PETETY1968

VIP Member

- Joined

- Jun 7, 2022

- Messages

- 20

- Age

- 56

- Location

- FLINT

- Country

- USA

- Snowmobile

- 2009 Yamaha NYTRO XTX

2998 ARCTIC CAT F1000

2007 YAMAHA VECTOR

I have a 2007 Vector ER that when I bought it the guy said it would run better once it warmed up. Giving what I found I can believe that statement.

I thought I had a carb issue, turns out after a compression check low on compression....

I started on the clutch side. 90 psi, middle 120 psi and mag side 80 psi.

after adding oil to the cylinders pressure did climb a bit but not on all 3. My thinking is it needs new piston rings and the valve train needs to be adjusted. Would anyone agree? Also does anyone have any idea or know the pressure ratings on this model? And the best place to buy new piston rings? My theory is to replace the rings and adjust the valve train. Only my second 4 stroke I have taken apart. Machine has 11,500K on it.

Not sure if I stuck this in the right posting area?

Circling back on this thread. Today I performed a leak down test. discovering that by doing so I have air coming up from the lower end of the motor through the cam chain area.

Even tho the valve lash was done too I now know...

Also discovered that I have a ton of carbon on the exhaust valve stems.

Anyone have new piston rings to sell for my motor? Tear down begins soon.

New piston rings and head gasket.

Also does anyone know anyone in the Michigan area {FLINT} that does that kind of motor work or checking to see where this sled sits for head work or cylinder work?

Everything needs to be taken apart and cleaned, valves, buckets. Anyone have any suggestions for removal?

I thought I had a carb issue, turns out after a compression check low on compression....

I started on the clutch side. 90 psi, middle 120 psi and mag side 80 psi.

after adding oil to the cylinders pressure did climb a bit but not on all 3. My thinking is it needs new piston rings and the valve train needs to be adjusted. Would anyone agree? Also does anyone have any idea or know the pressure ratings on this model? And the best place to buy new piston rings? My theory is to replace the rings and adjust the valve train. Only my second 4 stroke I have taken apart. Machine has 11,500K on it.

Not sure if I stuck this in the right posting area?

Circling back on this thread. Today I performed a leak down test. discovering that by doing so I have air coming up from the lower end of the motor through the cam chain area.

Even tho the valve lash was done too I now know...

Also discovered that I have a ton of carbon on the exhaust valve stems.

Anyone have new piston rings to sell for my motor? Tear down begins soon.

New piston rings and head gasket.

Also does anyone know anyone in the Michigan area {FLINT} that does that kind of motor work or checking to see where this sled sits for head work or cylinder work?

Everything needs to be taken apart and cleaned, valves, buckets. Anyone have any suggestions for removal?

Last edited:

- Joined

- Jun 1, 2004

- Messages

- 7,745

- Location

- sudbury on

- Country

- Canada

- Snowmobile

- 2016 apex xtx

2011 apex xtx

2009 phaser rtx/x

1997 et410t/r

1988 vk 540

check the valves. some times in off season they stick but possible could use adjustment.

Mooseman

I'm not all knowing. Post your question in forum.

- Joined

- Nov 3, 2009

- Messages

- 3,964

- Location

- Greely, Ontario

- Country

- Canada

- Snowmobile

- '07 Venture MP (gone)

'07 Phazer FX (gone)

'09 Phazer GT (gone)

'10 RS Venture GT (My current ride)

'10 Nytro FX (son's)

- LOCATION

- Greely, ON Canada

The valves may also be leaking. Best way to tell without opening it is with a leakdown test. That's how I determined that I had a bad head gasket and leaky valves. I gave my valves a good lapping, proper adjustment (they were almost all tight), got the head flat and new gasket and she was as good as new.

ty4stroke.com

ty4stroke.com

RS Venture GT losing coolant

Related to RS Venture GT takes forever to warm up, now I find myself losing coolant. To recap, it had low coolant with no obvious leak, replaced the thermostat, refilled and it idles fine and gets up to temp and pressure. I also installed a temp gauge and bled the system of air (had it...

PETETY1968

VIP Member

- Joined

- Jun 7, 2022

- Messages

- 20

- Age

- 56

- Location

- FLINT

- Country

- USA

- Snowmobile

- 2009 Yamaha NYTRO XTX

2998 ARCTIC CAT F1000

2007 YAMAHA VECTOR

Thank you, both of you for helping me out. 3 more bolts and the motor will be out. One more learning curve. My Nitro is slightly different but much the same. The valve train is where I will be starting and leak down procedure as well. I will let you know what turns up for me.

Fast Lane

Expert

- Joined

- Feb 6, 2020

- Messages

- 250

- Age

- 47

- Location

- Winnipeg

- Country

- Canada

- Snowmobile

- 2007 Yamaha Nytro ER

- LOCATION

- Winnipeg

They should be 190+ so thats pretty low. Probably valves are out of spec or crud on them.

PETETY1968

VIP Member

- Joined

- Jun 7, 2022

- Messages

- 20

- Age

- 56

- Location

- FLINT

- Country

- USA

- Snowmobile

- 2009 Yamaha NYTRO XTX

2998 ARCTIC CAT F1000

2007 YAMAHA VECTOR

THANK YOU, love this site!!!! Best money I ever spent!

- Joined

- Jun 1, 2004

- Messages

- 7,745

- Location

- sudbury on

- Country

- Canada

- Snowmobile

- 2016 apex xtx

2011 apex xtx

2009 phaser rtx/x

1997 et410t/r

1988 vk 540

did you get it?

PETETY1968

VIP Member

- Joined

- Jun 7, 2022

- Messages

- 20

- Age

- 56

- Location

- FLINT

- Country

- USA

- Snowmobile

- 2009 Yamaha NYTRO XTX

2998 ARCTIC CAT F1000

2007 YAMAHA VECTOR

no I work too much, but today I have decided to pull the engine no matter what. Leak down can be done on the bench for sure. Trouble is my NYTRO I had to take the nose cone off that sled however I am am at point where the rear motor hanger bolt will come out and the motor will be free. Does anyone know if the motor will come straight out or does the nose cone (skis etc..) need to be removed however I can't see how that is possible.

Sorry the holidays and me working too much lately has this stalled this project...

but I am ready to remove the motor and bleed-down and valving investigation will commence.

Just need to ge the motor out.

Sorry the holidays and me working too much lately has this stalled this project...

but I am ready to remove the motor and bleed-down and valving investigation will commence.

Just need to ge the motor out.

Last edited:

PETETY1968

VIP Member

- Joined

- Jun 7, 2022

- Messages

- 20

- Age

- 56

- Location

- FLINT

- Country

- USA

- Snowmobile

- 2009 Yamaha NYTRO XTX

2998 ARCTIC CAT F1000

2007 YAMAHA VECTOR

I may have jumped the gun a bit because I did not perform a leak down test I went right to valve clearance. And I measured and will post the picture of my findings but I need to find the valve clearances and I do not know them. If anyone can help me with these measurements please do.

Cylinder 1 - INTAKE EXHAUST

VALVE 1 VALVE 2 VALVE 1 VALVE 2

.004/[.005] .006/[.007] .002/[.003] .002[.003]

Cylinder 2 - INTAKE EXHAUST

VALVE 1 VALVE 2 VALVE 1 VALVE 2

.006/[.007] .006/[.007] .003/[.004]. .003[.004]

Cylinder 3 - INTAKE EXHAUST

VALVE 1 VALVE 2 VALVE 1 VALVE 2

.007/[.008] .007/[.008] .004/[.005]. .004[.005]

[INDICATES FEELER GAUGE WON’T GO THROUGH]

Cylinder 1 - INTAKE EXHAUST

VALVE 1 VALVE 2 VALVE 1 VALVE 2

.004/[.005] .006/[.007] .002/[.003] .002[.003]

Cylinder 2 - INTAKE EXHAUST

VALVE 1 VALVE 2 VALVE 1 VALVE 2

.006/[.007] .006/[.007] .003/[.004]. .003[.004]

Cylinder 3 - INTAKE EXHAUST

VALVE 1 VALVE 2 VALVE 1 VALVE 2

.007/[.008] .007/[.008] .004/[.005]. .004[.005]

[INDICATES FEELER GAUGE WON’T GO THROUGH]

PETETY1968

VIP Member

- Joined

- Jun 7, 2022

- Messages

- 20

- Age

- 56

- Location

- FLINT

- Country

- USA

- Snowmobile

- 2009 Yamaha NYTRO XTX

2998 ARCTIC CAT F1000

2007 YAMAHA VECTOR

I think my valve are within spec, because if they warm up then they will swell past the .000 range.

Yamajon1

VIP Member

- Joined

- Nov 6, 2016

- Messages

- 986

- Location

- Oshkosh Wisconsin

- Country

- USA

- Snowmobile

- 2016 SR Viper RTX DX

Former Yamaha sleds:

2004 Venture 600 2002 SX Viper 700

1997 Vmax 600 SX 1994 Vmax 600 1989 Exciter

1986 Vmax 540 1986 Phaser 1981 SRX 440

Those numbers you got sound tight.

PETETY1968

VIP Member

- Joined

- Jun 7, 2022

- Messages

- 20

- Age

- 56

- Location

- FLINT

- Country

- USA

- Snowmobile

- 2009 Yamaha NYTRO XTX

2998 ARCTIC CAT F1000

2007 YAMAHA VECTOR

engine

Even tho the valve lash was done too I now know...

Also discovered that I have a ton of carbon on the exhaust valve stems.

Anyone have new piston rings to sell for my motor? Tear down begins soon.

New piston rings and head gasket.

Also does anyone know anyone in the Michigan area {FLINT} that does that kind of motor work or checking to see where this sled sits for head work or cylinder work?

Head was removed, no gouges in the cylinder walls, can these be honed?

I was hoping for new rings, hone and new head gasket and back together I go? ANYONE OFFERING ANY ADVICE???

Circling back on this thread. Today I performed a leak down test. Discovering that by doing so I have air coming up from the lower end of the motor through the cam chain area which to me points to pistons rings.check the valves. some times in off season they stick but possible could use adjustment.

Even tho the valve lash was done too I now know...

Also discovered that I have a ton of carbon on the exhaust valve stems.

Anyone have new piston rings to sell for my motor? Tear down begins soon.

New piston rings and head gasket.

Also does anyone know anyone in the Michigan area {FLINT} that does that kind of motor work or checking to see where this sled sits for head work or cylinder work?

Head was removed, no gouges in the cylinder walls, can these be honed?

I was hoping for new rings, hone and new head gasket and back together I go? ANYONE OFFERING ANY ADVICE???

- Joined

- Jun 1, 2004

- Messages

- 7,745

- Location

- sudbury on

- Country

- Canada

- Snowmobile

- 2016 apex xtx

2011 apex xtx

2009 phaser rtx/x

1997 et410t/r

1988 vk 540

you could try running yamaha ring free through it in the gas as it was a known issue with the 03 rx1 sleds. it removes the carbon from the rings allowing them work how they should. i have used oven cleaner on an old carboned up polaris sled to get the rings unstuck as it only had 20 psi on that cyl when i started. it came up to 90 psi when i got it started.

PETETY1968

VIP Member

- Joined

- Jun 7, 2022

- Messages

- 20

- Age

- 56

- Location

- FLINT

- Country

- USA

- Snowmobile

- 2009 Yamaha NYTRO XTX

2998 ARCTIC CAT F1000

2007 YAMAHA VECTOR

Started tearing the motor down today, getting to the pistons and rings. Cylinders look great, still have cross hatching on them. I haven't pulled pistons yet.

If I remember on my Nytro I could get manuals sent to me. I realazied that I let my subscription last so doing that again.

I am hoping the manual will help with my rebuild. Does anyone know the best place to order seal kit and piston rings that doesn't take a month to get parts?

If I remember on my Nytro I could get manuals sent to me. I realazied that I let my subscription last so doing that again.

I am hoping the manual will help with my rebuild. Does anyone know the best place to order seal kit and piston rings that doesn't take a month to get parts?

Last edited:

PETETY1968

VIP Member

- Joined

- Jun 7, 2022

- Messages

- 20

- Age

- 56

- Location

- FLINT

- Country

- USA

- Snowmobile

- 2009 Yamaha NYTRO XTX

2998 ARCTIC CAT F1000

2007 YAMAHA VECTOR

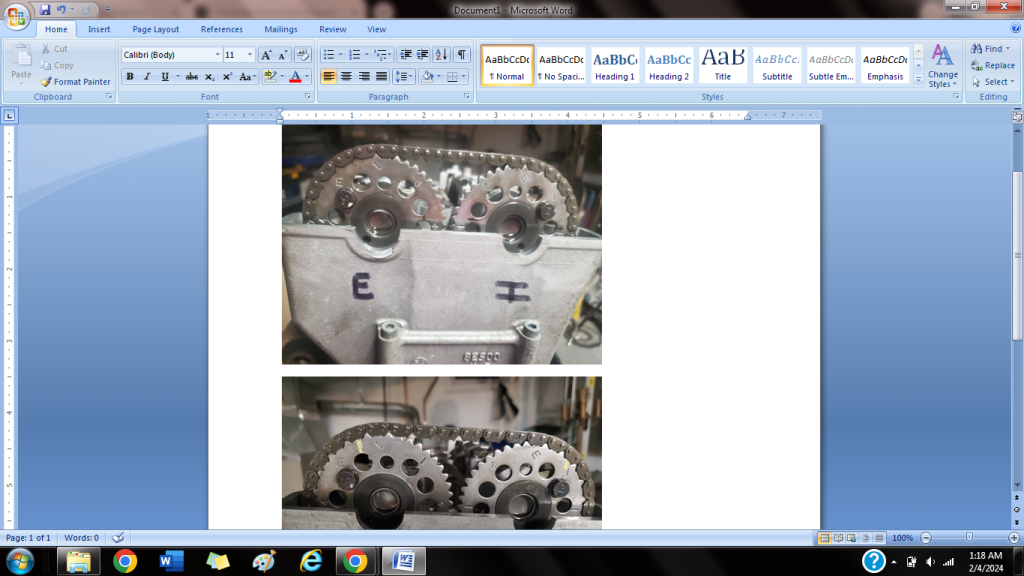

Good day to all whom read my post. Motor is going back together and I am not sure if I messed up and need advice. I installed the cams, timing chains and I think I may have screwed up by not knowing which cams was intake side and which was Exhaust. Thought I had them labeled or set aside correctly. I am hoping I can post the pictures before tear down and after reinstall. I will try to explain and maybe someone will catch if I did indeed made a mistake. Can anyone tell me if the cams are alike/same just depends how they get installed or does it truly matter that the INTAKE cam and the EXHAUST cam must be in the exact slot or can the be swapped? Asking can I install the Intake cam in the Exhaust side and the Exhaust cam in the INTAKE slot? I hope this question makes sense to those whom read my post!!!! Top picture is before the tear down and the bottom is after. Also the manual refers to the top holes in the cams pointing upward however if I were to align the cams to me will not make sense. Before the motor goes back in the sled I really could use some help here. If you need a better picture or more questions answered please state your question. Also I do have 18 pins from inside "I" marks on the cams. There are a few Arctic Cat videos on YouTube however I cant find one single YAMAHA engine 4 stroke video to same my life but I assume they are the same and the Arctic Cat / Yamaha motors. Maunal does state the cam holes need to be pointing upwards however the cams do not resemble anything I stated with.

HELP -HELP - HELP - HELP -HELP

Please of coarse!!!! x 10000000000

HELP -HELP - HELP - HELP -HELP

Please of coarse!!!! x 10000000000

Similar threads

- Replies

- 3

- Views

- 2K

- Replies

- 6

- Views

- 2K

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.