Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

We get back to the house and find the issue. I talked him into using a gasket for the oil tank this year. I made one for mine from some PTFE material we have at work and if you don’t know by now, if I make something for my sled, I make 2.

What’s strange about this failure is, he had the oil tank back on 3 weeks prior to this day and it had oil in it but never leaked before today.

I’m thinking the same thing as you, looks like it was overtorqued. But it didn’t show any sign of split gasket or leaks before so it had me thinking the heat from the muffler being so close had to play a contributing factor somehow because I would think it would have leaked before now if it was too tight. Someone told me maybe I used wrong material which caused it or at least helped.

Mine is still holding up fine. So it can’t be material issue. We have rolls of this rubber at work. Some is EPDM for caustic soda, Viton for bleach and this PTFE for pumps and other general stuff. I know I used the right stuff.

Here’s mine.

What’s strange about this failure is, he had the oil tank back on 3 weeks prior to this day and it had oil in it but never leaked before today.

I’m thinking the same thing as you, looks like it was overtorqued. But it didn’t show any sign of split gasket or leaks before so it had me thinking the heat from the muffler being so close had to play a contributing factor somehow because I would think it would have leaked before now if it was too tight. Someone told me maybe I used wrong material which caused it or at least helped.

Mine is still holding up fine. So it can’t be material issue. We have rolls of this rubber at work. Some is EPDM for caustic soda, Viton for bleach and this PTFE for pumps and other general stuff. I know I used the right stuff.

Here’s mine.

Last edited:

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

He got busy pulling his muffler and then removing oil tank after draining it.

Put on some gasket maker and installed tank without tightening it down. Put his Hindle muffler back on and we called it a night.

The next day he tightened the oil tank down the rest of the way and then filled it with oil. No leaks! So now he swears off the gasket and says he would have broke an ear off before he overtightened that tank.

So we did some miles that next morning without any issues.

Put on some gasket maker and installed tank without tightening it down. Put his Hindle muffler back on and we called it a night.

The next day he tightened the oil tank down the rest of the way and then filled it with oil. No leaks! So now he swears off the gasket and says he would have broke an ear off before he overtightened that tank.

So we did some miles that next morning without any issues.

Last edited:

2015ViperMTX

Pro

- Joined

- Feb 20, 2019

- Messages

- 154

- Reaction score

- 35

- Points

- 313

- Location

- Iowa

- Country

- USA

- Snowmobile

- 2015 viper mtx

How’s does the hurricane turbo set perform compared to your turbo kit?

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

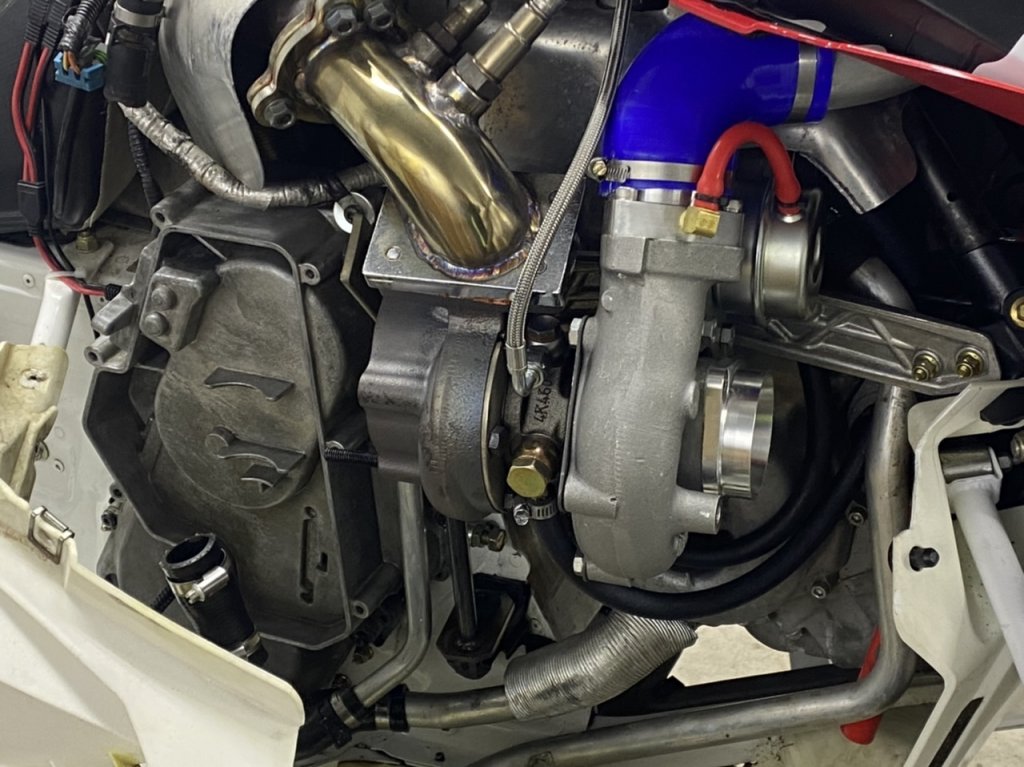

Very comparable. What I don’t like about the Hurricane kit is air filter placement. I don’t think it’s a good idea to pull air right next to the muffler. Cooler air the better. My kit plumbs the intake into the front nose for cold air but has frogskin on front of intake pipe and also there frogskin on front of sled so it’s double layer but no filter like he has. Hurricane kit doesn’t have the intercooler but it’s not like we compared intake air temp either. The Hurricane kit uses a Garrett turbo and I don’t know the brand of my Push turbo. But I do know Garrett is a good brand. The Hurricane kit sits the turbo a little lower than my push kit, not that is an issue either way but it is just a comparison. He had to trim the oil separator heat shield for waste gate clearance and my push came with a new heat shield because it actually moved the thermostat housing up and back a little, not much. The Hurricane kit didn’t come with fittings or lines to hook up coolant to turbo, I thought it would at least come with plugs and not leave open holes on sides of turbo. My brother bought a bunch of different bends and offsets of silicone piping to route his intake into the engine bay and get the filter away from the exhaust. His aluminum intake was a little harder to install than my silicone piping intake but I don’t see any benefit to either one. He had the same 430cc Ulmer injectors. His oil fitting that goes in the engine and feeds the turbo is bigger than mine. Seems like my oil fitting is restricted feeding oil to turbo. Not sure what that’s about. He had an extra fitting and I almost used it but I’m not sure if push did that for a reason. His directions told him to plumb his blow off valve reference hose into the rear vacuum port on throttle body because the nipple has a bigger opening than the front nipple. Push kit said use the front fitting but I opted for the rear anyway. I believe his kit has hoses going to every throttle body and all connect to a fitting. I don’t see why that would be necessary either. Mine used the exhaust side throttle body nipple for blow off valve and I have a little nipple on my intercooler for boost gauge. Hurricane kit came with a heat shield protecting the side panel from the heat where mine did not. I bought a T4 turbo blanket and it actually fit nice but ended up being a pile of you know what. I cut it off before I left and will buy a better quality one. But at least I know the T4 will fit. His kit came with the factory O2 bung and the wideband 18mm bung but no autotune or Wideband2 so if he didn’t have a gauge he would have to just plug it. His kit also had him plug factory O2 back into the harness where mine came with a resistor that plugged into harness. I gave him my spare autotune so he’s adding another bung and so am I for my autotune.How’s does the hurricane turbo set perform compared to your turbo kit?

One of the biggest things to consider, you can actually communicate with Hurricane and I actually leaned on Terry at Thunder Products for a few things during my install because Ken at Push is IMPOSSIBLE to get a hold of.

I hope this helps and answers some of your questions. If you want to see anything in particular, just ask. I may have a picture and if not I will get it next time I’m up.

Oh, I should probably mention the most obvious thing you’re probably wondering about, who’s faster? Off the line, it’s like we’re tied together. At about 20-25 foot I start pulling away from him and can put 2-1/2 maybe 3 sled lengths if we’re talking short tracks. Once we hit about 65-70 mph he starts closing the gap and is at my side right around 82-84mph. When we hit 90, he’s walking past me and keeps going. But I will say, I started to see an over boost and was peaking close to 9 so I let out of it in fear of lifting the head. Have yet to turn it down because I’m not pinning the throttle while in the trails so I’ll mess with it later.

It’s a hard comparison when it comes to that. I have a 153 compared to his 141. I did change my gear so we are on an even playing field in that department. But I have 7 tooth drivers compared to his 8. I installed a 47/43 helix and using the blue spring run at 6-2 and still have my heavy hitters. He did a different weight setup, secondary spring and I can’t remember his helix but it’s not a straight cut either.

And that about sums it up in a nut shell.

Last edited:

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

Ordered a pickle protector and it arrived the other day. At first I was thinking a piece of aluminum like the BOP one would at least give me some added protection but then I said, I’ll just order the pickle protector just to be safe. It’s expensive but not as much as the down time and chain case halves. I gotta say, this is a quality piece and a work of art. Hate that is getting mounted under the sled.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

More parts showed up. I’ve been wanting to do the J&T stealth big wheel kit for the last couple years now.

Clyder6R

Extreme

- Joined

- Dec 24, 2015

- Messages

- 99

- Reaction score

- 61

- Points

- 283

- Location

- Atlantic Canada

- Country

- Canada

- Snowmobile

- 2015 Yamaha Viper MTX 153 McXpress 190 kit

what size did you order? i dont think i have ever measured the stock wheels haha I was looking at doing i think 8" or 9" wheels from the alpha

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

They are 8.5” wheels. The website gives you the size you need for your sled. The XTX 141 was only an 8” but 137 and up (besides the 141 for some reason) were listed at 8.5”. http://www.jtatv.com/STEALTH_BIG_WHEEL_KIT_p/stealth big wheel kit.htmwhat size did you order? i dont think i have ever measured the stock wheels haha I was looking at doing i think 8" or 9" wheels from the alpha

TheNatural

Newbie

- Joined

- Jan 22, 2019

- Messages

- 17

- Reaction score

- 2

- Points

- 333

- Location

- Fort Nelson

- Country

- Canada

- Snowmobile

- 2016 SRViper M-TX 162

Where did you find those idler? I have a 162 MTX and I'd love to add a couple wheels there to help with slider wear.We put on maybe 200 miles between Saturday and a few hours on Sunday. We spent some time trying to lube up his lower ball joint and I installed a few idlers to spread the load off my slides. Also installed a lower front shock shaft on the skid with one that is suppose to be a better quality part. I heard the horror stories of people breaking theirs so I was just being proactive.

View attachment 160212

View attachment 160214

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

I ordered the parts from Partzilla. I looked up the order and this was all the parts I ordered. I can’t remember what sled they were listed for. Maybe an XTX. Hope this helps. It’s been working great for me.Where did you find those idler? I have a 162 MTX and I'd love to add a couple wheels there to help with slider wear.

Sorry for the late response.

| 8JM-RA322-00-00 - NUT,FLG. M6-1.0 Shipped: Monday, January 25, 2021 | 2 | 2 | $0.22 |

| 8JP-G7310-10-00 - SUSPENSION WHEEL A Shipped: Monday, January 25, 2021 | 2 | 2 | $79.14 |

| 8JP-G7419-10-00 - BRACKET 7 Shipped: Monday, December 28, 2020 | 2 | 2 | $13.82 |

| 8JP-RA1B5-00-00 - BOLT, FLANGE 1 Shipped: Monday, December 28, 2020 Shipped: Thursday, February 4, 2021 | 2 | 2 | $5.50 |

| 8JP-RA1B6-00-00 - BOLT, FLANGE 2 Shipped: Monday, December 28, 2020 | 2 | 2 | $1.74 |

| 8JP-RA289-00-00 - SCREW, 10-14X3/4 Shipped: Monday, December 28, 2020 | 2 | 2 | $0.38 |

| 8JP-RA379-00-00 - NUT, LOCK 1 Shipped: Monday, December 28, 2020 | 2 | 2 | $0.74 |

| 8JP-RA466-00-00 - WASHER, 9 Shipped: Monday, December 28, 2020 | 2 | 2 | $2.36 |

| 8JR-G7513-00-00 - RIM,GUIDE WHEEL Shipped: Monday, December 28, 2020 |

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

I’ve taken this machine as far as I wanted without pulling the engine and doing internals along with oil pump mod and ARP hardware. It would have been close to another $4000 for engine work and 300hp upgrade. That wasn’t the issue for me though. My issue is engine management and lack of knock sensors. Stacking on a timing module to the Dynojet was an option to pull timing as boost increased but I finally decided to bite the bullet and just go to the Sidewinder. I absolutely love this Viper and all the upgrades and modifications have been great improvements but I came to the realization that if I wanted safe reliable power above 250, I had to go with the SW with its Mitsubishi ECU for the fail safe engine management. Gonna be hard to give up this machine but all good things must come to an end.

My new to me 18 XTX LE 137. Not a fan of the yellow but that’s the easiest thing to change.

My new to me 18 XTX LE 137. Not a fan of the yellow but that’s the easiest thing to change.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

Some of you may already know but I couldn’t bring myself to sell the Viper. I did all my preseason maintenance even though I knew I’d be spending more time on the Winder.

At the start of season I rode the winder the first 2 trips but I still had to install the DMC top gear. So I took the case apart and thankfully David from DMC reached out and said to check if I had the bad gear, sure enough, I did. So I decided I would ride the Viper until I sent back the bad gear and get it back together.

Next trip up I took the Viper for a shake down run when we got up there and I felt what seemed like my track dragging or out of alignment. Stopped and checked but the rear axle was tight and the track looked good as far as alignment so I continued on another 2 miles. The next intersection I pulled off, removed my helmet and told my buddy, something isn’t right. He said maybe if you let go of your brake it would be better. What?! Said my brake light has been in the entire time. Sure enough, my brake lever wasn’t going back out completely. About 1/2” of free travel from fully extended to where it contacted the piston in the master. I limped it home nice and easy and figured the piston is stuck in the bore. Pulled the master off and since I didn’t have parts I had to put the winder chain case back together with the stock gear (bushing was still good but I didn’t want to fill it and drain again when I got the new gear). Oh well, I can’t be down so that what I did and ride the winder again that trip.

Brought the master home with me and ordered a rebuild kit. Didn’t see anything that raised an eyebrow but the brake fluid was dirty so I chocked it up to maybe moisture in the fluid and it froze but was thawed out by the time I rebuilt it. Idk, it’s rebuilt so I’ll be ready to ride the Viper next trip.

Went back the next weekend, put the master on but the brake lever did the same thing.

Now I have to dig in to see what the issue is. Is it a bad line, not allowing fluid to return? Bad caliper pistons or pads sticking?

First thing I did was try to push the pistons in. They wouldn’t budge! To eliminate the line being the issue, I removed the banjo bolt and line from the caliper and tried to push the pads in again. If they push in and fluid comes out the hole, I know my line is collapsed or pinched somewhere. Nothing! Pistons in caliper are stuck. I sprayed penetrating oil in behind each pad trying to soak around the pistons but still didn’t work. I used a pick to scrape around the pistons best I could to see if there was any build up or debris holing them from pushing in but nothing. After prying, soaking and scraping I was able to force them in about 1/8”.

I’m running a lightweight rotor from BDX and the pad is taller than the rotor surface area so the bottom of the pad (closest to the driveshaft) had more pad material than the upper portion that contacts the rotor. This made it hard to pull pad out. But I finally got the pads out.

I shoved 2 pieces of 3/4” X 1.5” wood fur strips in where the pads sit, hooked up the brake line and used the brake to push the caliper pistons out so I could see what was going on. Thought I would see some rust or crud on the pistons that was not allowing them to push back in but I didn’t. So off came the caliper.

Loosened track and supported the driveshaft with a pipe inside the shaft and then used wood to keep tension off the inner chaincase bearing from the weight of the track while the caliper was off.

At the start of season I rode the winder the first 2 trips but I still had to install the DMC top gear. So I took the case apart and thankfully David from DMC reached out and said to check if I had the bad gear, sure enough, I did. So I decided I would ride the Viper until I sent back the bad gear and get it back together.

Next trip up I took the Viper for a shake down run when we got up there and I felt what seemed like my track dragging or out of alignment. Stopped and checked but the rear axle was tight and the track looked good as far as alignment so I continued on another 2 miles. The next intersection I pulled off, removed my helmet and told my buddy, something isn’t right. He said maybe if you let go of your brake it would be better. What?! Said my brake light has been in the entire time. Sure enough, my brake lever wasn’t going back out completely. About 1/2” of free travel from fully extended to where it contacted the piston in the master. I limped it home nice and easy and figured the piston is stuck in the bore. Pulled the master off and since I didn’t have parts I had to put the winder chain case back together with the stock gear (bushing was still good but I didn’t want to fill it and drain again when I got the new gear). Oh well, I can’t be down so that what I did and ride the winder again that trip.

Brought the master home with me and ordered a rebuild kit. Didn’t see anything that raised an eyebrow but the brake fluid was dirty so I chocked it up to maybe moisture in the fluid and it froze but was thawed out by the time I rebuilt it. Idk, it’s rebuilt so I’ll be ready to ride the Viper next trip.

Went back the next weekend, put the master on but the brake lever did the same thing.

Now I have to dig in to see what the issue is. Is it a bad line, not allowing fluid to return? Bad caliper pistons or pads sticking?

First thing I did was try to push the pistons in. They wouldn’t budge! To eliminate the line being the issue, I removed the banjo bolt and line from the caliper and tried to push the pads in again. If they push in and fluid comes out the hole, I know my line is collapsed or pinched somewhere. Nothing! Pistons in caliper are stuck. I sprayed penetrating oil in behind each pad trying to soak around the pistons but still didn’t work. I used a pick to scrape around the pistons best I could to see if there was any build up or debris holing them from pushing in but nothing. After prying, soaking and scraping I was able to force them in about 1/8”.

I’m running a lightweight rotor from BDX and the pad is taller than the rotor surface area so the bottom of the pad (closest to the driveshaft) had more pad material than the upper portion that contacts the rotor. This made it hard to pull pad out. But I finally got the pads out.

I shoved 2 pieces of 3/4” X 1.5” wood fur strips in where the pads sit, hooked up the brake line and used the brake to push the caliper pistons out so I could see what was going on. Thought I would see some rust or crud on the pistons that was not allowing them to push back in but I didn’t. So off came the caliper.

Loosened track and supported the driveshaft with a pipe inside the shaft and then used wood to keep tension off the inner chaincase bearing from the weight of the track while the caliper was off.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

After removing the caliper, I found my issue and it was my own fault. When I had this caliper off before I sandblasted it and painted it with POR15 high heat black paint. I never cured it with heat like you are suppose to do. Figured it would cure with heat cycles from use on its own. Well, it must have never fully cured and after installing the turbo and driving it like I’m sponsored, it got hot and some of the paint got on the pistons. Probably the last ride of the season and it sat all summer and that paint cured to the pistons. When I first painted it I taped off the pistons and stayed away from the piston bore so this paint wouldn’t get into the gap but it made its way in when it got hot. Anyone who’s worked with this stuff knows it’s some good stuff and it sealed the piston to the caliper. Totally my fault. So the Viper didn’t get but 15 miles on it this past season.

Picture from when I first painted it.

Ordered a rebuild kit that came with new pistons, seals and o-ring that goes between the two halves. Rebuilt it and installed it this summer.

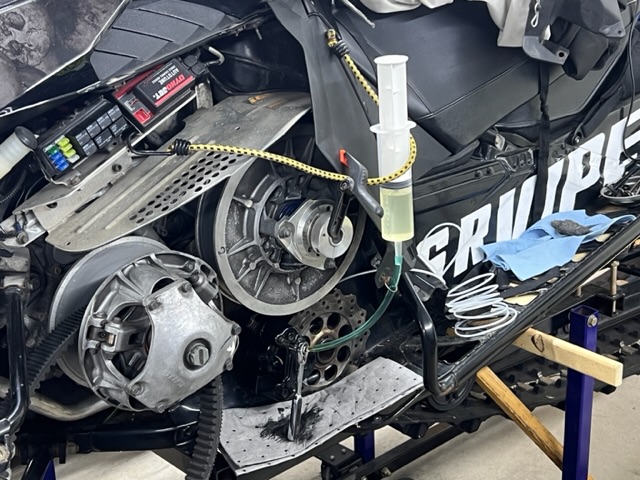

I’ve only ever had good luck reverse bleeding these things. Use syringe to push fluid to the master.

I removed almost all the fluid from the master with a mighty vac hand pump and pushed fluid to the master. It wouldn’t push into master. Pulled the line off master and put open end of line into a catch can and was able to get fluid up and out the line without issue. Ok, now what?

Put line back on master and could not push anything into master. Lever to bar, lever all the way out, half way, quarter way, didn’t matter. Fluid would not go past seal in master.

Off comes master again! Pulled piston and found the umbrella seal swelled like fluid contamination but I only used DOT4 from a sealed container. Wrong materials of construction from factory? This is starting to really make me mad. I only have limited time up north and this is already taking way too long. No parts near there so I pulled out the master rebuild kit with all the old parts I saved and figured, the problem wasn’t the master to begin with so these should actually be ok. Right?

Look at how much the new seal swelled compared to the old one.

Put master back together, pushed fluid right thru it like it should have and filled the master.

Had to empty the master a few times to get all the air out but finally, I have working brakes again.

And yes, I cleaned the POR15 off from around the pistons and heat soaked that thing 3 times before putting it back together.

Picture from when I first painted it.

Ordered a rebuild kit that came with new pistons, seals and o-ring that goes between the two halves. Rebuilt it and installed it this summer.

I’ve only ever had good luck reverse bleeding these things. Use syringe to push fluid to the master.

I removed almost all the fluid from the master with a mighty vac hand pump and pushed fluid to the master. It wouldn’t push into master. Pulled the line off master and put open end of line into a catch can and was able to get fluid up and out the line without issue. Ok, now what?

Put line back on master and could not push anything into master. Lever to bar, lever all the way out, half way, quarter way, didn’t matter. Fluid would not go past seal in master.

Off comes master again! Pulled piston and found the umbrella seal swelled like fluid contamination but I only used DOT4 from a sealed container. Wrong materials of construction from factory? This is starting to really make me mad. I only have limited time up north and this is already taking way too long. No parts near there so I pulled out the master rebuild kit with all the old parts I saved and figured, the problem wasn’t the master to begin with so these should actually be ok. Right?

Look at how much the new seal swelled compared to the old one.

Put master back together, pushed fluid right thru it like it should have and filled the master.

Had to empty the master a few times to get all the air out but finally, I have working brakes again.

And yes, I cleaned the POR15 off from around the pistons and heat soaked that thing 3 times before putting it back together.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

This last time I was up I replaced the DuPonts with actual MTX ones. The 129-146 DuPonts do work on the 153 but the inserts do not go all the way to the rear of the rails. They do now.

Put on a set of tunnel scratchers also. Was able to get them installed in the lower hole and the suspension bolt actually helps hold the spring tension so all the force is not on the drilled hole. Worked out great.

Installed the brackets on the tunnel and they tuck up nice and out of the way when not in use.

Put on a set of tunnel scratchers also. Was able to get them installed in the lower hole and the suspension bolt actually helps hold the spring tension so all the force is not on the drilled hole. Worked out great.

Installed the brackets on the tunnel and they tuck up nice and out of the way when not in use.

Snowbound98

Expert

- Joined

- Mar 11, 2019

- Messages

- 317

- Reaction score

- 184

- Points

- 388

- Location

- Chicagoland

- Country

- USA

- Snowmobile

- 2015 SR Viper M-TX 153

Similar threads

- Replies

- 5

- Views

- 3K

- Replies

- 20

- Views

- 9K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.