AK Jake

Newbie

- Joined

- Dec 27, 2017

- Messages

- 4

- Age

- 42

- Location

- Wasilla, AK

- Country

- USA

- Snowmobile

- 2015 Viper MTX, 270 MCX Turbo

Hey Guys,

I was hoping someone could help me troubleshoot an idling issue with my new 2015 Viper MCX 270 turbo kit. I installed everything according to the installation instructions on the MCX website and the engine will not idle at all. If i let it sit overnight and try to start it is will idle for 5-10 seconds then load up and die. After that it will only run if I keep it at or above 1500 rpm. Above 1500 rpm it seems to run good although I have not take it out for a test drive yet because of how easily it dies. The spark plugs show a rich condition (black and sooty).

So far I have done the following:

1) Cam timing: I was concerned the time chain jumped a tooth on the cam gear so I took it apart again and everything appears to be aligned properly. And yes, I notched the cam gears so the cams will not be advanced after installing the head shim.

2) Auxiliary injectors: When I took off the inter-cooler/intake manifold I notice a small amount of fuel was accumulating on the front side of the throttle air valves suggesting the auxiliary injectors were releasing fuel at idle and low rpm, I have not revved the engine above 3000 rpm since installing the turbo kit. To check if the auxiliary injectors are firing and flooding the engine at idle, I disconnected the auxiliary injector power wire from the MCX control box. This reflected no change in the idle.

3) TPS sensor: I checked the TPS sensor which using the gauge pod/interface showed 0 when closed and 99 when wide open. The throttle has just a minor amount of initial play in it. I don't think this is the problem the engine idled well before the turbo install and will still fire without the throttle engaged.

4) Idle air tube: I checked the idle air tube which connects the throttle body to the intake and it was not obstructed or leaking.

5) Misc checks: All vacuum lines and electrical connections where checked and no loose or disconnected hoses/wires could be located. Spark plugs gaps were in the stock range until I changed them to 0.020". It's my understanding that a lot of turbo guys are running 0.018-0.020" to avoid losing spark at high boost. I would think this shouldn't affect idle though.

Any help would be greatly appreciated!

I was hoping someone could help me troubleshoot an idling issue with my new 2015 Viper MCX 270 turbo kit. I installed everything according to the installation instructions on the MCX website and the engine will not idle at all. If i let it sit overnight and try to start it is will idle for 5-10 seconds then load up and die. After that it will only run if I keep it at or above 1500 rpm. Above 1500 rpm it seems to run good although I have not take it out for a test drive yet because of how easily it dies. The spark plugs show a rich condition (black and sooty).

So far I have done the following:

1) Cam timing: I was concerned the time chain jumped a tooth on the cam gear so I took it apart again and everything appears to be aligned properly. And yes, I notched the cam gears so the cams will not be advanced after installing the head shim.

2) Auxiliary injectors: When I took off the inter-cooler/intake manifold I notice a small amount of fuel was accumulating on the front side of the throttle air valves suggesting the auxiliary injectors were releasing fuel at idle and low rpm, I have not revved the engine above 3000 rpm since installing the turbo kit. To check if the auxiliary injectors are firing and flooding the engine at idle, I disconnected the auxiliary injector power wire from the MCX control box. This reflected no change in the idle.

3) TPS sensor: I checked the TPS sensor which using the gauge pod/interface showed 0 when closed and 99 when wide open. The throttle has just a minor amount of initial play in it. I don't think this is the problem the engine idled well before the turbo install and will still fire without the throttle engaged.

4) Idle air tube: I checked the idle air tube which connects the throttle body to the intake and it was not obstructed or leaking.

5) Misc checks: All vacuum lines and electrical connections where checked and no loose or disconnected hoses/wires could be located. Spark plugs gaps were in the stock range until I changed them to 0.020". It's my understanding that a lot of turbo guys are running 0.018-0.020" to avoid losing spark at high boost. I would think this shouldn't affect idle though.

Any help would be greatly appreciated!

AK Jake

Newbie

- Joined

- Dec 27, 2017

- Messages

- 4

- Age

- 42

- Location

- Wasilla, AK

- Country

- USA

- Snowmobile

- 2015 Viper MTX, 270 MCX Turbo

Alright Fellas,

After spending some more time troubleshooting my idling issue I found the problem. And what I found doesn’t exactly make me feel like the sharpest tool in the shed, if you know what I mean.

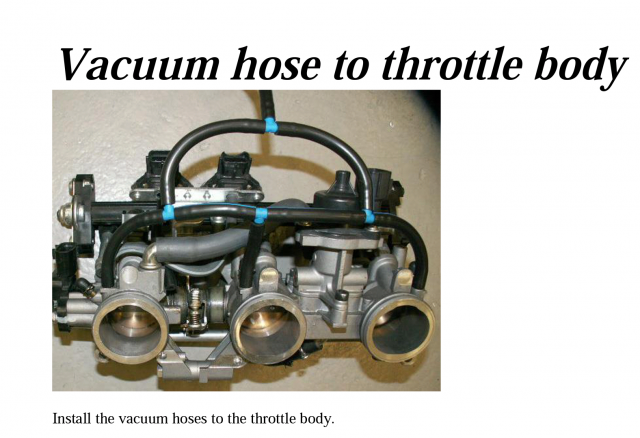

To encourage others to not make to same mistake I did, here is what the problem was. When connecting the three vacuum lines to the throttle bodies as required by the MCX kit I was under the impression that all of the seven vacuum ports on the throttle bodies provided the same vacuum/pressure readings. I was wrong and I should have checked it. It appears that the three vacuum ports closest to the intake side of the throttle bodies provide the same vacuum/pressure as the intake/intercooler. The other four ports (closer to the engine) provide the vacuum /pressure from the engine side of the air throttle valves.

In the image above you can barely see three of the four vacuum ports for the engine side of the throttle bodies which are located directly behind the shown vacuum lines.

Normally this shouldn’t be a big deal unless you decide to reroute vacuum lines to different ports with the intent of streamlining the vacuum system. Total newbie mistake! This is a perfect time to acknowledge that by attempting to make something better you can cause yourself more grief then its worth. With that said, my ultimate error was changing the vacuum line from the MAP sensor (on the throttle body) to the post throttle valve side (closer to the engine). This caused the MAP sensor to receive incorrect vacuum readings which then caused the ECU to tell the injectors to release excess fuel at idle which flooded the engine. Once I switched the line back to the correct port the Viper idles like a champ!

BTW, Brad at Prince George MCX has been trying to help me troubleshoot the problem. I’m just glad I was able to figure it out before sharing too much of my headache with him. He and Don have provided me good customer service and I am pleased with the MCX 270 kit I bought from them.

Hopefully someone will benefit from this post as I have benefited from reading so many other posts on this forum.

After spending some more time troubleshooting my idling issue I found the problem. And what I found doesn’t exactly make me feel like the sharpest tool in the shed, if you know what I mean.

To encourage others to not make to same mistake I did, here is what the problem was. When connecting the three vacuum lines to the throttle bodies as required by the MCX kit I was under the impression that all of the seven vacuum ports on the throttle bodies provided the same vacuum/pressure readings. I was wrong and I should have checked it. It appears that the three vacuum ports closest to the intake side of the throttle bodies provide the same vacuum/pressure as the intake/intercooler. The other four ports (closer to the engine) provide the vacuum /pressure from the engine side of the air throttle valves.

In the image above you can barely see three of the four vacuum ports for the engine side of the throttle bodies which are located directly behind the shown vacuum lines.

Normally this shouldn’t be a big deal unless you decide to reroute vacuum lines to different ports with the intent of streamlining the vacuum system. Total newbie mistake! This is a perfect time to acknowledge that by attempting to make something better you can cause yourself more grief then its worth. With that said, my ultimate error was changing the vacuum line from the MAP sensor (on the throttle body) to the post throttle valve side (closer to the engine). This caused the MAP sensor to receive incorrect vacuum readings which then caused the ECU to tell the injectors to release excess fuel at idle which flooded the engine. Once I switched the line back to the correct port the Viper idles like a champ!

BTW, Brad at Prince George MCX has been trying to help me troubleshoot the problem. I’m just glad I was able to figure it out before sharing too much of my headache with him. He and Don have provided me good customer service and I am pleased with the MCX 270 kit I bought from them.

Hopefully someone will benefit from this post as I have benefited from reading so many other posts on this forum.

Great info!

M7000

Newbie

Hi! I am having similar issues after installing MCX 190 kit to my M7000. I purchased a used kit, and after install the sled wont idle properly. I have to pump the throttle a little to keep it going, if not it will shut down. Just did a little test run, did not rev it hard - but it didn't seem to run very well. I had help installing the kit as I myself am no expert.

Other info: The fuel that was in the tank was a mixture of 95 octane and 98 octane. Could this cause issues with idling?

Do I understand you correctly that your issue was that you misplaced one or more of the vacuum hose(s)? We connected the vacuum hoses to the throttle body like in the picture you posted, then connected the vacuum line to the MCX EFI-box and the other one from the T-fitting to the turbo`s blow-off valve I think it is called (shown on page 13 in the mcx 190 hp manual picture where it points to a nipple on the turbo and says "connect to throttle body").

Is there a difference when connecting the vacuum lines to throttle body depending on whether I am using and intercooler or not? Im not using an intercooler.

Saw some pictures on how to install a MPI 190 kit to viper, and they had connected the vacuum hoses differently. This in shown in Step4 and 5 in the manual for MPI 190 kit.

Ill use the picture from MCX as a reference here: They connected first line (left side in picture) to the nipple furthest to the left in the picture, the nipple that is pointing out in a 45 degree. The second line (in the middle) they connected to nipple that is not showing in the picture (as in the nipple that is behind the vacuum line that is already connected, in this picture). The third line (on the right side in the picture) is also connected to the nipple that is not showing in the picture.

Im sorry for the poor description, but I am on a computer at work and cant upload a picture from the MPI install to show the difference.

Other info: The fuel that was in the tank was a mixture of 95 octane and 98 octane. Could this cause issues with idling?

Do I understand you correctly that your issue was that you misplaced one or more of the vacuum hose(s)? We connected the vacuum hoses to the throttle body like in the picture you posted, then connected the vacuum line to the MCX EFI-box and the other one from the T-fitting to the turbo`s blow-off valve I think it is called (shown on page 13 in the mcx 190 hp manual picture where it points to a nipple on the turbo and says "connect to throttle body").

Is there a difference when connecting the vacuum lines to throttle body depending on whether I am using and intercooler or not? Im not using an intercooler.

Saw some pictures on how to install a MPI 190 kit to viper, and they had connected the vacuum hoses differently. This in shown in Step4 and 5 in the manual for MPI 190 kit.

Ill use the picture from MCX as a reference here: They connected first line (left side in picture) to the nipple furthest to the left in the picture, the nipple that is pointing out in a 45 degree. The second line (in the middle) they connected to nipple that is not showing in the picture (as in the nipple that is behind the vacuum line that is already connected, in this picture). The third line (on the right side in the picture) is also connected to the nipple that is not showing in the picture.

Im sorry for the poor description, but I am on a computer at work and cant upload a picture from the MPI install to show the difference.

AK Jake

Newbie

- Joined

- Dec 27, 2017

- Messages

- 4

- Age

- 42

- Location

- Wasilla, AK

- Country

- USA

- Snowmobile

- 2015 Viper MTX, 270 MCX Turbo

Howdy M7000,

Did you figure out what your problem is? I haven’t installed a MCX 190 kit but I assume the vacuum lines should be installed in the same location as the MCX 270 kit. The vacuum signals should be from the same locations. I know the MPI kits use different vacuum ports and control box so I’d stick with what MCX recommends. With the vacuum lines in the wrong location my machine would not idle at all. I had to keep the throttle so the engine was at least 1500rpm. Anything less and it would die instantly. After switching the vacuum lines it idled perfectly. The engine does not rely on the MCX control box at idle. The engine’s ability to idle is based on the stock ECM and fuel system. I would double check the vacuum lines, all electrical connectors and the throttle position sensor settings. Hopefully one of these will get it running. Mine has been running like a top and is insanely fun since installing the turbo!

Did you figure out what your problem is? I haven’t installed a MCX 190 kit but I assume the vacuum lines should be installed in the same location as the MCX 270 kit. The vacuum signals should be from the same locations. I know the MPI kits use different vacuum ports and control box so I’d stick with what MCX recommends. With the vacuum lines in the wrong location my machine would not idle at all. I had to keep the throttle so the engine was at least 1500rpm. Anything less and it would die instantly. After switching the vacuum lines it idled perfectly. The engine does not rely on the MCX control box at idle. The engine’s ability to idle is based on the stock ECM and fuel system. I would double check the vacuum lines, all electrical connectors and the throttle position sensor settings. Hopefully one of these will get it running. Mine has been running like a top and is insanely fun since installing the turbo!

M7000

Newbie

Howdy M7000,

Did you figure out what your problem is? I haven’t installed a MCX 190 kit but I assume the vacuum lines should be installed in the same location as the MCX 270 kit. The vacuum signals should be from the same locations. I know the MPI kits use different vacuum ports and control box so I’d stick with what MCX recommends. With the vacuum lines in the wrong location my machine would not idle at all. I had to keep the throttle so the engine was at least 1500rpm. Anything less and it would die instantly. After switching the vacuum lines it idled perfectly. The engine does not rely on the MCX control box at idle. The engine’s ability to idle is based on the stock ECM and fuel system. I would double check the vacuum lines, all electrical connectors and the throttle position sensor settings. Hopefully one of these will get it running. Mine has been running like a top and is insanely fun since installing the turbo!

I might have, not sure yet. After going thoroughly through the vacuum hoses and such. We figured out they were all according to MCX plans. Except the baro pressure hose from plenum to the baro sensor, we had connected it to a wrong hose and not the nipple below the baro pressure sensor. This might the fault. The reason i dont know yet, is because it has been a week+ since we installed the turbo, and changed the oil etc,. And tonight we tried a startup at first. The same problems with idling, it would shut down. But after re-organazing the baro hose, it would not start at all. This had us even more confused. But then i checked the oil tank for oil level, and the oil tank was dry. Just hoping no engine damage or turbo damage occured whilst we tried to start up the engine with no oil in the oil tank. Wierdly the oil lamp did not light up when there was no oil in the tank. We did fill the oil tank a week ago when we first installed the turbo, but there has been a leak somewhere. Also made the mistake when changing the chain case oil to dismantle it from the oil tank, so had to make new gasket for the oil tank. Maybe this is the reason for the oil leaking, or it might be from below the engine where you connect the oil hose for the turbo.

Any of you know if the engine has a sensor that wont allow the engine to start when there is no oil in the oil tank, to prevent damage?

So this is where we are at now. First have to find where the oil leak is, fix that, and then try to start up the engine to see if the baro hose was the issue.

AK Jake

Newbie

- Joined

- Dec 27, 2017

- Messages

- 4

- Age

- 42

- Location

- Wasilla, AK

- Country

- USA

- Snowmobile

- 2015 Viper MTX, 270 MCX Turbo

I might have, not sure yet. After going thoroughly through the vacuum hoses and such. We figured out they were all according to MCX plans. Except the baro pressure hose from plenum to the baro sensor, we had connected it to a wrong hose and not the nipple below the baro pressure sensor. This might the fault. The reason i dont know yet, is because it has been a week+ since we installed the turbo, and changed the oil etc,. And tonight we tried a startup at first. The same problems with idling, it would shut down. But after re-organazing the baro hose, it would not start at all. This had us even more confused. But then i checked the oil tank for oil level, and the oil tank was dry. Just hoping no engine damage or turbo damage occured whilst we tried to start up the engine with no oil in the oil tank. Wierdly the oil lamp did not light up when there was no oil in the tank. We did fill the oil tank a week ago when we first installed the turbo, but there has been a leak somewhere. Also made the mistake when changing the chain case oil to dismantle it from the oil tank, so had to make new gasket for the oil tank. Maybe this is the reason for the oil leaking, or it might be from below the engine where you connect the oil hose for the turbo.

Any of you know if the engine has a sensor that wont allow the engine to start when there is no oil in the oil tank, to prevent damage?

So this is where we are at now. First have to find where the oil leak is, fix that, and then try to start up the engine to see if the baro hose was the issue.

It sounds like you’re heading in the right direction. Note that there are two pressure sensors on the throttle body. One measures intake manifold pressure and the other atmospheric pressure (this one is open to the atmosphere and does not have a hose connected to it although it still has a nipple). It is my understanding that the engine control unit (ECM, computer, or whatever you want to call it) monitors oil pressure through a sensor next to the oil filter. This is also the location that I tapped into to for the hose that provides oil to the turbo. When the control unit does not read oil pressure you can not start the engine. From what I’ve read it sounds like the oil pressure has to be very low for this to happen. If you tried to start the engine without oil, as long as you didn’t run it with a load or run it at high rpm the residual oil should have remained on critical engine parts and should not have caused premature wear. Thankfully Yamaha engines are pretty tough. You could pull the engine oil pan drain plug to see if there are any metal shavings. I found some after my first oil change during break in. If you don’t see anything significant, the engine should be alright.

M7000

Newbie

It sounds like you’re heading in the right direction. Note that there are two pressure sensors on the throttle body. One measures intake manifold pressure and the other atmospheric pressure (this one is open to the atmosphere and does not have a hose connected to it although it still has a nipple). It is my understanding that the engine control unit (ECM, computer, or whatever you want to call it) monitors oil pressure through a sensor next to the oil filter. This is also the location that I tapped into to for the hose that provides oil to the turbo. When the control unit does not read oil pressure you can not start the engine. From what I’ve read it sounds like the oil pressure has to be very low for this to happen. If you tried to start the engine without oil, as long as you didn’t run it with a load or run it at high rpm the residual oil should have remained on critical engine parts and should not have caused premature wear. Thankfully Yamaha engines are pretty tough. You could pull the engine oil pan drain plug to see if there are any metal shavings. I found some after my first oil change during break in. If you don’t see anything significant, the engine should be alright.

Thank you for the replies btw

Yea, ive uploaded a picture. Nr 1 is the hose where we originally connected the baro hose with a T split. Nr 2 is the manifold intake pressure? There is nothing connected to this nipple now. And the baro pressure is where the pic says it is.

We have now connected the hose from the plenum to the nipple below where it says baro sensor in the pic. No we did not run it on load or high rpm, just tried to start the engine and it shut down pretty quickly at like 1500 rpm, was checking if it would idle. Thanks for the tips, we are going to investigate further on friday.

Attachments

M7000

Newbie

Ok, idling issues solved. Turns out the problem was a misplaced hose from the plenum to the baro sensor as ive showed in the pic above. As for the oil leak, it seems there wasnt any leak, cause i had some oil containers close to the snowmobile. The reason for the low oil in oil tank must have been because after installing the turbo, you empty out all of the oil in the machine, and the just fill the oil tank. When the oil starts circulating in the machine and turbo, there will be less oil in the oil tank.

Didnt get to try it that much today cause it was -25c outside. But it seemed to not idle in a constant Rpm still, before shutting down the machine i let it idle and it idled between 1450-1750 rmp. Could this be because i noticed there is a small leak on the exhaust, in the connection between the muffler and the turbo. I checked with MCX and there is not supposed to be a gasket there. But from what ive seen it sure needs a gasket. The reason why im suspecting this to tamper with idling is because exhaust will get into the engine room and then get sucked in by the turbo, since im not running a snorkel kit.

Any thoughts?

Didnt get to try it that much today cause it was -25c outside. But it seemed to not idle in a constant Rpm still, before shutting down the machine i let it idle and it idled between 1450-1750 rmp. Could this be because i noticed there is a small leak on the exhaust, in the connection between the muffler and the turbo. I checked with MCX and there is not supposed to be a gasket there. But from what ive seen it sure needs a gasket. The reason why im suspecting this to tamper with idling is because exhaust will get into the engine room and then get sucked in by the turbo, since im not running a snorkel kit.

Any thoughts?

rat4020

Extreme

- Joined

- Oct 28, 2011

- Messages

- 110

- Age

- 101

- Location

- Cold Spring Minnesota

- Country

- USA

- Snowmobile

- Polaris and Turboed Apex in a off road buggy

I have a 08 Apex with a Garret 2860 I’ve been useing a steel gasket since I put the turbo on with no leaks

I got mine from Ulmer Racing

I got mine from Ulmer Racing

M7000

Newbie

Okey, might have to make myself a gasket from steel or copper. Does my exhaust theory seem to fit the idling issue? It also doesnt run very smooth at very low speed, like when your driving and u almost stop, and then want to rev up again. This could ofc also be because at lower speeds not much air is passing in the engine room which leaves room for the exhaust to get into the turbo intake. So first priority is to make a gasket for the exhaust and then see if it will run smoother at very low speed and idling. When giving close to WOT it seemed very good, and also while driving 40-50km/h and then pinning it the response is very good.I have a 08 Apex with a Garret 2860 I’ve been useing a steel gasket since I put the turbo on with no leaks

I got mine from Ulmer Racing

rat4020

Extreme

- Joined

- Oct 28, 2011

- Messages

- 110

- Age

- 101

- Location

- Cold Spring Minnesota

- Country

- USA

- Snowmobile

- Polaris and Turboed Apex in a off road buggy

Just how bad is your leak. I don't think a small leak would affect idle that much but any exhaust leak under the hood would be bad. My apex is not in a sled and is out in the open

Do u have an afr gauge

Do u have an afr gauge

M7000

Newbie

The gap is so big you can see it when you have tightened the bolts, a few mm i suppose. No im not using an AFR gauge, the MCX ecu comes mapped specific to viper engine, so there should be no _need_ for afr or boost gauge, but ofc it can be handyJust how bad is your leak. I don't think a small leak would affect idle that much but any exhaust leak under the hood would be bad. My apex is not in a sled and is out in the open

Do u have an afr gauge

rat4020

Extreme

- Joined

- Oct 28, 2011

- Messages

- 110

- Age

- 101

- Location

- Cold Spring Minnesota

- Country

- USA

- Snowmobile

- Polaris and Turboed Apex in a off road buggy

That’s bad if I was to guess with that bad of leak at idle your over fueling like crazy. I don’t care what MCX sez u neeed a AFR gauge just to monitor what’s goin on with a turboed motor expeshly for classes as wat u got going now. For start you need to adresss your warped flanges and if the gap is that big it’s doubtful a steel gasket will solve the leak

M7000

Newbie

Tried driving it some more today finally. It seems to work very well when driving 40km/h. But it is having difficulties maintaining the same rpm when driving slowly. Im keeping the throttle position the same, but the rpm flickers on its own. Wonder what could be causing that?

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 3

- Views

- 783

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.