Marks MP

Veteran

- Joined

- Dec 14, 2016

- Messages

- 26

- Reaction score

- 8

- Points

- 203

- Location

- Carleton Place Ontario

- Country

- Canada

- Snowmobile

- 2018 Yamaha SR Venture DX 146

- LOCATION

- Carleton Place

I have a 2016 venture MP and having some serious problems with my clutch. The secondary is held together with a snap ring on the hilicle side of the clutch. I had the clutch apart to change the plastic sliders as they where worn out. Cleaned and reassembled it and reinstalled it on the machine. The clutch worked perfect. Put another 500 K on it.... all fine. Two days ago I was crossing a lake and managed to get 115 KPH but shortly after heard a grinding noise. Took the panels off the PTO side and after driving around a bit realized the snap ring was gone and the washer under it was gone as well. Found pieces of the washer and snap ring in the plastic bottom panel. Buy this time the hilicle was ruined as it was rubbing on the bolts behind the clutch (jackshaft bearing bolts). My Yamaha dealer gave me brand new parts from a new machine in the showroom and reassembled the clutch for me and I reinstalled it on the machine. Tried it again at 110 KPH or so and it happened again. This time I jammed the brakes on so no further damage was done and reassembled everything on the side of the trail. Now I’m paranoide so I don’t go over 80 KPH for the rest of the trip. Could it be that cintrifical force is to much for the lock that is spec for this clutch? Has anyone else ever heard of such a problem?

Mooseman

I'm not all knowing. Post your question in forum.

- Joined

- Nov 3, 2009

- Messages

- 4,021

- Reaction score

- 1,039

- Points

- 1,733

- Location

- Greely, Ontario

- Country

- Canada

- Snowmobile

- '07 Venture MP (gone)

'07 Phazer FX (gone)

'09 Phazer GT (gone)

'10 RS Venture GT (My current ride)

'10 Nytro FX (son's)

- LOCATION

- Greely, ON Canada

Whenever that snap ring is removed it MUST be replaced and it must be installed in the proper way. It has a sharp and rounded side. The sharp side has to be outwards in the groove. And usually, when they fail like that, I have heard that the whole unit has to be replaced. I don't know how yours was replaced so if the dealer took that new one apart and didn't replace the snap ring, well, he could have caused the second failure.

I have taken mine apart as well but replaced the snap ring, no issues including 100km/h+ jaunts.

If you want to replace it with an entirely different unit, this thread has lots of info and also talks about the clip.

https://ty4stroke.com/threads/secondary-clutch-for-mp.148170/

BTW, we're practically neighbours! I haven't seen a lot of other VL/MP's around here, maybe two.

I have taken mine apart as well but replaced the snap ring, no issues including 100km/h+ jaunts.

If you want to replace it with an entirely different unit, this thread has lots of info and also talks about the clip.

https://ty4stroke.com/threads/secondary-clutch-for-mp.148170/

BTW, we're practically neighbours! I haven't seen a lot of other VL/MP's around here, maybe two.

Marks MP

Veteran

- Joined

- Dec 14, 2016

- Messages

- 26

- Reaction score

- 8

- Points

- 203

- Location

- Carleton Place Ontario

- Country

- Canada

- Snowmobile

- 2018 Yamaha SR Venture DX 146

- LOCATION

- Carleton Place

Well that's finicky. Not impressed with the clutch design. I'm going to research some other options.Whenever that snap ring is removed it MUST be replaced and it must be installed in the proper way. It has a sharp and rounded side. The sharp side has to be outwards in the groove. And usually, when they fail like that, I have heard that the whole unit has to be replaced. I don't know how yours was replaced so if the dealer took that new one apart and didn't replace the snap ring, well, he could have caused the second failure.

I have taken mine apart as well but replaced the snap ring, no issues including 100km/h+ jaunts.

If you want to replace it with an entirely different unit, this thread has lots of info and also talks about the clip.

https://ty4stroke.com/threads/secondary-clutch-for-mp.148170/

BTW, we're practically neighbours! I haven't seen a lot of other VL/MP's around here, maybe two.

My wife comes from Osgood. It wouldn't surprise me if we know the some of the same people.

We have 3000 km on this sled and I could count on one hand the amount of VL and MP's ive seen.

You can email if you want to. Markh@sideshift.com

Sent from my SM-G930W8 using Tapatalk

Mooseman

I'm not all knowing. Post your question in forum.

- Joined

- Nov 3, 2009

- Messages

- 4,021

- Reaction score

- 1,039

- Points

- 1,733

- Location

- Greely, Ontario

- Country

- Canada

- Snowmobile

- '07 Venture MP (gone)

'07 Phazer FX (gone)

'09 Phazer GT (gone)

'10 RS Venture GT (My current ride)

'10 Nytro FX (son's)

- LOCATION

- Greely, ON Canada

It's an old design which surprises me of Yamaha using it when there are obviously way better designs.

Only 3k? And it needed new buttons? I did mine around 10k. Glad to have this forum for good info which I checked before doing it. The collective knowledge here is immense.

Only 3k? And it needed new buttons? I did mine around 10k. Glad to have this forum for good info which I checked before doing it. The collective knowledge here is immense.

Marks MP

Veteran

- Joined

- Dec 14, 2016

- Messages

- 26

- Reaction score

- 8

- Points

- 203

- Location

- Carleton Place Ontario

- Country

- Canada

- Snowmobile

- 2018 Yamaha SR Venture DX 146

- LOCATION

- Carleton Place

Thanks Mooseman, I'm going to explore some options. I have a machine shop as part of our company so, it may be my own special mod soon. It will never come off again i can assure you of that. I had the clutch dialed in really nice with polished ramps/helix/bushings, changed the settings from factory to B2. It shifted really nice from top to bottom. I actually was really pleased with the performance until it exploded.

Marks MP

Veteran

- Joined

- Dec 14, 2016

- Messages

- 26

- Reaction score

- 8

- Points

- 203

- Location

- Carleton Place Ontario

- Country

- Canada

- Snowmobile

- 2018 Yamaha SR Venture DX 146

- LOCATION

- Carleton Place

I also changed the belt deflection so it doesn't start in second gear.

Marks MP

Veteran

- Joined

- Dec 14, 2016

- Messages

- 26

- Reaction score

- 8

- Points

- 203

- Location

- Carleton Place Ontario

- Country

- Canada

- Snowmobile

- 2018 Yamaha SR Venture DX 146

- LOCATION

- Carleton Place

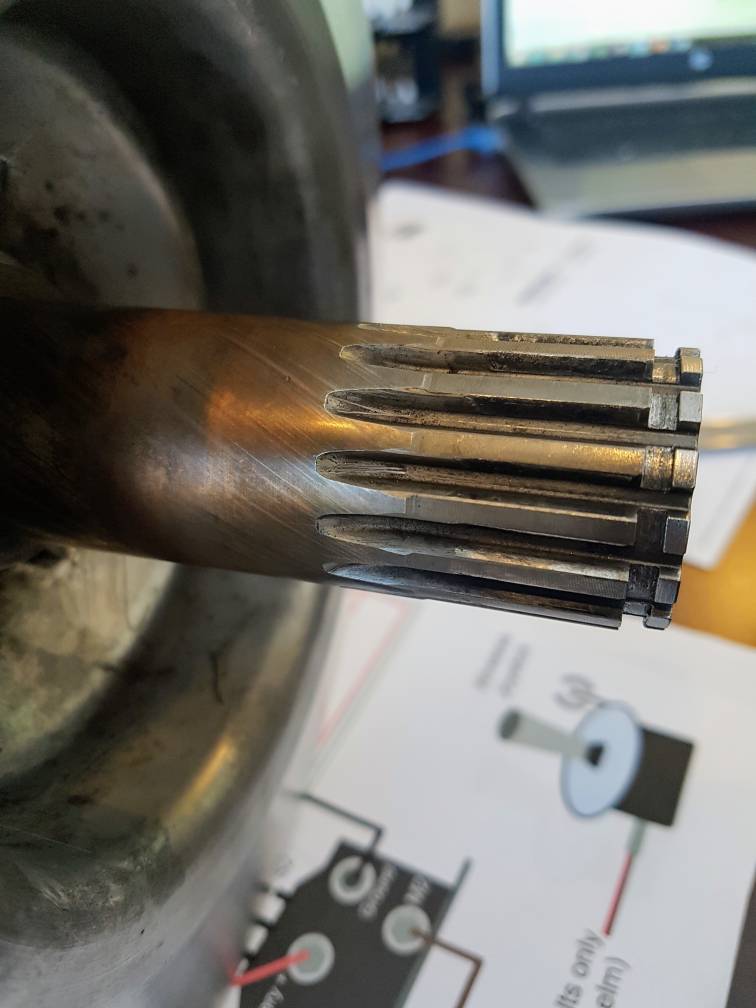

This is my clutch spline. If you zoom in you will see that the groove is damaged. The original lock will no lo get work. I have a really good solution.

Sent from my SM-G930W8 using Tapatalk

Sent from my SM-G930W8 using Tapatalk

Marks MP

Veteran

- Joined

- Dec 14, 2016

- Messages

- 26

- Reaction score

- 8

- Points

- 203

- Location

- Carleton Place Ontario

- Country

- Canada

- Snowmobile

- 2018 Yamaha SR Venture DX 146

- LOCATION

- Carleton Place

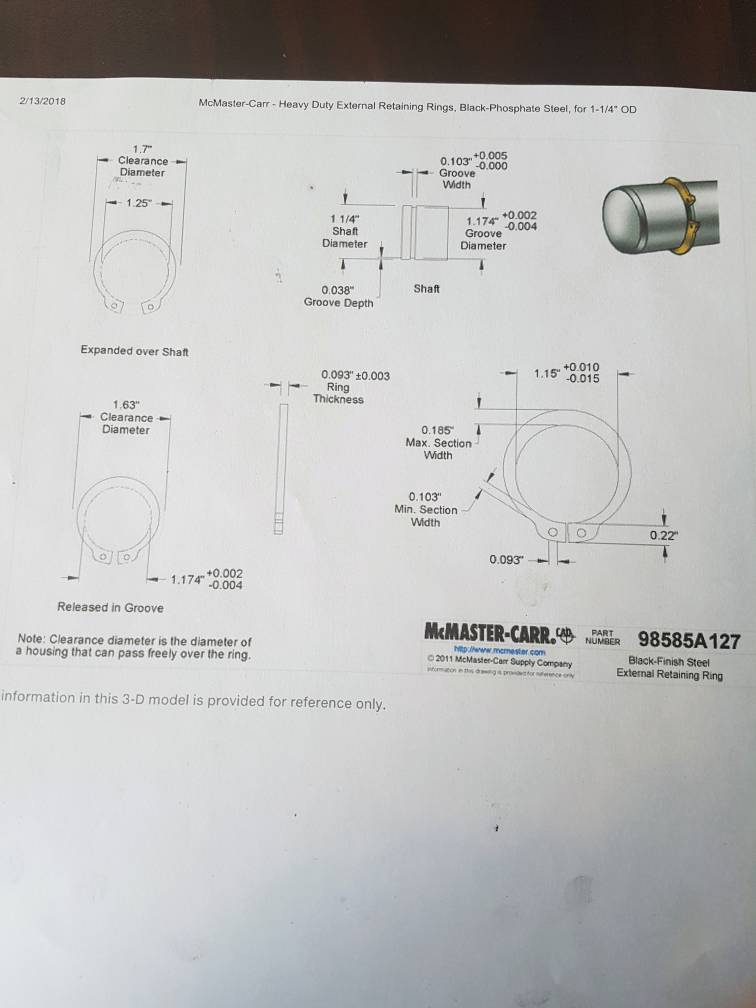

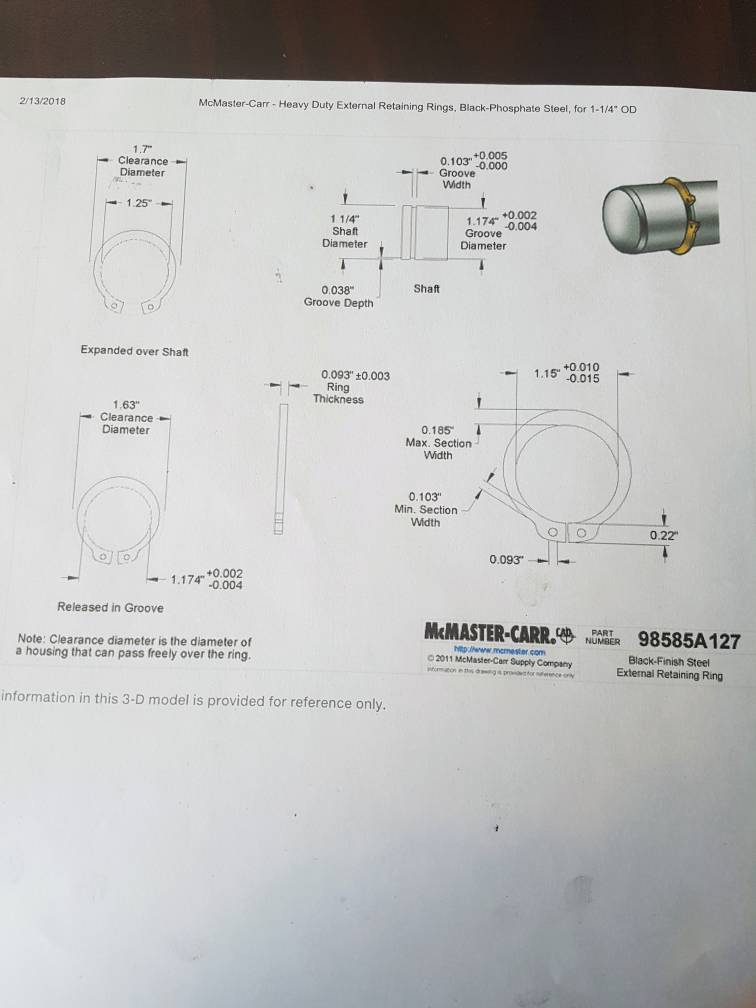

This is the lock I went to for a replacement. This gives me a couple of things. It is a HD lock with 2X the holding power at least. It also was slightly smaller in diameter and wider. This gave me just enough material to work with.

Sent from my SM-G930W8 using Tapatalk

Sent from my SM-G930W8 using Tapatalk

Marks MP

Veteran

- Joined

- Dec 14, 2016

- Messages

- 26

- Reaction score

- 8

- Points

- 203

- Location

- Carleton Place Ontario

- Country

- Canada

- Snowmobile

- 2018 Yamaha SR Venture DX 146

- LOCATION

- Carleton Place

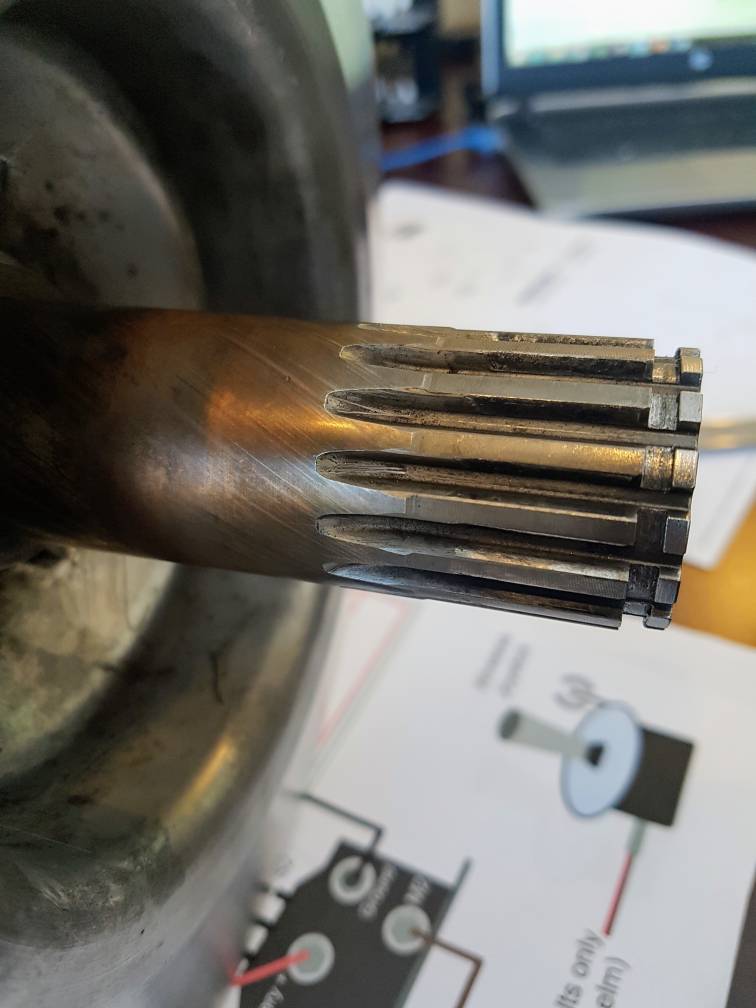

I cut the groove to spec from the engineering drawings.

Sent from my SM-G930W8 using Tapatalk

Sent from my SM-G930W8 using Tapatalk

Marks MP

Veteran

- Joined

- Dec 14, 2016

- Messages

- 26

- Reaction score

- 8

- Points

- 203

- Location

- Carleton Place Ontario

- Country

- Canada

- Snowmobile

- 2018 Yamaha SR Venture DX 146

- LOCATION

- Carleton Place

Another pic. Look at the bottom of the spline and you will how square and true it is.

Sent from my SM-G930W8 using Tapatalk

Sent from my SM-G930W8 using Tapatalk

Marks MP

Veteran

- Joined

- Dec 14, 2016

- Messages

- 26

- Reaction score

- 8

- Points

- 203

- Location

- Carleton Place Ontario

- Country

- Canada

- Snowmobile

- 2018 Yamaha SR Venture DX 146

- LOCATION

- Carleton Place

This picture shows the final cut to the top of the spline on the end of the shaft. I had to bring this into spec so the lock would not stretch upon installation.Another pic. Look at the bottom of the spline and you will how square and true it is.

Sent from my SM-G930W8 using Tapatalk

Sent from my SM-G930W8 using Tapatalk

Marks MP

Veteran

- Joined

- Dec 14, 2016

- Messages

- 26

- Reaction score

- 8

- Points

- 203

- Location

- Carleton Place Ontario

- Country

- Canada

- Snowmobile

- 2018 Yamaha SR Venture DX 146

- LOCATION

- Carleton Place

This solution is a fix. The lock does not even think about moving. I can now bring this machine to top speed with absolutely no concern of it coming apart. The old light duty lock could not handle the centrifugal forces and would spin and ware the groove down. This will never happen again.This picture shows the final cut to the top of the spline on the end of the shaft. I had to bring this into spec so the lock would not stretch upon installation.

Sent from my SM-G930W8 using Tapatalk

Sent from my SM-G930W8 using Tapatalk

Royboy

Veteran

- Joined

- Nov 21, 2016

- Messages

- 30

- Reaction score

- 12

- Points

- 208

- Location

- Winnipeg

- Country

- Canada

- Snowmobile

- Yamaha venture multi purpose

Is that a complete new shaft or re-cut the old one?

Marks MP

Veteran

- Joined

- Dec 14, 2016

- Messages

- 26

- Reaction score

- 8

- Points

- 203

- Location

- Carleton Place Ontario

- Country

- Canada

- Snowmobile

- 2018 Yamaha SR Venture DX 146

- LOCATION

- Carleton Place

Recut the old one on a lathe. The new lock is almost double the width and a little deeper in the groove.Is that a complete new shaft or re-cut the old one?

Sent from my SM-G930W8 using Tapatalk

Mooseman

I'm not all knowing. Post your question in forum.

- Joined

- Nov 3, 2009

- Messages

- 4,021

- Reaction score

- 1,039

- Points

- 1,733

- Location

- Greely, Ontario

- Country

- Canada

- Snowmobile

- '07 Venture MP (gone)

'07 Phazer FX (gone)

'09 Phazer GT (gone)

'10 RS Venture GT (My current ride)

'10 Nytro FX (son's)

- LOCATION

- Greely, ON Canada

Nice work! And good find on that clip. Have you installed the clutch yet? I wonder if the reduced diameter and smaller clip will need a thin washer.

Similar threads

- Replies

- 5

- Views

- 1K

- Replies

- 14

- Views

- 3K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.