1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,307

- Reaction score

- 2,722

- Points

- 1,733

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Does this apply to the sidewinder also?

STAIN

Lifetime Member

- Joined

- Feb 29, 2004

- Messages

- 4,516

- Reaction score

- 3,782

- Points

- 1,713

- Location

- Vermont

- Country

- USA

- Snowmobile

- 2024 Arctic Cat Riot 9000

- LOCATION

- Vermont

I would guess "yes"

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,307

- Reaction score

- 2,722

- Points

- 1,733

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Reason why I posted was to see if the sidewinder needs this or does it already have a self bleeding hose on it.

Looking at my waterpump it has a small hose coming off the top of it and going where I can't see.

Looking at my waterpump it has a small hose coming off the top of it and going where I can't see.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,865

- Reaction score

- 2,880

- Points

- 1,113

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

I think the small one you're looking at probably goes to throttle bodies.

As most of us know, these 998s are relatively tough to bleed to get ALL the air out of them. There are TY threads on this subject with good info on what seems to work.

As most of us know, these 998s are relatively tough to bleed to get ALL the air out of them. There are TY threads on this subject with good info on what seems to work.

twyztid

VIP Member

- Joined

- Feb 14, 2011

- Messages

- 1,011

- Reaction score

- 511

- Points

- 1,328

- Location

- Middleville, MI

- Country

- USA

- Snowmobile

- 2025 Sidewinder LTX LE EPS

2017 Sidewinder LTX SE

2012 Apex XTX

2012 RS Vector LTX

- LOCATION

- Middleville, MI

Who has successfully installed a Dasa billet water pump? I have one that I was planning on installing but then I read about the covers being different between the Wildcat and the Sidewinder. My sled only has 850 miles on it. I don't want to tear it apart if the impeller isn't going to fit.

SideHogger

TY 4 Stroke Guru

- Joined

- Apr 16, 2016

- Messages

- 938

- Reaction score

- 410

- Points

- 788

- Location

- upstate ny

- Country

- USA

- Snowmobile

- 2017 Ltx-Le Sidewinder

Anybody?Who has successfully installed a Dasa billet water pump? I have one that I was planning on installing but then I read about the covers being different between the Wildcat and the Sidewinder. My sled only has 850 miles on it. I don't want to tear it apart if the impeller isn't going to fit.

Spaceman

Extreme

- Joined

- Apr 20, 2017

- Messages

- 64

- Reaction score

- 50

- Points

- 433

- Location

- Ohio

- Country

- USA

- Snowmobile

- 18 Thundercat

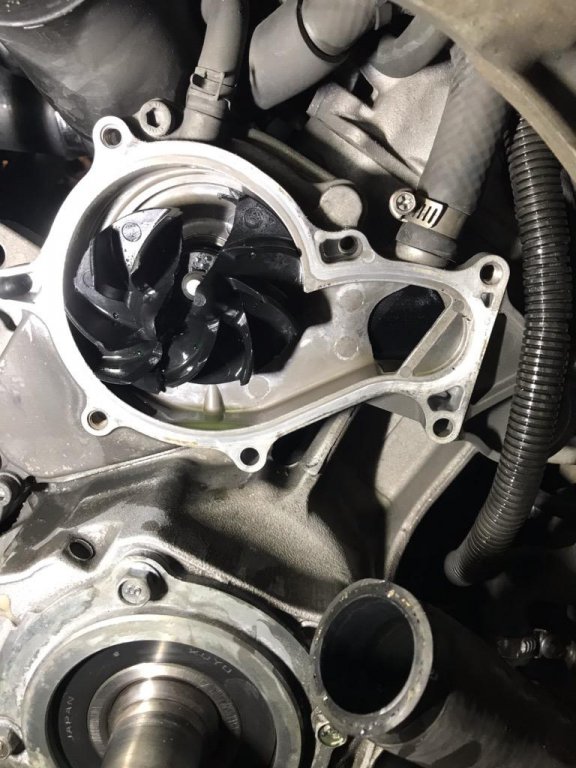

Hello All, 18 T cat. Stock. 10000 miles. Tiny weep from weep hole for 21 season. My son rode the sled and did not realize how easy these overheat when idling for long periods. Still had coolant in overflow. I let it idle too long and it did not want to cool down. Opened pressure cap and could not see coolant. I lightly blew into overflow to push what as in there to engine. Ran fine. Got back to camp and fully loaded and bled the system. Was fine the rest of trip. I saw more than the usual wetness around weep hole. Ordered seal and shaft just in case. Tore down today. I think loss of coolant from weep was original problem. Second this overheating may be the cause of this failure. See photo. It is tight. But melting has to be the cause.

Attachments

twyztid

VIP Member

- Joined

- Feb 14, 2011

- Messages

- 1,011

- Reaction score

- 511

- Points

- 1,328

- Location

- Middleville, MI

- Country

- USA

- Snowmobile

- 2025 Sidewinder LTX LE EPS

2017 Sidewinder LTX SE

2012 Apex XTX

2012 RS Vector LTX

- LOCATION

- Middleville, MI

This is my brother-in-law's 2nd water pump failure in 4000 miles. It was not from overheating. He has installed the the Dasa Racing billet impeller now.

max rolph

Expert

- Joined

- Feb 10, 2021

- Messages

- 455

- Reaction score

- 277

- Points

- 408

- Location

- horse shoe valley

- Country

- Canada

- Snowmobile

- 998 turbo

does shaft come out easy, is this a big job, rather do preventitive maintenance now... rather than break down on long trip.... FN hate being that guy since im the one whos running hard leading pack.

that speed werx bleed.... hmmm what if we add a nipple to the top of the reservoir above the oil tank and run it back to coolant reservoir with a grommet and elbow .. or "T" into hose (36) in parts diagram, sort of like the fuel line return???? would that not work? thoughts

that speed werx bleed.... hmmm what if we add a nipple to the top of the reservoir above the oil tank and run it back to coolant reservoir with a grommet and elbow .. or "T" into hose (36) in parts diagram, sort of like the fuel line return???? would that not work? thoughts

Last edited:

Spaceman

Extreme

- Joined

- Apr 20, 2017

- Messages

- 64

- Reaction score

- 50

- Points

- 433

- Location

- Ohio

- Country

- USA

- Snowmobile

- 18 Thundercat

Its not hard. You do have to take all the bolts out of the torque arm so you can rotate it up to get to the bolts on the pump. Also have to put number 3 cylinder at tdc. That way you can remove the pump..

GT Mills

Extreme

- Joined

- Oct 26, 2016

- Messages

- 51

- Reaction score

- 20

- Points

- 728

- Location

- West Columbia, SC

- Country

- USA

- Snowmobile

- RX1

After-market all-metal water pump impeller replacements are NOT the end-all answer to YG3 (Yamaha Genesis 3 cyl) water pump failures. I personally know of at least 8 failures, INCLUDING billet cut impellers that were installed on engines that never had any history of overheating of pump failure - as a preventative measure (that sucked donkyes).

Granted, we run these things hard, typical hit the redline and hold it there to take off for a minute of two, then 6500-7500 RPM for hours on end without letting up until landing, easily 50 - 100 hrs/year, equivalent to 4000 - 7500 sled miles per season.

I guess running a bleed line back up to the burp tank is one way to do it, but this idea of mine is a ball check valve that only allows air to pass. The cheaper ones spittle a bit of juice, maybe a drop or two. Better ones spit less. I built an in-floor hydronic heating system in my house in Michigan and placed several of these throughout the high points in the piping circuits. One failed after a few years and I had to replace it, none of the others leaked. Haven't tried one on an engine yet. If you want tp try this, you might want to isolate the valve from engine vibration, and mill out the inside of the 1" x 1/8" NPT "Sensor Adapter T" to make a cove to help trap steam gasses more efficiently.

For $30 bucks, hey - why not?

visit www.MohawkAero.com

Granted, we run these things hard, typical hit the redline and hold it there to take off for a minute of two, then 6500-7500 RPM for hours on end without letting up until landing, easily 50 - 100 hrs/year, equivalent to 4000 - 7500 sled miles per season.

I guess running a bleed line back up to the burp tank is one way to do it, but this idea of mine is a ball check valve that only allows air to pass. The cheaper ones spittle a bit of juice, maybe a drop or two. Better ones spit less. I built an in-floor hydronic heating system in my house in Michigan and placed several of these throughout the high points in the piping circuits. One failed after a few years and I had to replace it, none of the others leaked. Haven't tried one on an engine yet. If you want tp try this, you might want to isolate the valve from engine vibration, and mill out the inside of the 1" x 1/8" NPT "Sensor Adapter T" to make a cove to help trap steam gasses more efficiently.

For $30 bucks, hey - why not?

visit www.MohawkAero.com

Attachments

Last edited:

Keith Schmitz

Pro

- Joined

- Jan 12, 2015

- Messages

- 132

- Reaction score

- 88

- Points

- 383

- Location

- Dousman Wi

- Country

- USA

- Snowmobile

- APEX

I’ve actually been through 2 water pumps on my 17. One, the seal went on, and the other, i can’t remember . First one went with maybe 2k miles, the 2nd at 7500 miles

beanie

Extreme

- Joined

- Jun 11, 2005

- Messages

- 119

- Reaction score

- 40

- Points

- 863

Hi I spotted this today . What was your fix ? whole pump or parts ?

1nc 2000

Lifetime Member Tim

- Joined

- Feb 26, 2010

- Messages

- 3,307

- Reaction score

- 2,722

- Points

- 1,733

- Location

- Marquette, MI

- Country

- USA

- Snowmobile

- Yamaha FX Nytro RTX SE

Hi I spotted this today . What was your fix ? whole pump or parts ?

Complete pump replacement. Went with stock.

Turboflash

Lifetime Member

- Joined

- Mar 18, 2019

- Messages

- 2,865

- Reaction score

- 2,880

- Points

- 1,113

- Location

- Southern MN

- Country

- USA

- Snowmobile

- '17 ZR9000 Ltd. 137 - PEFI Stage 4

These failures are very strange to me. What in world would cause this EXCEPT just p*## poor quality from China. How does an impeller just break like that?!

Similar threads

- Replies

- 15

- Views

- 9K

- Replies

- 13

- Views

- 4K

- Replies

- 5

- Views

- 3K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.