If you had one you know it sucks to replace and could lead to engine damage from overheating. They usually crack at left engine mount where it’s welded to exchanger. Offtrail guys are plagued by this issue but even trail sleds have been afflicted. Mine did it end of last season. I noticed the Sidewinders had an aluminum tube connecting the two mounts and one long bolt vs our two. So I came up with a kit to do the same. Cannondale did same thing to solve issue of engine mounts breaking off. I really believe this will help if not solve. Limited availability. $100 shipped in USA. Murdered you want second one!

GR8BBQ

TY 4 Stroke Master

- Joined

- Mar 23, 2018

- Messages

- 1,365

- Location

- Hamlin, NY

- Country

- USA

- Snowmobile

- 2017 Yamaha SRViper X-TX SE

2017 Ski-Doo Blizzard 900 ACE

2001 Yamaha SXR 700 Triple

1995 Polaris Indy Lite

What does it take to install this? What's the process and time estimate? I'm interested.

Seat,Shield,Tank and Exhaust header has to be removed and the Jackshaft Spar rotated then each engine mount bolt one at a time with left first. Stick bolt in then remove right bolt. Install tube and washers as you push bolt in. I would say 2hrs. I added Instructions with pics below.What does it take to install this? What's the process and time estimate? I'm interested.

Last edited:

DennyTuna

RIP-Logan-Dylan-Never forgotten!

- Joined

- Jan 28, 2017

- Messages

- 727

- Age

- 62

- Location

- Ohio

- Country

- USA

- Snowmobile

- 18 Winder LTX 50th

16 SR Viper RTX (red)

02 SX Viper ER (red)

97 SX Vmax 600 (red)

Yes it does, replaced one this summer on my nephews Viper. Big job! Nice work Steve, I too believe this will be a game changer for high mile trail guys.If you had one you know it sucks to replace

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,268

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Great idea, I'm jealous I didn't think of it first!

Do you think this will prevent breaking in that common area, or was that just a problem on the first couple years?

Do you think this will prevent breaking in that common area, or was that just a problem on the first couple years?

DennyTuna

RIP-Logan-Dylan-Never forgotten!

- Joined

- Jan 28, 2017

- Messages

- 727

- Age

- 62

- Location

- Ohio

- Country

- USA

- Snowmobile

- 18 Winder LTX 50th

16 SR Viper RTX (red)

02 SX Viper ER (red)

97 SX Vmax 600 (red)

I believe it's all Viper MY sleds. So, I can say that we had a high-quality welder do some reinforcing on the new heat exchanger and he had this to say. The aluminum used is very low quality and it's machined welded from the supplier and not very good at that. He worked his magic and gave us back a much better weld job with reinforcement. Will it last longer than factory weld? Maybe, only time will tell. I believe what Steve is doing will have better results than just beefing up the welds. The welds are breaking on the clutch side top near motor mount, think about how much torque is being placed on that spot from the motor and clutches. The weakest link will fail...the factory weld. Can't believe I didn't' think of this as well because I knew my Sidewinder only used 1 bolt and Sidewinders don't share this problem with the Viper. Using one bolt allows this torque to be placed across a larger area unlike the Viper which is two smaller independent mounts placing the mount closet to the clutches to bear a tremendous load. I will say that this problem will not show up on all Vipers, only those that ride aggressive and put on a lot of miles. This is my groups 3rd heat exchanger break and they suck to replace.Do you think this will prevent breaking in that common area, or was that just a problem on the first couple years?

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,268

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

I'm working on a Viper valve adjustment today. The only issue I see is that it won't be easy to get that long bolt in there as both sides have obstructions.I believe it's all Viper MY sleds. So, I can say that we had a high-quality welder do some reinforcing on the new heat exchanger and he had this to say. The aluminum used is very low quality and it's machined welded from the supplier and not very good at that. He worked his magic and gave us back a much better weld job with reinforcement. Will it last longer than factory weld? Maybe, only time will tell. I believe what Steve is doing will have better results than just beefing up the welds. The welds are breaking on the clutch side top near motor mount, think about how much torque is being placed on that spot from the motor and clutches. The weakest link will fail...the factory weld. Can't believe I didn't' think of this as well because I knew my Sidewinder only used 1 bolt and Sidewinders don't share this problem with the Viper. Using one bolt allows this torque to be placed across a larger area unlike the Viper which is two smaller independent mounts placing the mount closet to the clutches to bear a tremendous load. I will say that this problem will not show up on all Vipers, only those that ride aggressive and put on a lot of miles. This is my groups 3rd heat exchanger break and they suck to replace.

Yes you have to rotate the spar holding jackshaft speaking of that. Ever notice there is a hole in that spar that directly lines up with the engine mounts. I bet at one time they were going to use a even longer bolt and go through the hole with spacers.I'm working on a Viper valve adjustment today. The only issue I see is that it won't be easy to get that long bolt in there as both sides have obstructions.

Last edited:

Instructions:

Get spar to this point. Be careful of Brakeline and Wiring. Pulling coolant overflow line out of way first helps make this easy. Of course if chaincase is apart just remove Jackshaft. But not necessary. I left my header on and was easily able to do this with some finesse and extendable magnet. I do not know if able to with stock header. Do not lose the washers/spacers provided. They determine the overall length.

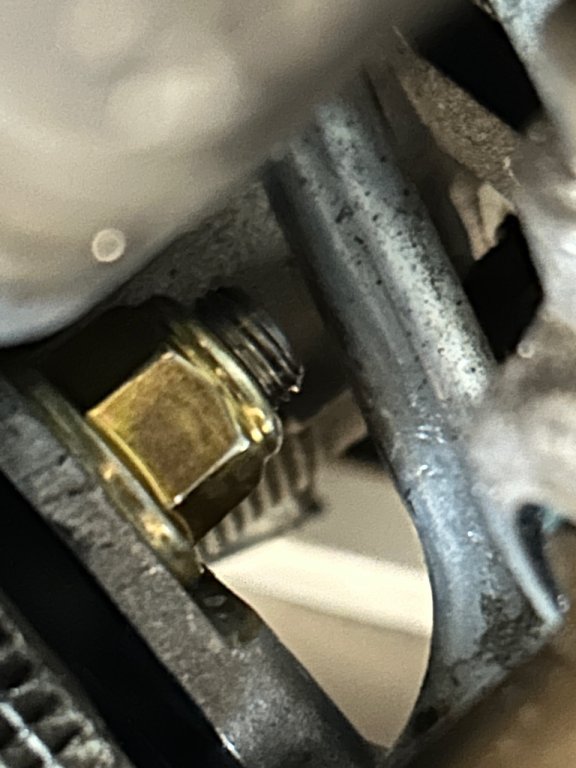

18mm nut and 15mm bolthead remove this nut then using the new long bolt which is lubed very lightly with grease but not on threads gently drive the left bolt out with soft face hammer stop when original bolt falls out. Will fall right out access panel on bottom for changing oil.

At this point remove the right side Engine Mount Bolt. Put one washer(Flat Ground Side Toward Mount) provided on the slightly protruding new bolt then using a magnet fish the spacer in between the Washer and right Mount. Once bolt is in far enough to support spacer tube put other washer(Flat Ground Side toward Mount) in between tube and right hand mount. This is pretty easy since is a ledge around bottom of mount which wont allow washer to fall out. Lightly tap the bolt in till it is protruding about 1/8in out right mount. Using extendable magnet Put some red loctite on nut threads and hold the nut in line with bolt. Start turning bolt clockwise to get nut started on bolt. Then switch to a 18mm open end wrench on nut and Torque Wrench with 15mm socket and extension. Torque to 65FtLbs.

Removing right side nut and bolt using extension and a swivel on socket

Holding the nut with a magnet to get threads started.

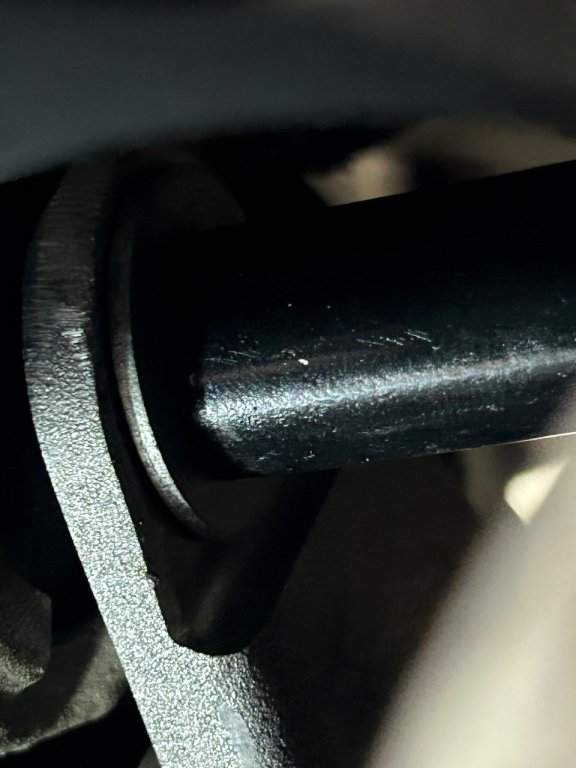

Make sure you have clearance with this coolant tube. A good 1/8in. If not reposition the tube

Make sure both washers are still in position. The thickness of both washers and length of tube determines overall length. Do not substitute washers. They can vary big time in thickness. Whole setup is made within .003in so always a set of two washers and tube.

When rotating spar back into position make sure brake line is in this spot.

Thank You!

Get spar to this point. Be careful of Brakeline and Wiring. Pulling coolant overflow line out of way first helps make this easy. Of course if chaincase is apart just remove Jackshaft. But not necessary. I left my header on and was easily able to do this with some finesse and extendable magnet. I do not know if able to with stock header. Do not lose the washers/spacers provided. They determine the overall length.

18mm nut and 15mm bolthead remove this nut then using the new long bolt which is lubed very lightly with grease but not on threads gently drive the left bolt out with soft face hammer stop when original bolt falls out. Will fall right out access panel on bottom for changing oil.

At this point remove the right side Engine Mount Bolt. Put one washer(Flat Ground Side Toward Mount) provided on the slightly protruding new bolt then using a magnet fish the spacer in between the Washer and right Mount. Once bolt is in far enough to support spacer tube put other washer(Flat Ground Side toward Mount) in between tube and right hand mount. This is pretty easy since is a ledge around bottom of mount which wont allow washer to fall out. Lightly tap the bolt in till it is protruding about 1/8in out right mount. Using extendable magnet Put some red loctite on nut threads and hold the nut in line with bolt. Start turning bolt clockwise to get nut started on bolt. Then switch to a 18mm open end wrench on nut and Torque Wrench with 15mm socket and extension. Torque to 65FtLbs.

Removing right side nut and bolt using extension and a swivel on socket

Holding the nut with a magnet to get threads started.

Make sure you have clearance with this coolant tube. A good 1/8in. If not reposition the tube

Make sure both washers are still in position. The thickness of both washers and length of tube determines overall length. Do not substitute washers. They can vary big time in thickness. Whole setup is made within .003in so always a set of two washers and tube.

When rotating spar back into position make sure brake line is in this spot.

Thank You!

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,268

- Age

- 52

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Yes, I see that on the one I'm working on now that you mention it. I wonder why they abandoned that idea.

DennyTuna

RIP-Logan-Dylan-Never forgotten!

- Joined

- Jan 28, 2017

- Messages

- 727

- Age

- 62

- Location

- Ohio

- Country

- USA

- Snowmobile

- 18 Winder LTX 50th

16 SR Viper RTX (red)

02 SX Viper ER (red)

97 SX Vmax 600 (red)

Nice write up with pics Steve. Getting that torque arm clear is cleaver.

I had to do it once before but not sure why. Valve adjustment possibly. Allows easy access to Waterpump to if that ever goes.Nice write up with pics Steve. Getting that torque arm clear is cleaver.

murdered141

Snow Punisher

- Joined

- Nov 24, 2015

- Messages

- 1,456

- Age

- 43

- Location

- U.P Michigan

- Country

- USA

- Snowmobile

- Yamaha sr viper 15 ltx dx, mpi 190 turbo, straight line header, 38" mtx front end, mtx steering, mtx seat, xtx 141" skid and 2.25" power claw track

2019 sidewinder xtx le, sleeping for now

I did mine mid season last year, not too motivated to add it now but definitely looks like a good ideaIf you had one you know it sucks to replace and could lead to engine damage from overheating. They usually crack at left engine mount where it’s welded to exchanger. Offtrail guys are plagued by this issue but even trail sleds have been afflicted. Mine did it end of last season. I noticed the Sidewinders had an aluminum tube connecting the two mounts and one long bolt vs our two. So I came up with a kit to do the same. Cannondale did same thing to solve issue of engine mounts breaking off. I really believe this will help if not solve. Limited availability. $100 shipped in USA. Murdered you want second one!View attachment 174677View attachment 174678View attachment 174679

Mitch Desorcy

MAX PRO

- Joined

- May 6, 2014

- Messages

- 201

- Age

- 59

- Location

- Winnipeg Manitoba

- Country

- Canada

- Snowmobile

- 2014 Yamaha SR Viper LTX SE

Where does a guy purchase this kit? I'd like to put it on my Turbo Viper.

RobX-1

VIP Member

- Joined

- Apr 13, 2003

- Messages

- 2,160

- Location

- Coldwater, OH

- Country

- USA

- Snowmobile

- 18 50th Apex XT-X, 08 40th Apex LTX GT, 08 40th Nytro RTX, & 03 RX-1

Contact/PM Steve @cannondale27

Similar threads

- Replies

- 2

- Views

- 3K

- Replies

- 21

- Views

- 37K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.