE's we had made were soft. Piston Pin would wear right into them,some just broke and the rings also wore very fast. CP last forever and very strong design with Web under piston. Rings lasted forever. I believe Wiseco copied the CP Web design. Have heard of many that had good luck with them but I never had luck with their rings. Digital why are you using a head shim if you are changing pistons?

Hmm. Thats good to know. Those CP's are silly expensive tho. I wonder if Hurricane can't maybe get some better pricing on them. I was just your average Joe calling in so maybe they just quoted me the high retail/MSRP price? It would be great if I could get a package deal on rods and pistons from CP/Carillo.

I ordered the shim just to have. The intent isnt/wasnt to put in the motor with pistons (the 2010 motor), it was for this 08 motor to use while I build the 2010. I was going to try to build both motors at the same time, but I couldnt figure out what to do for pistons and there was pretty much no way I would get them in 6 weeks for our end-of-year trip to Togowotee that I shelved the idea until the off season.

That brings me to my next struggle. I cannot figure out what I want to do about that. Do I run the shim, 2x head gaskets, or a single gasket. This decision is really holding me up big time and I need to figure something out because I could put the 08 motor together if I wanted to test the rust-on-the-valve-seat theory.

Couple pics for you.

Similar threads

- Replies

- 2

- Views

- 979

- Replies

- 8

- Views

- 3K

- Replies

- 2

- Views

- 552

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.