RobX-1

VIP Member

- Joined

- Apr 13, 2003

- Messages

- 2,418

- Reaction score

- 1,607

- Points

- 1,583

- Location

- Coldwater, OH

- Country

- USA

- Snowmobile

- 18 50th Apex XT-X, 08 40th Apex LTX GT, 08 40th Nytro RTX, & 03 RX-1

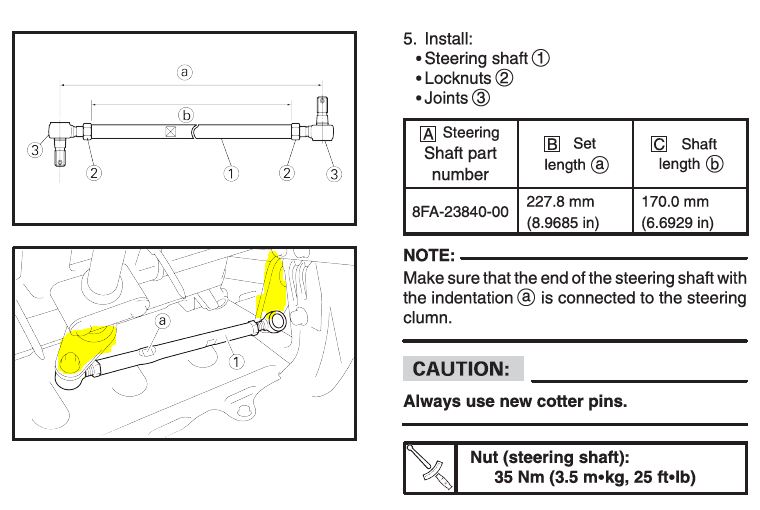

Am in the process of replacing these two joints on the steering shaft. After loosening the nuts, they appeared to be pressed in and had to use a hammer to remove. When replacing them, what have others done to get the joints pressed back in? I don't think you can just use the nut to tighten and seat the joint properly. One option would be to take the steering shaft with the joints installed and put it in the freezer for a couple of days and then heat up the tabs on the two steering columns (highligted in yellow in pic below) where these joints insert into so as to be able to seat them. Outside of removing the complete steering linkage to be able to press the joints back in, really wasn't sure what else to do. Thoughts or suggestions?

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,570

- Reaction score

- 4,219

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Just torque to spec is all that's required.

Also, I noticed that the end was hit with a hammer. That is the wrong place to strike. A hammer is required to remove them, but they are to be struck on the side of the arm with the hole.

Also, I noticed that the end was hit with a hammer. That is the wrong place to strike. A hammer is required to remove them, but they are to be struck on the side of the arm with the hole.

Last edited:

Yes just tighten to torque. If you look in the Phazer section there is a direct replacement I believe would work for those. YFZ Fourwheeler tierod joints. Beefier and sealed better. Will never get slop. In your case I think you can use inner and outer.

ty4stroke.com

ty4stroke.com

Phazer Tierod inner End Upgrade

Yes these rust and get sloppy way to soon.Scary.I found the older YFZ rod ends have same taper and same thread.So I bought 3 and tried them out.This is preliminary because its obvious there is a geometry change.I am no Engineer so I have no idea what effect this will have maybe less bumpsteer...

Last edited:

RobX-1

VIP Member

- Joined

- Apr 13, 2003

- Messages

- 2,418

- Reaction score

- 1,607

- Points

- 1,583

- Location

- Coldwater, OH

- Country

- USA

- Snowmobile

- 18 50th Apex XT-X, 08 40th Apex LTX GT, 08 40th Nytro RTX, & 03 RX-1

Just torque to spec is all that's required.

Yes just tighten to torque.

Thanks, 74Nitro and Steve!

When I initially tried just inserting the joint and tigthening the nut, I didn't think the torque of 25ft/lbs was going to clear the cotterpin hole enough and hence why I thought they were to be pressed in or something. Although the service manual does not state otherwise, is there some initial torque I should use or just go with the 25ft/lbs?

Also, I noticed that the end was hit with a hammer. That is the wrong place to strike. A hammer is required to remove them, but the are to be struck on the side of the arm with the hole.

As for hitting the end with the hammer, I always like to learn what I'm doing wrong and I realized afterwards that it was a mistake as it mushroomed the end of the threads where it would not pass thru the hole. However, since it was the old joint, I didn't think hitting it with a hammer would matter as long as it came out. The one above the exhaust joints came out with just a few blows and did no damage to the joint but the one on the steering shaft along the side was the one that gave me fits and mushroomed when getting it out.

With that said, I would like to do it right the next time but am not sure I follow you when you state they are to be struck on the side of the arm with the hole? I realize those steering column tabs with the holes the joints go into our pretty thick but unless I am missing something, couldn't they possible bend when being hit with the hammer?

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,570

- Reaction score

- 4,219

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

Like in this video, although usually just a few hard hits will do, not '30'.

Sometimes on cars and trucks they actually provide a 'bump' of metal in that area where it is to be struck.

Sometimes on cars and trucks they actually provide a 'bump' of metal in that area where it is to be struck.

RobX-1

VIP Member

- Joined

- Apr 13, 2003

- Messages

- 2,418

- Reaction score

- 1,607

- Points

- 1,583

- Location

- Coldwater, OH

- Country

- USA

- Snowmobile

- 18 50th Apex XT-X, 08 40th Apex LTX GT, 08 40th Nytro RTX, & 03 RX-1

RobX-1

VIP Member

- Joined

- Apr 13, 2003

- Messages

- 2,418

- Reaction score

- 1,607

- Points

- 1,583

- Location

- Coldwater, OH

- Country

- USA

- Snowmobile

- 18 50th Apex XT-X, 08 40th Apex LTX GT, 08 40th Nytro RTX, & 03 RX-1

Goods news/bad news. Bad news first, it does not appear just torquing to 25ft/lbs is going to properly seat these joints as doing so does not expose the cotterpin hole. Now for the good news, thanks to the tip 74Nitro passed along, I was able to get the new joint out very easily without damaging its threaded stud.

74Nitro

VIP Member

- Joined

- Feb 18, 2013

- Messages

- 5,570

- Reaction score

- 4,219

- Points

- 1,853

- Location

- Dublin Ontario

- Country

- Canada

- Snowmobile

- 2019 Sidewinder LTX

That's the wrong nut. Should be flange with no nylock if I remember right.View attachment 174488

Goods news/bad news. Bad news first, it does not appear just torquing to 25ft/lbs is going to properly seat these joints as doing so does not expose the cotterpin hole. Now for the good news, thanks to the tip 74Nitro passed along, I was able to get the new joint out very easily without damaging its threaded stud.

RobX-1

VIP Member

- Joined

- Apr 13, 2003

- Messages

- 2,418

- Reaction score

- 1,607

- Points

- 1,583

- Location

- Coldwater, OH

- Country

- USA

- Snowmobile

- 18 50th Apex XT-X, 08 40th Apex LTX GT, 08 40th Nytro RTX, & 03 RX-1

Good point as I'm multi-tasking and may have mistakenly grab the incorrect nuts. I have my '18 to compare. Good catch!

RobX-1

VIP Member

- Joined

- Apr 13, 2003

- Messages

- 2,418

- Reaction score

- 1,607

- Points

- 1,583

- Location

- Coldwater, OH

- Country

- USA

- Snowmobile

- 18 50th Apex XT-X, 08 40th Apex LTX GT, 08 40th Nytro RTX, & 03 RX-1

OMG, you were right again @74Nitro; those nuts are actually for the track deflection adjusters.

Had the suspension out to have @cannondale27 service the EC Ohlins shock and also had to replace some idler wheel bearings and the hyfax and must have laid those nuts on top of the tunnel while working on these steering shaft joints. Found the correct nuts and all is good. Thanks again!

Had the suspension out to have @cannondale27 service the EC Ohlins shock and also had to replace some idler wheel bearings and the hyfax and must have laid those nuts on top of the tunnel while working on these steering shaft joints. Found the correct nuts and all is good. Thanks again!

Similar threads

- Replies

- 65

- Views

- 34K

- Replies

- 3

- Views

- 1K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.