hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,875

- Reaction score

- 2,750

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

Making some progress on my solid axle rear wheel kit. By now many have already purchased 4th wheel kits, but the nice thing about my design is it will allow for any combination of wheels that you may already have whether it be J&T, Yamaha or even the stock tri hub wheels. This will allow many to upgrade to a true solid axle for less money and not make their previous wheel kit purchase obsolete.

In addition my kit upgrades the track adjusters to a billet piece.

Details to follow as I progress!

In addition my kit upgrades the track adjusters to a billet piece.

Details to follow as I progress!

Nice hurry up only 180 days till snow!!!!

Hammer70

GRIPNRIP

- Joined

- Sep 6, 2015

- Messages

- 824

- Reaction score

- 649

- Points

- 1,128

- Location

- Niagara, Ontario.

- Country

- Canada

- Snowmobile

- 82SS440/96VMAX/02SRX/08APE/15SRVIPER/17SIDEWINDER

Sounds interesting I was just going to purchase J&T keep me posted thanksMaking some progress on my solid axle rear wheel kit. By now many have already purchased 4th wheel kits, but the nice thing about my design is it will allow for any combination of wheels that you may already have whether it be J&T, Yamaha or even the stock tri hub wheels. This will allow many to upgrade to a true solid axle for less money and not make their previous wheel kit purchase obsolete.

In addition my kit upgrades the track adjusters to a billet piece.

Details to follow as I progress!

franklin

Pro

Keep us posted, I'm sure it will be another addition to these sleds.

bleedyamaha

TY 4 Stroke Master

- Joined

- Sep 28, 2013

- Messages

- 1,494

- Reaction score

- 742

- Points

- 1,308

- Location

- Northern Iowa

- Country

- USA

- Snowmobile

- 2017 Yamaha Sidewinder Rtx Le 2012 Yamaha Vector Ltx

Watching. I am back to two wheels temperaily

Snowaddict

TY 4 Stroke Master

- Joined

- Feb 28, 2005

- Messages

- 1,107

- Reaction score

- 327

- Points

- 1,188

- Location

- Menasha, WI

- Country

- USA

- Snowmobile

- '17 Sidewinder LTX-LE

- mstahl88

So, if I already only added the 2 Yamaha wheels to the outside, your axle can just replace the stock axle and be used with all 4 existing wheels? And this is still addressing the common issue of stock tri hub failure? If so, I'm subscribed. Was going to get a replacement kit for next season and this may just be the ticket.

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,875

- Reaction score

- 2,750

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

So, if I already only added the 2 Yamaha wheels to the outside, your axle can just replace the stock axle and be used with all 4 existing wheels? And this is still addressing the common issue of stock tri hub failure? If so, I'm subscribed. Was going to get a replacement kit for next season and this may just be the ticket.

The design is quite versatile which will allow me to cater to almost anyone's desire.

The tri hub is a strong design, it just is not forgiving if you slack off on bearing upkeep and loose a bearing in one of the wheels. My kit will give you the option to use the stock tri hub wheels or replace them with independent wheels. Another alternative is you can just cut off the 3 posts that joint the two tri hub wheels to make them independent. As for the outside wheels as long as they have a 6004 or 6205 bearing they can be used with my axle kit.

The kit will require modification to the rail slot and I have slick set up designed. Once i get my prototype plates back and do an install I will post some pictures.

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,875

- Reaction score

- 2,750

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

After a few different mock ups I think I have come up with a design that suits me. Despite different rail designs on the 129, 137 and 141 skids I was able to come up with one design that will work for all. Hope to meet up with my machinist next week to discuss some things and get him started on some of the components.

**sj**

Lifetime Member

- Joined

- Mar 2, 2004

- Messages

- 6,064

- Reaction score

- 969

- Points

- 1,983

- Location

- southeastern Mich

- Country

- USA

- Snowmobile

- 2019 SRX

The design is quite versatile which will allow me to cater to almost anyone's desire.

The tri hub is a strong design, it just is not forgiving if you slack off on bearing upkeep and loose a bearing in one of the wheels. My kit will give you the option to use the stock tri hub wheels or replace them with independent wheels. Another alternative is you can just cut off the 3 posts that joint the two tri hub wheels to make them independent. As for the outside wheels as long as they have a 6004 or 6205 bearing they can be used with my axle kit.

The kit will require modification to the rail slot and I have slick set up designed. Once i get my prototype plates back and do an install I will post some pictures.

I hope not

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,875

- Reaction score

- 2,750

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

Been awhile since I posted anything on this. Some have raised concern of having to modify the rails, but reality is if you want to run a true 25mm axle the slot has to be enlarged. Below are a few pictures and I will explain my logic. I would like some feedback once you see what I'm proposing.

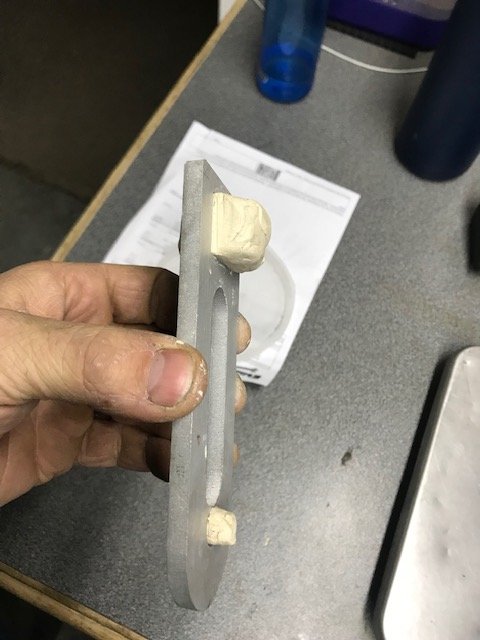

The rail adaptor plates will have track adjustment blocks integrated into them. The rail plate will likely be 1 machined billet piece as shown below. It would snap into the rail, self locating itself and would be fixed in place. Similar concept as a rail extension. I used some clay to depict the concept for photo below.

Once the plate is snapped in place you would then mark the new slot on the rail. Using a burr( which I would provide with the kit) you simply use an air tool or drill to enlarge the slot in the rail. The slot does not have to be perfect and can be oversized....it just needs to be opened so the axle can clear. Once you snap the rail plate on have a perfectly aligned slot and your grinding work is completely hidden. Its approximately 3.5 mm that need to be removed on top and bottom of slot.

Please provide some feedback so I can determine if this is worth pursuing. There are more details to sort out, but main thing I need to know is if you would consider modifying the rail.

The rail adaptor plates will have track adjustment blocks integrated into them. The rail plate will likely be 1 machined billet piece as shown below. It would snap into the rail, self locating itself and would be fixed in place. Similar concept as a rail extension. I used some clay to depict the concept for photo below.

Once the plate is snapped in place you would then mark the new slot on the rail. Using a burr( which I would provide with the kit) you simply use an air tool or drill to enlarge the slot in the rail. The slot does not have to be perfect and can be oversized....it just needs to be opened so the axle can clear. Once you snap the rail plate on have a perfectly aligned slot and your grinding work is completely hidden. Its approximately 3.5 mm that need to be removed on top and bottom of slot.

Please provide some feedback so I can determine if this is worth pursuing. There are more details to sort out, but main thing I need to know is if you would consider modifying the rail.

I wonder if this jig would allow conversion to 19 axle and 6205 bearings?Been awhile since I posted anything on this. Some have raised concern of having to modify the rails, but reality is if you want to run a true 25mm axle the slot has to be enlarged. Below are a few pictures and I will explain my logic. I would like some feedback once you see what I'm proposing.

The rail adaptor plates will have track adjustment blocks integrated into them. The rail plate will likely be 1 machined billet piece as shown below. It would snap into the rail, self locating itself and would be fixed in place. Similar concept as a rail extension. I used some clay to depict the concept for photo below.

View attachment 142234

Once the plate is snapped in place you would then mark the new slot on the rail. Using a burr( which I would provide with the kit) you simply use an air tool or drill to enlarge the slot in the rail. The slot does not have to be perfect and can be oversized....it just needs to be opened so the axle can clear. Once you snap the rail plate on have a perfectly aligned slot and your grinding work is completely hidden. Its approximately 3.5 mm that need to be removed on top and bottom of slot.

View attachment 142235

Please provide some feedback so I can determine if this is worth pursuing. There are more details to sort out, but main thing I need to know is if you would consider modifying the rail.

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,875

- Reaction score

- 2,750

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

Ok...so not much feed back on modifying the rail. I'm going to assume many will no want to and going to move ahead with my plan B.

Plan B will still be a stronger option that utilizes a solid axle and no rail modifications. This option will also work as an upgrade kit and utilize all the wheels existing in the various 4th wheel kits on the market. Stay tuned. More details to follow soon!

Plan B will still be a stronger option that utilizes a solid axle and no rail modifications. This option will also work as an upgrade kit and utilize all the wheels existing in the various 4th wheel kits on the market. Stay tuned. More details to follow soon!

race24x

TY 4 Stroke Master

- Joined

- Dec 29, 2003

- Messages

- 1,038

- Reaction score

- 44

- Points

- 988

- Location

- Belgrade, Maine

- Website

- www.r-scomputer.com

I am very interested in this. I am getting ready to place an order with you and would like to get all at once. I did not see a price for your ice scratchers and the mounts for skis. I also want the belt adjustor/belt change tool a belly pan protector and the 4th wheel kit. You know all of the stuff these things need to be right.

race24x

TY 4 Stroke Master

- Joined

- Dec 29, 2003

- Messages

- 1,038

- Reaction score

- 44

- Points

- 988

- Location

- Belgrade, Maine

- Website

- www.r-scomputer.com

Just want to put this back up top as I want to upgrade this before I ride this year

hibshman25

Vendor

- Joined

- Sep 25, 2005

- Messages

- 2,875

- Reaction score

- 2,750

- Points

- 1,603

- Location

- Lebanon, PA 17042

- Country

- USA

- Snowmobile

- 2017 sidewinder ltx dx

2018 snoscoot

I should have all components in a week or 2 and then I will post up pics of the whole set up and pricing.

In my opinion the weak point in all rear axle set ups except the Larson is the 2 mounting bolts. My kits will address this at a more affordable price. Will share as soon as I have parts in hand!

In my opinion the weak point in all rear axle set ups except the Larson is the 2 mounting bolts. My kits will address this at a more affordable price. Will share as soon as I have parts in hand!

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 5

- Views

- 4K

- Replies

- 7

- Views

- 2K

- Replies

- 42

- Views

- 7K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.